Manufacture method of flexible glue-free double-face copper clad

A technology of double-sided copper clad foil, applied in the field of preparation of flexible non-adhesive double-sided copper clad foil, can solve problems affecting the dimensional stability of copper clad foil, poor dimensional stability of mechanical properties, complex preparation methods and processes, etc., to achieve improved Dimensional stability, good thermal stability, and excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Provide a kapton polyimide film with a thickness of 18 microns.

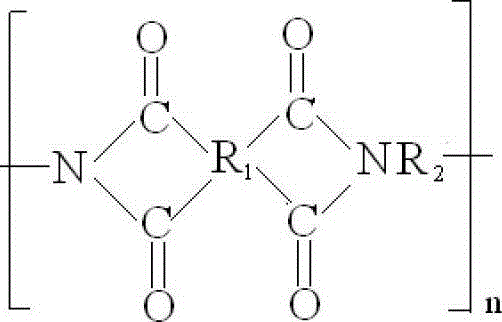

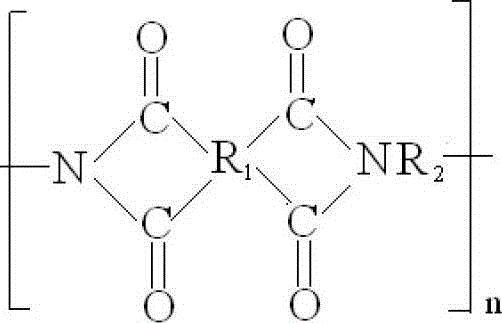

[0023] (2) Prepare thermoplastic polyimide precursor solution: dissolve 16.96g 3,3'-diaminobenzophenone and 4.96g 4,4'-diaminodiphenylsulfone in 100ml xylene and 400mlN respectively, In N-dimethylacetamide solvent, stir and mix well. Then 22g of pyromellitic dianhydride was added to the above solution in batches. After stirring and reacting at low temperature for 10 hours, a viscous thermoplastic polyamic acid solution (intrinsic viscosity η int =1.8dl / g).

[0024] (3) Coat both sides of the kapton film with a thermoplastic polyimide precursor solution with a thickness of 20 microns, and dry it at 60, 100, 120, 160, and 120°C for 10 seconds to obtain a three-layer composite film, and then follow the copper Foil, three-layer composite film, and copper foil are stacked from top to bottom (the bright side of the copper foil faces outward), and hot-pressed at 180°C under the protection of nitrogen, wit...

Embodiment 2

[0026] (1) Provide a dupont polyimide film with a thickness of 8 microns.

[0027] (2) Prepare thermoplastic polyimide precursor solution: Dissolve 18.44,4’-diaminodiphenyl ether and 1.6g aliphatic diamine X-173 in 100ml xylene and 400ml NMP solvent respectively, stir and mix well. Then 22g of pyromellitic dianhydride was added to the above solution in batches. After stirring and reacting at low temperature for 10 hours, a viscous thermoplastic polyamic acid solution (intrinsic viscosity η int =1.8dl / g).

[0028] (3) Coat both sides of the dupont polyimide film with a thermoplastic polyimide precursor solution with a thickness of 30 microns, and dry it at 60, 100, 120, 160, and 120°C for 10 seconds to obtain a three-layer composite film , and then stacked from top to bottom in the order of copper foil, three-layer composite film, and copper foil (the smooth side of the copper foil faces outward), and hot-pressed at 220°C under the protection of nitrogen, with a pressure of 5...

Embodiment 3

[0030] (1) Provide upliex polyimide film with a thickness of 12 microns.

[0031] (2) Prepare thermoplastic polyimide precursor solution: dissolve 11.96g of bis-diphenylaminomethane and 16.4g of 1,4'-bis(4-aminophenoxy)benzene in 100ml of xylene and 400ml of N, N - In dimethylacetamide solvent, stir to mix well. Then 31g of 4,4'-diphenyl ether tetra-acid dianhydride was added to the above solution in batches. After stirring and reacting at low temperature for 10 hours, a viscous thermoplastic polyamic acid solution (intrinsic viscosity η int =1.8dl / g).

[0032] (3) Coating a 10-micron-thick thermoplastic polyzimide precursor solution on both sides of a 12-micron thermosetting polyimide film, drying at 60, 100, 120, 160, and 120°C for 10 seconds respectively to obtain The three-layer composite film is then stacked from top to bottom in the order of copper foil, three-layer composite film, and copper foil (the smooth side of the copper foil faces outward), and hot-pressed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com