Polyimide polymer, transparent polyimide thin film and preparation method of transparent polyimide thin film

A technology of transparent polyimide and polyimide, applied in the fields of polyimide polymer, transparent polyimide film and preparation thereof, can solve the problems of poor flexibility of transparent polyimide film, etc. Improved optical transmittance, good flex resistance, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

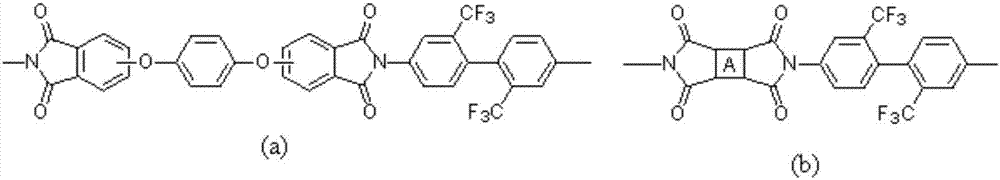

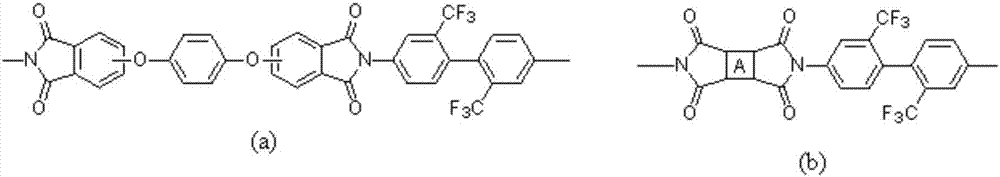

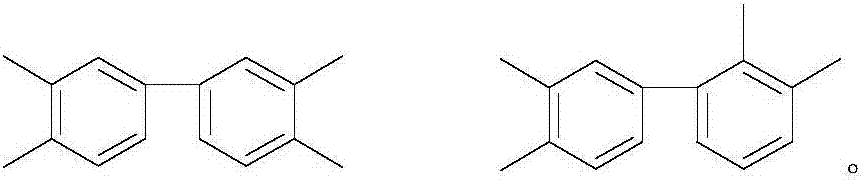

Method used

Image

Examples

Embodiment 1

[0132] Add 16.0115g (50mmol) 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl monomer, 100mL N,N-dimethylacetamide in a dry and clean 250mL three-necked flask, Stir at room temperature under protection, and after the diamine monomers are completely dissolved, slowly add 4.0232g (10mmol) of triphenyldiethene tetracarboxylic dianhydride monomer, 16.8811g (38mmol) of 3,3',4,4'-biphenyl tetra Formic dianhydride monomer, 45mL N,N-dimethylacetamide, react at room temperature for 6 hours, add 0.59g (4mmol) phthalic anhydride monomer, react at room temperature 4 to obtain a polyamic acid solution, filter, and vacuum defoam , and then coated on a dry and clean glass plate to form a film, put it on a heating plate at 80 ° C for 30 minutes, dry it in a blast oven at 360 ° C for 2 hours, take it out of the oven after cooling, and put it into boiling hot water until the colorless transparent polyimide film was removed from the glass plate to obtain a transparent polyimide film with a thickness...

Embodiment 2

[0134] Add 16.0115g (50mmol) 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl monomer, 100mL N,N-dimethylacetamide in a dry and clean 250mL three-necked flask, Stir at room temperature under protection. After the diamine monomer is completely dissolved, slowly add 10.0580g (25mmol) triphenylenediethene tetracarboxylic dianhydride monomer, 7.0612g (24mmol) 3,3',4,4'-biphenyl tetra Formic acid dianhydride monomer, 50mL N,N-dimethylacetamide, react at room temperature for 18 hours, add 0.30g (2mmol) phthalic anhydride monomer, react at room temperature for 3 hours to obtain polyamic acid solution, filter, and vacuum bubble, and then coat it on a dry and clean glass plate to form a film, put it on a heating plate at 80°C for 30 minutes, dry it in a vacuum oven at 30°C for 3 hours, and take it out of the oven after it cools down. Put in boiling hot water until the colorless transparent polyimide film is removed from the glass plate to obtain a transparent polyimide film with a thicknes...

Embodiment 3

[0136] Add 16.0115g (50mmol) 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl monomer, 120mL N,N-dimethylacetamide in a dry and clean 250mL three-necked flask, Stir at room temperature under protection. After the diamine monomer is completely dissolved, slowly add 2.0116g (5mmol) of triphenylenediyl ether tetracarboxylic dianhydride monomer, 11.7686g (40mmol) of 3,3',4,4'-biphenyl tetra Formic acid dianhydride monomer, 30mL N,N-dimethylacetamide, react at room temperature for 2 hours, add 1.4811g (10mmol) phthalic anhydride monomer, react at room temperature for 10 hours to obtain a polyamic acid solution, filter, and vacuum Then, coat it on a dry and clean glass plate to form a film, put it on a heating plate at 50°C for 90 minutes, dry it in a blast oven at 400°C for 0.5 hour, and take it out of the oven after it cools down , into boiling hot water until the colorless transparent polyimide film was removed from the glass plate to obtain a transparent polyimide film with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com