Ground calcium carbonate production process, ground calcium carbonate suspension and paper

A technology of grinding calcium carbonate and production process, which is applied in the production process of grinding calcium carbonate, grinding calcium carbonate suspension and paper, which can solve the problems of skin and respiratory tract irritation, flammability, strong irritation of acrylic acid, etc., and achieve tearing and Effect of improving cohesion and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

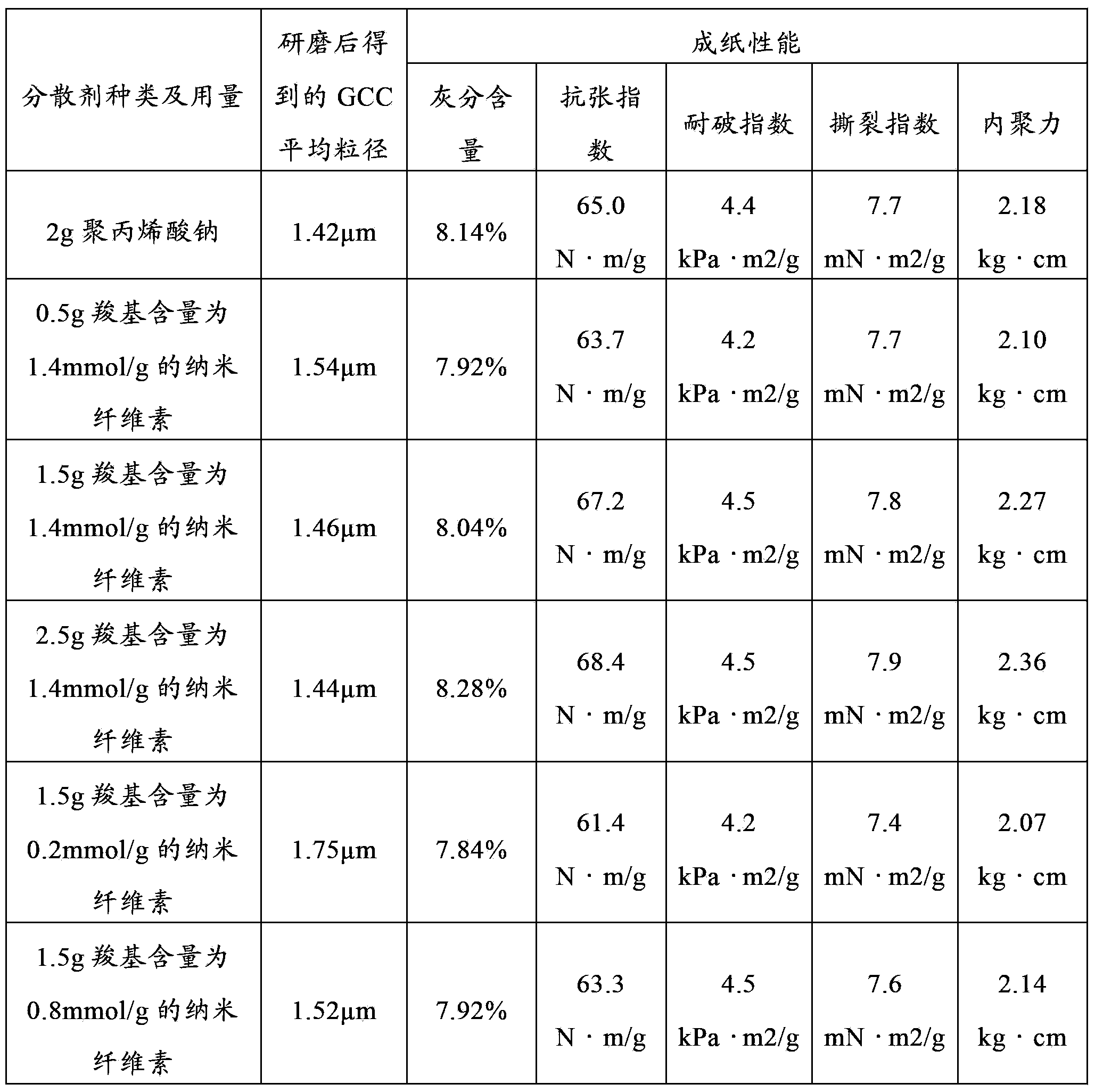

[0037] Under stirring conditions, 505g of water was added to 1kg of GCC dry powder, and then 100g of nanocellulose solution with a carboxyl content of 1.4mmol / g was added, wherein the effective concentration of nanocellulose was 0.5% (that is, 0.5g of carboxyl content was 1.4mmol / g of nanocellulose), stirred for 5 minutes to obtain a mixed solution; the mixed solution was ground and dispersed for 12 minutes using a GCC grinder (WAB DYNO-Mill), and the average particle size of GCC was measured to be 1.54 μm after grinding; The ground GCC is mixed with papermaking pulp, and the filling amount of GCC is 20% (for absolute dry fiber). After the pulp and GCC are mixed evenly, 1% cationic starch (for absolute dry pulp) is added, and then made into paper and tested. Paper performance, see the following table for specific performance parameters.

Embodiment 2

[0039] Under stirring conditions, 305g of water was added to 1kg of GCC dry powder, and then 300g of nanocellulose solution with a carboxyl content of 1.4mmol / g was added, wherein the effective concentration of nanocellulose was 0.5% (that is, 1.5g of carboxyl content was 1.4mmol / g of nanocellulose), stirred for 5 minutes to obtain a mixed solution; the mixed solution was ground and dispersed for 12 minutes using a GCC grinder (WAB DYNO-Mill), and the average particle size of GCC was measured to be 1.46 μm after grinding; The ground GCC is mixed with papermaking pulp, and the filling amount of GCC is 20% (for absolute dry fiber). After the pulp and GCC are mixed evenly, 1% cationic starch (for absolute dry pulp) is added, and then made into paper and tested. Paper performance, see the following table for specific performance parameters.

Embodiment 3

[0041] Under stirring conditions, add 105g of water to 1kg of GCC dry powder, after that, add 500g of nanocellulose solution with a carboxyl content of 1.4mmol / g, wherein the effective concentration of nanocellulose is 0.5% (that is, 2.5g of carboxyl content is 1.4mmol / g of nanocellulose), stirred for 5 minutes to obtain a mixed solution; the mixed solution was ground and dispersed for 12 minutes using a GCC grinder (WAB DYNO-Mill), and the average particle size of GCC was determined to be 1.44 μm after grinding; The ground GCC is mixed with papermaking pulp, and the filling amount of GCC is 20% (for absolute dry fiber). After the pulp and GCC are mixed evenly, 1% cationic starch (for absolute dry pulp) is added, and then made into paper and tested. Paper performance, see the following table for specific performance parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dimension diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com