Self-assembly method of inorganic nano particle hybridization organic membrane

An inorganic nanoparticle and nanoparticle technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as self-assembly methods of hybrid inorganic nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

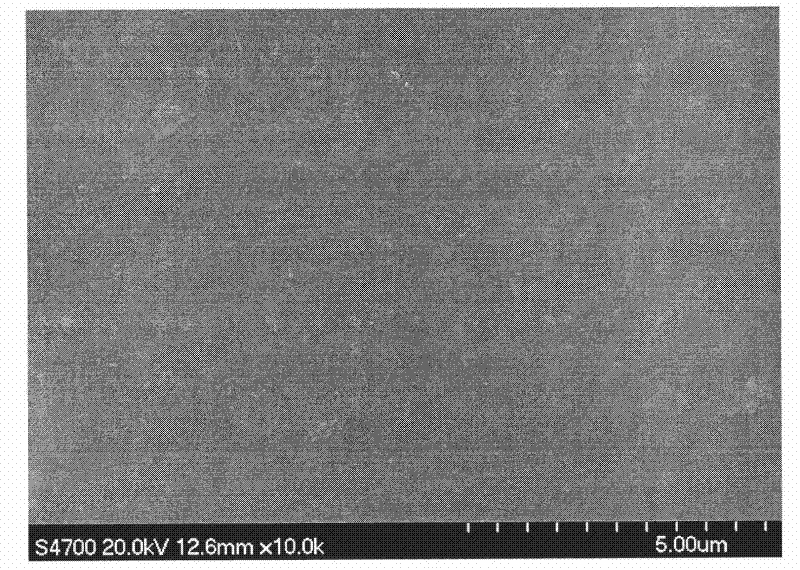

specific Embodiment 1

[0031] The substrate is quartz glass, the polycation material used is polyethyleneimine (PEI, with a molecular weight of 60,000), the polyanion is polyacrylic acid (PAA, with a molecular weight of 4 million), and nano-sized zirconia particles (ZrO 2 , within 100nm, 5wt%), the solvents of polyethyleneimine and polyacrylic acid are all water.

[0032] Assembly conditions and methods:

[0033] (1) Polyethyleneimine is made into 500ml of a 0.5wt% solution with deionized water, and left to defoam; Polyacrylic acid is made into 500ml of a 0.05wt% solution with deionized water, left to stand for defoaming, and nano-oxidized Zirconium particle solution 1ml;

[0034] (2) Ultrasonic the polyacrylic acid solution for 120 minutes to uniformly disperse the nanoparticles, centrifuge for 10 minutes, and replace the supernatant with an equal volume of deionized water after centrifugation; repeat 3 times to obtain a polyacrylic acid nanoparticle solution;

[0035] (3) Soak the substrate in a...

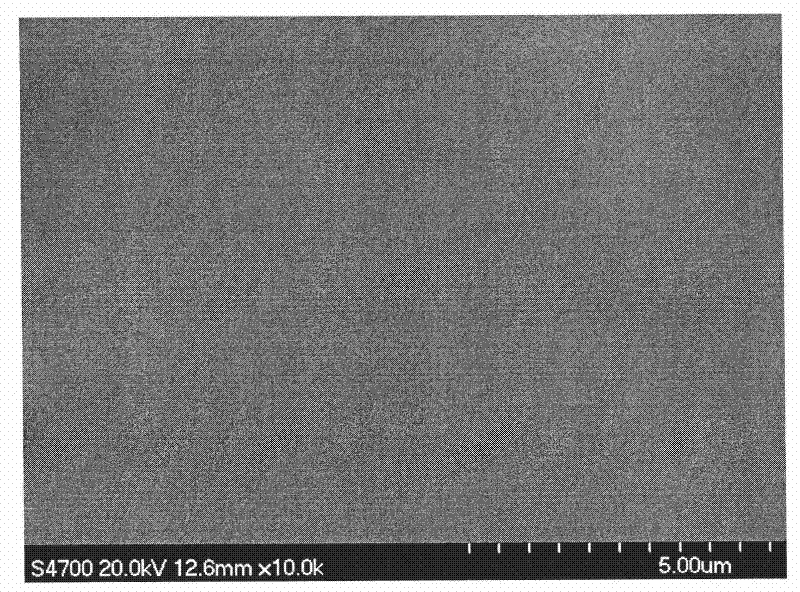

specific Embodiment 2

[0056] The substrate is quartz glass, the polycation material used is polydiallyldimethylammonium chloride (PDDA, the molecular weight is 100000-200000), the polyanion is polystyrene sulfonate sodium (PSS, the molecular weight is 70000), Nano zirconia particles (ZrO 2 , within 100nm, 5wt%), the solvents of polydiallyl dimethyl ammonium chloride and sodium polystyrene sulfonate are water.

[0057] Assembly conditions and methods:

[0058] (1) Polydiallyldimethylammonium chloride is made into 0.94wt% solution 500ml with deionized water, and left to defoam; with deionized water, polystyrene sulfonate is made into 1.2wt% Solution 500ml, let it stand for defoaming, add 8ml of nano zirconia particles;

[0059] (2) Sonicate the sodium polystyrene sulfonate solution for 120 minutes to uniformly disperse the nanoparticles, centrifuge for 10 minutes, and replace the supernatant with an equal volume of deionized water after centrifugation; repeat 3 times to obtain polystyrene sulfonate...

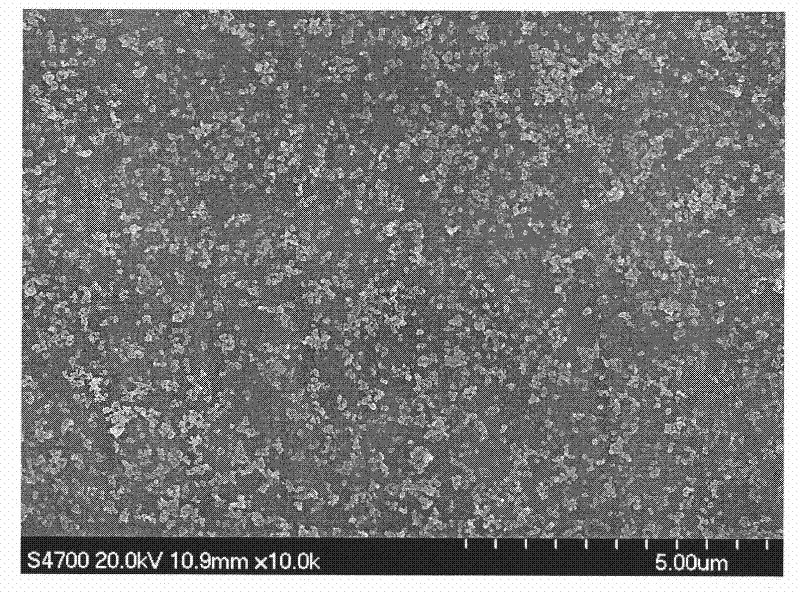

specific Embodiment 3

[0081] The base membrane is made of polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off and a membrane area of 28cm 2 , the polycation material used is polyethyleneimine (PEI, with a molecular weight of 60,000), the polyanion is polyacrylic acid (PAA, with a molecular weight of 4 million), and nano-sized zirconia particles (ZrO 2 , within 100nm of nanometer particle size, 5wt%), the solvent of polyethylenimine and polyacrylic acid is water.

[0082] Assembly conditions and methods:

[0083] (1) Polyethyleneimine is made into 500ml of a 0.5wt% solution with deionized water, and left to defoam; Polyacrylic acid is made into 500ml of a 0.05wt% solution with deionized water, left to stand for defoaming, and nano-oxidized Zirconium particles 1ml;

[0084] (2) Ultrasonic the polyacrylic acid solution for 120 minutes to uniformly disperse the nanoparticles, centrifuge for 10 minutes, and replace the supernatant with an equal volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com