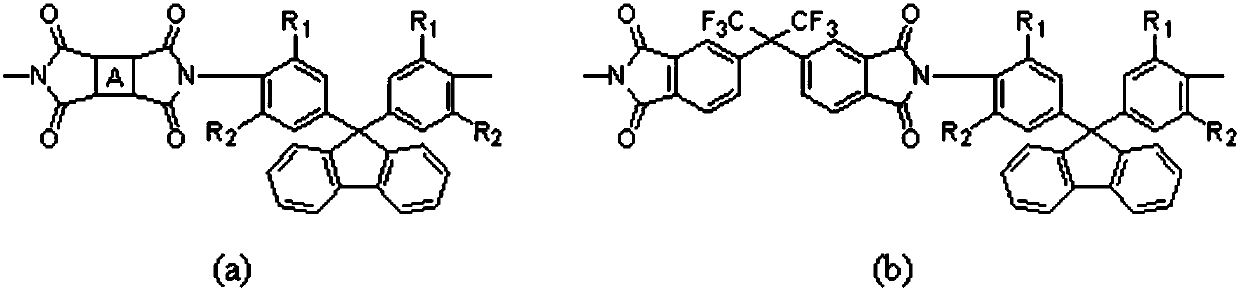

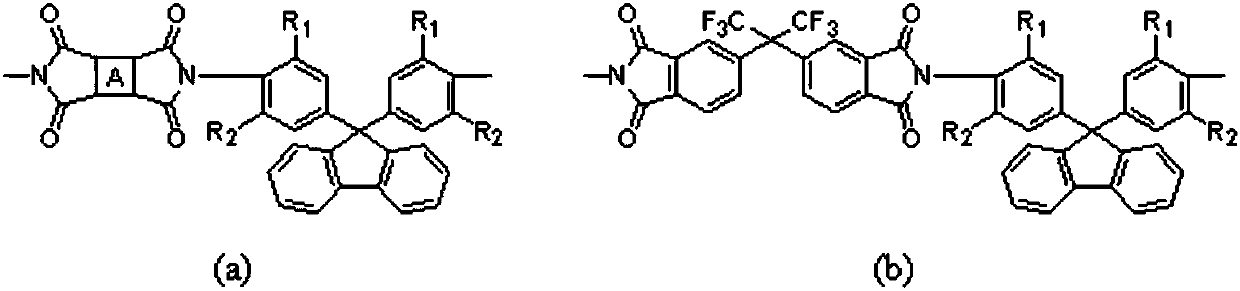

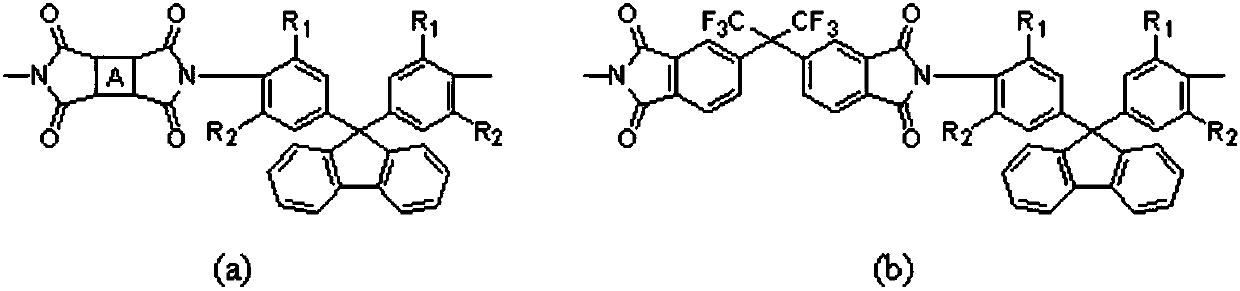

Polyimide resin and transparent polyimide film

A technology of polyimide resin and transparent polyimide, applied in the field of polyimide, can solve problems such as poor solubility of polyimide resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] The preparation method of polyimide resin provided by the invention:

[0122] (1) In the reaction vessel, add dianhydride monomer, diamine monomer, and organic solvent and mix thoroughly, and polycondensation reaction occurs under heating under basic catalyst conditions to generate polyimide;

[0123] (2) Cool the reaction product in step (1), pour it into a precipitant to precipitate, filter, collect the precipitate, wash thoroughly, and dry to obtain polyimide resin powder.

[0124] Another preparation method of polyimide resin provided by the invention:

[0125] (1) In the reaction vessel, add the diamine monomer into an organic solvent protected by nitrogen or an inert gas, stir to dissolve it completely, then add the dianhydride monomer for polycondensation reaction, and stir for 3 to 48 hours to obtain a polyamic acid solution ;

[0126] (2) Adding a mixed solution of acetic anhydride and a basic catalyst to the polyamic acid solution obtained in step (1), stirr...

Embodiment 1

[0142] Add 19.2210g (0.050mol) 9,9-bis(3-fluoro-4-aminophenyl) fluorene monomer, 19.9908g (0.045mol) 4,4'-(hexafluoroiso Propylene) diphthalic anhydride monomer, 4,4'-(4,4'-hexafluoroisopropylene diphenoxy) diphthalic anhydride 2.6025g (0.005mol) bisphenol A diether dianhydride monomer, 360mL m-formaldehyde Phenol, 12 drops of isoquinoline, under the protection of nitrogen, react at 120°C for 2 hours; then heat up to 200°C for 10 hours, cool to 100°C, add 1.1850g (0.008mol) phthalic anhydride, continue to react for 2 hours , cooled to room temperature, the reaction solution was slowly poured into 2L ethanol to precipitate, filtered, the obtained filter cake was boiled and washed twice with ethanol, and then dried in a vacuum oven at 150°C for 8 hours to obtain 38.39g of white polyimide resin powder , the productive rate is 91.8%; after dissolving the white polyimide resin powder in tetrahydrofuran, it is coated on a dry and clean glass plate to form a film, then dried on a hea...

Embodiment 2

[0144] Add 19.2210g (0.050mol) 9,9-bis(3-fluoro-4-aminophenyl) fluorene monomer and 200mL N,N-dimethylacetamide into a dry and clean 500mL three-necked flask, under nitrogen protection Stir at room temperature, after the diamine monomer is completely dissolved, add 2.2212g (0.005mol) 4,4'-(hexafluoroisopropylene) diphthalic anhydride monomer, 23.4221g (0.045mol) bisphenol A diether dianhydride mono solid, 50mL N,N-dimethylacetamide, reacted at room temperature for 24 hours, added 30ml of a mixed solution of acetic anhydride and triethylamine (22mL of acetic anhydride, 8mL triethylamine), continued to react at room temperature for 12 hours, and the reaction solution Slowly pour it into 2L of deionized water for precipitation, filter, and boil and wash the obtained filter cake with ethanol for 3 times, and then place it in a vacuum oven at 140°C for 6 hours to obtain 40.96 g of white polyimide resin powder, with a yield of 91.3%; After the white polyimide resin powder was dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com