Five-layer co-extruded fiber felt reinforced plastic composite board and manufacturing method thereof

A technology of reinforced plastics and fiber mats, which is applied in the field of five-layer co-extruded fiber felt reinforced plastic composite boards and its manufacture, which can solve the problems of large coefficient of thermal expansion and contraction, easily scalded plastic building templates, and lack of water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

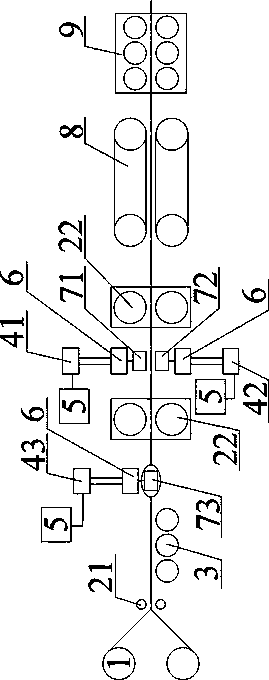

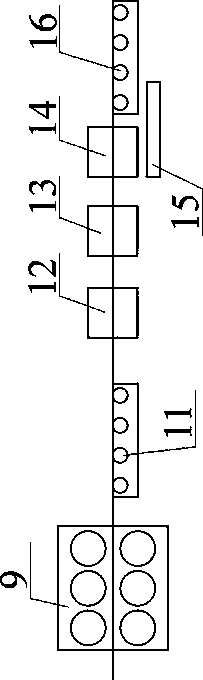

Method used

Image

Examples

Embodiment 1

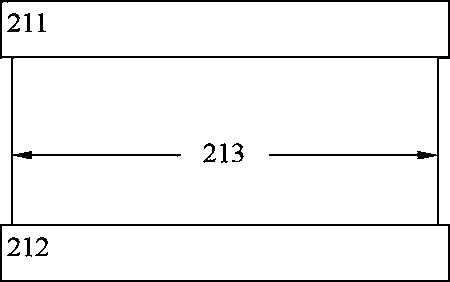

[0105] A five-layer co-extruded fiber felt reinforced plastic composite board, which is composed of a plastic layer and a fiber felt: there are three layers of plastic layers, two layers of fiber felt, three layers of plastic layers are arranged in parallel, and the three layers of plastic layers are respectively the top layer, the middle layer Layer and bottom layer, a layer of fiber mat is lined between the top plastic layer and the middle plastic layer and between the middle plastic layer and the bottom plastic layer; the plastic layer is made of polypropylene, and the fiber mat is made of glass fiber; the fiber mat Continuous felt is selected, and the single layer quality of fiber felt is 200g / m 2 ~3000g / m 2 , the diameter of a single glass fiber is 10 μm to 25 μm, and the length of a single glass fiber is not less than 50 mm; the glass fiber of the fiber mat is treated by surface impregnation and grafting, that is, the outer surface of the glass fiber is bonded with a fil...

Embodiment 2

[0151] A five-layer co-extruded fiber felt reinforced plastic composite board, which is composed of a plastic layer and a fiber felt: there are three layers of plastic layers, two layers of fiber felt, three layers of plastic layers are arranged in parallel, and the three layers of plastic layers are respectively the top layer, the middle layer Layer and bottom layer, between the top plastic layer and the middle plastic layer, and between the middle plastic layer and the bottom plastic layer, each lined with a layer of fiber mat; the plastic layer is made of polyethylene, and the fiber mat is made of mixed fibers. The mixed fiber is mixed with glass fiber and polyethylene fiber, the mass percentage of polyethylene fiber in the mixed fiber is 20% to 80%, and the single filament diameter of polyethylene fiber in the mixed fiber is between 0.1mm and 1.0mm; the fiber mat is selected from short Cut felt, the single layer quality of fiber felt is 200g / m 2 ~3000g / m 2 , the diameter ...

Embodiment 3

[0196] A five-layer co-extruded fiber mat reinforced plastic composite board is composed of a plastic layer and a fiber mat, the plastic layer is made of hard polyvinyl chloride, the fiber mat is made of glass fiber; the fiber mat is made of continuous mat.

[0197] The contents of each component of the top plastic layer and the bottom plastic layer are as follows:

[0198] Component Mass percentage (%)

[0199] Rigid PVC 63.6

[0200] Montmorillonite 25

[0201] Tetrakis[β-3,5-di-tert-butyl-4-hydroxyphenylpropionic acid]pentaerythritol ester 0.9

[0202] N,N’-Ethylene bisstearamide 2

[0203]carbon black 2

[0204] Decabromodiphenylethane 6.5;

[0205] The content of each component of the middle layer plastic layer is as follows:

[0206] Component Mass percentage (%)

[0207] Rigid PVC 64.2

[0208] Montmorillonite 25

[0209] Tetrakis[β-3,5-di-tert-butyl-4-hydroxyphenylpropionic acid]pentaerythritol ester 0.3

[0210] N,N’-Ethylene bisstearamide 2

[0211] carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com