Method for preparing aluminum-gadolinium-samarium alloy by fused salt electrolysis

A molten salt electrolysis and alloy technology, applied in the field of non-ferrous metals, can solve the problems of easy segregation of alloy components, long production process, complicated process, etc., and achieve the effect of realizing experimental conditions, simple production process, and easy experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

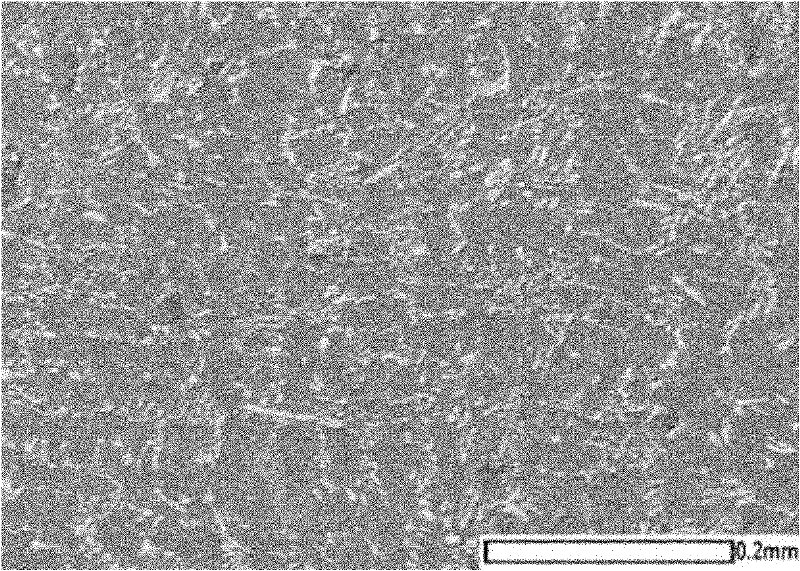

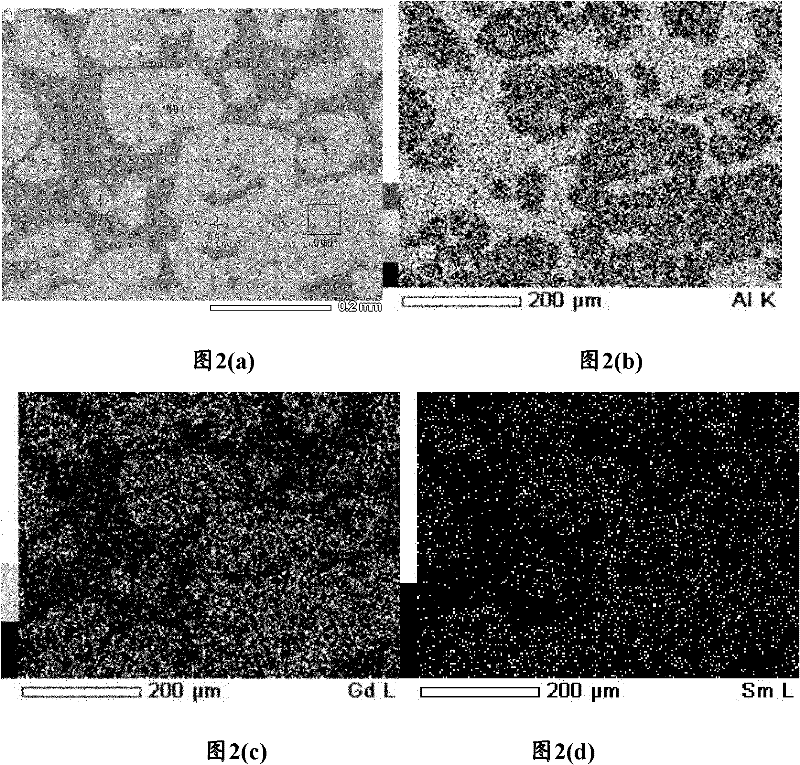

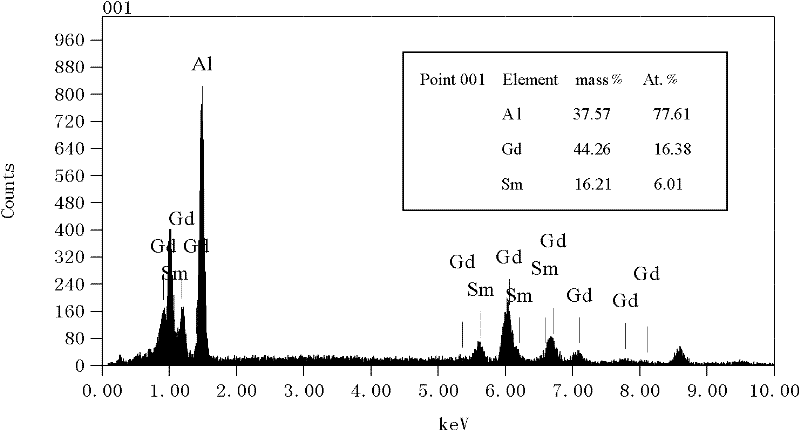

[0019] Embodiment 1: with AlF 3 +NaCl+KCl is the electrolyte system, AlF 3 , NaCl, and KCl mass percentages are 10%, 40%, and 50% respectively, and then press AlF 3 Add 10% of the mass to anhydrous Sm 2 o 3 and Gd 2 o 3 mixed powder, the electrolysis temperature is 740°C, and the cathode current density is 6.2A / cm 2 , the cell voltage is 4.5-4.8V, after 2 hours of electrolysis, Al-Gd-Sm ternary alloy is deposited near the cathode of the molten salt electrolytic cell, and the contents of aluminum, gadolinium and samarium are respectively: 81.4%, 9.0%, 9.6% . Its current efficiency is 70.5%.

Embodiment 2

[0020] Embodiment 2: with AlF 3 +NaCl+KCl is the electrolyte system, AlF 3 , NaCl, and KCl mass percentages are 9%, 41%, and 50% respectively, and then press AlF 3 Add 20% of the mass to anhydrous Sm 2 o 3 and Gd 2 o 3 The mixed powder, with the inert metal molybdenum (Mo) as the cathode, graphite as the anode, the electrolysis temperature is 790 ° C, and the cathode current density is 6.2A / cm 2 , anode current density 0.5A / cm 2 , the cell voltage is 4.4-4.7V, after 1.8h of electrolysis, Al-Gd-Sm ternary alloy is deposited near the cathode of the molten salt electrolytic cell, and the contents of aluminum, gadolinium and samarium are respectively: 75.1%, 20.8%, 4.1% %. Its current efficiency is 65.7%.

Embodiment 3

[0021] Embodiment 3: with AlF 3 +NaCl+KCl is the electrolyte system, AlF 3, NaCl, and KCl mass percentages are 11.1%, 38.9%, and 50% respectively, and then press AlF 3 Add 10% of the mass to anhydrous Sm 2 o 3 and Gd 2 o 3 mixed powder, the electrolysis temperature is 640°C, and the cathode current density is 6.2A / cm 2 , anode current density 0.5A / cm 2 , the cell voltage is 4.6-5.0V, after 2 hours of electrolysis, Al-Gd-Sm ternary alloy is deposited near the cathode of the molten salt electrolytic cell, and the contents of aluminum, gadolinium and samarium are respectively: 90.8%, 5.6%, 3.6% . Its current efficiency is 30.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com