Filtrate loss reducer for high-temperature-resistant oil field drilling fluid and preparation method thereof

An oil field drilling and fluid loss reducing agent technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of poor thermal stability of quaternary ammonium groups, polluted heavy metal ions, high price, etc., and achieve excellent high temperature resistance, The effect of low cost and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method for an oilfield drilling fluid with high temperature resistant fluid loss reducer, comprising the following steps:

[0048] ① mixing lignin or lignosulfonate and its derivative components with a redox initiator in a mass ratio of 40:3;

[0049] ②Mix vinyl monomers and their derivative components with persulfate at a mass ratio of 200:3;

[0050] ③ Dissolve the above two in water respectively, stir evenly, and activate under nitrogen protection at 50-60°C for 10-30 minutes respectively;

[0051] ④ Mix the solution after initiation and pour it into the reactor, add the crosslinking agent and turn on the stirring, pass in nitrogen for oxygen barrier protection, react at 60-90°C for 3-7 hours, the pressure is normal pressure, and the product obtained after the reaction is completed It is a dark brown liquid, spray-dried into powder.

[0052] Test Conditions:

[0053] Normal temperature and normal pressure: room temperature, standard atmospheric press...

Embodiment 1

[0056] Dissolve 8g of S-lignin in water, add 0.6g of ferrous ammonium sulfate hexahydrate and 0.05g of hydrogen peroxide, fill it with nitrogen gas and activate it in a water bath at 50°C for 20min; mix 13.72g of acrylamide (AM) and 2 -Acrylamide-2-methylpropanesulfonic acid (AMPS) 10g (according to the molar ratio of 4:1), add 0.36g potassium persulfate to the two vinylic monomers, fill with nitrogen gas, seal and activate in a water bath at 50°C 20min; add the first two into a 500mL three-necked bottle, add 0.36g of N,N-methylenebisacrylamide, turn on the stirring and reflux device, raise the temperature to 70°C under nitrogen protection and normal pressure, and react for 4 hours. At the end of the reaction, a dark brown liquid is obtained, and after spray drying, a powdery fluid loss reducer for oilfield drilling fluid with good water solubility and high temperature resistance is obtained.

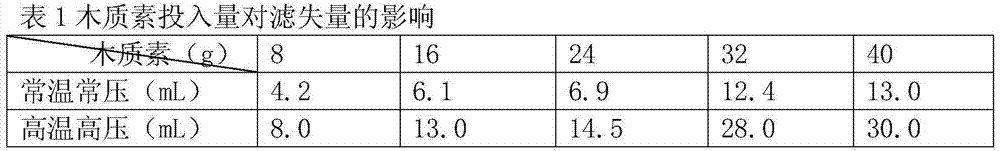

[0057]See Table 1 for the influence of different lignin inputs on the fluid loss co...

Embodiment 2

[0059] Take 16g of lignosulfonate and dissolve it in water, add 1.2g of ferrous ammonium sulfate hexahydrate and 0.1g of hydrogen peroxide, fill it with nitrogen gas and activate it in a water bath at 50°C for 20min; g, 2-acrylamide-2-methylpropanesulfonic acid (AMPS) 10g, (according to the molar ratio is 4:1) add 0.28g potassium persulfate to the two vinylic monomers, fill it with nitrogen and seal it at 50 ℃ Activate in a water bath for 20 minutes; put the first two into a 500mL three-neck flask, add 0.81g of N,N-methylenebisacrylamide, turn on the stirring and reflux device, and raise the temperature to 60°C under nitrogen protection at normal pressure. Reaction for 7 hours. The liquid obtained after the reaction is dark brown, and after spray drying, a powdery fluid loss reducer for oilfield drilling fluid with good water solubility and high temperature resistance is obtained.

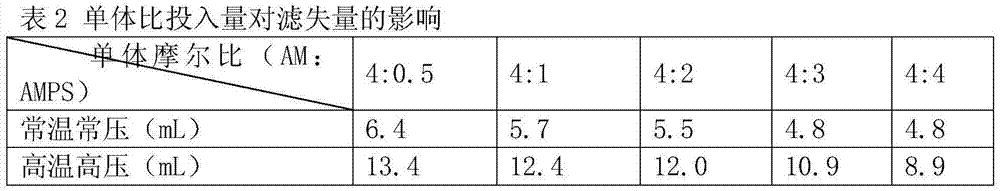

[0060] See Table 2 for the influence of different monomer ratio conditions on the fluid loss c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com