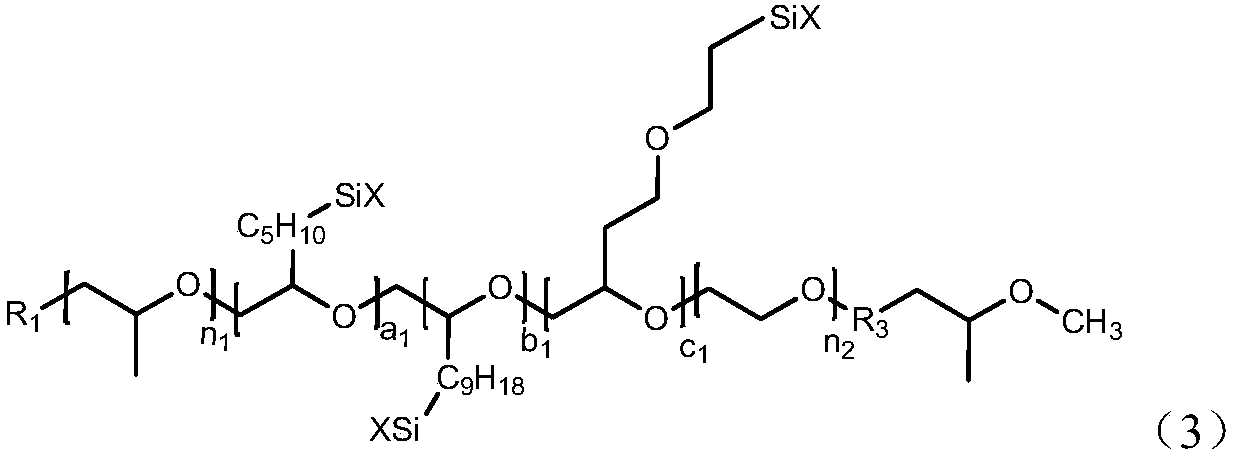

Polyether with controllable silicon content and preparation method and application thereof

A silicon content, polyether technology, applied in polyether adhesives, adhesive types, adhesives, etc., can solve problems such as insufficient sealing performance, and achieve the effect of excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

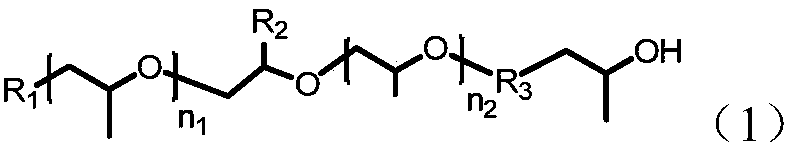

Embodiment 1

[0069] The design structure of this embodiment (1) has a molecular weight of 5000, wherein PO units (78.9mol) account for 92.1% of the total monomer mass, and 1,2-epoxy-5-hexene (4mol) is used as a special monomer, accounting for the total monomer mass. 7.90% of the body weight, the theoretical hydroxyl value is 11.2 mgKOH / g, and the theoretical unsaturation is 0.8 mmol / g; the theoretical end-capping rate is 100% with methoxyl capping; the theoretical unsaturation of hydrosilylation is 0 mmol / g g. As the silane, dimethoxymethylhydrogensilane is used.

[0070] Add 3.2g of methanol to a 1L kettle as a starter, add 0.5g (0.1%) of catalyst sodium methoxide, replace with nitrogen, reduce the pressure to -0.1MPa, raise the temperature to 100°C to remove the water generated by the reaction for 1.5h; raise the temperature To 110°C, the mass of propylene oxide monomer required is calculated to be 457.5g, and the mass of 1,2-epoxy-5-hexene functional monomer required is 39.26g. After m...

Embodiment 2

[0075] The design structure of this embodiment (1) has a molecular weight of 8000, wherein PO units (123.33mol) account for 90.12% of the total monomer mass, and 1,2-epoxy-5-hexene (8mol) is used as a special monomer, accounting for the total monomer mass. 9.89% of the body weight, the theoretical hydroxyl value is 14.03 mgKOH / g, and the theoretical unsaturation is 1 mmol / g. The theoretical hydroxyl value is 0 mgKOH / g for methoxy end-capping, and the theoretical degree of unsaturation by hydrosilylation is 0 mmol / g. As the silane, dimethoxymethylhydrogensilane is used.

[0076] Add 6.2g of ethylene glycol into a 1L kettle as a starting agent, add 0.8g (0.1%) of catalyst sodium methoxide, replace with nitrogen, reduce the pressure to -0.1MPa, and raise the temperature to 100°C to remove the water generated by the reaction for 1.5h; High temperature to 110°C, calculate the required mass of propylene oxide monomer to be 715.2g, the required mass of 1,2-epoxy-5-hexene functional ...

Embodiment 3

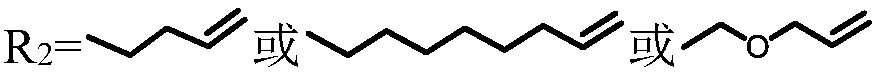

[0081] The design structure of this embodiment (1) has a molecular weight of 10000, wherein PO units (78.9mol) account for 90.77% of the total monomer mass, and allyl glycidyl ether (8mol) is used as a special monomer, accounting for 9.23% of the total monomer mass. The theoretical hydroxyl value is 11.22 mgKOH / g, and the theoretical unsaturation is 0.8 mmol / g. The theoretical hydroxyl value is 0 mgKOH / g for methoxy end-capping, and the theoretical degree of unsaturation by hydrosilylation is 0 mmol / g. As the silane, trimethoxyhydrosilane was used.

[0082] Add 10.4 g of neopentyl glycol into a 1 L kettle as an initiator, add 1 g (0.1%) of catalyst sodium methoxide, replace with nitrogen, reduce the pressure to -0.1 MPa, and raise the temperature to 100° C. to remove the water generated by the reaction for 1.5 h; High temperature to 110°C, calculate the required mass of propylene oxide monomer to be 898.26g, the required mass of allyl glycidyl ether functional monomer to be 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com