Gas-shield water-based quenching device

A water-based quenching and gas protection technology, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of human health and environmental pollution, affecting the service life of lead pots, and high production costs, changing mechanical strength and avoiding environmental pollution. And the effect of damage to human body and reduction of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific drawings and embodiments.

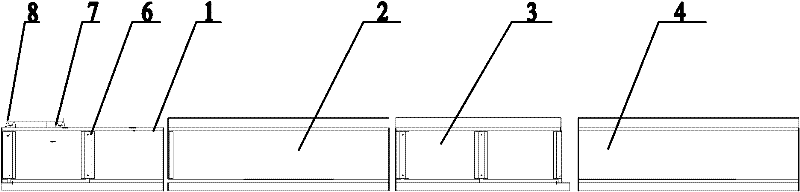

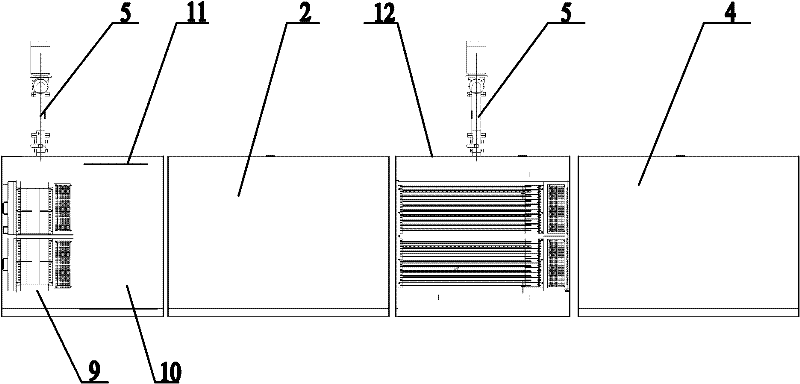

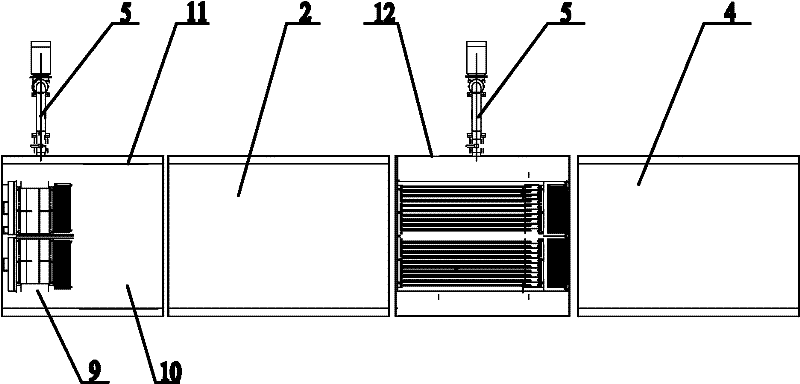

[0013] like Figure 1~Figure 2 As shown: the present invention includes a first water-based quenching tank 1, a first gas protection tank 2, a second water-based quenching tank 3, a second gas protection tank 4, a centrifugal pump 5, a positioning block 6, a moving roller 7, and a diversion Plate 8 , overflow plate 9 , overflow area 10 , first tank body 11 and second tank body 12 .

[0014] like figure 1 and figure 2 As shown: one end of the first water-based quenching tank 1 is provided with a second water-based quenching tank 3, and both the first water-based quenching tank 1 and the second water-based quenching tank 3 have a water-based quenching liquid, which can Water-based quenching of steel wire. The first water-based quenching tank 1 and the second water-based quenching tank 3 will be provided with a first gas protection box 2, and the second water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com