Patents

Literature

37results about How to "High tensile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

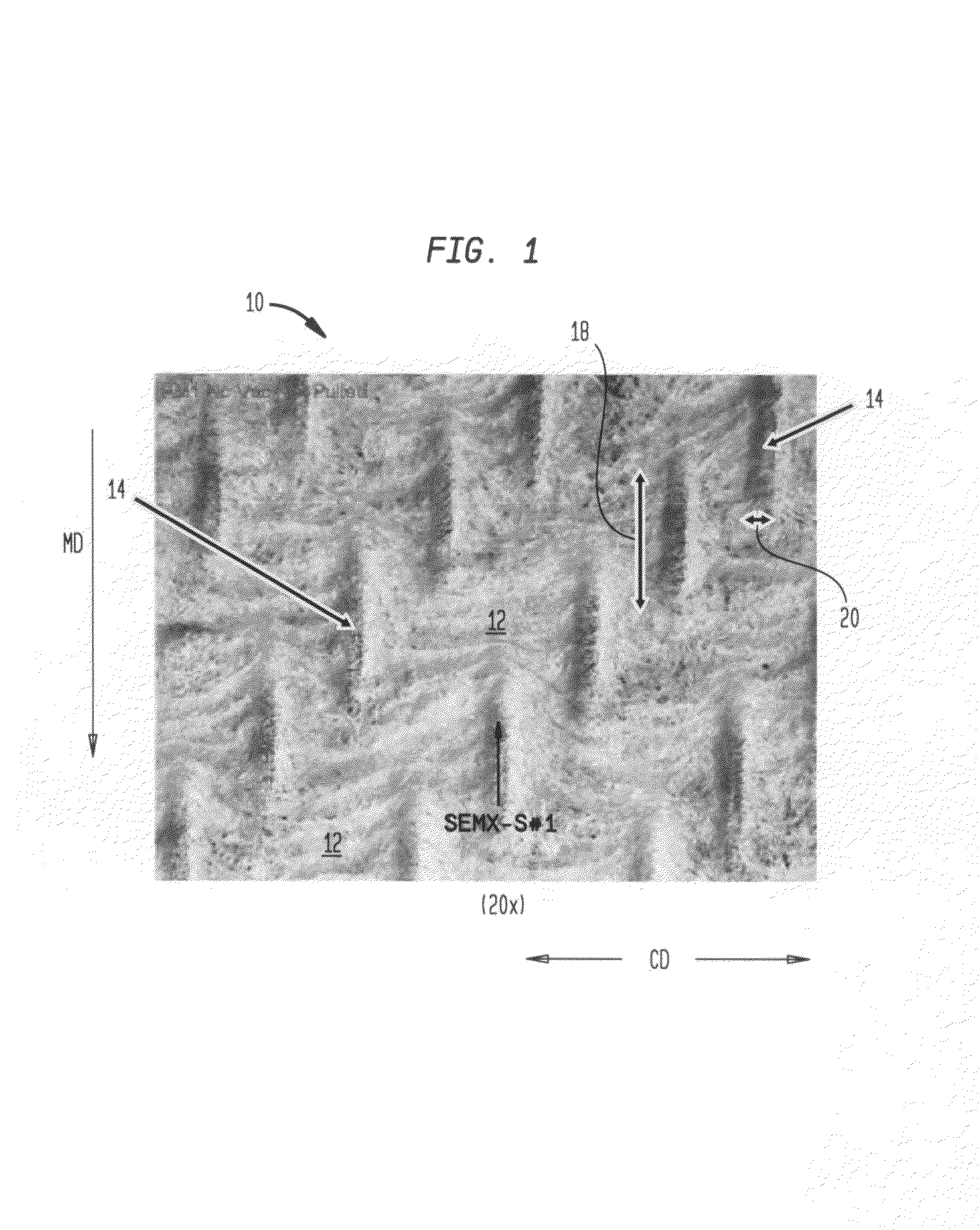

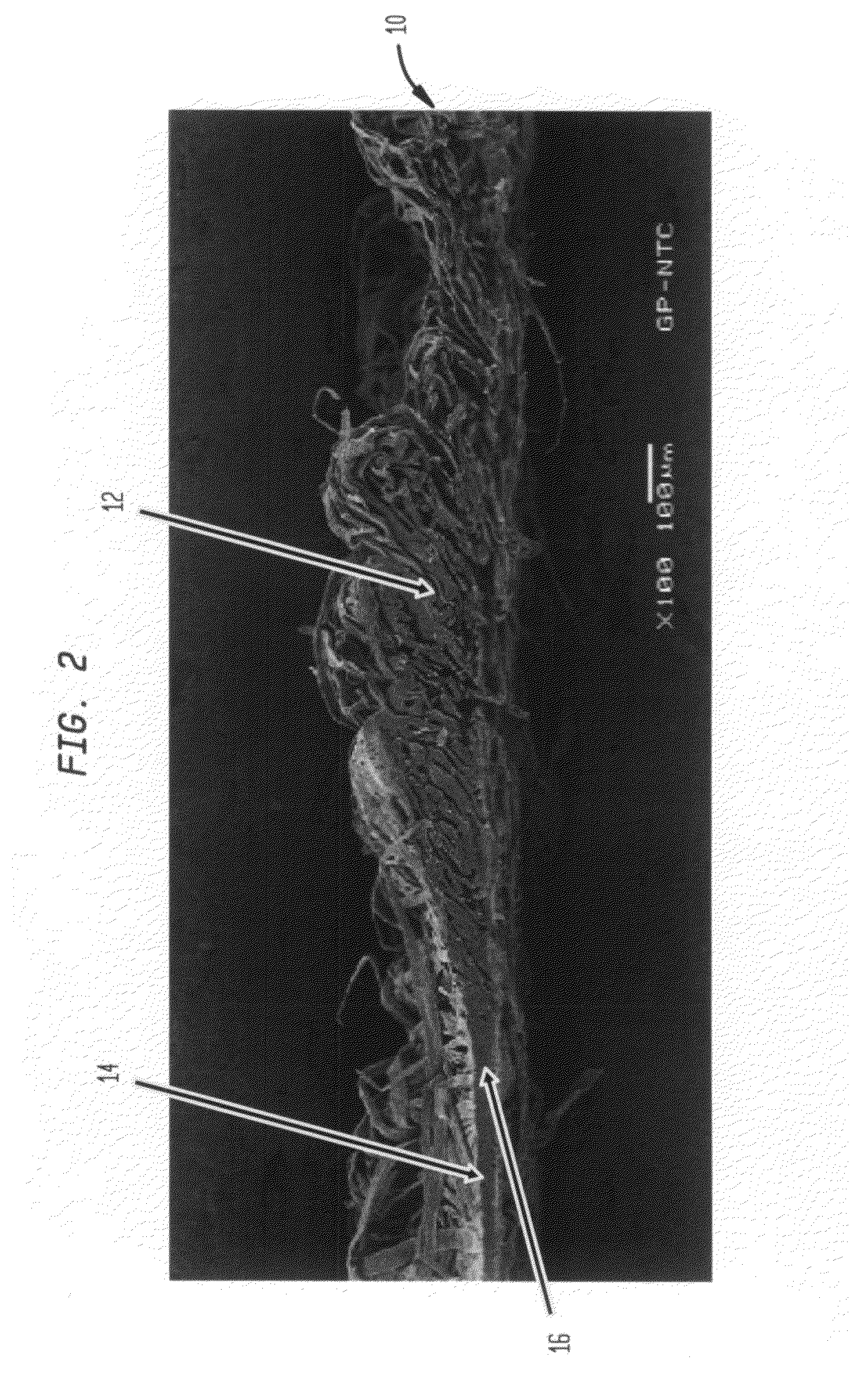

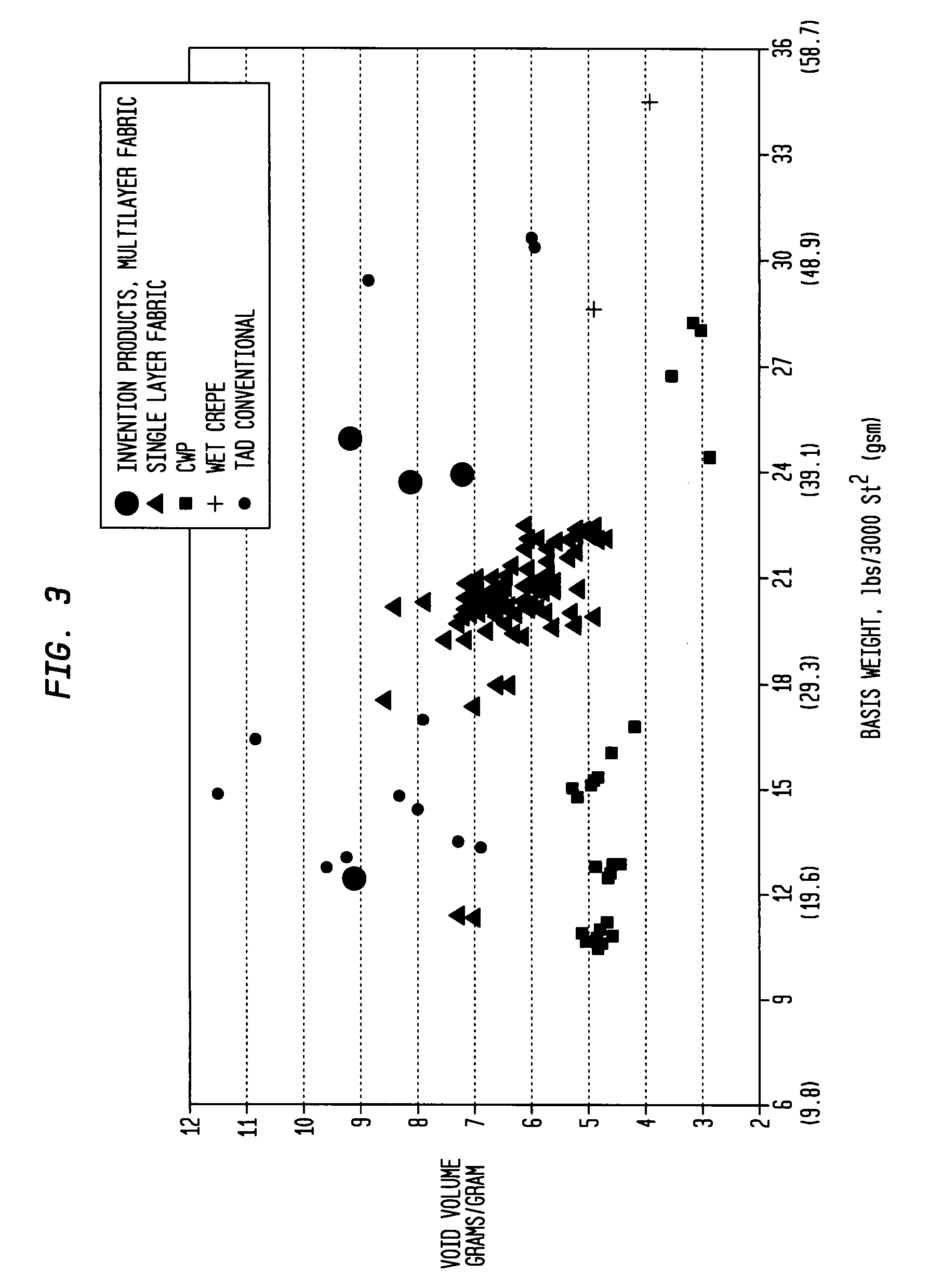

Fabric creped absorbent sheet with variable local basis weight

InactiveUS7494563B2Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

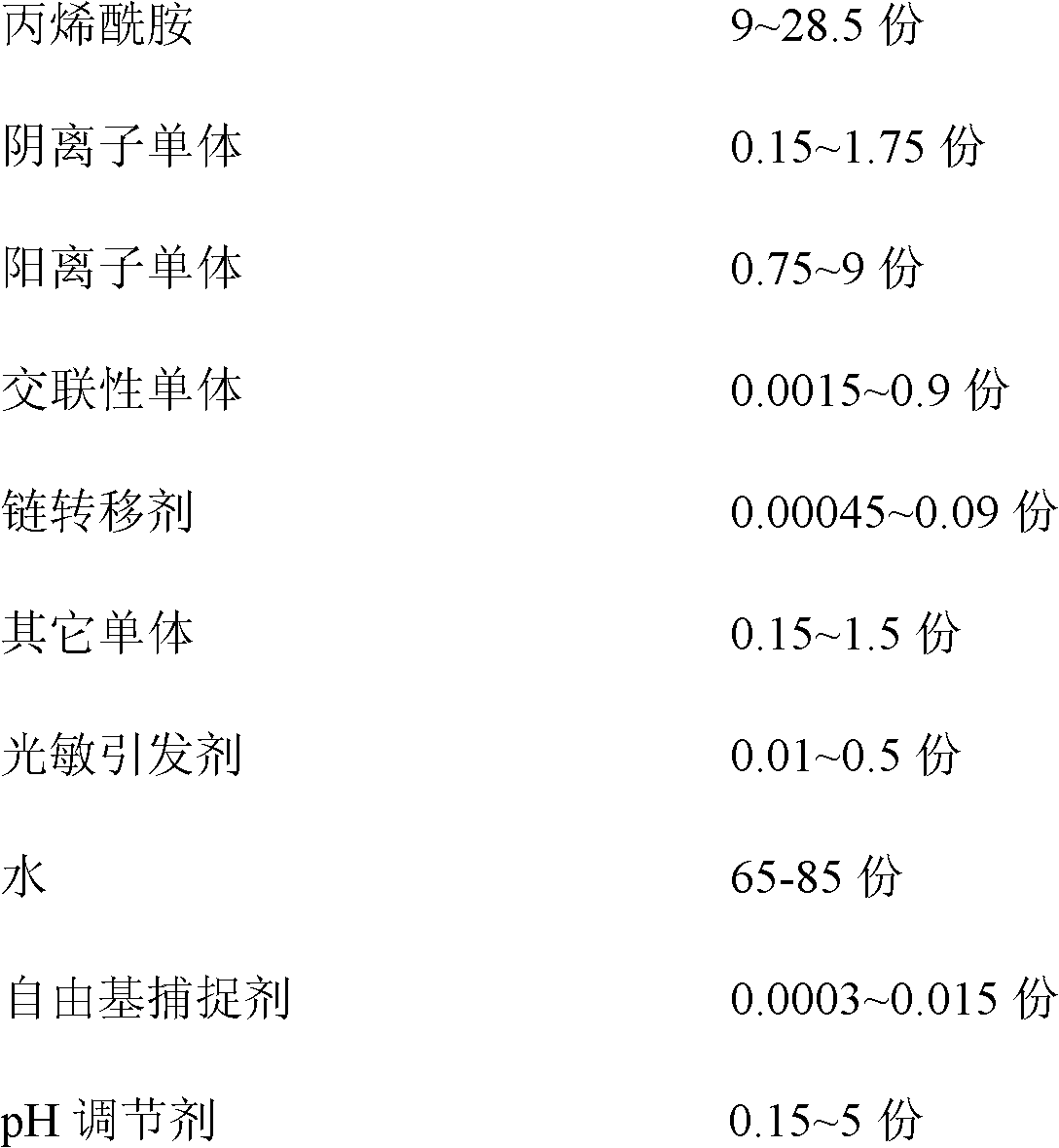

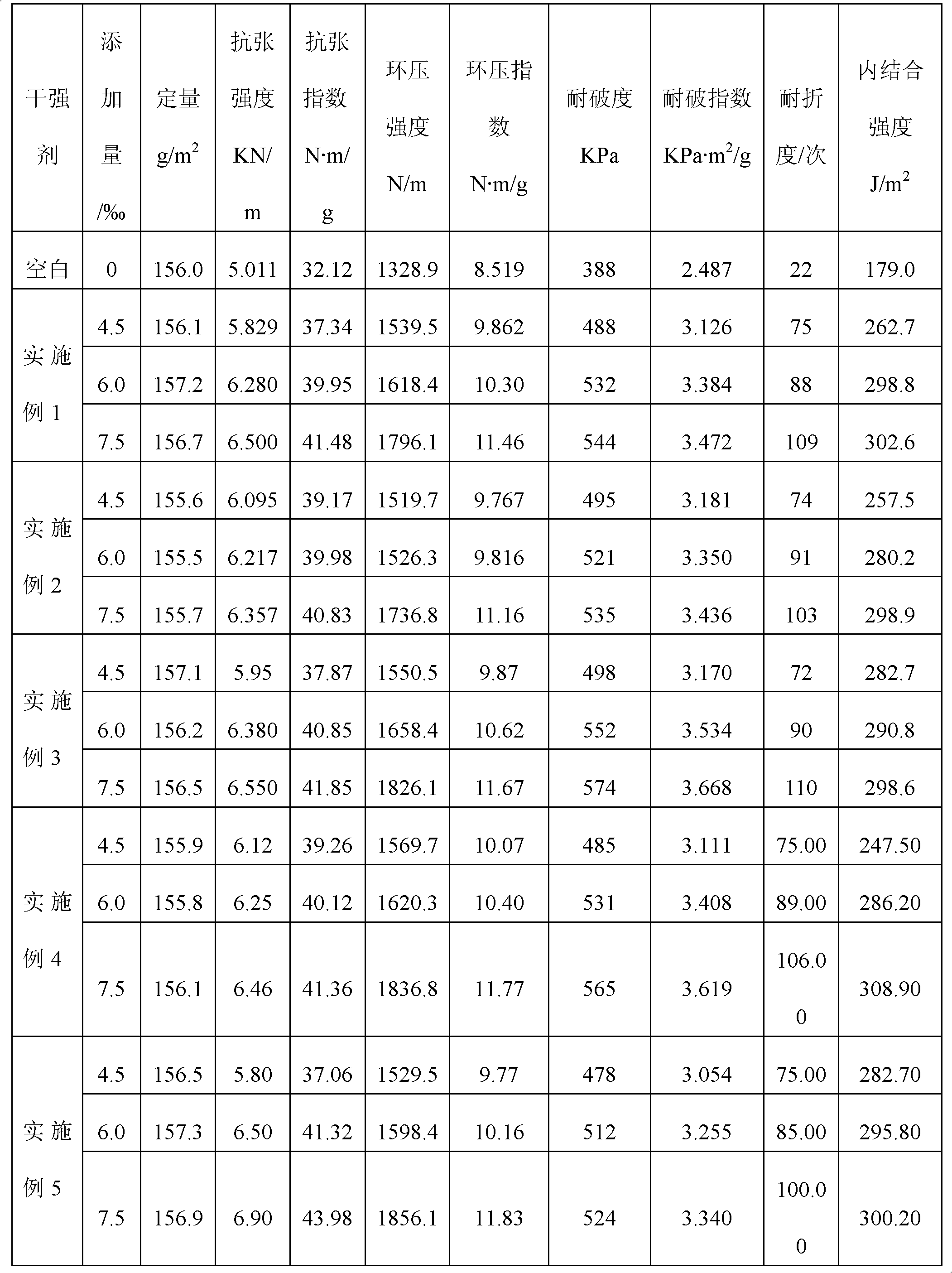

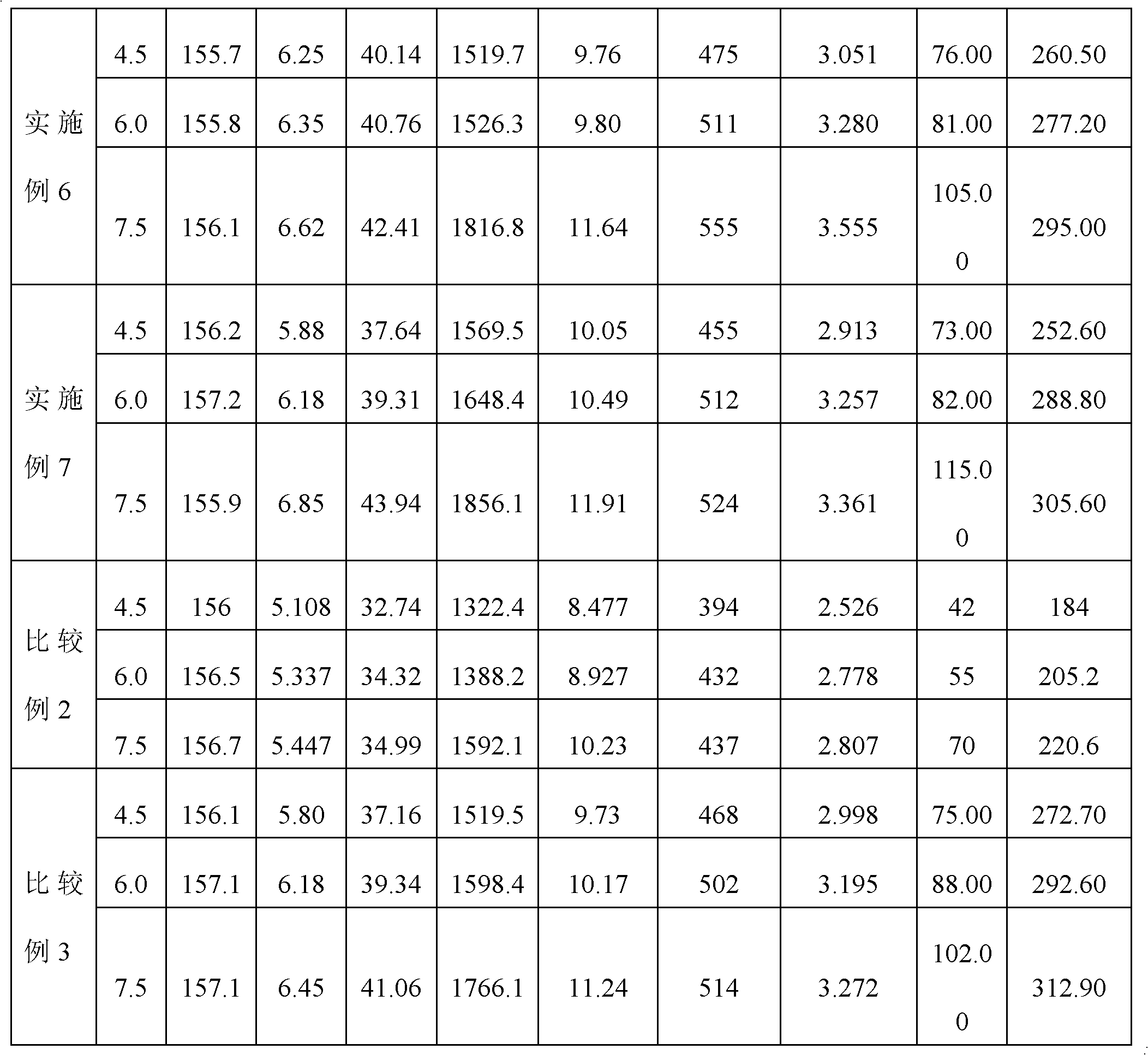

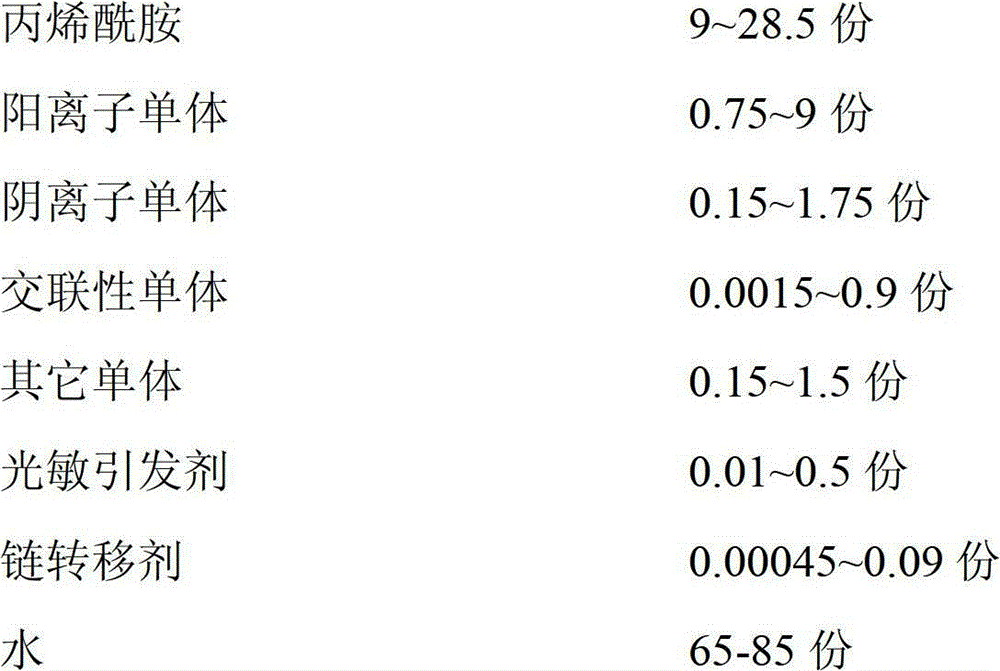

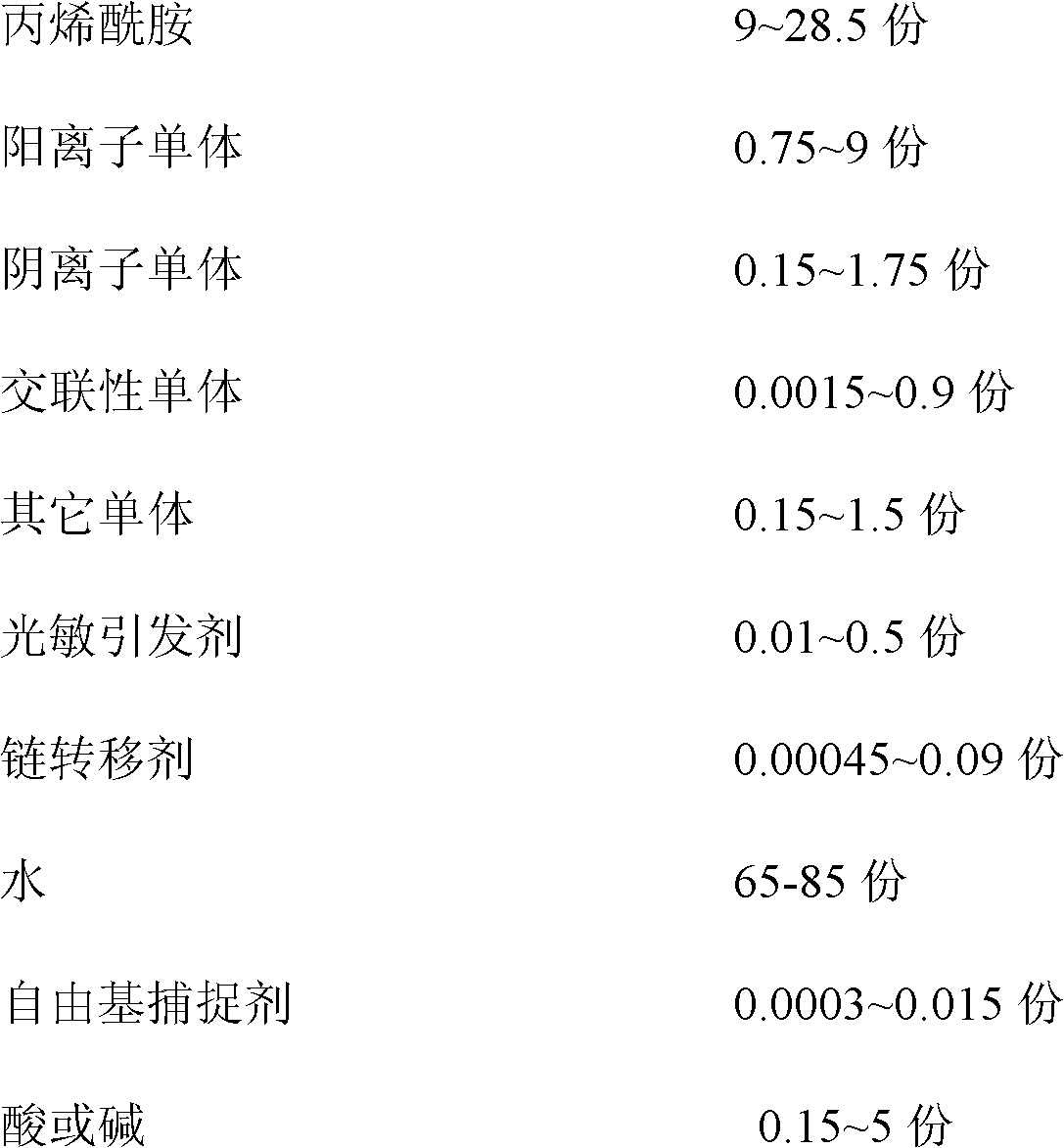

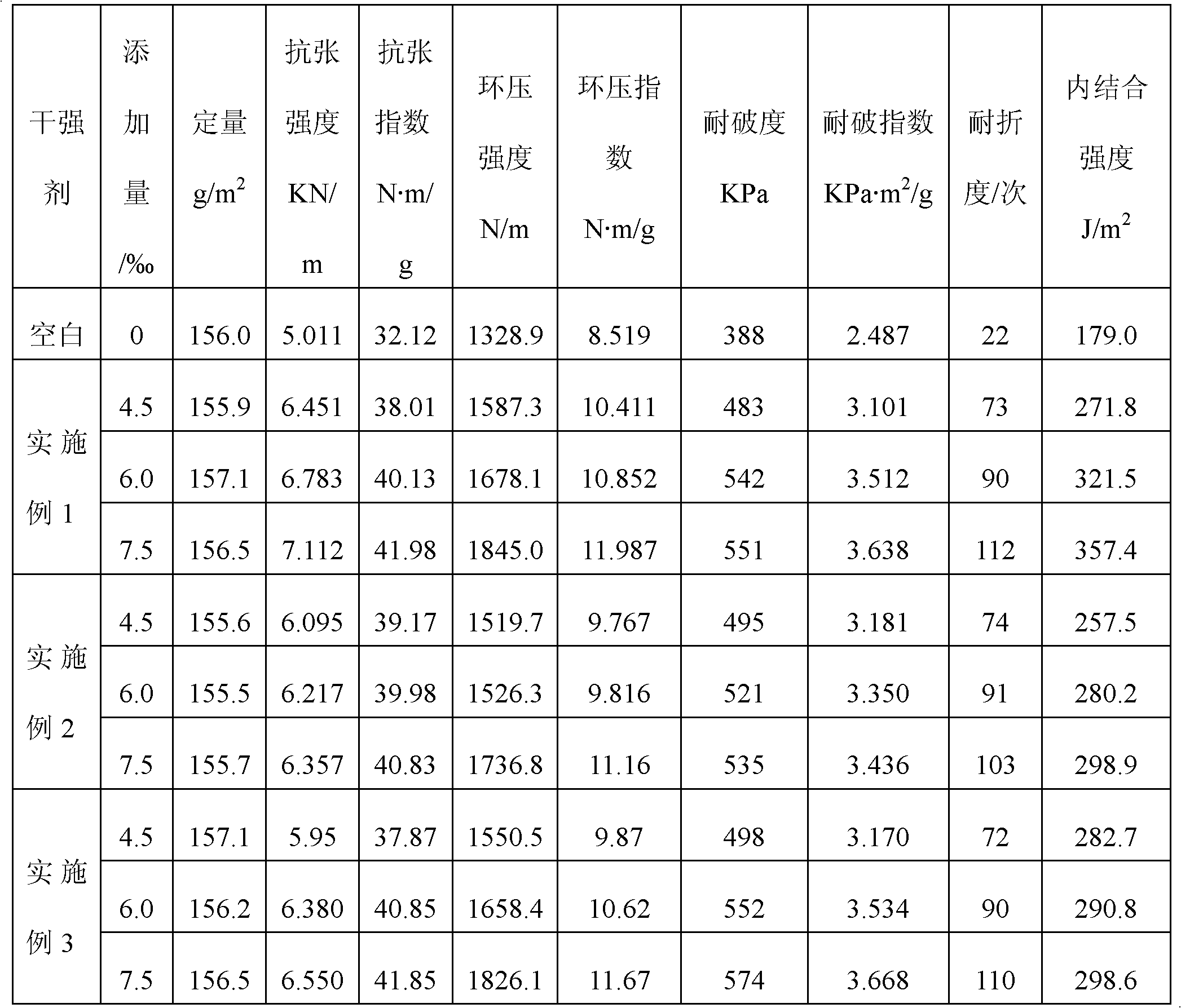

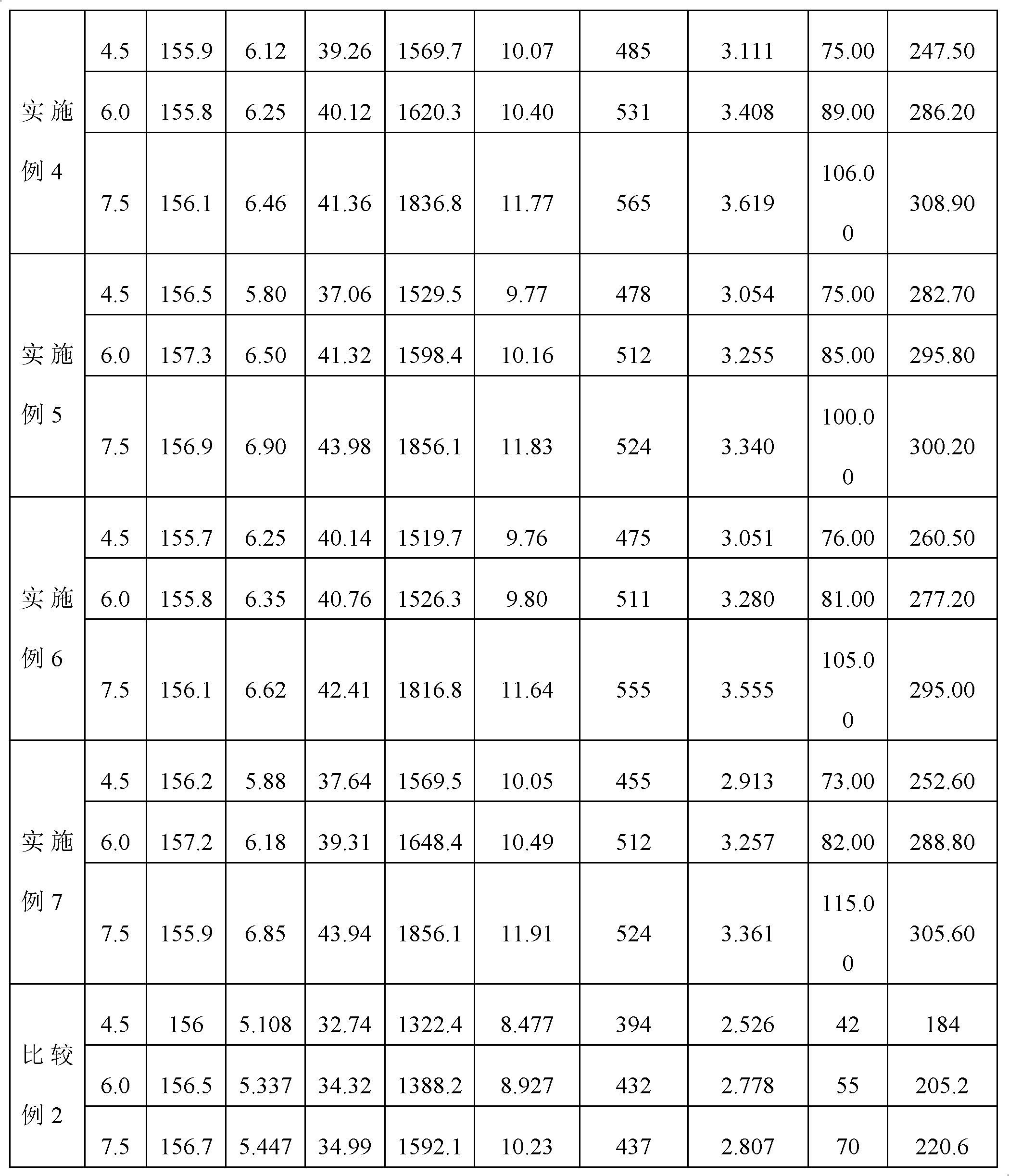

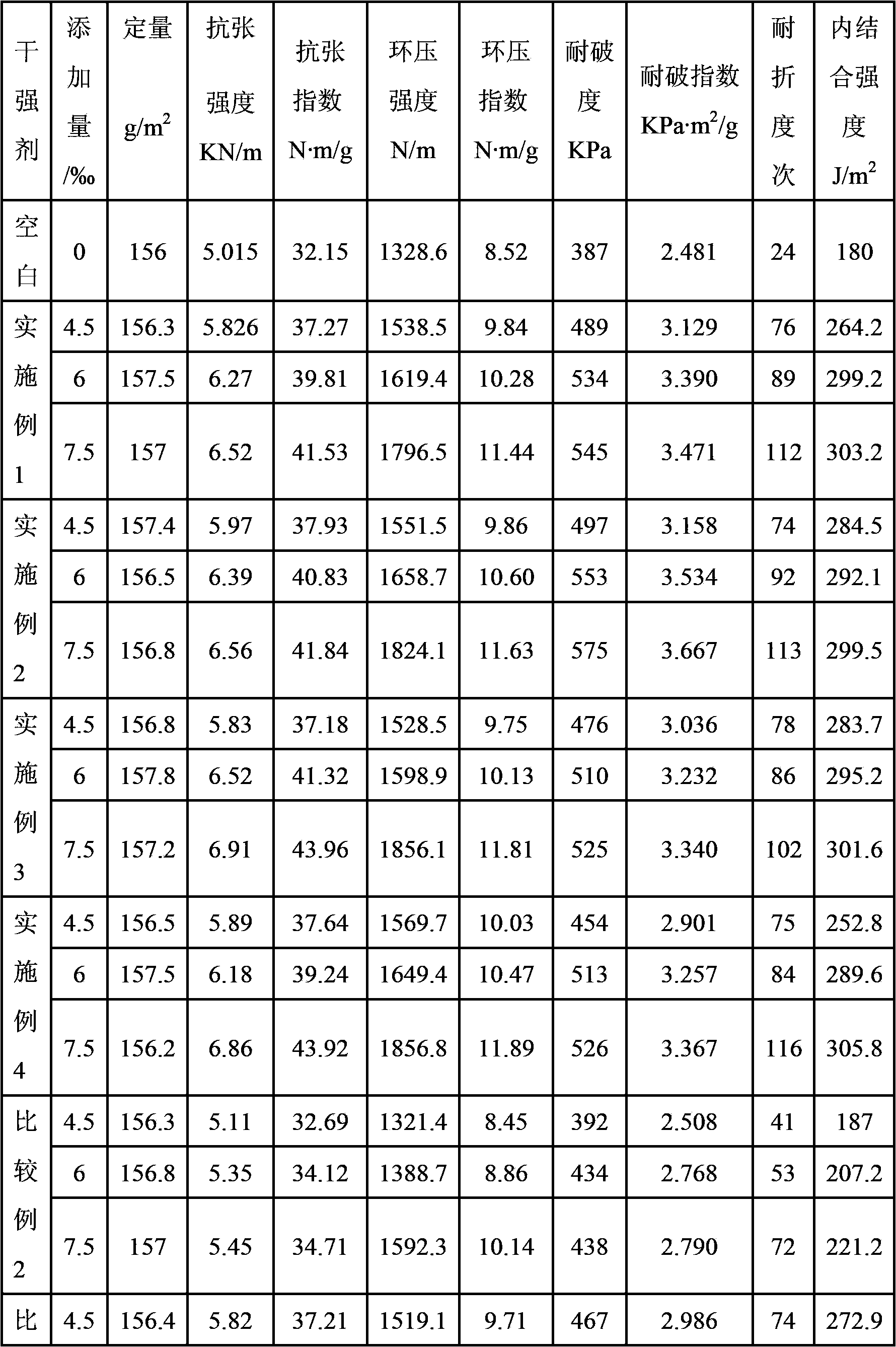

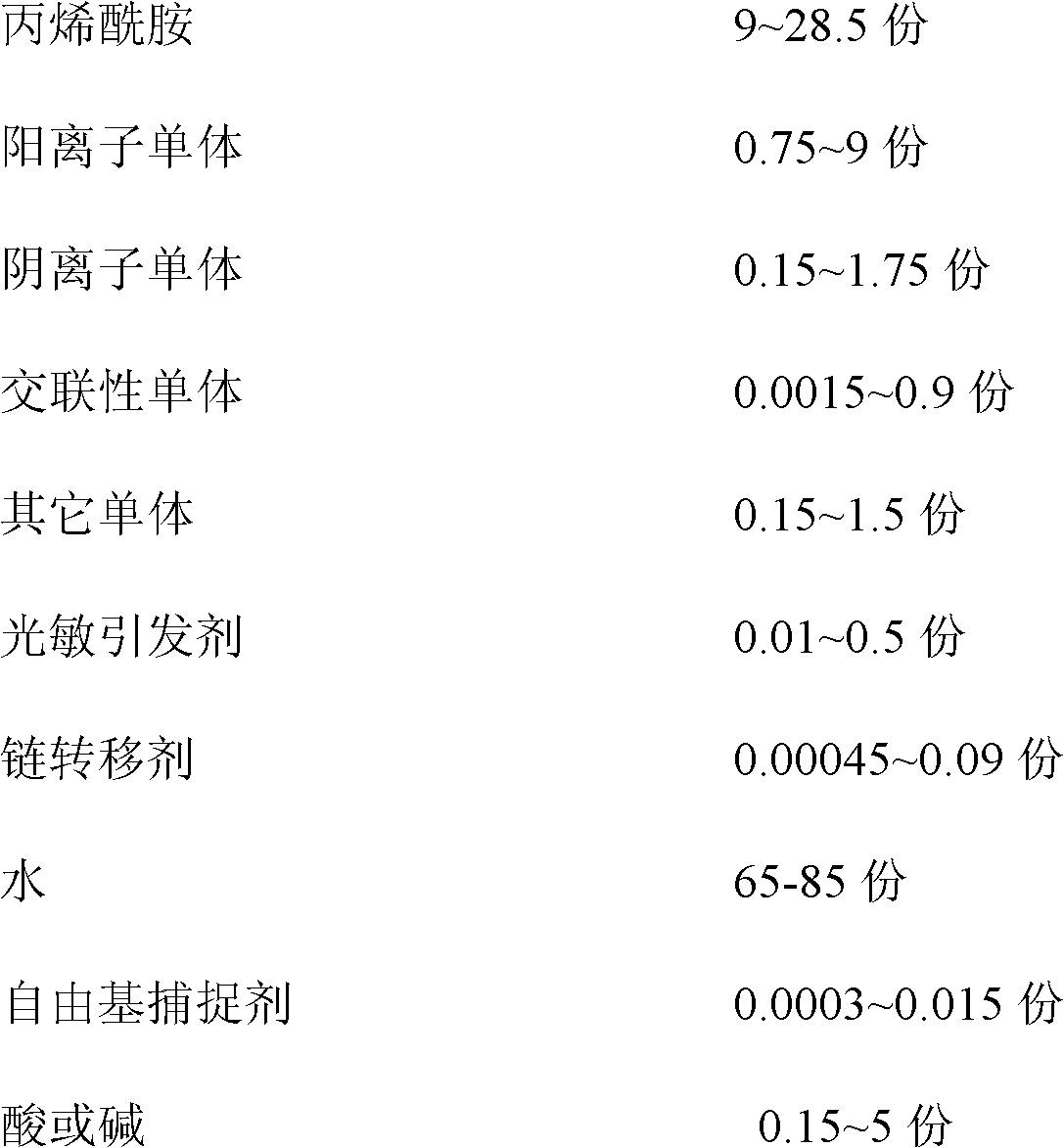

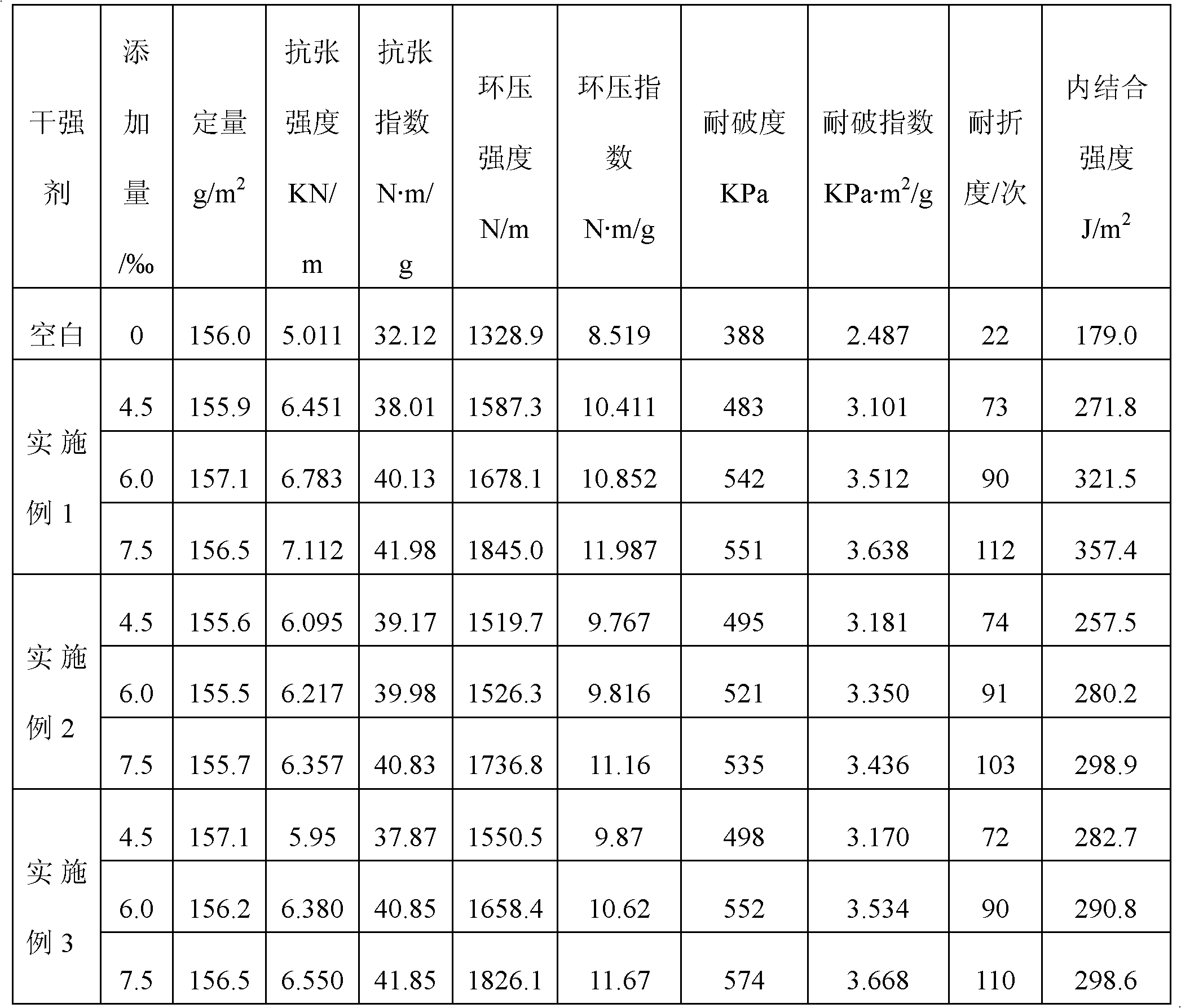

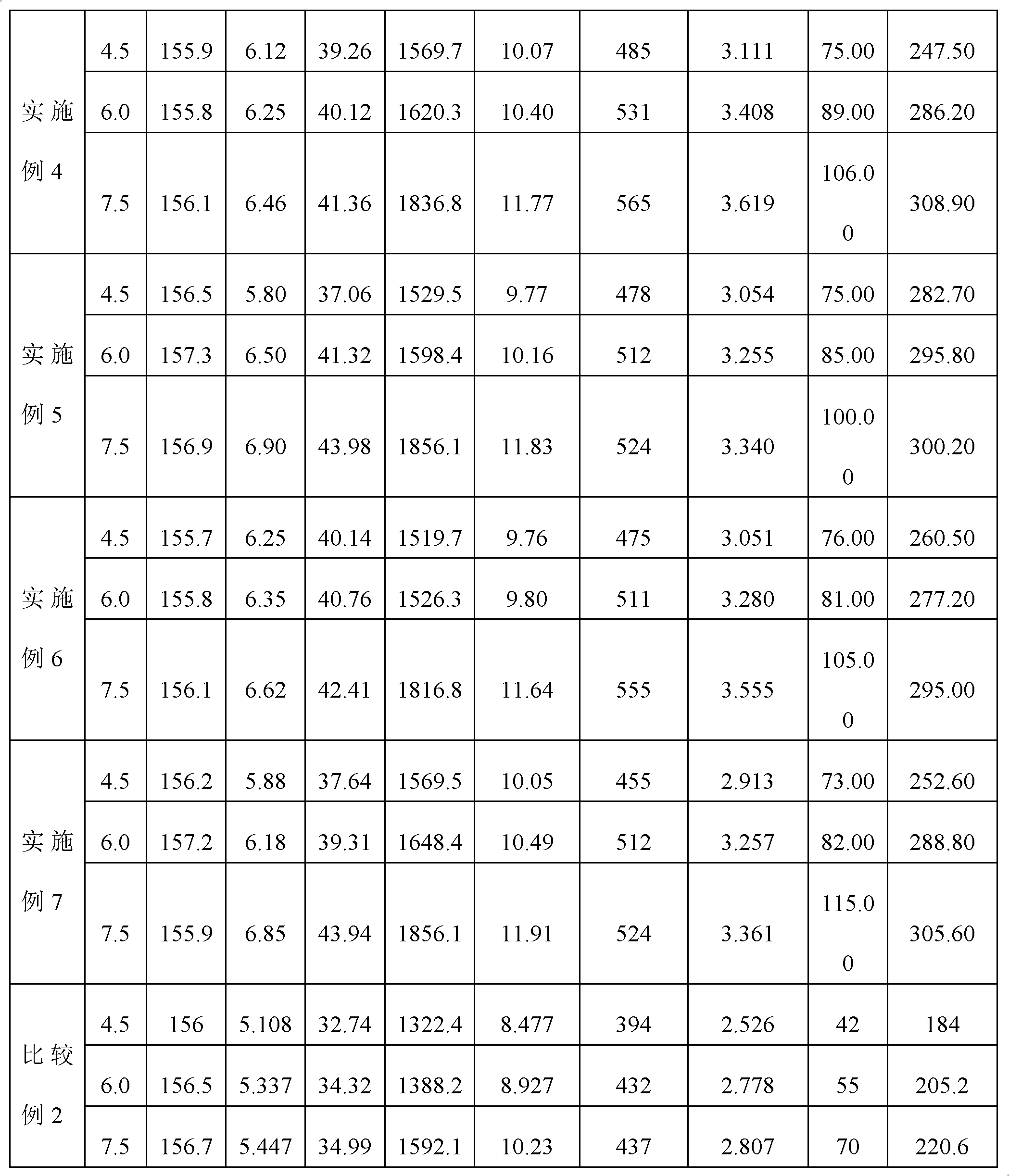

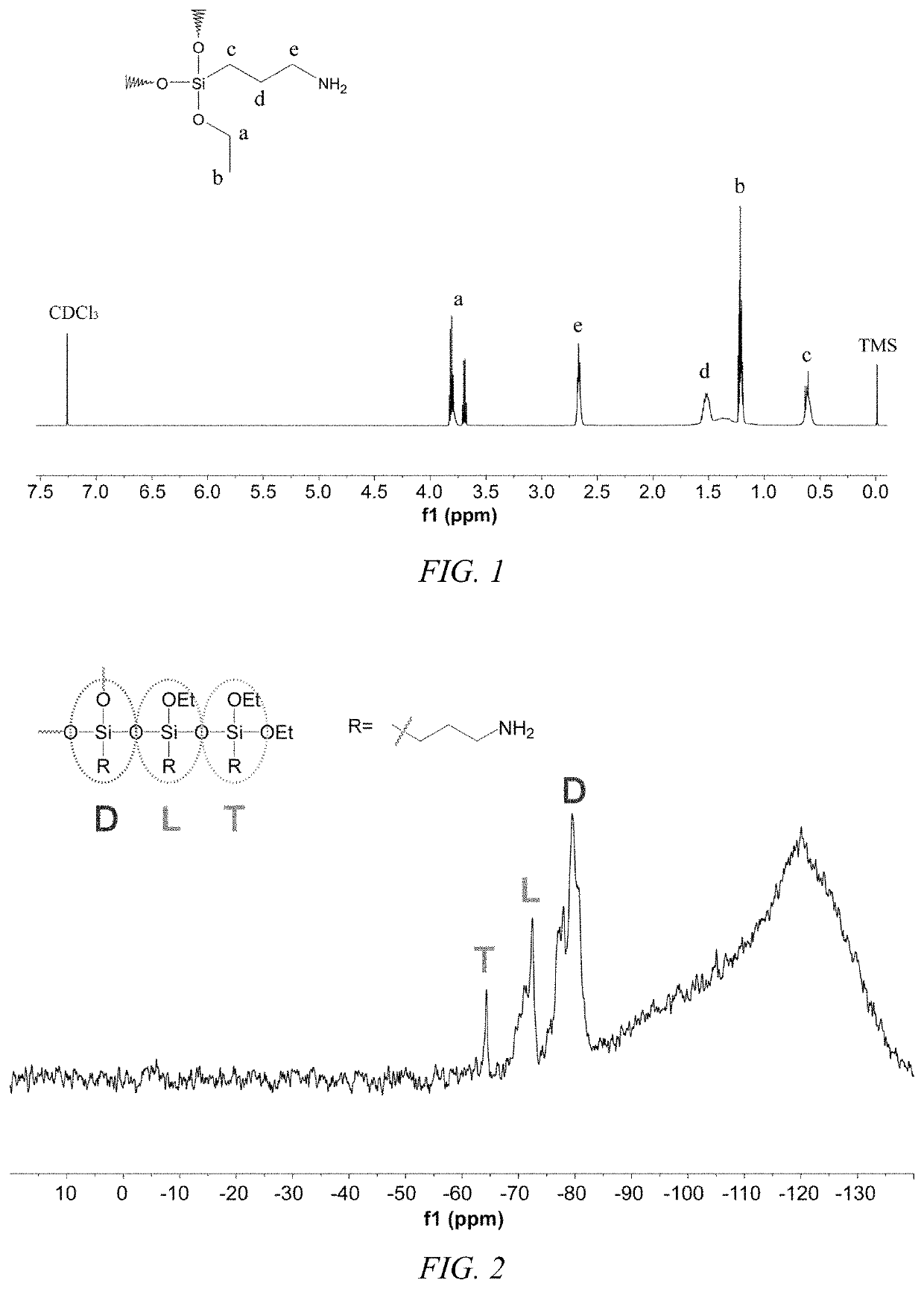

Paper dry intensifier and preparation method thereof

ActiveCN102627724AModerate molecular weightModerate degree of branchingReinforcing agents additionPaper/cardboardCross-linkFunctional monomer

The invention provides a paper dry intensifier and a preparation method thereof. The preparation method comprises the following steps: in nitrogen atmosphere, reacting water, acrylamide, an anionic monomer, a cationic monomer, a cross-linked monomer, a chain transfer agent, other functional monomers and a photoinitiator under ultraviolet irradiation; adding a pH regulator for regulating the pH value to be 4-6; and adding a radical catcher, and mixing to obtain the paper dry intensifier. The intensifier synthesized by the method has the characteristics of low usage amount and good effect. The intensifier can be used in production of various paper such as case board paper, corrugating base paper, coated paper, cop tube paper, specialty paper and the like, and has the effect of improving the paper dry intensity, which is more remarkable when the recovered waste paper is used as papermaking raw materials. The intensifier can have an excellent paper dry enhancement effect without being added with aluminum sulfate.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

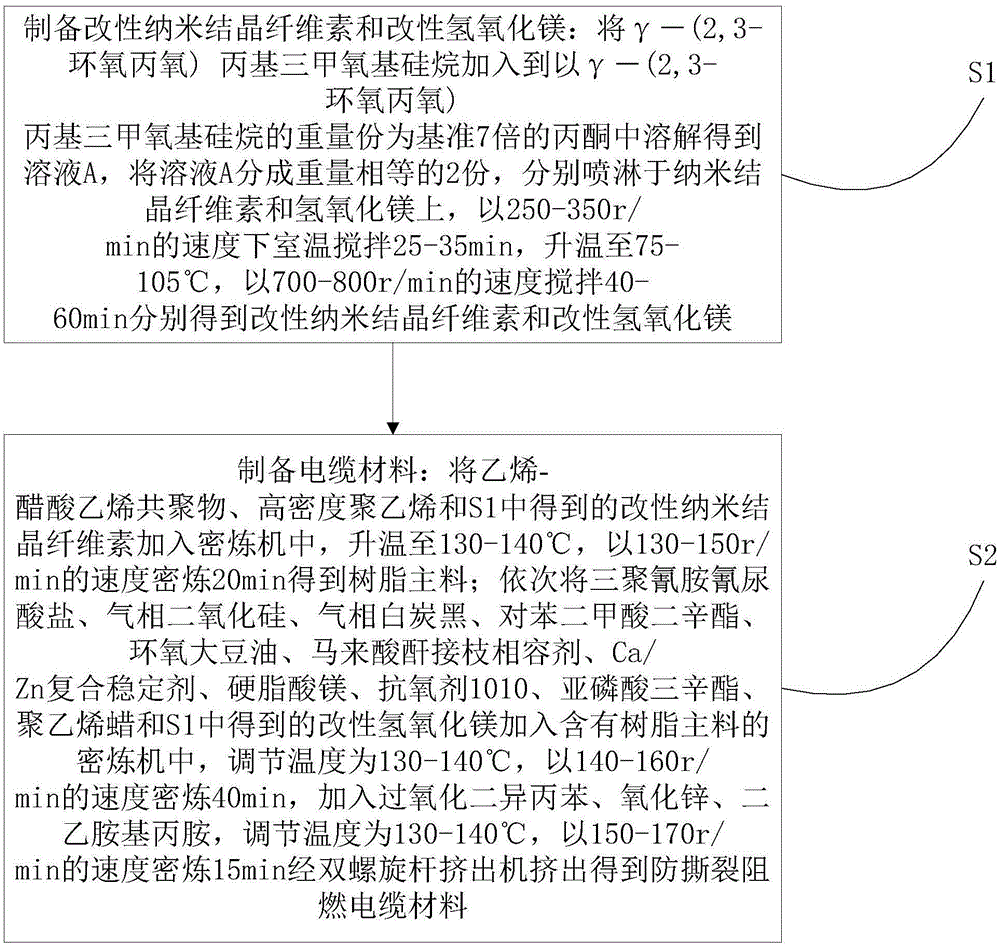

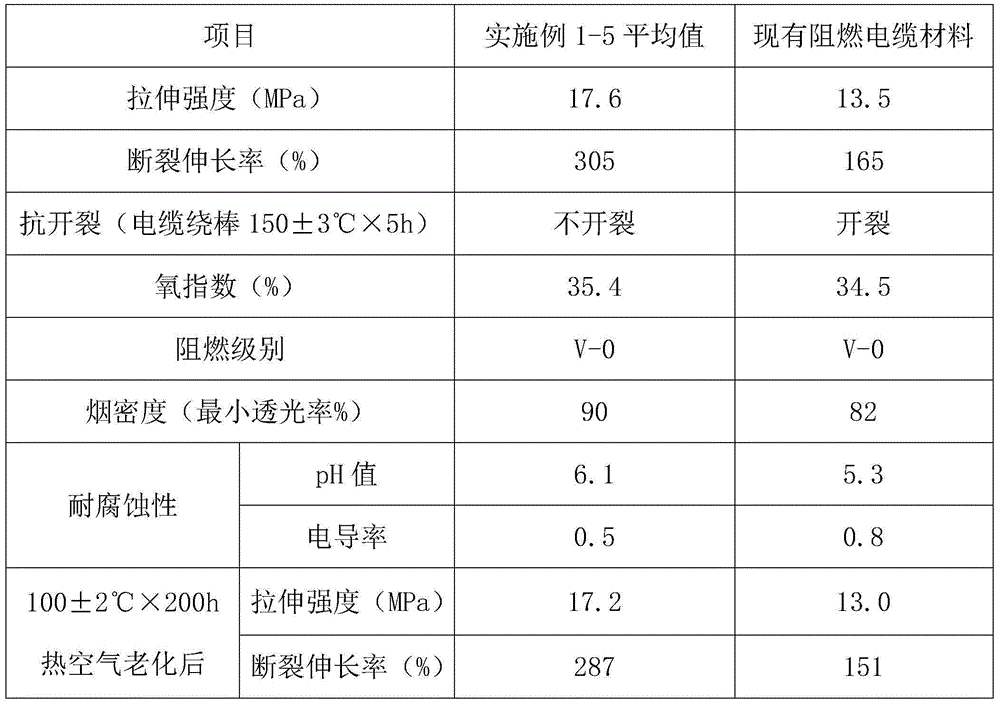

Anti-tearing flame-retardant cable material and method for manufacturing same

InactiveCN105153529AHigh grafting rateImprove adsorption capacityPlastic/resin/waxes insulatorsPhosphorous acidGas phase

The invention discloses an anti-tearing flame-retardant cable material. The anti-tearing flame-retardant cable material comprises, by weight, 70-80 parts of ethylene-vinyl acetate copolymers, 20-30 parts of high-density polyethylene, 30-50 parts of gas-phase white carbon black, 10-15 parts of nano crystalline cellulose, 3-4 parts of gamma-(2, 3-trimethoxysilyl) propyl methacrylate, 40-50 parts of magnesium hydroxide, 1-3 parts of melamine cyanurate, 3.5-4.5 parts of gas-phase silicon dioxide, 15-30 parts of dioctyl terephthalate, 15-30 parts of epoxy soybean oil, 0.4-1 part of dicumyl peroxide, 0.5-1.5 parts of zinc oxide, 0.5-1.5 parts of diethylin propylamine, 5-10 parts of maleic anhydride grafting compatilizer, 2-4 parts of Ca / Zn compound stabilizers, 1-2 parts of magnesium stearate, 0.1-0.3 part of antioxidants 1010, 0.1-0.2 part of trioctylphosphine phosphorous acid ester and 1-3 parts of polyethylene wax. The invention further discloses a method for manufacturing the anti-tearing flame-retardant cable material.

Owner:无为县茂林电缆材料有限公司

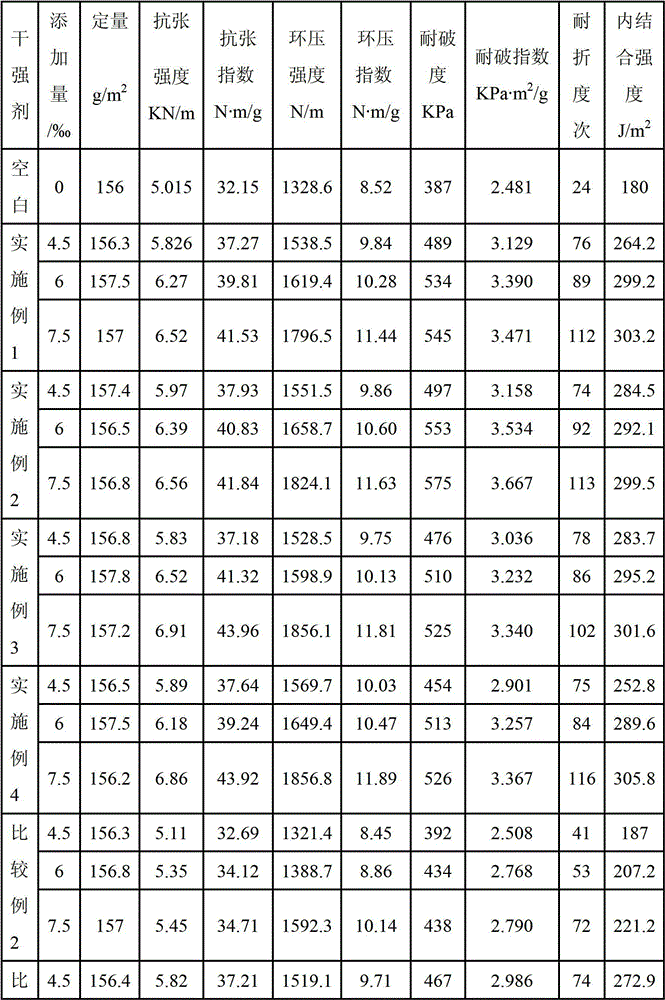

Paper dry strength agent

ActiveCN106968132ANarrow molecular weight distributionHigh active ingredientReinforcing agents additionPaper sheetEmulsion

The invention discloses a paper dry strength agent. Polyvinyl alcohol is etherified by a cationic etherifying agent to serve as a polymer emulsifier for preparation of a soap-free polymerization cross-linked polyacrylamide emulsion, which is used as a paper dry strength agent. The paper dry strength agent provided by the invention has the advantages of good strengthening effect, small loss in white water, good fixation, few jello, and environmental protection, etc. After being added into paper pulp, the dry strength agent can well improve the circumferential pressure, folding resistance, breakage resistance, tension, paper internal bonding strength and other performance of finished paper.

Owner:ZHEJIANG KESIKE CHEM NEW MATERIAL CO LTD

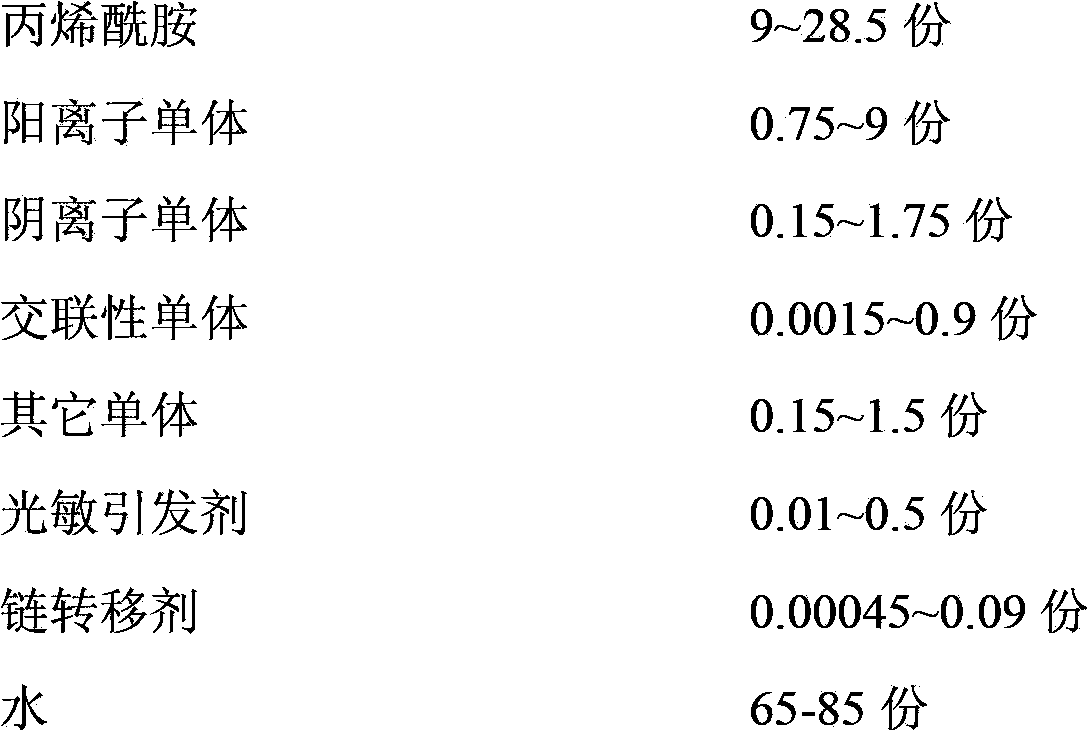

Branch type dry strength agent and preparation method thereof

ActiveCN102720094AAvoid one joinAvoid incremental dripping of respective issuesReinforcing agents additionFunctional monomerUltraviolet

The invention discloses a branch type dry strength agent and a preparation method thereof. The preparation method comprises the following steps of: firstly, mixing acrylamide, negative ion monomers, positive ion monomers, crosslinking agent monomers, a photoinitiator, water and other functional monomers to obtain solution A; secondly, mixing a chain transfer agent and water to obtain solution B; thirdly, polymerizing 40%-60% of the solution A and 20%-40% of the solution B by ultraviolet ray irradiation; fourthly, adding 20%-30% of the solution A and 20%-30% of the solution B into the mixed solution in the third step to be subjected to polymerization by ultraviolet ray irradiation; fifthly, adding the residual solution A and the residual solution B into the mixed solution in the fourth step to be subjected to polymerization by ultraviolet ray irradiation until the viscosity of the solution meets requirements; and sixthly, adjusting the pH and solid content of weight of the mixed solution in the fifth step, and adding free radical catcher into the mixed solution to obtain the branch type dry strength agent. According to the branch type dry strength agent and the preparation method, the operation is simple, the viscosity is easy to control, the dispersibility of the branch type dry strength agent in water is good, the properties of ring crush, fold resistance, breaking resistance, tension resistance, internal bonding strength and the like of paper can be improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Elastic fluorocarbon paint and formula thereof

The invention relates to a formula of elastic fluorocarbon paint. The formula comprises the following ingredients: 40-50% of fluorocarbon resin, 15-20% of elastic resin, 0.3-0.5% of a wetting agent, 0.3-0.5% of a dispersant, 0.5-1% of a leveling agent, 15-20% of aluminium powder, 0.1-0.2% of an antifoaming agent, 0.1-0.5% of an anti-settling agent, 0-0.5% of a drier and 15-20% of a solvent. Long straight chain and low branched chain of a high-molecular elastic cross-linking agent react with a fluorine-containing polymer to form a highly-straight-chain and low-branched-chain polymer, the structure of which is jagged. The ultimate embodiment of properties is reflected in appropriate surface strength, excellent elasticity, telescopic springback function, high tensile strength and fracture resistance, low surface polarity and strong resistance to soiling and weatherability.

Owner:上海奥泽涂料有限公司

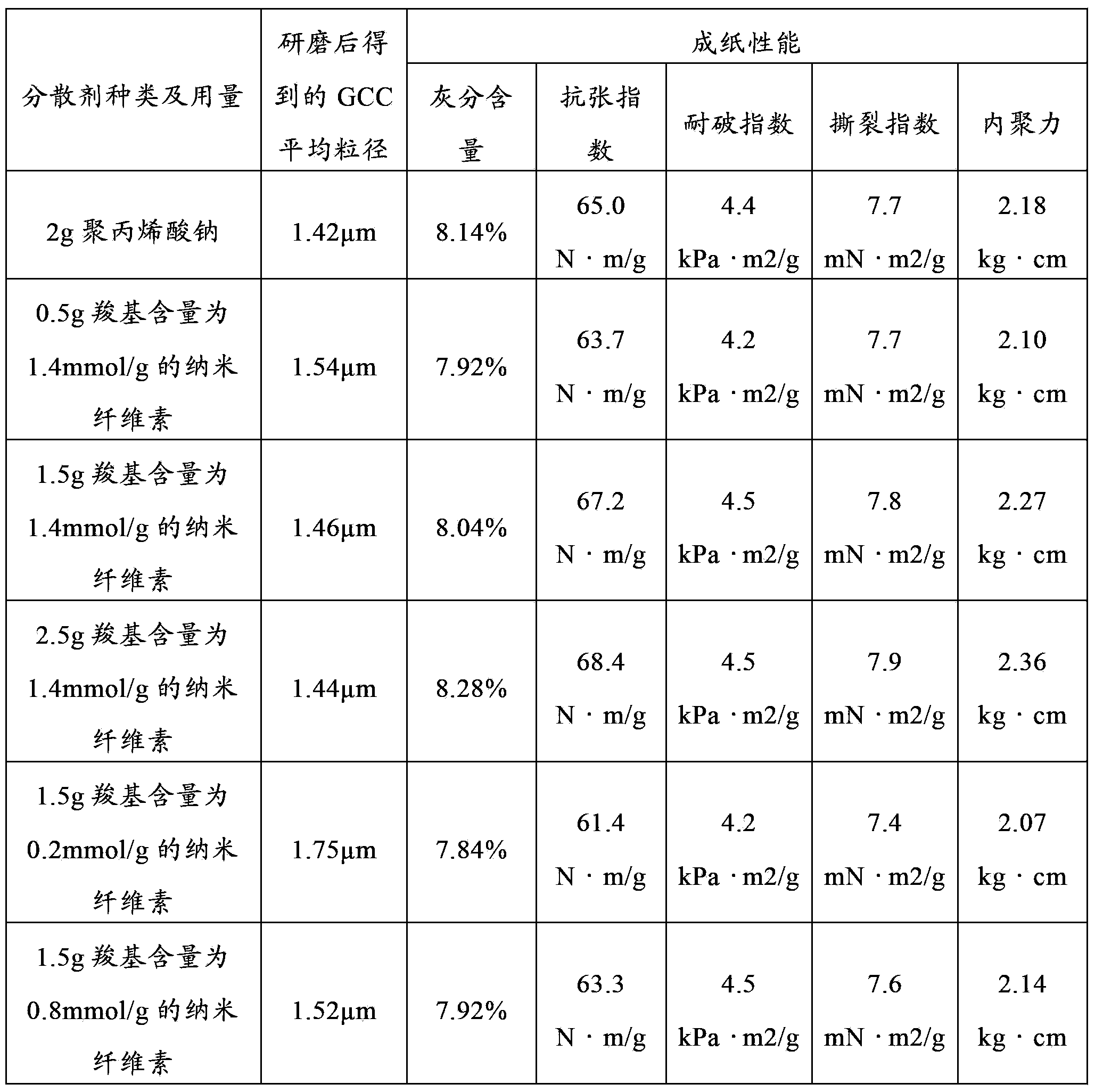

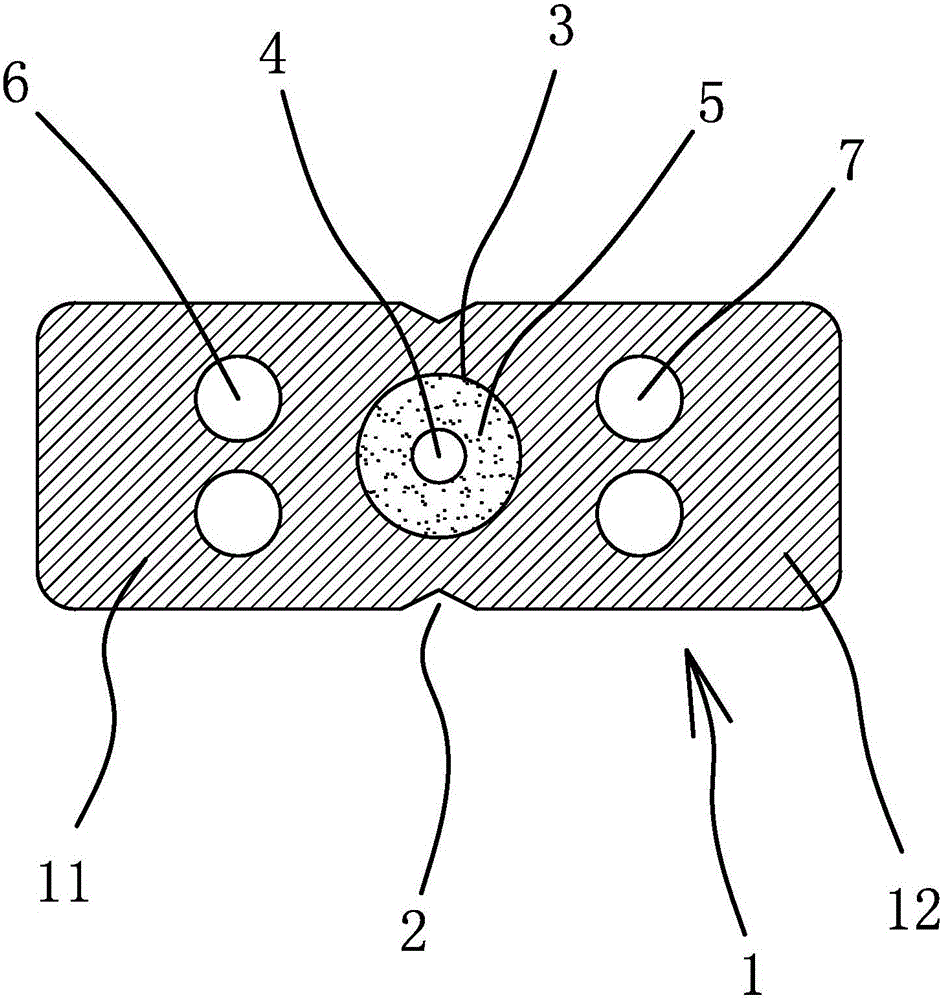

Ground calcium carbonate production process, ground calcium carbonate suspension and paper

ActiveCN104343043AAvoid damageLarge specific surface areaSpecial paperPaper/cardboardALLYL SUCROSESynthetic monomer

The invention relates to a ground calcium carbonate suspension production process. The ground calcium carbonate suspension production process comprises the following steps: providing a nano-crystalline cellulose solution of which the surface carboxyl content is 0.2-1.5mmol / g and the diameter is smaller than or equal to 100 nanometers; and providing calcium carbonate to be ground, preparing a mixed solution by taking the nano-crystalline cellulose solution as a dispersing agent according to a mixing proportion of adding 1-10kg by oven dry weight of the nano-crystalline cellulose solution into 1 ton of calcium carbonate, and grinding the mixed solution to obtain a ground calcium carbonate suspension. According to the ground calcium carbonate solution production process, the nano-crystalline cellulose solution of which the surface carboxyl content is 0.2-1.5mmol / g and the diameter is smaller than or equal to 100 nanometers is taken as the dispersing agent, instead of conventional sodium polyacrylate and salts thereof, so that the grain size of finished ground calcium carbonate meets the requirement, and damage to the skin and the respiratory tract of a person caused by a synthetic monomer in the preparation and use processes of polyacrylic acid and salts thereof is effectively avoided. The invention further relates to the ground calcium carbonate suspension and paper.

Owner:GOLD EAST PAPER JIANGSU

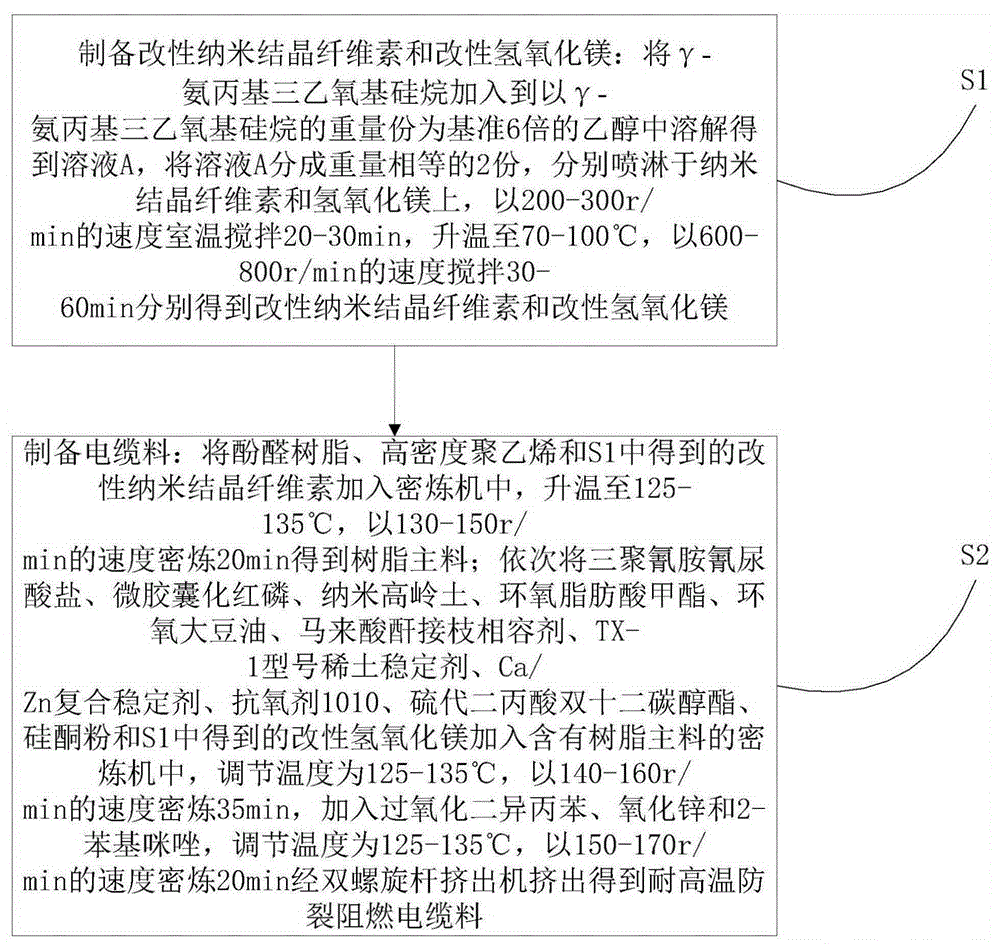

High-temperature-resistant crack-resistant flame-retardant cable material and preparation method thereof

The invention discloses a high-temperature-resistant crack-resistant flame-retardant cable material which is prepared from the following raw materials in parts by weight: 50-70 parts of phenolic resin, 30-50 parts of high-density polyethylene, 30-50 parts of nano kaolin, 10-15 parts of nano crystalline cellulose, 3-4 parts of gamma-aminopropyltriethoxy silane, 40-50 parts of magnesium hydroxide, 1-3 parts of melamine cyanurate, 7-9 parts of microcapsulated red phosphorus, 15-30 parts of epoxy fatty acid methyl ester, 15-30 parts of epoxy soybean oil, 0.4-1 part of dicumyl peroxide, 0.5-1.5 parts of zinc oxide, 0.5-1.5 parts of 2-phenyl iminazole, 5-10 parts of maleic anhydride graft compatilizer, 2-3 parts of TX-1 rare-earth stabilizer, 2-3 parts of Ca / Zn composite stabilizer, 0.1-0.3 part of antioxidant 1010, 0.1-0.2 part of bisdodecanol thiodipropionate and 2-4 parts of silicone powder. The invention also discloses a preparation method of the high-temperature-resistant crack-resistant flame-retardant cable material.

Owner:无为县茂林电缆材料有限公司

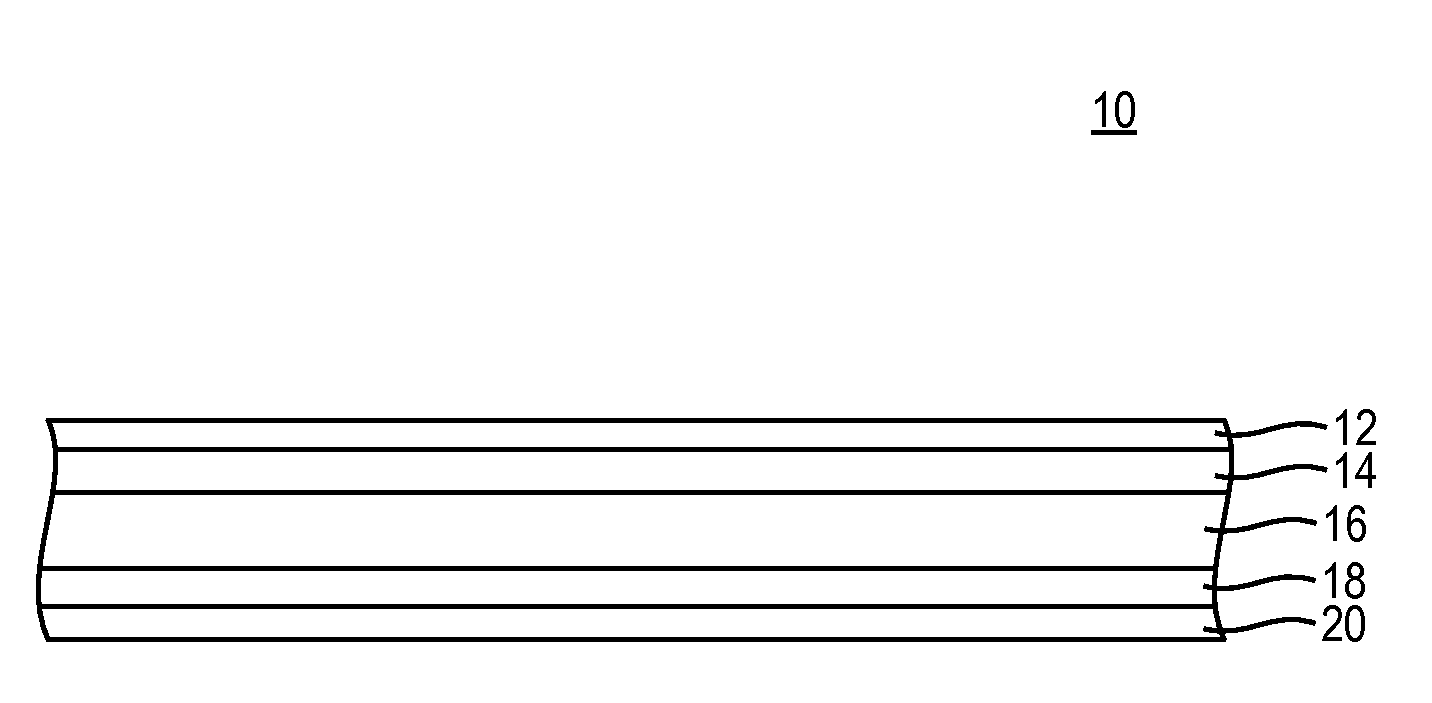

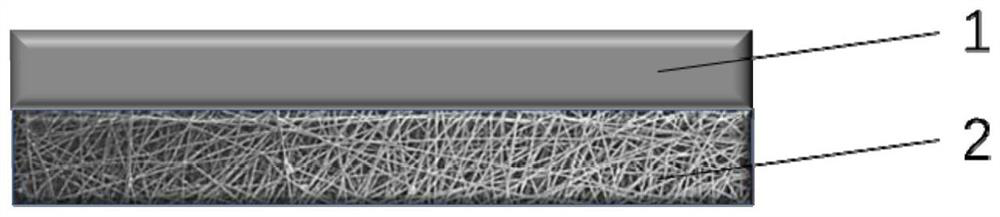

Thermal/acoustical liner

InactiveUS20150298440A1High tensileHigh strengthSynthetic resin layered productsAnimal housingMildewFluorocarbon

A multi-layer thermal acoustical liner is breathable, hydrophobic, oliophobic and fire-resistant rated. The liner includes a central insulation core layer contacted on a first surface by a first highly breathable layer and on a second surface by a second highly breathable layer. The first and second highly breathable layers are preferably an ePTFE membrane. The first highly breathable layer is adjacent a facing layer while the second highly breathable layer is adjacent a backing layer. The backing and facing layers are preferably nylon and treated with a fluorocarbon surface treatment for water repellency, UV resistance and mold / mildew resistance. At least one surface of one of the first or second highly breathable layers may include a carbon printing pattern to provide ESD protection. The layers of the liner are laminated to one another.

Owner:COCOON INC

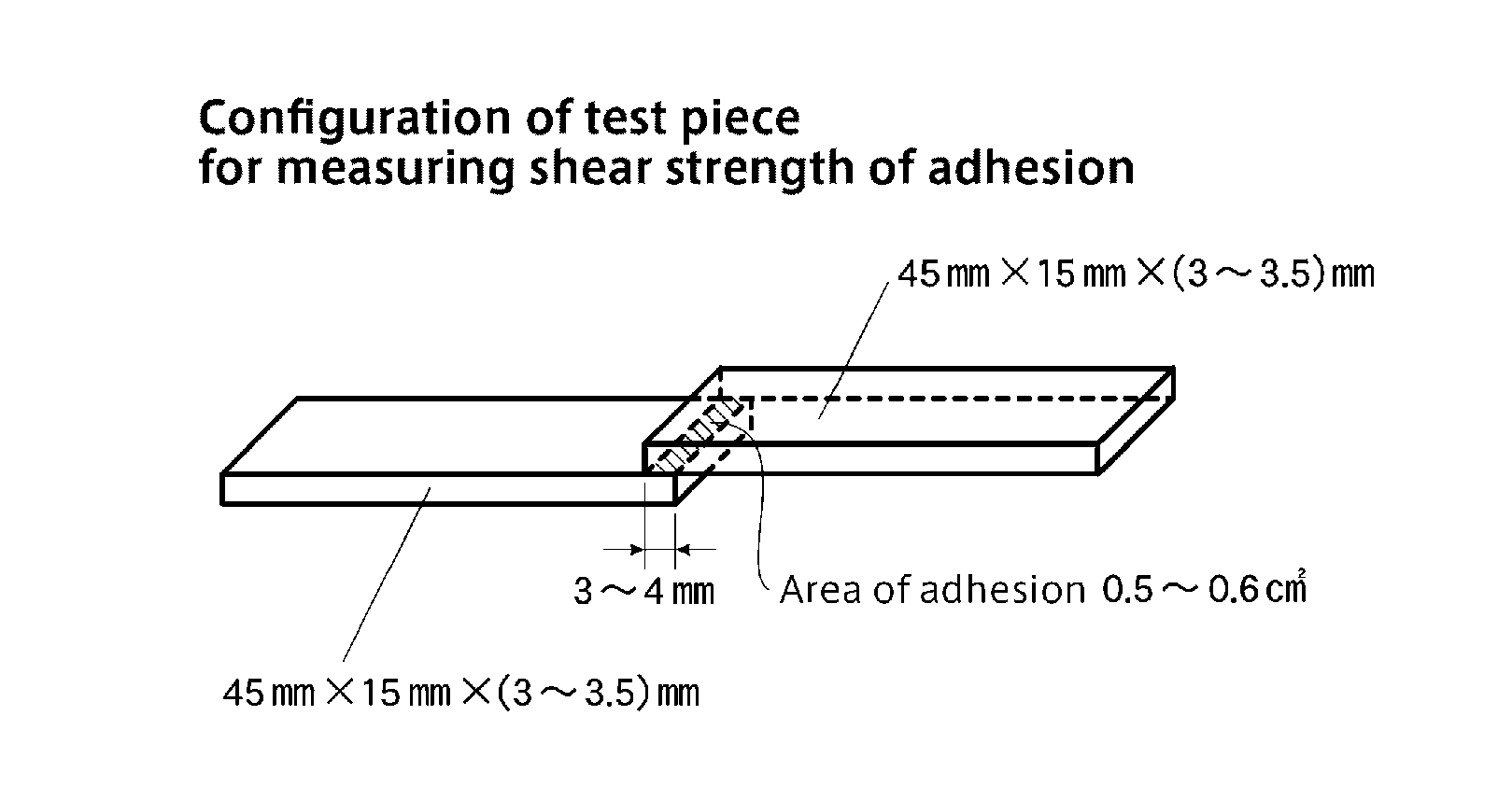

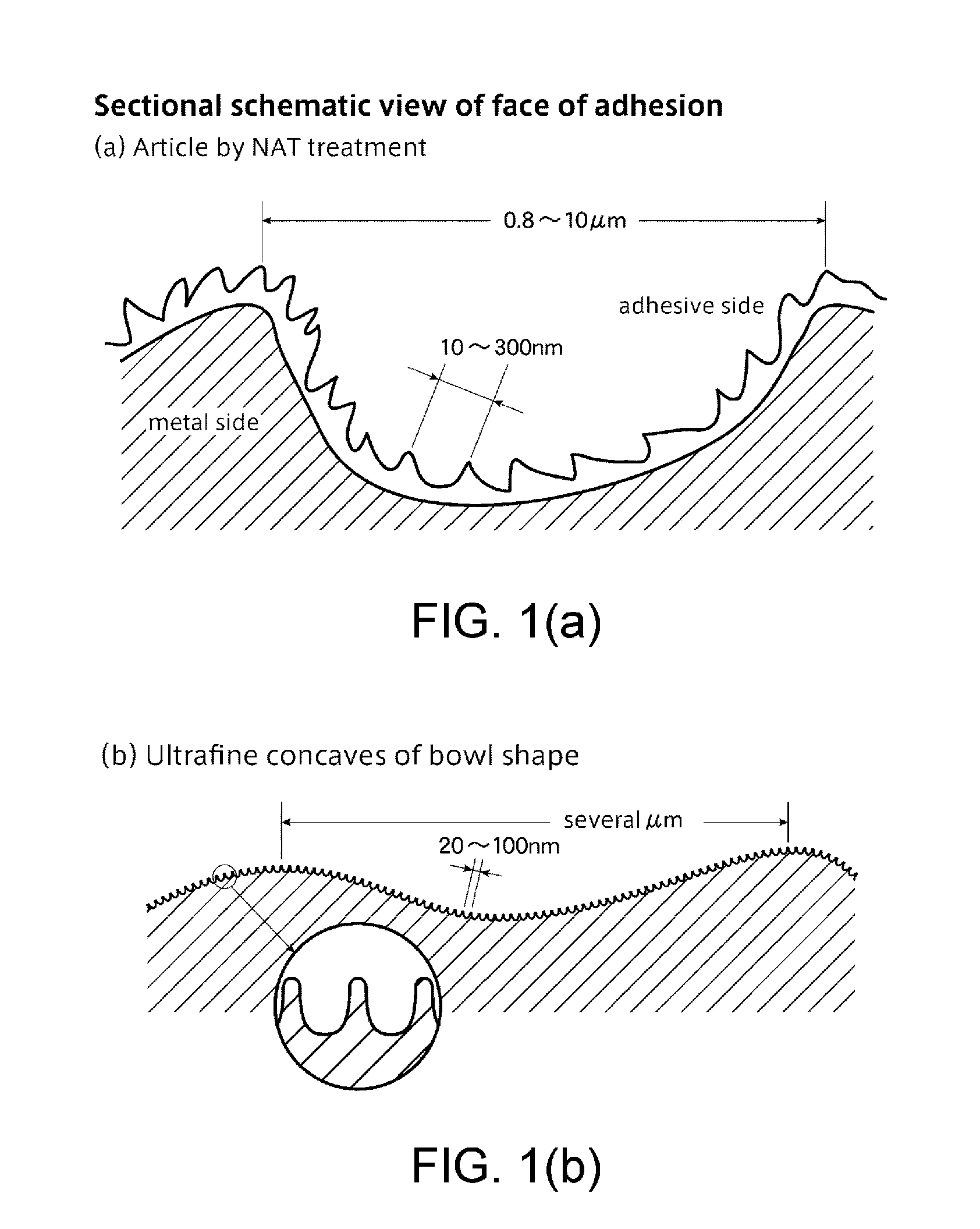

Method for producing metal containing composite and metal containing composite formed by adhesion

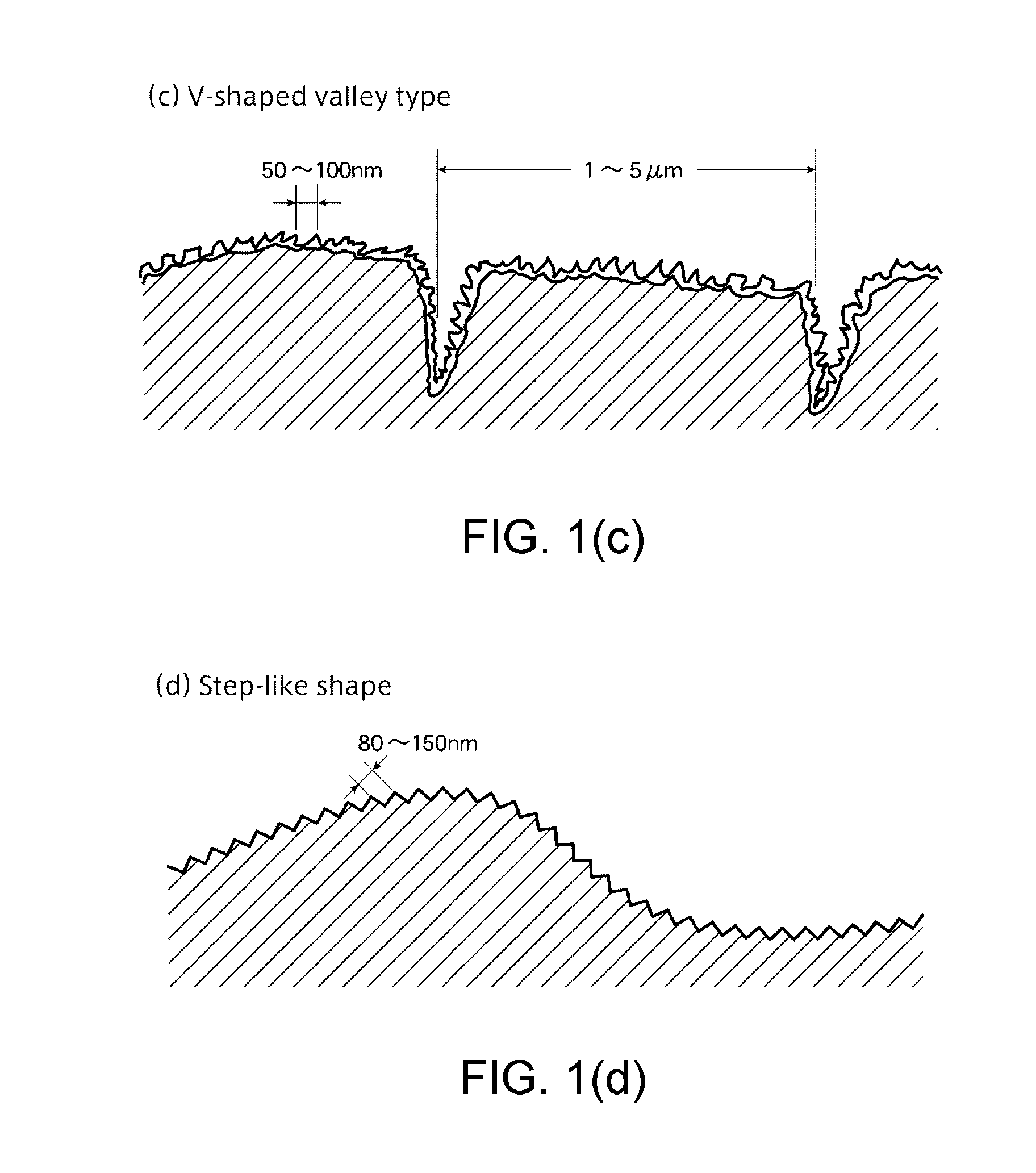

An adhesive (B) of solvent containing adhesive as a suspension of low viscosity is prepared by adding a solvent MIBK to a one-part epoxy adhesive of a dicyandiamide-curable type (A). Metal shaped articles (M1 to M5) as adherends are prepared each of which, through various surface treatment, has specific surface configuration of roughened face and / or ultrafine irregularities and the surface is entirely covered with a thin layer of ceramics such as a metal oxide or metal phosphate. The specified face of each metal shaped article (M1 to M5) is painted with the solvent containing adhesive (B). The faces painted with the adhesive of two metal shaped articles (M1 to M5) are caused to abut each other, the articles are heated to cure the one-epoxy adhesive to accomplish adhesion. With one of the adherends replaced by a CFRP shaped article (P2), a composite of a metal and CFRP can be formed.

Owner:TAISEI PLAS CO LTD

Metal strip for epitaxial coatings and method for the production thereof

InactiveUS20050031890A1High tensileLow magnetic lossSemiconductor/solid-state device detailsSolid-state devicesOxideNitrogen

The aim of the invention is to provide a metal strip for epitaxial coating with a biaxially textured layer, this metal strip, however, being able to be produced in an uncomplicated manner and having a high tensile strength, low magnetic losses and / or a high electrical conductivity. According to the invention, the metal strip is comprised of Nj, Cu, Ag or alloys thereof all serving as basic material, whereby the one-layer metal strip and, in the instance of a multilayer metal strip, at least one of its layers contains 10 nm to 5 μm large, strength-increasing dispersoids comprised of carbides, borides, oxides and / or nitrides with a volume proportion ranging from 0.1 to 5%. In the instance of a multilayer metal strip, the layers form a composite, and at least one of the layers does not contain any dispersoids and has a biaxial texture. For the production, a starting material is used, which is comprised of Ni, Cu, Ag or of alloys thereof all serving as basic material and which contains 0.2 to 5 atom percent of an additive comprised of oxidizable, nitridable, bondable and / or carbidable elements. A one-layer or a multilayer strip is produced from this starting material by means of deforming methods, whereby for producing the multilayer metal strip, a basic material that does not contain the aforementioned additive is used as one of its layers. Afterwards, the strip is subjected to a recrystallization annealing in order to form a cubical texture. Finally, the strip is subjected to an annealing under an oxygen, nitrogen, boron or carbon partial pressure, which is greater than the equilibrium partial pressure of oxides, nitrides, borides and carbides of the additive elements contained in the alloy, but is less than the equilibrium partial pressure of oxides, nitrides, borides and carbides of the basic elements Ni, Cu and Ag of the strip alloy.

Owner:EVICO GMBH

Gelatin-based papermaking sizing agent based on hydrogen-bond interaction and preparation method thereof

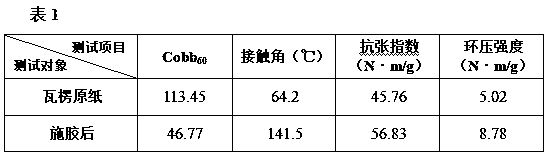

ActiveCN110904728AShort timeSimple processWater-repelling agents additionPaper coatingIsooctyl acrylateMethacrylate

The invention relates to a synthetic method for preparing an environment-friendly papermaking sizing agent from gelatin extracted from waste leather scraps. According to the method, the gelatin is modified by adopting monomers capable of forming hydrogen bonds with the gelatin and polymers(such as acrylic acid, methacrylic acid, acrylamide, methacrylamide, N-hydroxymethyl acrylamide and the like)of the monomers; and blending and toughening with polymerization emulsion of an elastomer(such as ethyl acrylate, butyl acrylate, n-octyl acrylate, isooctyl acrylate, isooctyl methacrylate and dodecylmethacrylate)to obtain the papermaking sizing agent which is low in cost, simple in process and capable of greatly improving the water resistance and physical and mechanical properties of paper.

Owner:SHAANXI UNIV OF SCI & TECH

Leather production process

InactiveCN107164583AImprove antioxidant capacityImprove the bactericidal effectTanning treatmentPre-tanning chemical treatmentSurface layerAntioxidant

The invention discloses a leather production process. The leather production process comprises the following steps of (1), material selection, specifically, animal furs are selected, and the furs of the similar thickness are placed in the same drum to be processed; (2), immersion with liquid, specifically, a proper amount of leather immersion liquid is added into the drum in the above step, the furs are made to recover to the fresh fur state, and meanwhile sterilization and inoxidizability of the furs can be improved. The leather immersion liquid contains a leaching agent, a sterilizing agent, an antioxidant and a degreaser, when moisture enters the furs under the action of the leaching agent, the sterilizing agent and the antioxidant can be carried into the furs, the inoxidizability and sterilizing effect of the leather are improved, the degreaser can remove oil stains on the surface layers of the furs, convenience is brought to full-filling of a coating in a subsequent process, the moisture is controlled to be 15-30 degrees, the leaching effect of the leather immersion liquid at the temperature can be the optimal, and the inoxidizability and sterilizing effect of the leather are promoted.

Owner:安徽英特罗斯服饰有限公司

Amphoteric dry strength agent for paper

InactiveCN106866886ANarrow molecular weight distributionHigh active ingredientReinforcing agents additionBursting strengthChemistry

The invention discloses an amphoteric dry strength agent for paper. By taking modified starch as a polymeric emulsifier, the starch is grafted to polyacrylamide chain macromolecules in the polymerization process to prepare a soap-free latent cross-linking type polyacrylamide emulsion as the dry strength agent for the paper. The amphoteric dry strength agent for the paper has the advantages of good strengthening effect, little loss of whitewater, good fixation, little jello, environmental protection and the like and can well improve the properties, including ring crush strength, folding strength, bursting strength, tensile strength and paper internal binding strength, of finished paper after paper pulp is added.

Owner:ZHEJIANG KESIKE CHEM NEW MATERIAL CO LTD

Water-based elastic fluorocarbon paint and formula thereof

The invention relates to a formula of a water-based elastic fluorocarbon paint. The formula comprises 20-25% of water, 0.3-0.5% of a dispersant, 0.2-0.3% of a wetting agent, 0.3-0.5% of an antifoaming agent, 15-20% of rutile titanium dioxide powder, 15-20% of a filling material, 0.2-0.3% of a multifunctional auxiliary agent, 0.5-1% of a coalescing agent, 0.5-1% of glycol, 10-15% of a fluorocarbon emulsion, 20-30% of an elastic emulsion, 0.3-0.5% of a thickening agent and 0.1-0.3% of a leveling agent. Long straight chain and low branched chain of a high-molecular elastic cross-linking agent react with a fluorine-containing polymer to form a highly-straight-chain and low-branched-chain polymer, the structure of which is jagged. The ultimate embodiment of properties is reflected in appropriate surface strength, excellent elasticity, telescopic springback function, high tensile strength and fracture resistance, low surface polarity and strong resistance to soiling and weatherability.

Owner:上海奥泽涂料有限公司

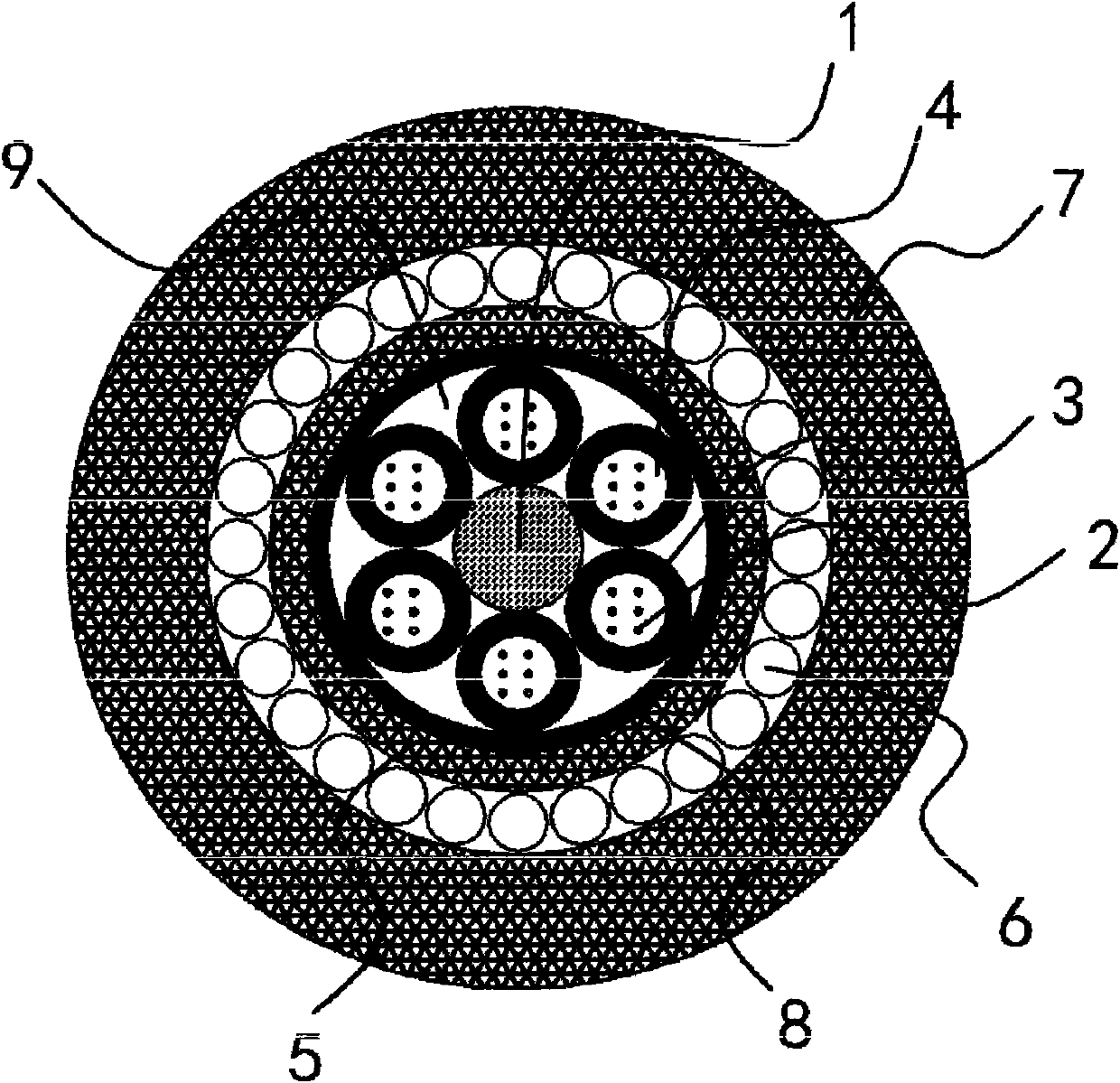

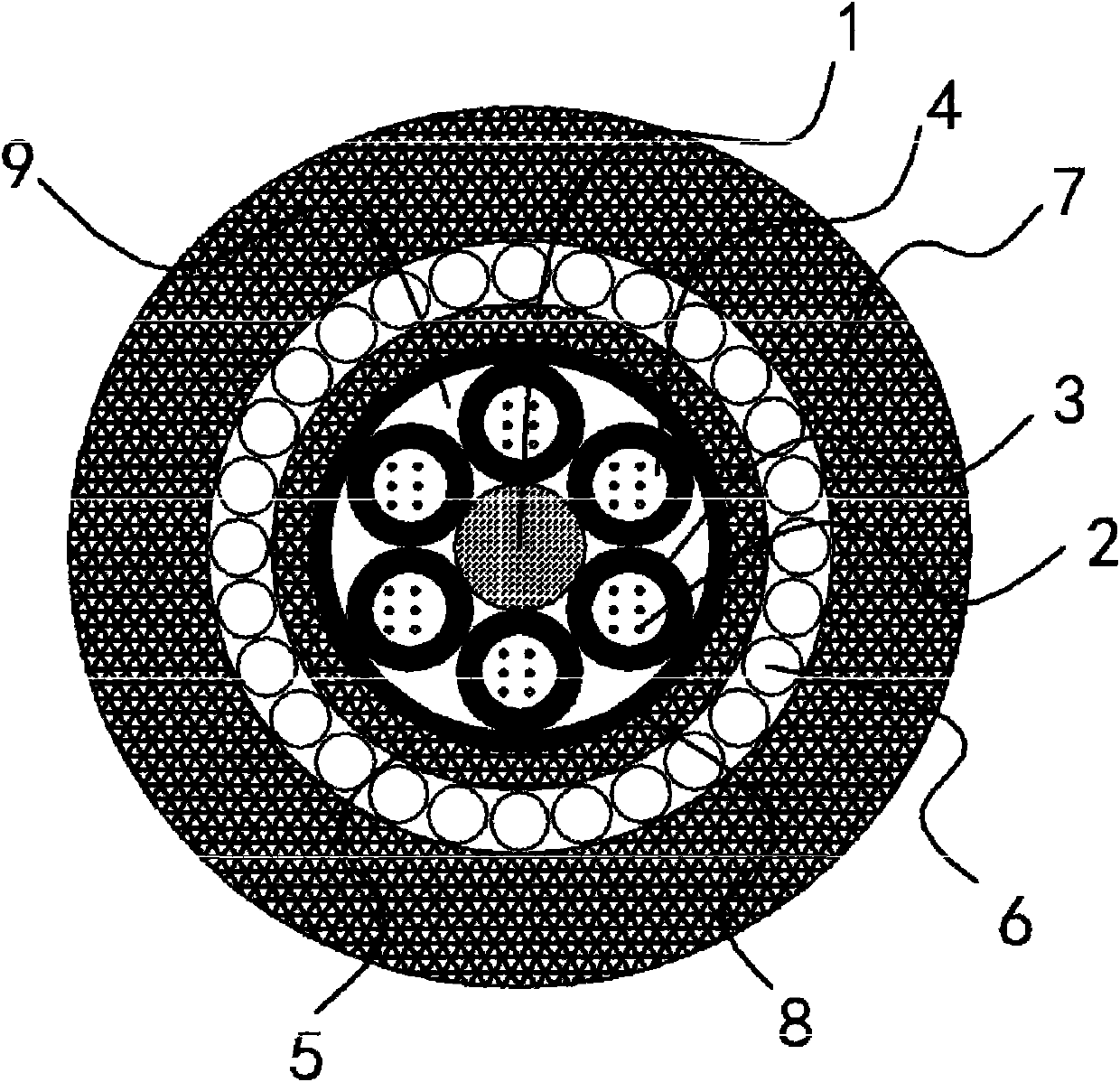

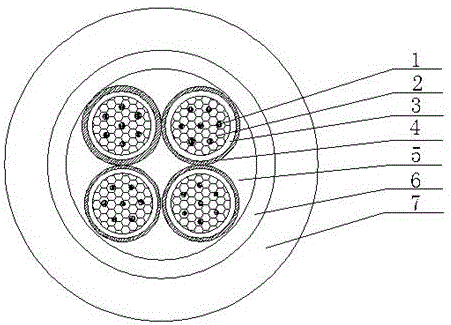

High-strength digital communication cable

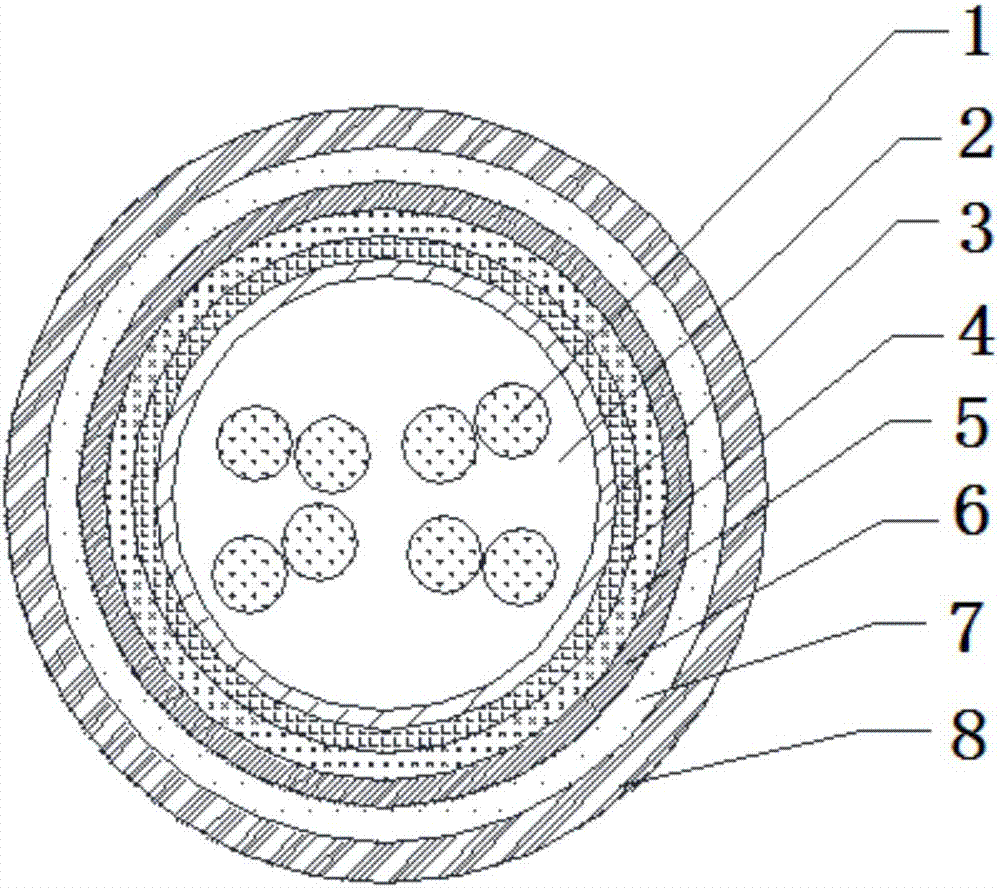

PendingCN107516554AHigh strengthGood flexibilityQuad constructionsFlexible cablesCopper conductorPolyurethane elastomer

The invention belongs to the technical field of communication cables, and relates to a high-strength digital communication cable. Two leads formed by wrapping solid copper conductors with polyethylene insulation layers are stranded to form a core wire group, 1-8 pairs of core wire groups are stranded and then lapped with wrapping tape layers to form a cable core with a circular cross section, gaps among the stranded core wire groups and the wrapping tape layers are filled with fillers, and a longitudinal wrapping layer, a braided shielding layer, an inner protective layer, an armor layer and an outer protective layer sequentially wrap the outside of the cable core from inside to outside to form the high-strength digital communication cable. Aramid fibers serve as the fillers, the 'S'-shaped steel screw interlocking armor layer is used, the composite outer protective layer comprises a polyurethane elastomer sheath, talcum powder and an irradiation crosslinking polyvinyl chloride sheath, so that the cable has high tensile strength, compressive capacity and good softening property, and high strength of the digital communication cable is realized. The high-strength digital communication cable is applicable to network cabling of protective environments which are easily trod and squeezed and free from pipelines, slots and the like.

Owner:BEIJING HENGTONG SIBO COMM TECH CO LTD

Amphoteric dry strength agent and preparation method thereof

ActiveCN102617791AModerate molecular weightModerate degree of branchingNon-fibrous pulp additionCross-linkFunctional monomer

The invention discloses an amphoteric dry strength agent and a preparation method thereof. The preparation method comprises the following steps: in a nitrogen atmosphere, the mixture of water, acrylamide, anionic monomer, cationic monomer, cross-link monomer, a chain transfer agent and other functional monomer and photoinitiator is subjected to ultraviolet irradiation reaction; pH regulator is added to adjust a pH value after the reaction is finished; and free radical catcher is added to obtain the product. The anionic monomer is the mixture of itaconate and sodium vinylsulfonate with the mass ratio of 1 to (3 to 5); the cationic monomer is the mixture of acrylic acid lignocaine ethyl ester and diallyl dimethyl ammonium chloride with the mass ratio of 1 to (2 to 3); and the functional monomer is the mixture of styrene and hydroxyethyl acrylate with the mass ratio of 1 to (1.5 to 3.5). The amphoteric dry strength agent has the characteristics of small dosage and good effect; particularly, when reclaimed waste paper pulp is adopted as papermaking raw material, the effect is more remarkable; and an excellent paper dry-strengthening effect is achieved under the condition that no aluminium sulphate is added.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Cable insulating material and preparation method thereof

InactiveCN108410021AImprove mechanical propertiesImprove insulation performanceBulk chemical productionCellulose substancesEpoxyCellulose

The invention provides a cable insulating material and a preparation method thereof. The cable insulating material is prepared from the following components: ethylene-vinyl acetate copolymer, epoxy resin, chloroprene rubber, hydrogenated nitrile rubber, high density polyethylene, modified bentonite, modified nano-crystalline cellulose, modified quick lime, titanium dioxide, zinc oxide, magnesium stearate, dibutyl phthalate, fusing agent, flame retardant, lubricant and antioxidant. The cable material prepared by the invention has excellent mechanical property and insulating property, good tensile resistance and impact resistance, has low water absorption rate and is less likely to be affected with damp, thereby having a good application prospect.

Owner:合肥羿振电力设备有限公司

Steel sheet having excellent weldability

ActiveUS20090252955A1Excellent in high-speed arc weldabilityHigh strengthRecord information storageFurnace typesMetallurgyArc welding

Disclosed is a steel sheet, containing: Si: 0.20-2% (the term “%” herein means “mass %”, the same is true hereinbelow), Mn: 1-2.5%, a total mass of Si and Mn being 1.5% or more, and O: 0.002% or less (exclusive of 0%), C: 0.02-0.25%, P: 0.1% or less (exclusive of 0%), S: 0.05% or less (exclusive of 0%), Al—0.02-0.2%, and N: 0.0015-0.015%. The steel sheet of the invention can be advantageously used for forming wide beads even in high-speed arc welding of 100 cm / min or higher.

Owner:KOBE STEEL LTD

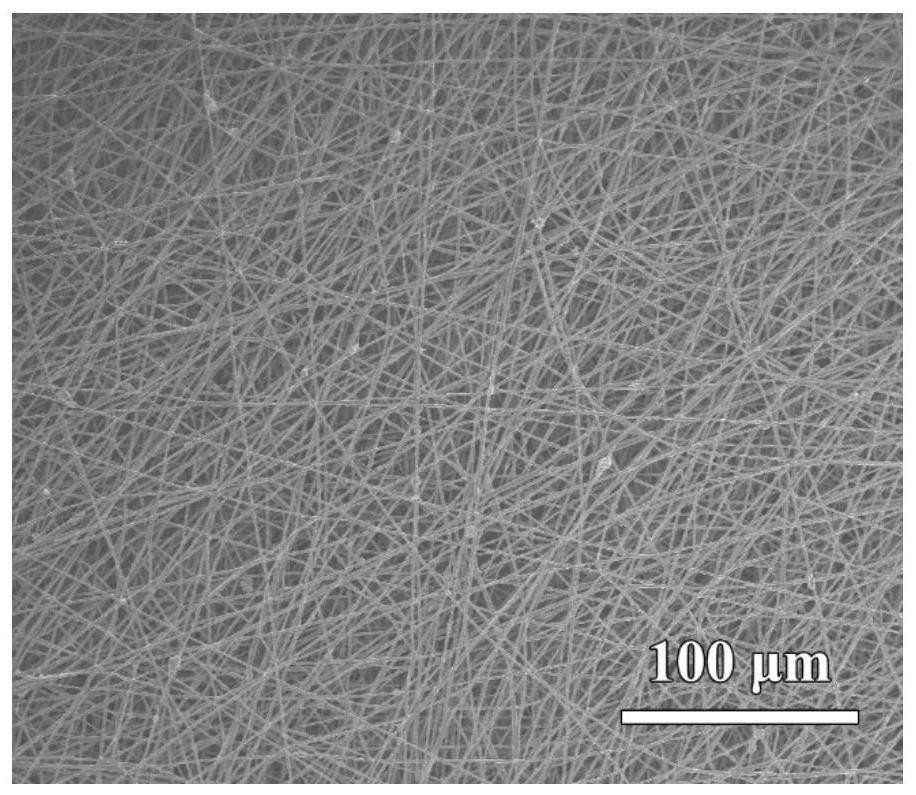

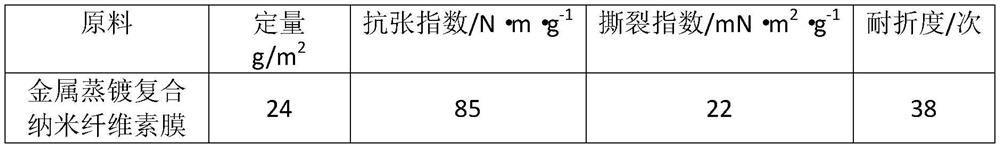

Metal evaporation composite nanocellulose membrane current collector and preparation method thereof

ActiveCN112126103AIncrease energy densityImprove bindingVacuum evaporation coatingSputtering coatingMembrane currentComposite nanofibers

The invention discloses a metal evaporation composite nanocellulose membrane current collector and a preparation method of the current collector, the current collector comprises a nanocellulose membrane and an evaporation metal layer, and the preparation method comprises the following steps: 1) mixing microcrystalline cellulose with 55-65% concentrated sulfuric acid, and stirring for 30-60 minutesto obtain a nanocellulose suspension; 2) adding ionized water into the nano cellulose suspension to dilute to 0.5-2 wt%; (3) carrying out vacuum filtration and vacuum drying to obtain a nanocellulosemembrane current collector, wherein the pore diameter of a filter membrane is 0.5-5 microns; (4) placing the nano-cellulose membrane in a vacuum environment, evaporating metal to one side of the nano-cellulose membrane to form an evaporated metal layer, wherein the evaporation process parameters are as follows: the deposition voltage is 4-10 V; the wire feeding amount is 60-350 mm / min; the vacuumdegree is 8*10<-4>-5*10<-2>mba; and the membrane running speed is 3-10 m / s. The tensile index of the current collector obtained by the technical scheme of the invention is 80-95N.m.g<-1>, the tearingindex is 20-25mN.m<2>. g<-1>, and the folding strength is 30-40 times.

Owner:浙江长宇新材料股份有限公司

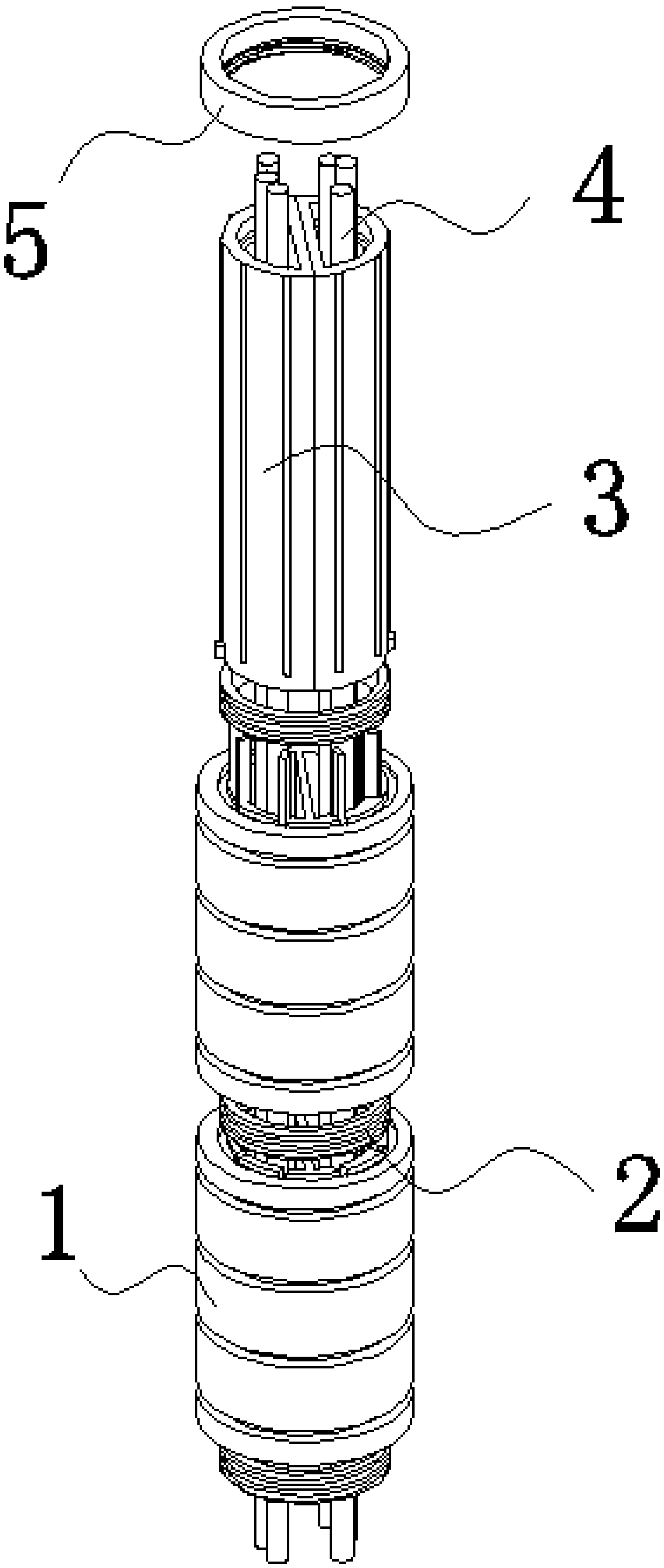

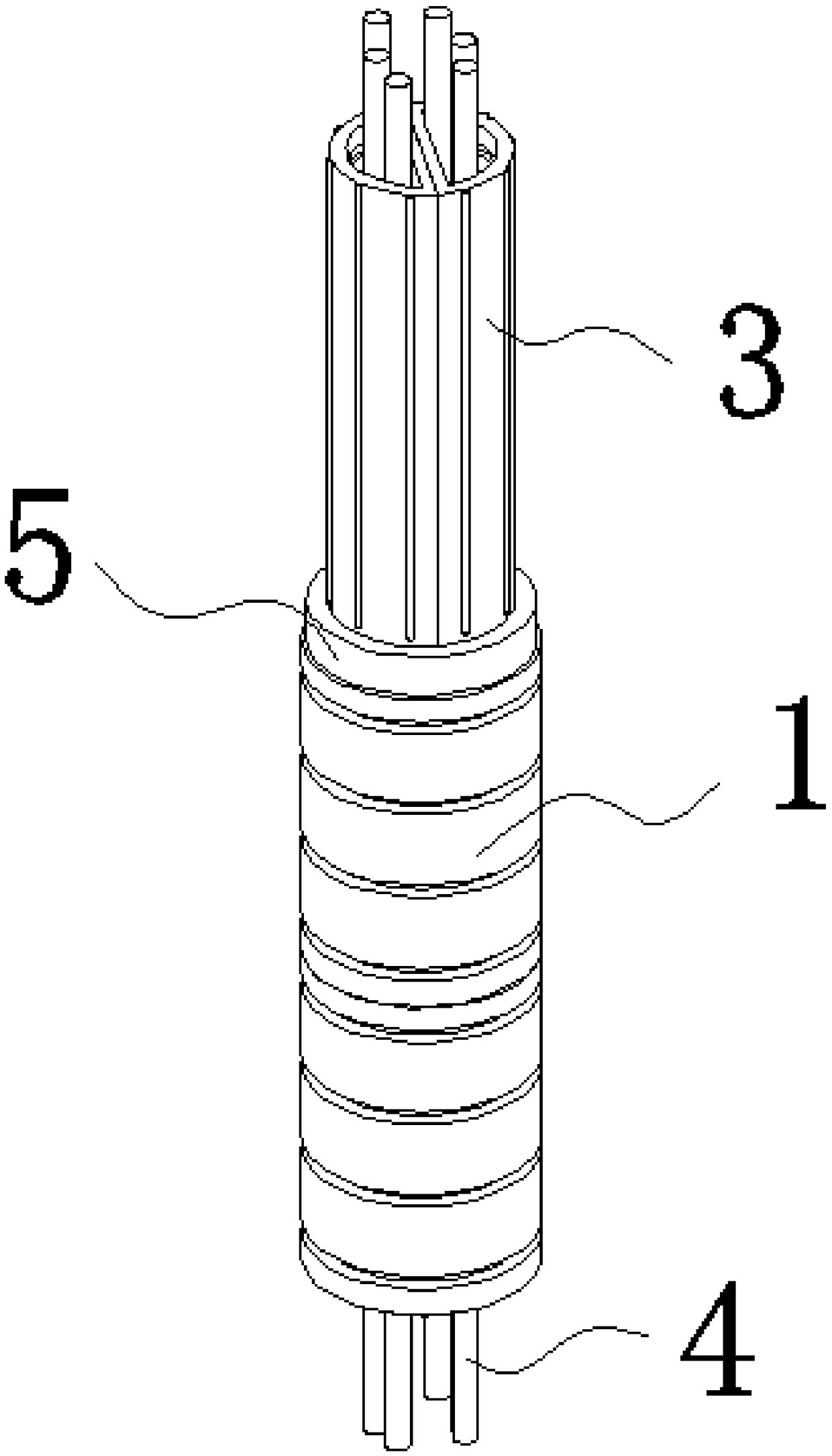

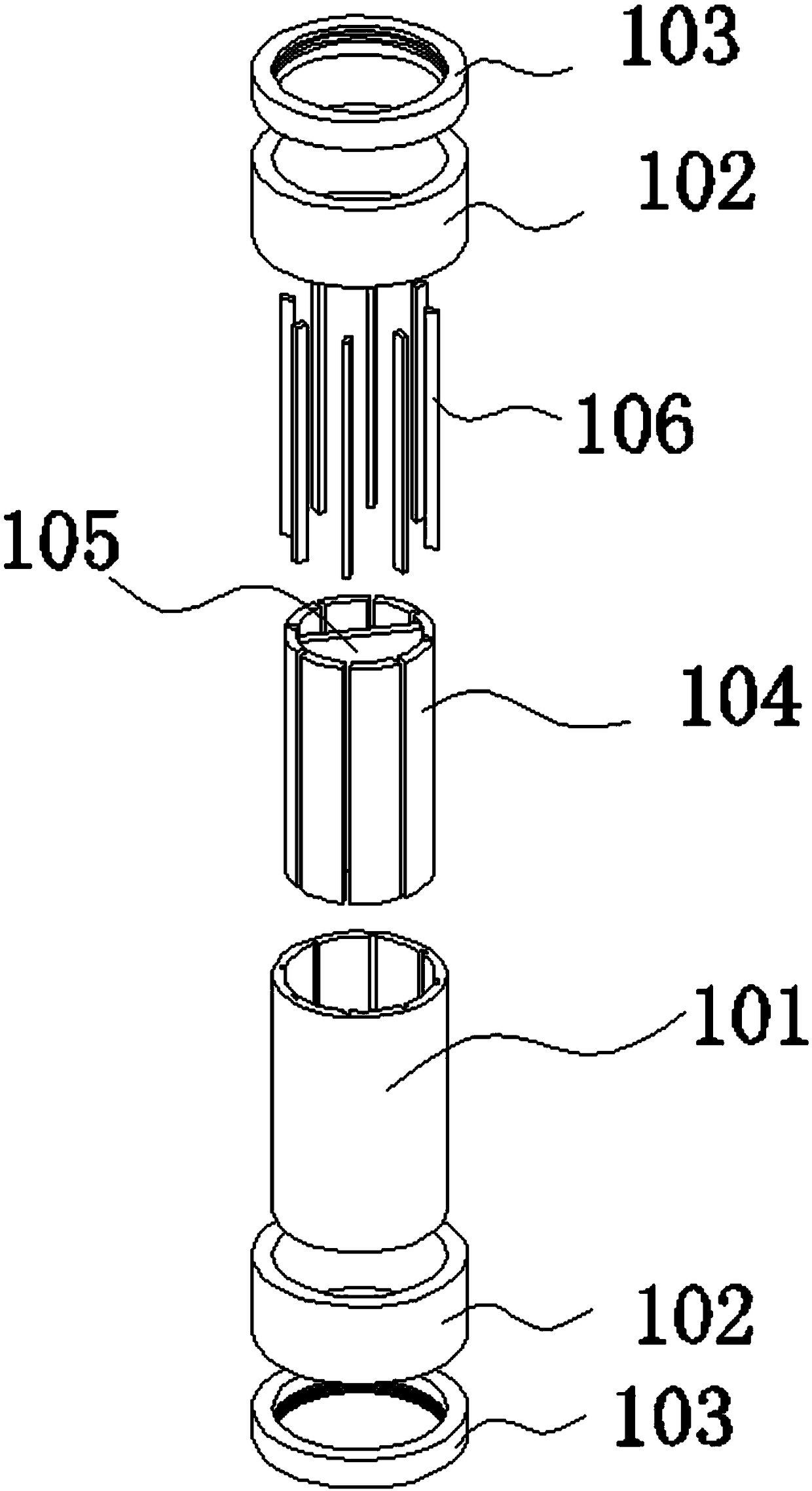

High-tenacity composite wire structure for shunting

The invention discloses a high-tenacity composite wire structure for shunting. The high-tenacity composite wire structure comprises two groups of conductive cables, wherein a connection threaded ringsand (a-1) protection sleeves fixedly sleeve the conductive cables, first threads are arranged on outer-circle side walls of the connection threaded rings, the connection threaded rings and the protection sleeves are arranged in a staggered way, the protection sleeves and the connection threaded rings are in threaded connection, a locking ring is in threaded connection with the connection threadedring at the uppermost part, and a second thread is arranged at a lower half part of an inner-circle side wall of the locking ring. With the adoption of a separable design, a detachable connection mode is used, the high-tenacity composite wire structure is relatively good in elasticity and has tenacity, and wiring operation is convenient; the high-tenacity composite wire structure has the advantages of tensile strength, chemical and thermal corrosion resistance, electrical insulation performance, aging resistance and corrosion resistance, the mechanical strength is improved, the tenacity is improved, the protection performance is further improved, and the power utilization safety is ensured.

Owner:何银亚

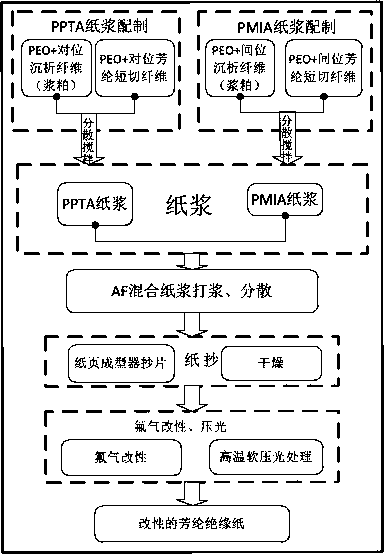

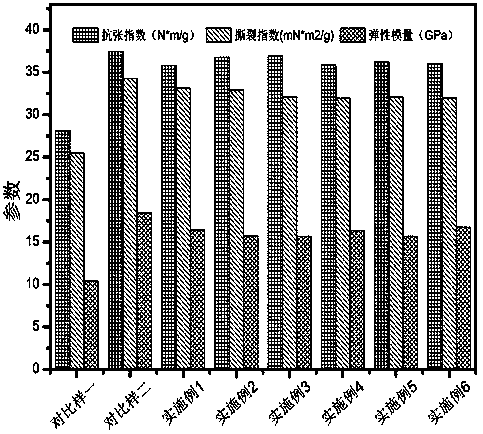

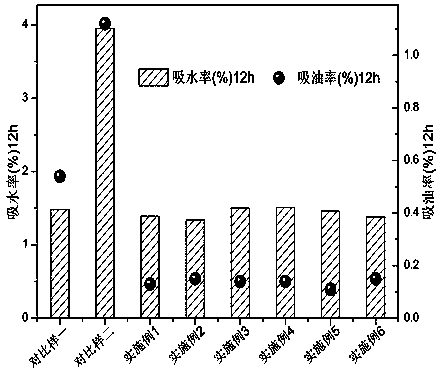

Method for improving mechanical properties and hydrophobic and oleophobic properties of aramid insulating paper

InactiveCN107663807AImprove mechanical propertiesIncreased tensile indexPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperPapermakingAramid

The invention relates to a method for improving mechanical properties and hydrophobic and oleophobic properties of aramid insulating paper. Para-position aramid fibers are added in a papermaking process of meta-position aramid insulating paper. Compared with meta-position aramid fibers, the para-position aramid fibers have better mechanical properties, so that the mechanical properties of the meta-position aramid insulating paper are further improved. The aramid insulating paper is modified by utilizing fluorine gas; after modification, a new group is introduced into the surface of the aramidinsulating paper so that the contact angle of the surface of the aramid insulating paper is enlarged and the hydrophobic and oleophobic properties of the aramid insulating paper are increased. A high-temperature soft calendering method is utilized so that the structure of the aramid insulating paper is not damaged and the crystallization degree of the aramid fibers can be greatly improved; meanwhile, the acting force between aramid cellulose chains is enhanced through a hot pressing manner, the combination is tighter and the linear density is increased; the tearing index and the tensile indexof the aramid insulating paper are greatly improved. The preparation method of the aramid insulating paper, provided by the invention, has the characteristics of simple technology, practicability andthe like.

Owner:SOUTHWEST UNIVERSITY

Anti-electromagnetic field powerful optical cable

InactiveCN101794006AImprove transmission lossGood weather resistanceFibre mechanical structuresFiberHydrogen

The invention belongs to the technical field of communication, and relates to an anti-electromagnetic field powerful optical cable. The anti-electromagnetic field powerful optical cable solves the technical problems that the prior art has low structural strength, poor performance and the like. The anti-electromagnetic field powerful optical cable comprises a center reinforcer and a plurality of cable cores, wherein a loose bushing is sleeved on the periphery of each cable core respectively; a fiber paste for enclosing and protecting the cable core is arranged in the loose bushing; the loose bushing is intertwisted around the center reinforcer; the periphery of the loose bushing is provided with a first protective cover for covering each loose bushing; the periphery of the first protective cover is provided with a plurality of galvanized steel wires enwound on the first protective cover; and the peripheries of the galvanized steel wires are provided with second protective covers for covering each galvanized steel wire. The anti-electromagnetic field powerful optical cable has the following advantages that: 1, the weatherability is good, the high and low temperature properties are excellent, and optical fibers have no hydrogen losses caused by the oxidation of phosphorized steel wire or steel strips; 2, the tensile strength, lateral pressure resisting intensity and impact resistance are high, metal components are completely isolated from the cable cores, and the optical cable can also be used normally in a strong electromagnetic field environment; and 3, the structure is compact, the production process is simple, and the optical cable can be produced by using existing equipment.

Owner:ZHEJIANG ZHONGTIAN WIRE & CABLE

Branch type dry strength agent and preparation method thereof

ActiveCN102720094BImprove performanceGood bonding strength in paperReinforcing agents additionFunctional monomerUltraviolet

The invention discloses a branch type dry strength agent and a preparation method thereof. The preparation method comprises the following steps of: firstly, mixing acrylamide, negative ion monomers, positive ion monomers, crosslinking agent monomers, a photoinitiator, water and other functional monomers to obtain solution A; secondly, mixing a chain transfer agent and water to obtain solution B; thirdly, polymerizing 40%-60% of the solution A and 20%-40% of the solution B by ultraviolet ray irradiation; fourthly, adding 20%-30% of the solution A and 20%-30% of the solution B into the mixed solution in the third step to be subjected to polymerization by ultraviolet ray irradiation; fifthly, adding the residual solution A and the residual solution B into the mixed solution in the fourth step to be subjected to polymerization by ultraviolet ray irradiation until the viscosity of the solution meets requirements; and sixthly, adjusting the pH and solid content of weight of the mixed solution in the fifth step, and adding free radical catcher into the mixed solution to obtain the branch type dry strength agent. According to the branch type dry strength agent and the preparation method, the operation is simple, the viscosity is easy to control, the dispersibility of the branch type dry strength agent in water is good, the properties of ring crush, fold resistance, breaking resistance, tension resistance, internal bonding strength and the like of paper can be improved.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Amphoteric dry strength agent and preparation method thereof

ActiveCN102617791BImprove performanceGood bonding strength in paperNon-fibrous pulp additionCross-linkFunctional monomer

The invention discloses an amphoteric dry strength agent and a preparation method thereof. The preparation method comprises the following steps: in a nitrogen atmosphere, the mixture of water, acrylamide, anionic monomer, cationic monomer, cross-link monomer, a chain transfer agent and other functional monomer and photoinitiator is subjected to ultraviolet irradiation reaction; pH regulator is added to adjust a pH value after the reaction is finished; and free radical catcher is added to obtain the product. The anionic monomer is the mixture of itaconate and sodium vinylsulfonate with the mass ratio of 1 to (3 to 5); the cationic monomer is the mixture of acrylic acid lignocaine ethyl ester and diallyl dimethyl ammonium chloride with the mass ratio of 1 to (2 to 3); and the functional monomer is the mixture of styrene and hydroxyethyl acrylate with the mass ratio of 1 to (1.5 to 3.5). The amphoteric dry strength agent has the characteristics of small dosage and good effect; particularly, when reclaimed waste paper pulp is adopted as papermaking raw material, the effect is more remarkable; and an excellent paper dry-strengthening effect is achieved under the condition that no aluminium sulphate is added.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

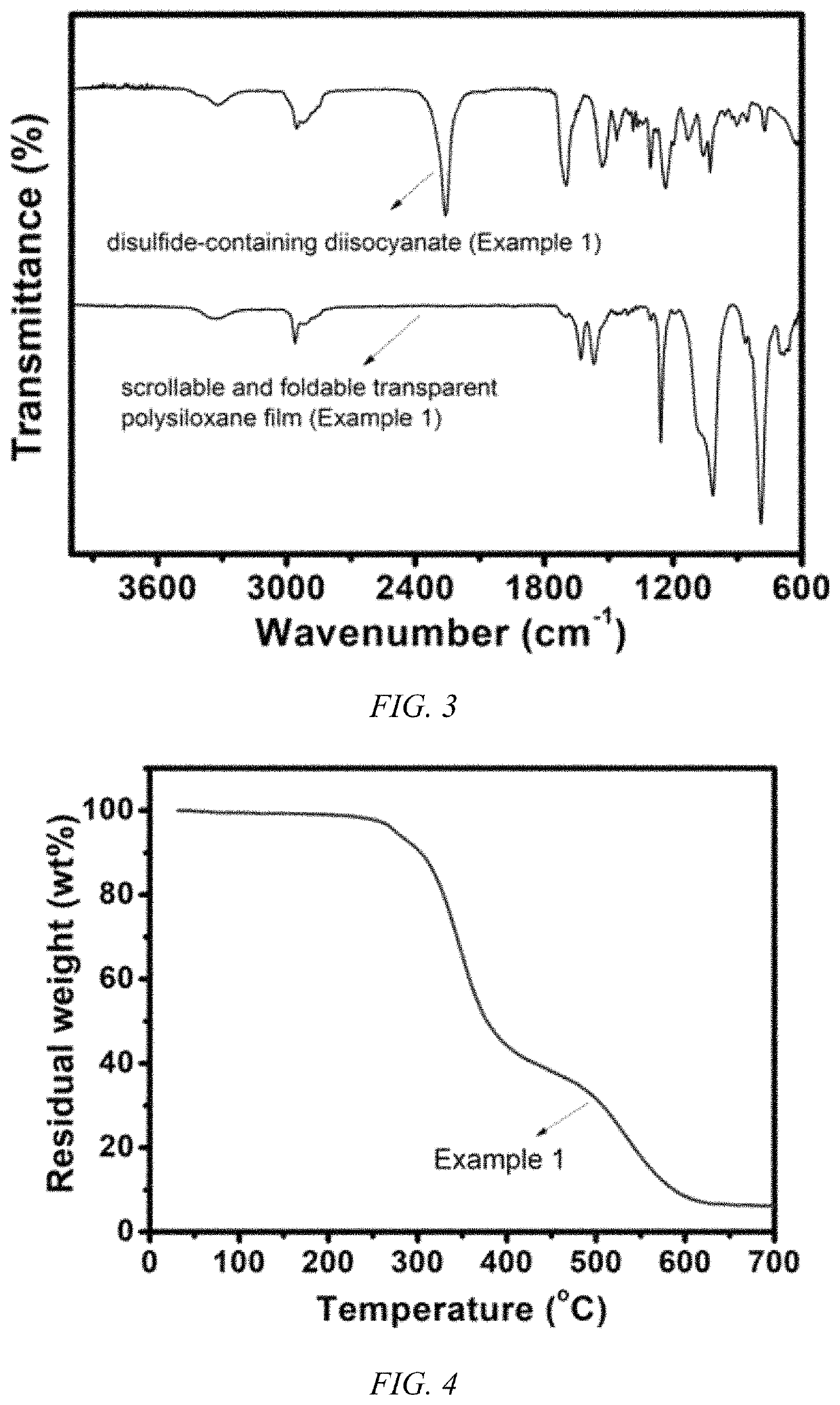

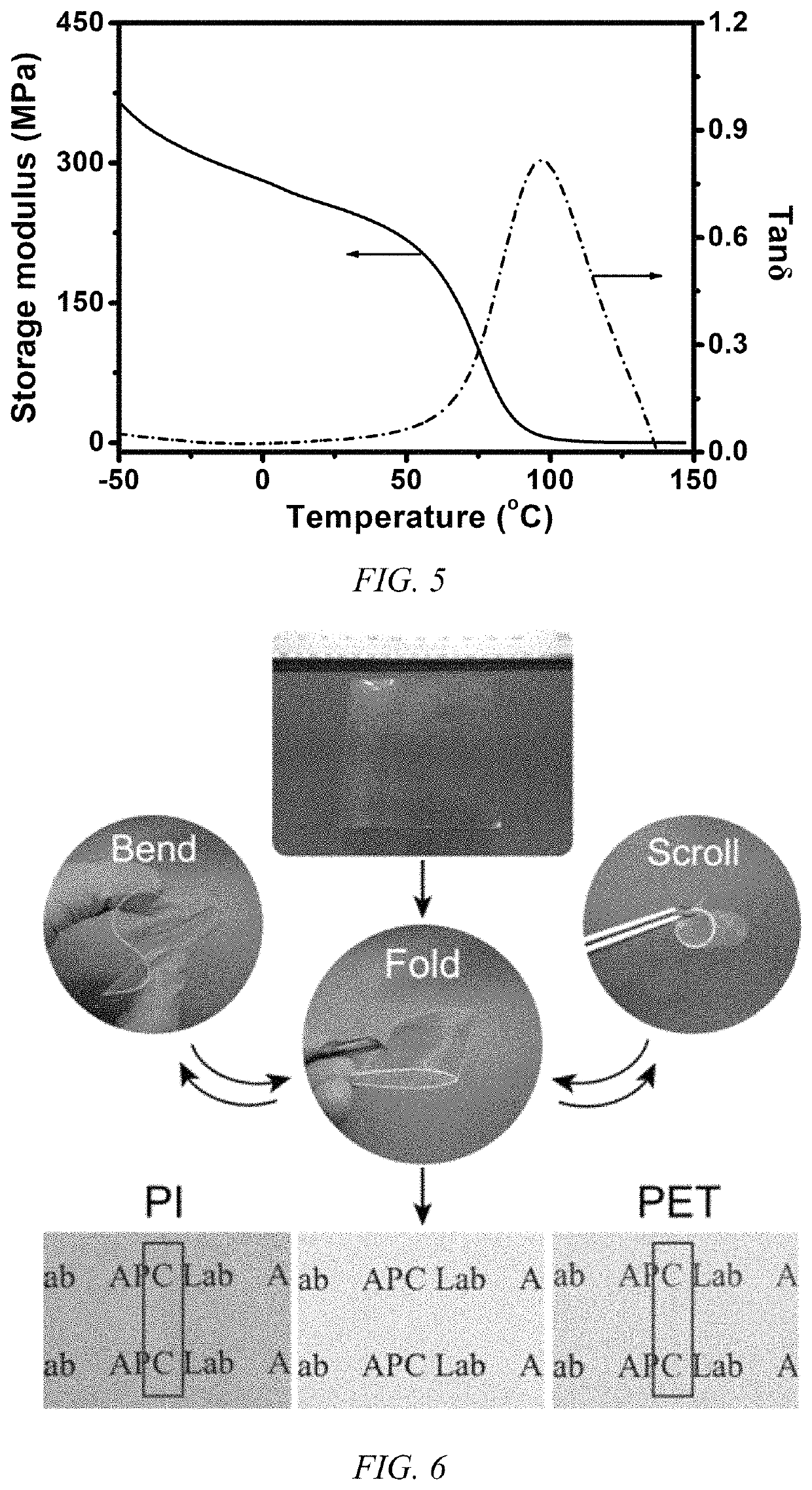

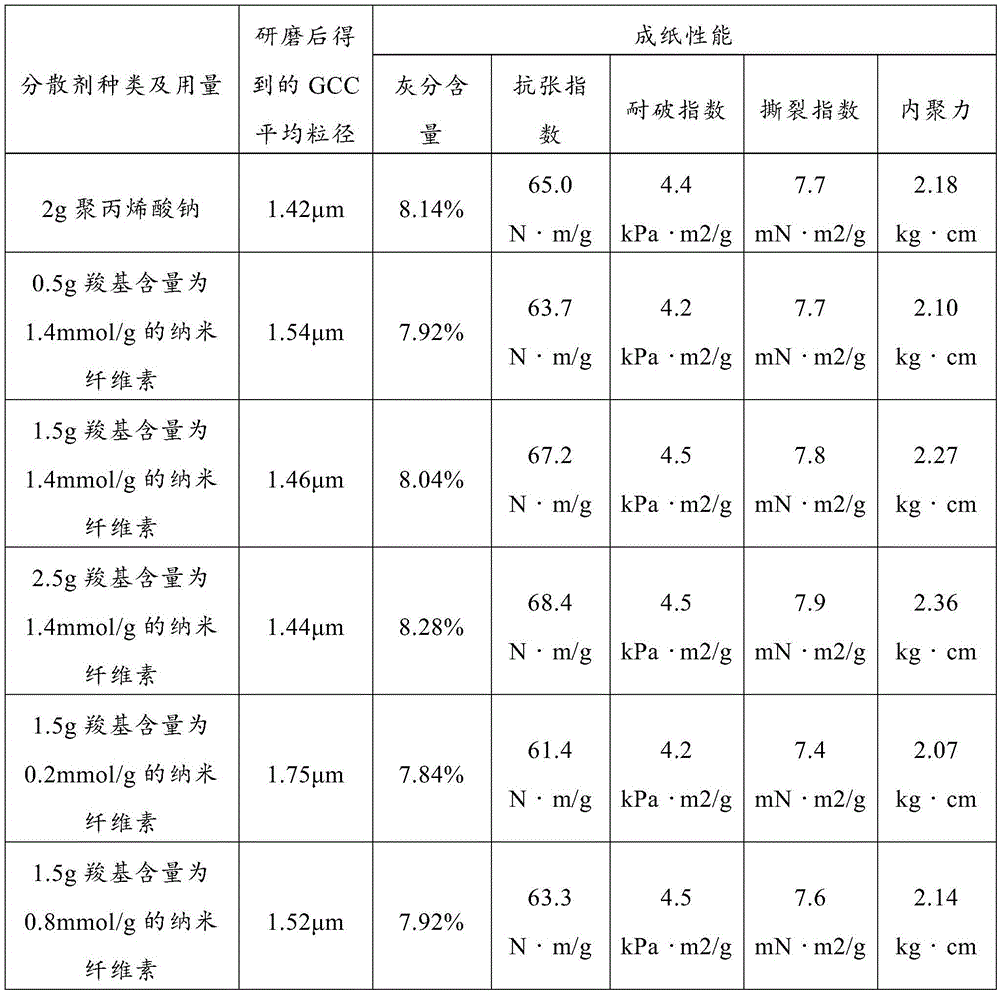

Transparent rollable folded polysiloxane film and preparation and self-repairing method thereof

This invention provides a scrollable and foldable transparent polysiloxane film and its preparation and self-healing method. 2-Hydroxyethyl disulfide, diisocyanate and alkane chloride were mixed and reacted to get disulfide-containing diisocyanate. α,ω-Aminopropyl terminated polydimethylsiloxane, diisocyanate and alkane chloride were mixed and reacted get linear chain-extended polydimethylsiloxane. Linear chain-extended polydimethylsiloxane, multi-amino terminated hyperbranched polysiloxane, disulfide-containing diisocyanate and alkane chloride were mixed and poured into a mould. After drying, the scrollable and foldable transparent polysiloxane film was obtained. The polysiloxane film described in this invention are constructed by dynamic physical crosslinking induced by hydrogen bond and permanent chemical crosslinking generated by hyperbranched polysiloxane. Hence, the polysiloxane film achieves both high stiffness and toughness. The good self-healing behavior of the polysiloxane films is originated from the temperature controlled dissociation of hydrogen bonds and exchange reaction rate of disulfide bonds.

Owner:SUZHOU UNIV

Grinding calcium carbonate suspension production process, grinding calcium carbonate suspension and paper

ActiveCN104343043BAvoid damageLarge specific surface areaSpecial paperPaper/cardboardALLYL SUCROSESynthetic monomer

The invention relates to a ground calcium carbonate suspension production process. The ground calcium carbonate suspension production process comprises the following steps: providing a nano-crystalline cellulose solution of which the surface carboxyl content is 0.2-1.5mmol / g and the diameter is smaller than or equal to 100 nanometers; and providing calcium carbonate to be ground, preparing a mixed solution by taking the nano-crystalline cellulose solution as a dispersing agent according to a mixing proportion of adding 1-10kg by oven dry weight of the nano-crystalline cellulose solution into 1 ton of calcium carbonate, and grinding the mixed solution to obtain a ground calcium carbonate suspension. According to the ground calcium carbonate solution production process, the nano-crystalline cellulose solution of which the surface carboxyl content is 0.2-1.5mmol / g and the diameter is smaller than or equal to 100 nanometers is taken as the dispersing agent, instead of conventional sodium polyacrylate and salts thereof, so that the grain size of finished ground calcium carbonate meets the requirement, and damage to the skin and the respiratory tract of a person caused by a synthetic monomer in the preparation and use processes of polyacrylic acid and salts thereof is effectively avoided. The invention further relates to the ground calcium carbonate suspension and paper.

Owner:GOLD EAST PAPER JIANGSU

Anti-electric arc nonmetallic leading-in optic cable

PendingCN105022129ASmooth transmissionHas no magnetic interferenceFibre mechanical structuresFiberPolyester

The invention provides an anti-electric arc nonmetallic leading-in optic cable, which belongs to the technical field of communication optical cable manufacturing, and solves the problem that the existing indoor optical cable is difficult to mount. The anti-electric arc nonmetallic leading-in optic cable comprises a sheath; the sheath is molded through injection by a low-smoke flame-retardant non-halogen polyolefin material; central places on the upper surface and the lower surface of the sheath are provided with V-shaped tearing grooves; the central place of the sheath is provided with a loose tube; the central place of the loose tube is provided with an optical fiber; the outer side wall of the optical fiber and the inner side wall of the loose tube are filled with ointment; the left side of the loose tube in the sheath is provided with a pair of left reinforcing parts made by polyester fiber and a gap exists between the pair of left reinforcing parts; the right side of the loose tube in the sheath is provided with a pair of right reinforcing parts made by polyester fiber, and a gap exists between the pair of right reinforcing parts. The anti-electric arc nonmetallic leading-in optic cable has the advantage of both elasticity and strength.

Owner:ZHEJIANG ZHONGTIAN WIRE & CABLE

Thermoplastic rubber particles and preparation method thereof

PendingCN113121947ANon-toxic and environmentally friendlyAging resistantVulcanizationPhysical chemistry

The invention relates to the technical field of cable materials, in particular to thermoplastic rubber particles and a preparation method thereof. The thermoplastic rubber particles prepared by the invention have the advantages of no toxicity, environmental protection, aging resistance, high and low temperature resistance, oil resistance, water resistance, corrosion resistance of general chemicals, soft texture, high tensile resistance, tensile property and low wear resistance, can be suitable for cables in mobile laying places with rated voltage of 450 / 750V and below, avoids a vulcanization process, and is relative low in the specific gravity.

Owner:剑越高分子材料科技有限公司

High-temperature bend-resistant mobile instantaneous tensile cable

InactiveCN105702353AControl tensile indexTensile resistance indicator does not appearFlexible cablesFlexible conductorsPolyesterCopper conductor

The invention discloses a high-temperature bend-resistant mobile instantaneous tensile cable, which comprises four groups of wire cores, a wrapping tape layer and a sheath layer, wherein each wire core comprises aramid ropes, tinned copper conductors, a high tear-resistant silicone rubber insulating layer and a polyester tape insulating wrapping tape layer; the aramid ropes are evenly arranged in the tinned copper conductors; the high tear-resistant silicone rubber insulating layers extrude and wrap the outside of the tinned copper conductors; each polyester tape insulating wrapping tape layer is arranged outside the corresponding high tear-resistant silicone rubber insulating layer; the four groups of wire cores are evenly extruded and wrapped with the wrapping tape layer; the sheath layer is arranged outside the wrapping tape layer; and a filling layer is also arranged in a gap between the wrapping tape layer and the wire cores. The high-temperature bend-resistant mobile instantaneous tensile cable has the characteristics of high-temperature resistance, wear-resisting property, good flexibility and high tensile property, and can meet the requirements of special performance of the cable in an operating condition; and the service lifetime of the cable is prolonged.

Owner:安徽华电线缆集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com