Light-sensitive transfer sheet, light-sensitive layers, method for forming image pattern and method for distribution pattern

A technology for transferring thin sheets and photosensitive layers, which can be used in photosensitive material processing, microlithography exposure equipment, photoplate making process of patterned surface, etc., and can solve problems such as cover film rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

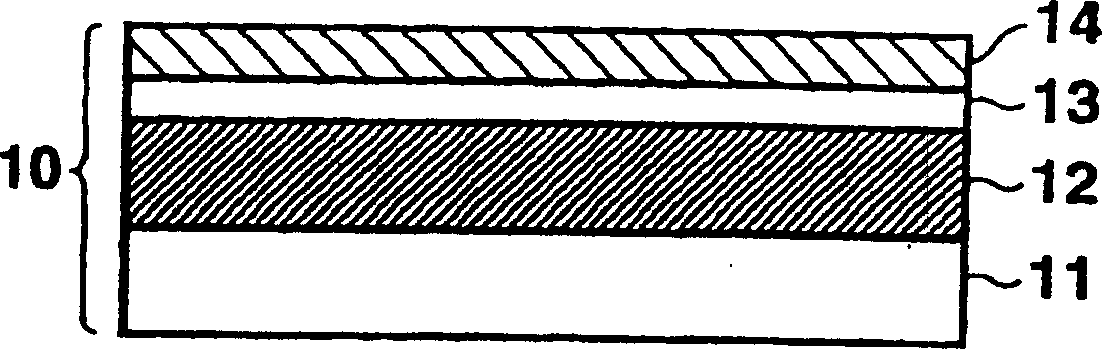

[0298] (Formation of the first photosensitive layer)

[0299] On a polyethylene terephthalate film having a thickness of 20 µm, a first photosensitive resin composition solution composed of the following components was coated and dried to form a first photosensitive layer having a thickness of 25 µm.

[0300] The first photosensitive resin composition solution

[0301] Methyl methacrylate / 2-ethylhexyl acrylate / benzyl methacrylate / methacrylic acid copolymer (copolymer composition (molar ratio): 55 / 11.7 / 4.5 / 28.8 mass average molecular weight: 90,000, Tg: 70 °C) 15 parts by mass

[0302] 1 / 2 molar ratio adduct of 1,6-hexamethylene diisocyanate and octaoxirane mono(meth)acrylate 8 parts by mass

[0303] 0.04 parts by mass of 4,4'-bis(diethylamino)benzophenone

[0304] Benzophenone 1.0 parts by mass

[0305] 0.5 parts by mass of 4-toluenesulfonamide

[0306] Malachite green oxalate 0.02 parts by mass

[0307] 1,2,4-triazole 0.01 parts by mass

[0308] Leuco gentian violet 0....

Embodiment 2

[0340] (Synthesis example of polyvinyl alcohol derivative)

[0341] 10 parts by mass of polyvinyl alcohol (PVA205 manufactured by Kuraray Co., Ltd.) was dissolved in 90 parts by mass of water. A solution of 2.3 parts by mass of methylolacrylamide dissolved in 20.7 parts by mass of water and 0.002 parts by mass of hydroquinone were added thereto. Further, 0.04 parts by mass of sulfuric acid was added thereto and reacted at 40°C for 4 hours to obtain a 10% by mass aqueous solution of polyvinyl alcohol having an acrylamide group in the side chain.

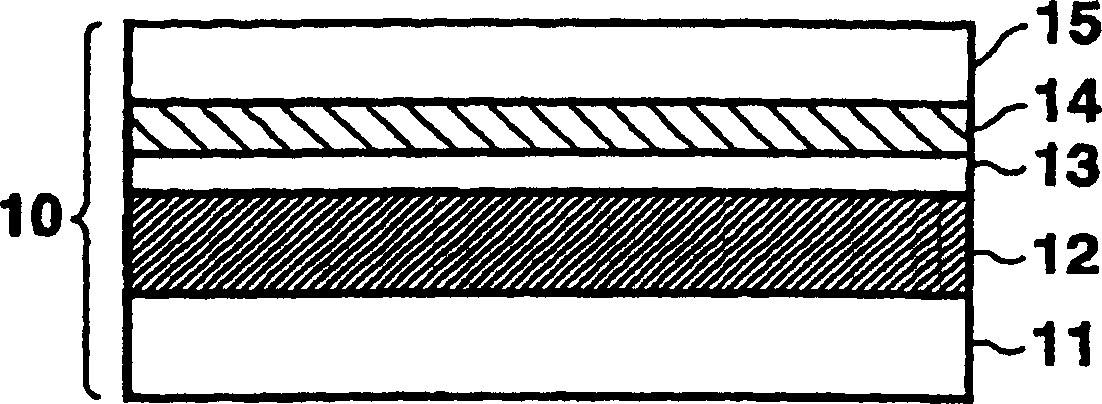

[0342] (Production of photosensitive transfer sheet)

[0343] A photosensitive transfer sheet was obtained in the same manner as in Example 1 except that the barrier layer solution in Example 1 was changed to the following.

[0344] Barrier solution

[0345] 130 parts by mass of a 10% aqueous solution of a synthetic polyvinyl alcohol derivative

[0346] 6 parts by mass of polyvinylpyrrolidone

[0347] Water 83 parts by mass

[0...

Embodiment 3

[0351] (Production of photosensitive transfer sheet)

[0352] A photosensitive transfer sheet was obtained in the same manner as in Example 1 except that the barrier layer solution in Example 1 was changed to the following.

[0353] Barrier solution

[0354] Polyvinyl alcohol (PVA205, manufactured by Kuraray Co., Ltd.) 13 parts by mass

[0355] 3 parts by mass of polyvinylpyrrolidone

[0356] 3 parts by mass of nonapropylene glycol diacrylate

[0357] 200 parts by mass of water

[0358] Methanol 180 parts by mass

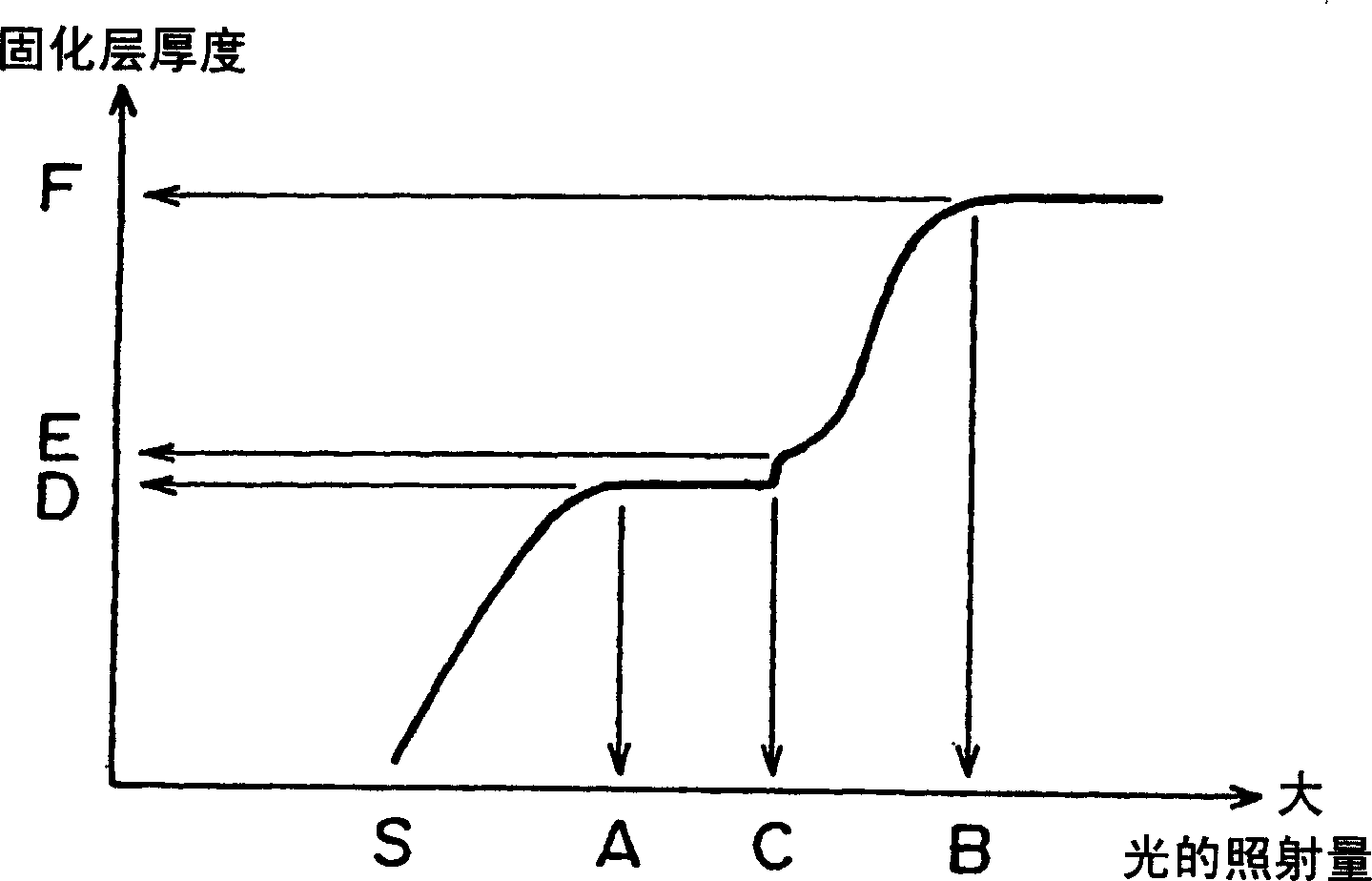

[0359] The film thickness deviation of any layer is within ±5%. The sensitivity of the thus-obtained photosensitive transfer sheet was measured by the method described later. As a result, the shortest developing time was 30 seconds, and the light energy A required for curing the second photosensitive layer was 4 mJ / cm 2 , the light energy B required for curing the first photosensitive layer is 40mJ / cm 2 , the light energy C required until the first photosensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com