Paper dry intensifier and preparation method thereof

A technology of dry strength agent and scavenger, used in papermaking, reinforcing agent addition, textile and papermaking, etc., can solve the problems of too large or too small polymer, gelation, etc., achieve good effect, prevent gelation, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

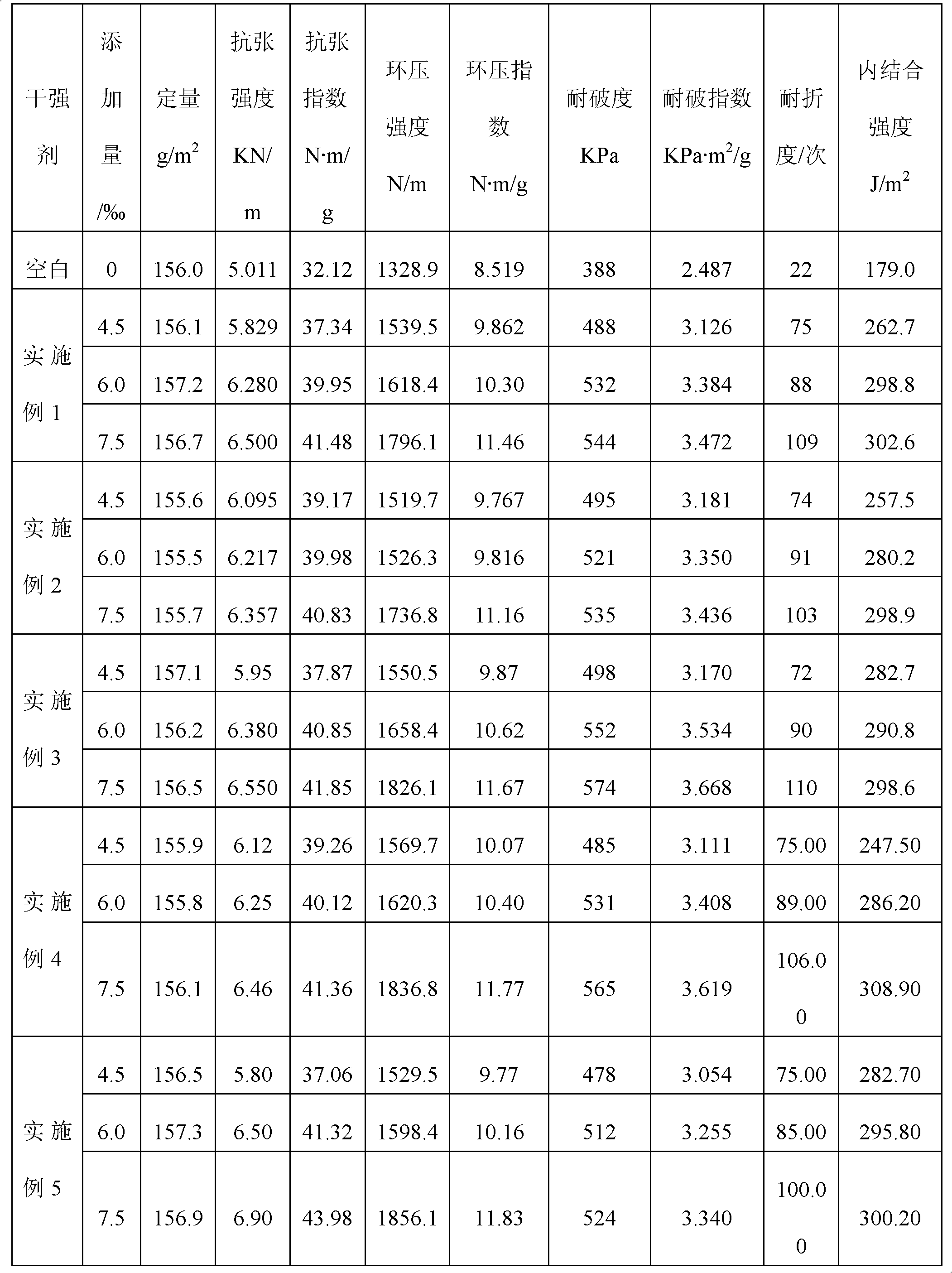

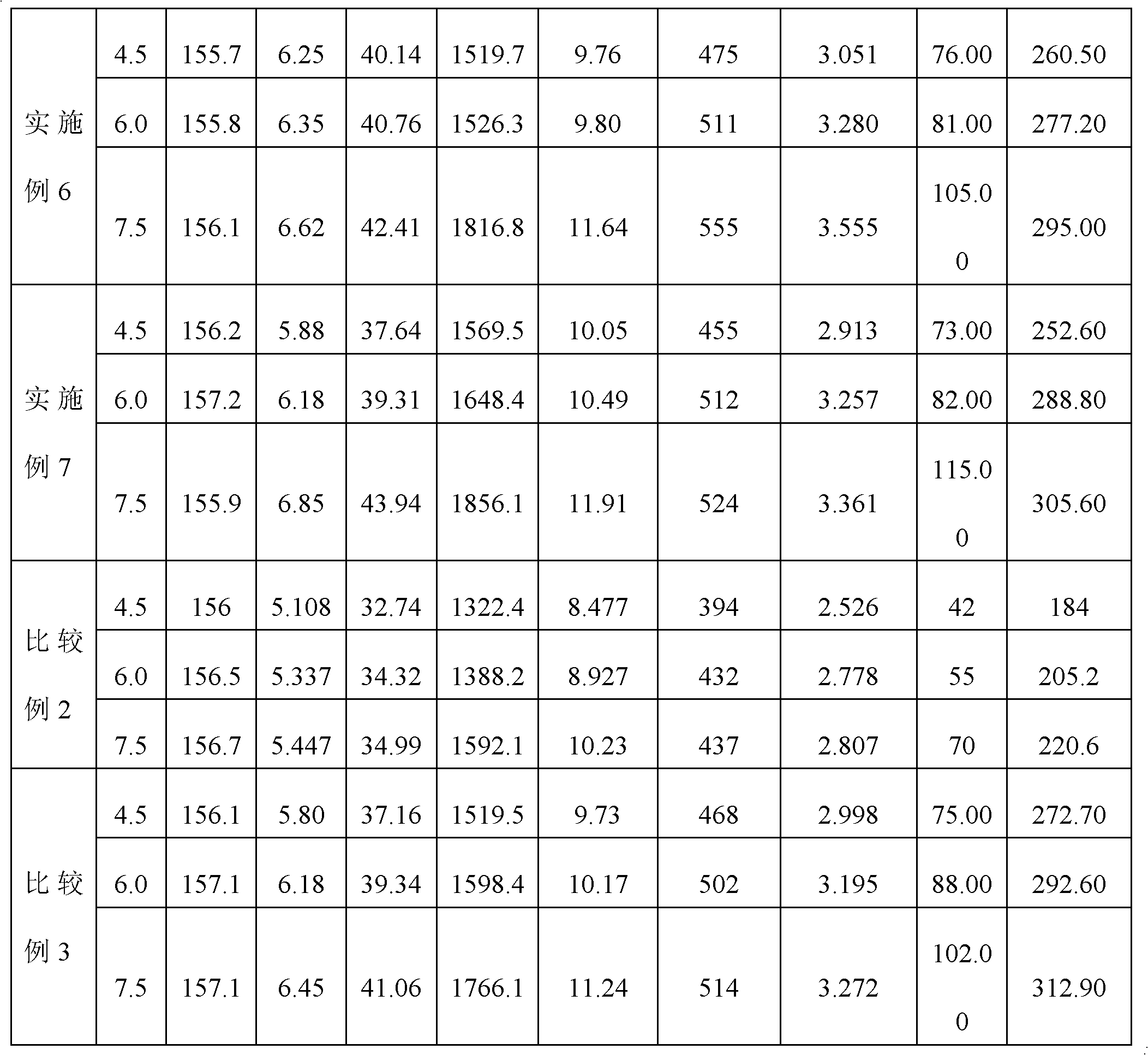

Embodiment 1

[0026] .In the reaction kettle, add 405g of water, 118g of acrylamide, 2g of itaconic acid, 16g of methacryloyloxyethyltrimethylammonium chloride, 0.08g of methylenebisacrylamide, and 1g of sodium allylsulfonate , 4 g of hydroxypropyl acrylate, 2 g of ethyl acrylate and 1 g of benzophenone were stirred evenly, and the reactor was repeatedly evacuated and nitrogen evacuated for 2 to 3 times, and then the nitrogen was maintained, and the temperature of the reactor was raised to 85° C. Irradiate ultraviolet light, react under the situation of keeping constant temperature substantially 1.5 hours, begin to take a sample every 20 minutes and carry out viscosity test afterwards, stop irradiating ultraviolet light after the viscosity reaches 4500mPa*s, add liquid caustic soda (32%, weight) 1.5g to adjust pH to 4. Finally, 0.02 g of hydroquinone is added, and water is added to adjust the weight solid content to 20%, which is the final product.

Embodiment 2

[0028] Add 400g of water, 100g of acrylamide, 2g of itaconic acid, 15g of methacryloyloxyethyltrimethylammonium chloride, 0.08g of methylenebisacrylamide, 0.8g of sodium allyl sulfonate, Stir 15g of hydroxypropyl acrylate, 5g of styrene and 0.5g of benzophenone evenly, repeatedly evacuate the reactor for 2 to 3 times, and then maintain the nitrogen, raise the temperature of the reactor to 75°C, and irradiate the reaction system Ultraviolet light, reacted for 2 hours under the condition of keeping a constant temperature, and then began to take samples every 20 minutes for viscosity testing. After the viscosity reached 5000mPa*s, stop irradiating ultraviolet light, and add 1.5g of liquid caustic soda (32% by weight) to adjust the pH to 6. Finally, 2 g of sodium bisulfite is added, and water is added to adjust the solid content to 20%, which is the final product.

Embodiment 3

[0030] .Add 410g of water, 110g of acrylamide, 2g of maleic anhydride, 10g of dimethylaminoethyl (meth)acrylate, 0.9g of dimethylacrylamide, 0.6g of sodium allyl sulfonate, methacrylic acid in the reaction kettle Stir 15g of hydroxypropyl ester, 5g of styrene and 0.7g of benzophenone evenly, repeatedly evacuate the reactor for 2 to 3 times, and then maintain the nitrogen, raise the temperature of the reactor to 75°C, and irradiate the reaction system with ultraviolet light light, reacted for 2 hours under the situation of keeping a constant temperature substantially, and then began to take samples every 20 minutes to carry out the viscosity test. Copper sulfate 0.01g, adjusting the weight solid content to 20%, is the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com