Novel controlled-release fertilizer coating agent and preparation method thereof

A technology of controlled-release fertilizer and coating agent, which is applied in the direction of fertilization device, fertilizer mixture, application, etc., to achieve good convenience and targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

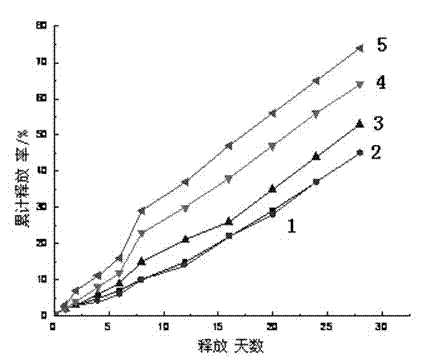

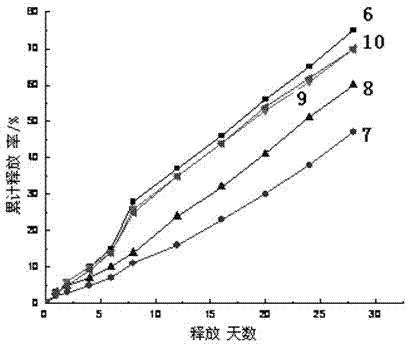

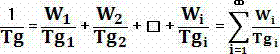

[0054] The glass transition temperature Tg of the monomer copolymer used in the design coating agent is 30°C, styrene (Tg=100°C) is selected as the rigid monomer, and n-butyl acrylate (Tg=-54°C) is used as the flexible monomer to carry out polymerization :

[0055] (1) Fully mix 60.75g of styrene and 29.25g of n-butyl acrylate to obtain mixed solution 1. Take out 13.5g of mixed solution 1 and add it to the reactor, add 0.225g of sodium bicarbonate, 0.18g of dodecyl mercaptan, 0.72g of sodium p-styrene sulfonate, 100mL of deionized water, stir for 30 minutes, and then heat up to 75 ℃, add 0.27g ammonium persulfate, and react for 30 minutes to obtain seed emulsion.

[0056] (2) The remaining 1.08 g of ammonium persulfate and 2.88 g of sodium p-styrenesulfonate were dissolved in 110 mL of deionized water to obtain a mixed solution 2.

[0057] (3) Raise the temperature of the reactor to 82°C, add the mixed solution 1 and the mixed solution 2 dropwise at the same time, and contro...

Embodiment 2

[0062] The Tg of the coating agent is designed to be 33°C, and methyl methacrylate (Tg=105°C) is selected as the rigid monomer, and n-butyl acrylate (Tg=-54°C) is used as the flexible monomer to carry out polymerization:

[0063] (1) 60.75 g of methyl methacrylate and 29.25 g of n-butyl acrylate were thoroughly mixed to obtain a mixed solution 1. Take out 13.5g of mixed solution 1 and add it to the reactor, add 0.225g of sodium bicarbonate, 0.18g of dodecyl mercaptan, 0.72g of sodium p-styrene sulfonate, 100mL of deionized water, stir for 30 minutes, and then heat up to 75 ℃, add 0.27g ammonium persulfate, and react for 30 minutes to obtain seed emulsion.

[0064] (2) The remaining 1.08 g of ammonium persulfate and 2.88 g of sodium p-styrenesulfonate were dissolved in 110 mL of deionized water to obtain a mixed solution 2.

[0065] (3) Raise the temperature of the reactor to 82°C, add the mixed solution 1 and the mixed solution 2 dropwise at the same time, and control the dro...

Embodiment 3

[0070] The coating agent Tg is designed to be 34°C, methyl methacrylate (Tg=105°C) is selected as rigid monomer, n-butyl acrylate (Tg=-54°C) is used as flexible monomer, acrylic acid (Tg=106°C) is Functional monomers, polymerized:

[0071] (1) 56.7 g of methyl methacrylate and 28.8 g of n-butyl acrylate were fully mixed to obtain a mixed solution 1. Take out the mixed solution 1 of 17.1g and add in the reactor, add 0.18g sodium bicarbonate simultaneously, 0.15g dodecyl mercaptan, 0.72g sodium p-styrene sulfonate, 100mL deionized water, after stirring for 30 minutes, heat up to At 75°C, 0.18g of potassium persulfate was added and reacted for 30 minutes to obtain a seed emulsion.

[0072] (2) The remaining 68.4 g of the mixed solution 1 was mixed with 4.5 g of acrylic acid to obtain the mixed solution 2 . The remaining 0.72 g of potassium persulfate and 2.88 g of sodium p-styrenesulfonate were dissolved in 110 mL of deionized water to obtain a mixed solution 3.

[0073] (3) R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com