Manufacture method of optical printed wiring board

A manufacturing method and optical printing technology, which is applied to the coupling of printed circuit components and optical waveguides, can solve problems such as limiting system performance, and achieve the effect of low transmission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

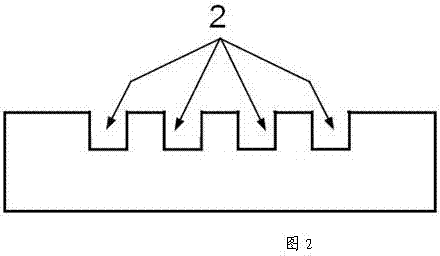

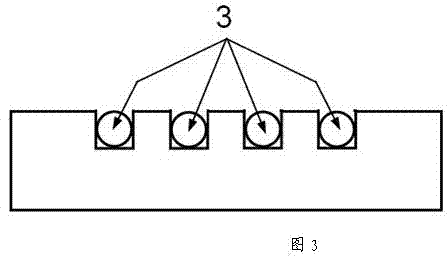

[0027] Such as Figures 1 to 4 As mentioned above, first prepare a clean FR4 sheet (glass fiber epoxy resin copper clad laminate) 1, such as figure 1 as shown, and then make groove 2, such as figure 2 As shown, the cross-sectional size of the groove is the diameter of the standard optical fiber 3, and then place the optical fiber 3 in the groove 2, such as image 3 shown. Finally, after the pressing process, the optical fiber 3 will be embedded in the printed circuit board to form an optical layer, and the general copper lines 4 can continue to be distributed on the surface of the circuit board, such as Figure 4 shown.

[0028] refer to Figure 5 , After forming the optical layer, the most critical issue is how to couple the light in and out, and how to turn the light by total reflection. Using the above-mentioned bevel cutting method, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com