Organic phosphonate concrete plastic retaining agent and preparation method thereof

A phosphonate and concrete technology, which is applied in the field of concrete admixture, can solve the problems of high cost and complicated preparation method of phosphobutane tricarboxylic acid, and achieve the effects of low equipment requirements, favorable industrial production, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

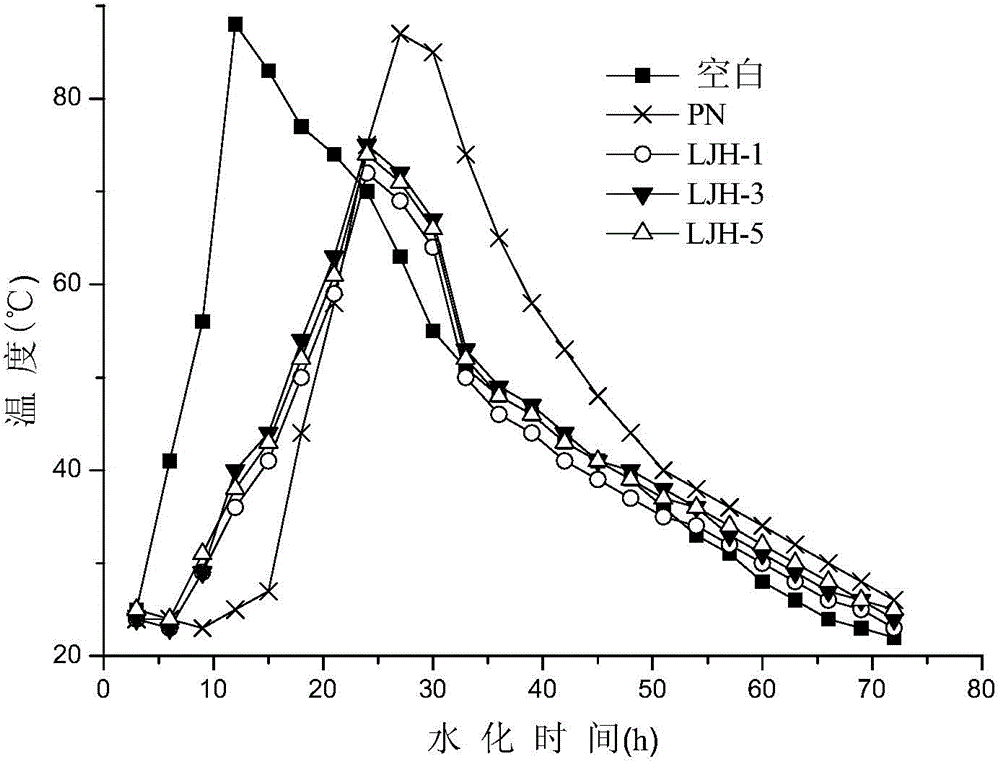

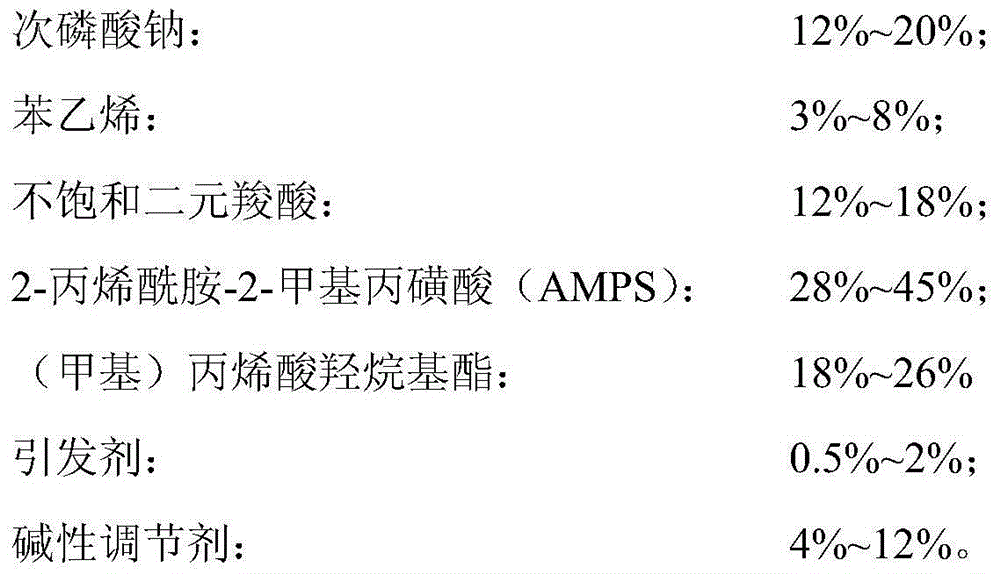

Embodiment 1

[0021] Add 83.2 parts of maleic anhydride, 27.5 parts of styrene, 176.3 parts of AMPS, 64.8 parts of sodium hypophosphite and 332.9 parts of water in a four-necked flask equipped with a stirrer, dropping funnel, condenser tube and thermometer, and heat while stirring to 60°C~70°C; add 36.8 parts of sodium hydroxide to adjust the pH of the reaction system to 5~7; add 107.6 parts of hydroxypropyl acrylate and 3.8 parts of ammonium persulfate to 167.1 parts of water to form a mixed solution, and in 3 hours ~5h to finish dripping; after the dropwise addition, keep the constant temperature reaction for 2h~4h; stop heating, cool to about 40°C and discharge the material to obtain a yellow and transparent plastic-preserving agent solution LJH-1.

Embodiment 2

[0023] Add 76.3 parts of fumaric acid, 18.8 parts of styrene, 193.5 parts of AMPS, 77.6 parts of sodium hypophosphite and 344.7 parts of water into a four-necked flask equipped with a stirrer, dropping funnel, condenser tube and thermometer, and heat while stirring to 60°C-70°C; add 30.3 parts of sodium hydroxide to adjust the pH of the reaction system to 5-7; add 98.6 parts of hydroxyethyl acrylate and 4.9 parts of ammonium persulfate to 155.3 parts of water to form a mixed solution, and in 3 hours After ~5 hours of dripping; after the completion of the dropping, keep the constant temperature for 2 hours ~ 4 hours; stop heating, cool to about 40°C and discharge, and the yellow transparent plastic preservation agent solution LJH-2 is obtained.

Embodiment 3

[0025] Add 67.8 parts of citraconic acid, 19.6 parts of styrene, 152.9 parts of AMPS, 92.5 parts of sodium hypophosphite and 308.3 parts of water into a four-neck flask equipped with a stirrer, dropping funnel, condenser tube and thermometer, and heat while stirring to 60°C-70°C; add 39.4 parts of triethanolamine to adjust the pH of the reaction system to 5-7; add 121.5 parts of hydroxyethyl methacrylate and 6.3 parts of potassium persulfate to 191.7 parts of water to form a mixed solution, and 3h~5h to finish the drop; after the dropwise addition, keep the constant temperature for 2h~4h; stop heating, cool to about 40°C and discharge the material, that is, the yellow transparent plastic-preserving agent solution LJH-3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com