Composition for cord coating, cord for rubber reinforcement made with the same, and rubber product made with the same

A composition and rubber technology, which is applied in the field of rubber products, can solve the problems of reduced bending fatigue resistance, and achieve the effects of high bending fatigue resistance, bending fatigue resistance, high and high dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

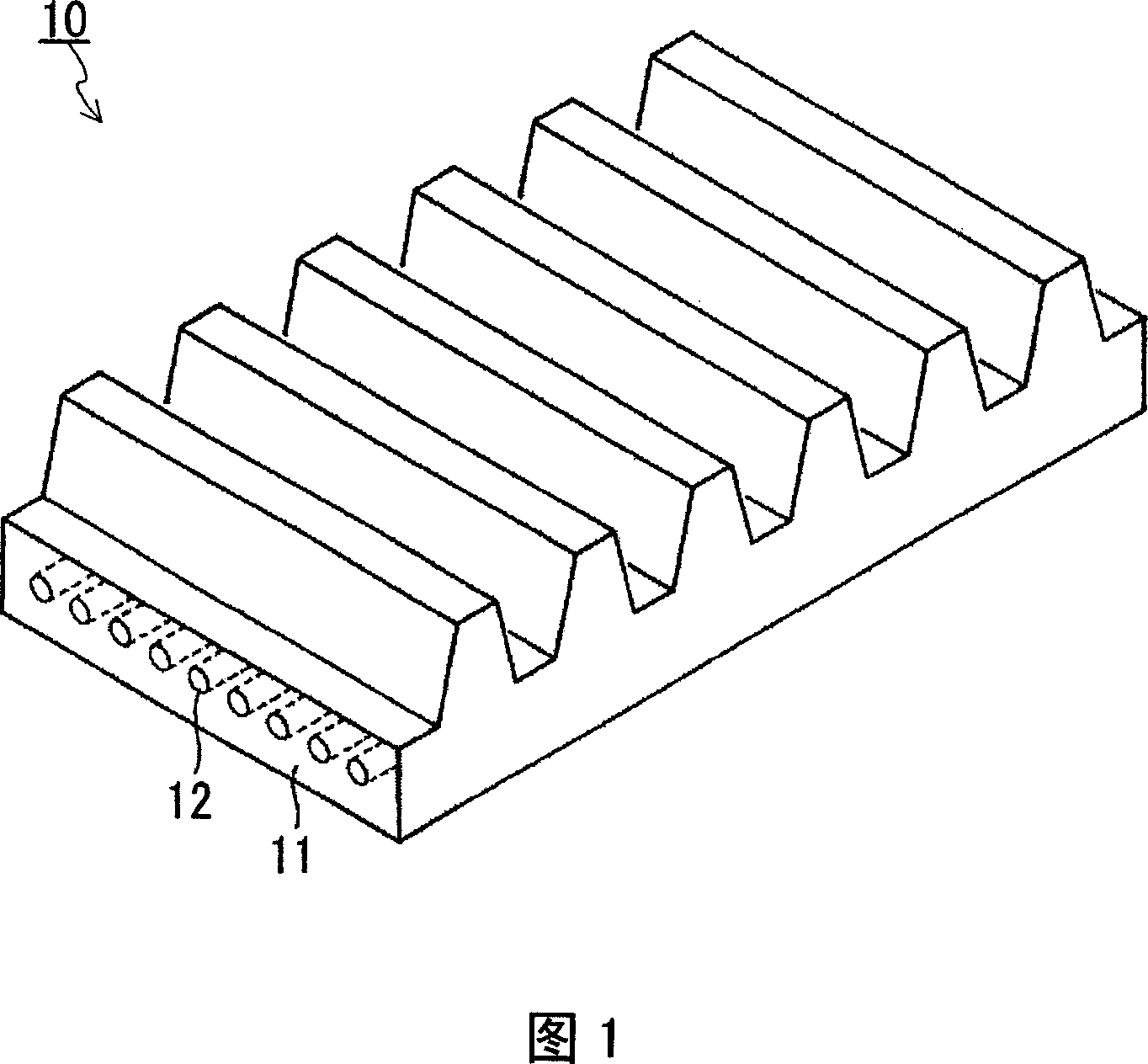

Image

Examples

Embodiment 1~5

[0074] Filaments of alkali-free glass with a diameter of 9 μm were spun and bundled with a sizing agent to obtain glass fibers of 33.7 tex. Three of these glass fibers were fused, impregnated with the covering composition (solid content: 30% by mass) shown in Table 1, and heat-treated to obtain a glass fiber cord. In addition, the covering composition contains ammonia water (NH 4 OH) and water as solvent. The coating amount of the coating composition was adjusted so that the mass of the film formed therefrom was 20% of the mass of the glass fibers. Table 1 below shows the compounding quantity (parts by mass) of the composition, and also shows the mass ratio (mass %) of the solid content.

[0075] [Table 1]

[0076] Element

[0077] Next, the glass fiber cord was initially twisted at a ratio of 2.0 times / 25 mm. Next, 11 glass fiber cords that were initially twisted were bundled, and the final twist was performed at a ratio of 2.0 times / 25 mm. In this manner, the...

Embodiment 6

[0079] The second coating composition (liquid) having the composition shown in Table 2 was further applied to the rubber-reinforced cord obtained in Example 1, and dried to obtain the rubber-reinforced cord of Example 6. In addition, the covering amount (solid content) of the second covering composition with respect to the reinforcing cord was 5% by mass.

[0080] [Table 2]

[0081] Element

Mixing ratio (parts by mass)

Methylene bis(4-phenylisocyanate)

4.5

CSM

5.25

p-Dinitrosobenzene

2.25

3.0

Mixed solvent of xylene and trichlorethylene

(mixing ratio (mass ratio) of xylene to trichloroethylene=1.5:1.0)

85.0

[0082] (characteristic evaluation)

[0083] Two matrix rubber sheets (width 10 mm, length 300 mm, thickness 1 mm) formed by the combination shown in Table 3 below were prepared. One reinforcing cord of the example with a length of 300 mm was arranged on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com