Anti-electric arc nonmetallic leading-in optic cable

A technology for introducing optical cables and non-metals, applied in the directions of light guides, optics, optical components, etc., can solve the problems of reduced transmission speed, unstable attenuation value, large elastic modulus, etc., to improve Internet speed, long service life, and elastic modulus. large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

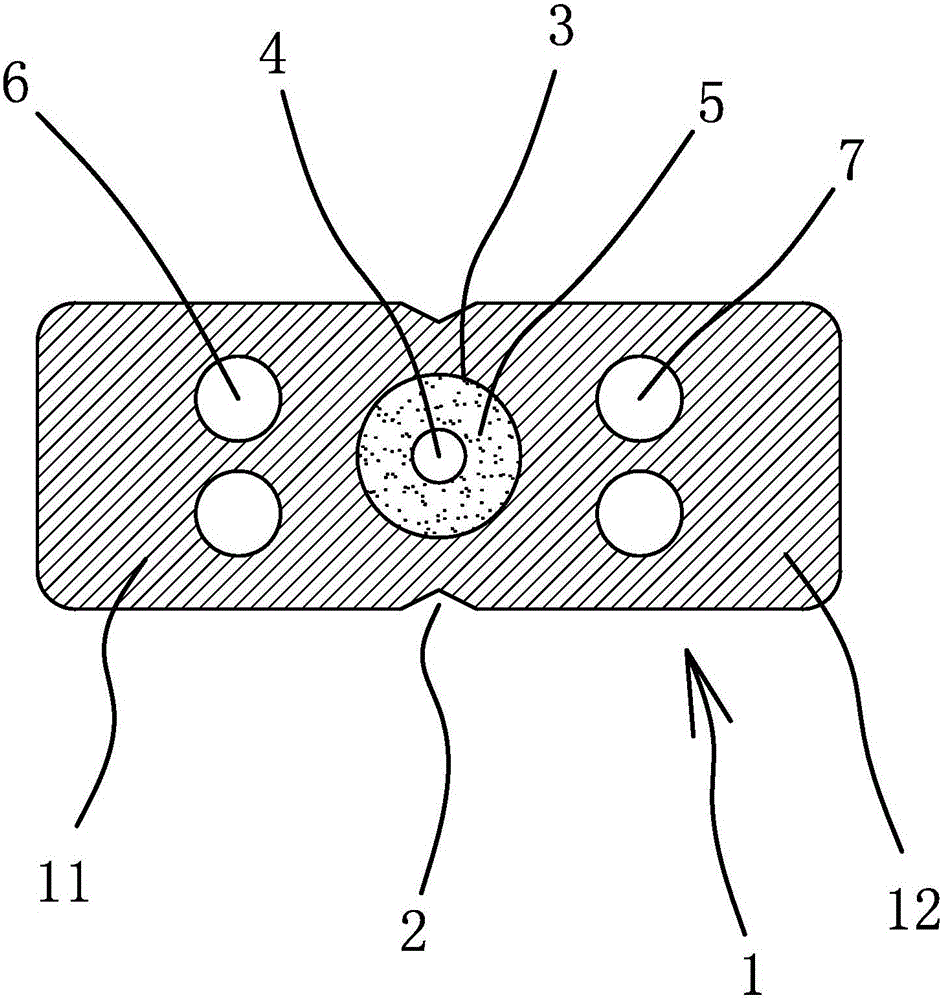

[0018] Such as figure 1 As shown, the arc-resistant non-metallic lead-in optical cable includes a sheath 1 with a rectangular cross section. The sheath 1 is injection-molded from a low-smoke, flame-retardant, halogen-free polyolefin material. The four corners of the sheath 1 are curved. The center of the upper and lower surfaces of the sheath 1 is provided with a V-shaped tearing groove 2, the center of the sheath 1 is provided with a loose tube 3, and the center of the loose tube 3 is provided with an optical fiber 4. Grease 5 is filled between the outer wall and the inner wall of the loose tube 3 .

[0019] The one on the left side of the tear groove 2 is the left sheath 11 , and the one on the right side of the tear gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com