Anti-electromagnetic field powerful optical cable

A powerful, electromagnetic field technology, applied in the field of communication, can solve the problems of increased transmission loss of optical cable, large electromagnetic signal interference, poor impact resistance, etc., to achieve the effect of increased transmission loss, high lateral pressure resistance, and high impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

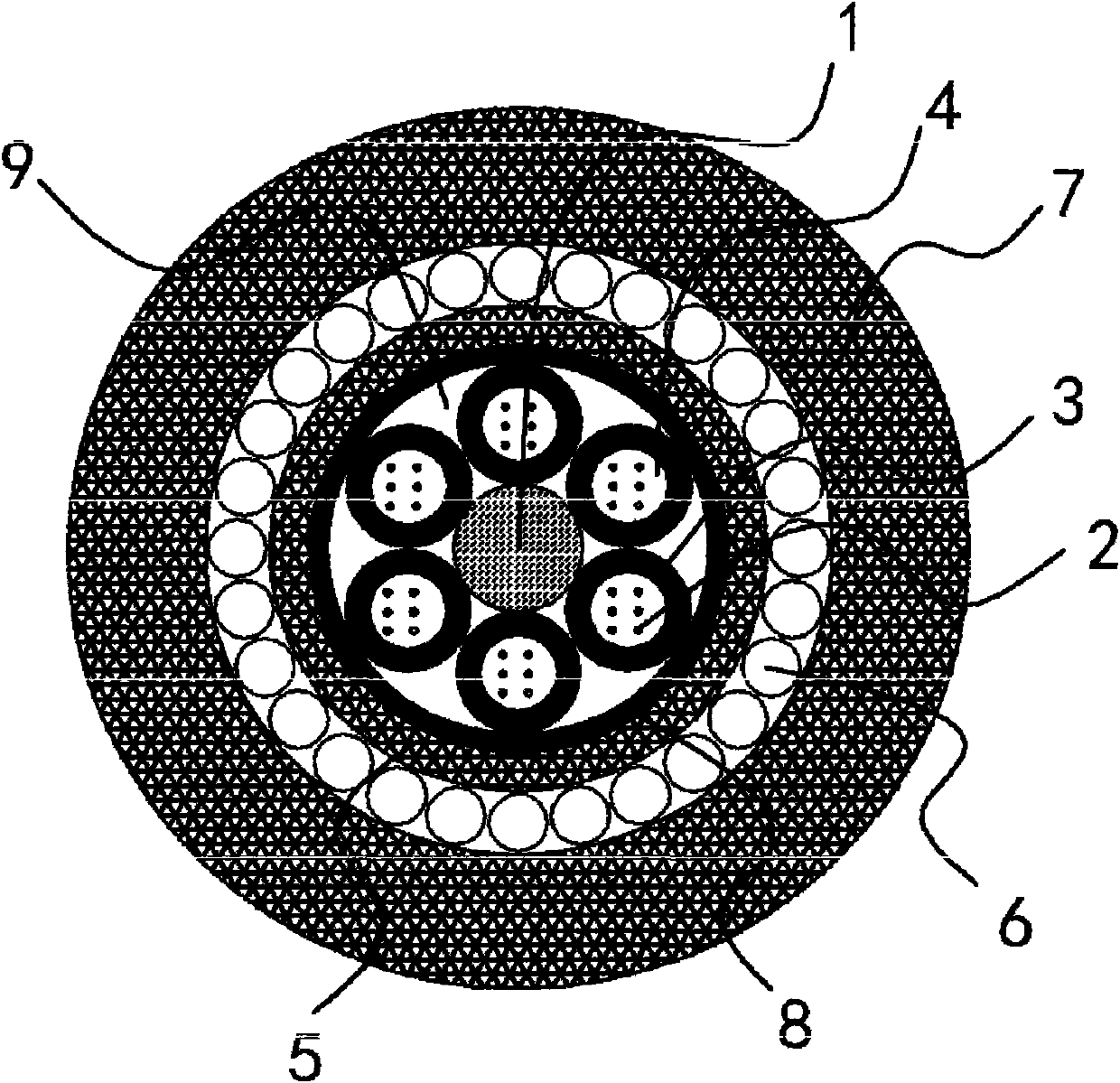

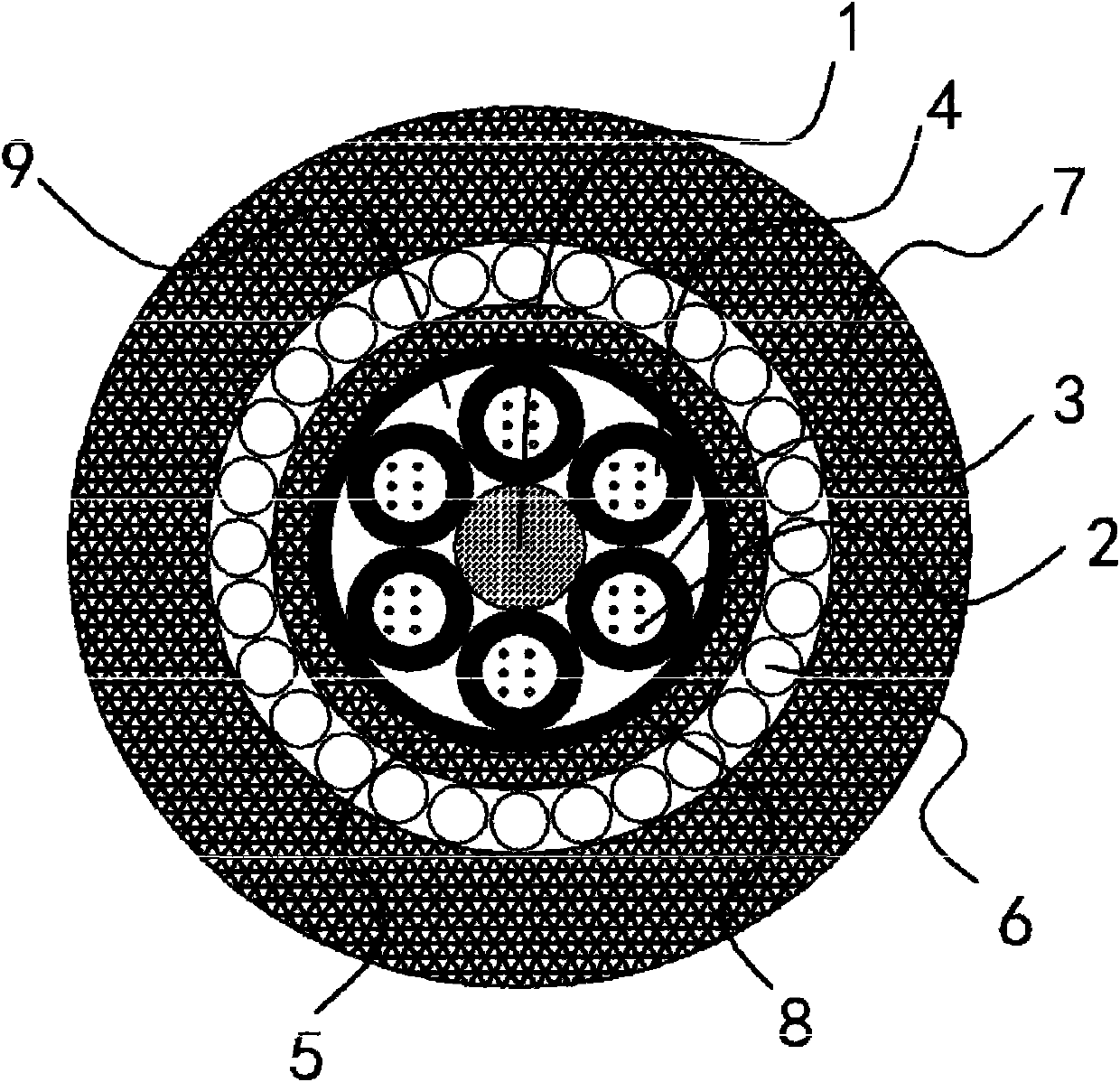

[0016] Such as figure 1 As shown, the anti-electromagnetic field strong optical cable includes a central strength member 1 and several cable cores 2 . The cable core 2 is an all-dielectric fiber bundle or fiber ribbon. The outer periphery of each cable core 2 is respectively covered with a loose tube 3 , and the fiber paste 4 surrounding the cable core 2 is arranged in the loose tube 3 , and the loose tube 3 is stranded around the central reinforcement 1 in a single layer. The outer periphery of the loose tube 3 is provided with a first protective cover 5 that covers each loose tube 3 , and a number of galvanized steel wires 6 wound thereon are arranged on the outer periphery of the first protective cover 5 . A second protective sheath 7 covering each galvanized steel wire 6 is arranged on the periphery.

[0017] In this embodiment, a waterproof layer 8 is also provided between the first protective sheath 5 and the loose tube 3, and the waterproof layer 8 is made of polyeste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com