Polyimide compound soft board and its making method

A technology of polyimide and polyimide film, applied in the direction of circuit substrate materials, chemical instruments and methods, lamination, etc., can solve the problems of unfavorable processing, bending, warping and other problems in the back-stage process, and achieve stable dimensions No warping or bending, high heat resistance, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

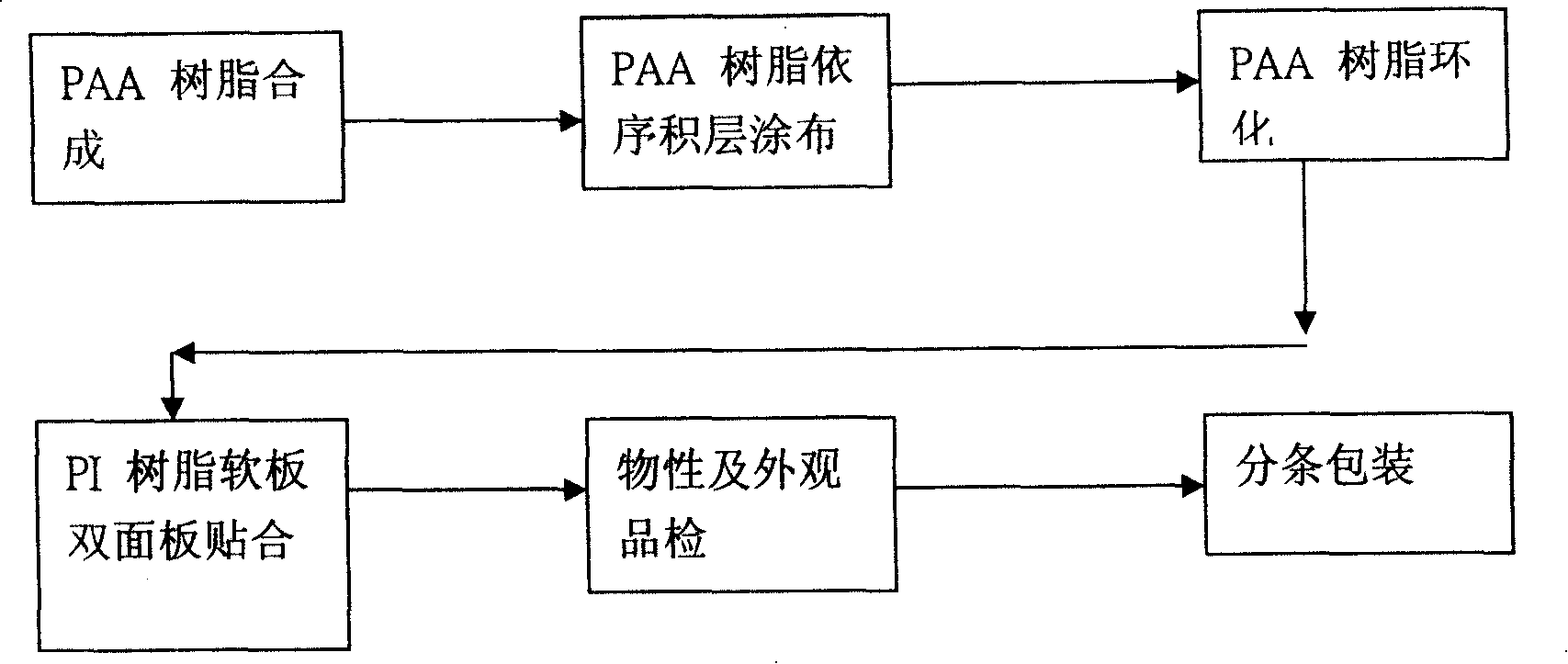

Method used

Image

Examples

Synthetic example

[0039] (a) Synthesis of polyamic acid 1-1 (cyclized polyamic acid with a CTE value greater than 20ppm)

[0040] In a four-neck reaction flask with a stirrer and a nitrogen conduit, under the blowing of a nitrogen flow rate of 20cc / min, put 5.4 grams (0.05 moles) of p-phenylenediamine (PDA) in the reaction flask and use N-methyl Pyrrolidone (NMP) was dissolved, and 15 minutes after the dissolution, 10 g (0.05 mol) of 4,4'-oxydiphenylamine (ODA) was fed and dissolved while maintaining the temperature at 15°C. In addition, take a first flask with a stirring bar, feed 8.82 grams (0.03 moles) of 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA) and 15 grams of NMP and stir to dissolve it, then The content of this first flask was added to the above-mentioned reaction flask, and the reaction was carried out for 1 hour by continuously introducing nitrogen gas and stirring. Another second flask was taken, and 16.1 grams (0.05 moles) of 3,3',4,4'-benzophenonetetracarboxylic dianhydr...

Embodiment 1 to Embodiment 14 and comparative example 1 to 3

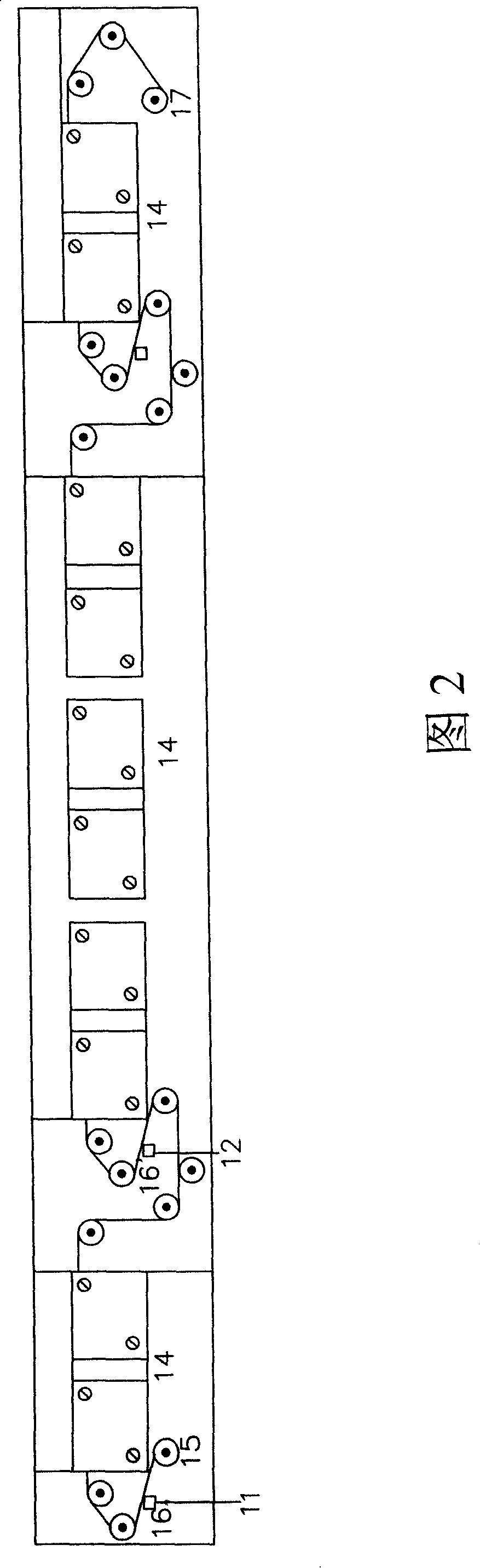

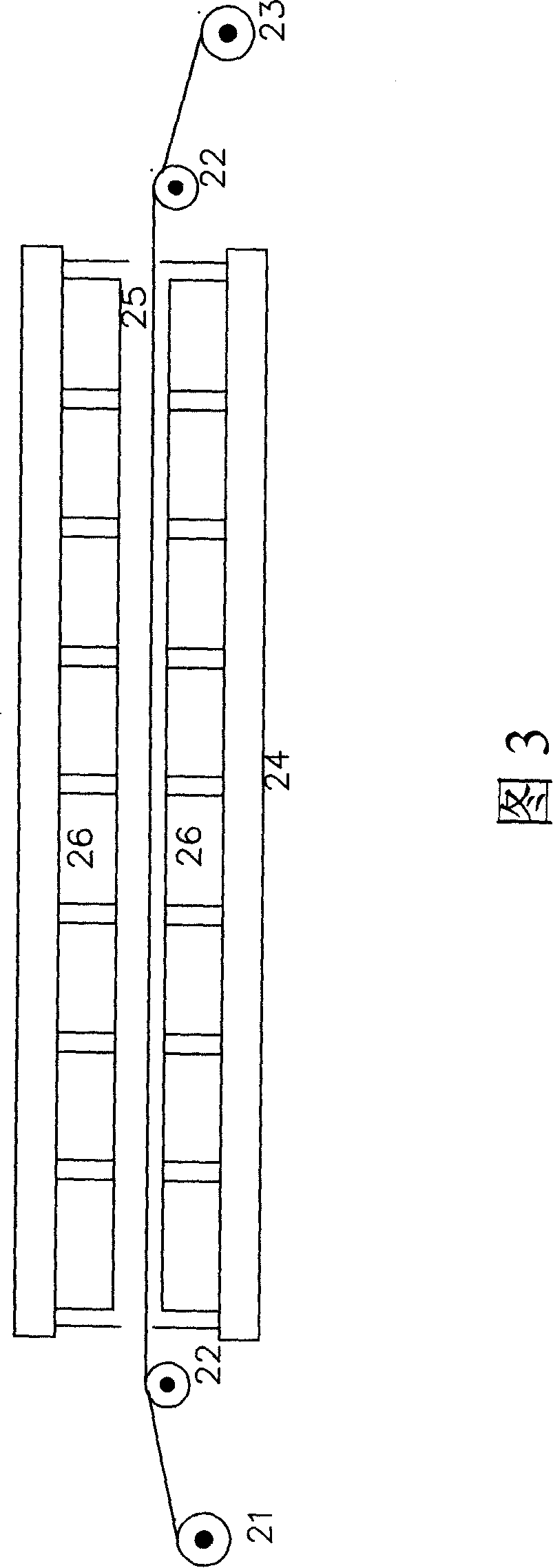

[0050] According to the compositions listed in Table 3 and Table 4, the polyamic acid resin 1 prepared in the above synthesis example was uniformly coated on a copper foil with a thickness of 18 microns by a wire bar, and the coating thickness was 3 microns. The solvent was removed by baking at 180°C for 3 minutes and at 180°C for 5 minutes. Take out the dried polyamic acid-coated copper foil, then apply polyamic acid resin 2 to a coating thickness of 17 microns, then bake in an oven at 120°C for 3 minutes and at 180°C for 7 minutes to remove the solvent. Then the obtained copper foil was placed in a nitrogen oven, placed at 180°C for 1 hour, at 220°C for 1 hour, at 300°C for 0.6 hour, and at 350°C for 0.5 hour to polyimide the polyamic acid ( Cyclization) reaction to make polyimide composite soft board. The structure of the composite soft board is copper foil / polyimide 1 (CTE greater than 20ppm) / polyimide 2 (CTE less than 20ppm).

[0051] Then, as described in (a) of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com