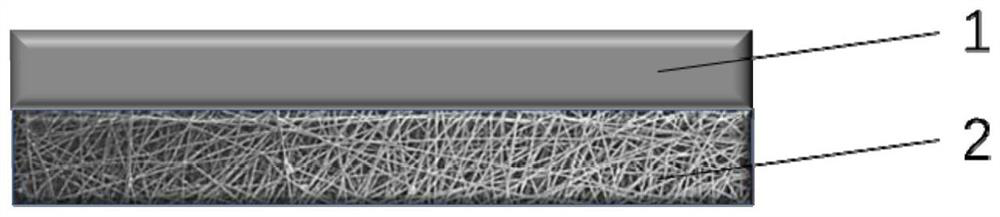

Metal evaporation composite nanocellulose membrane current collector and preparation method thereof

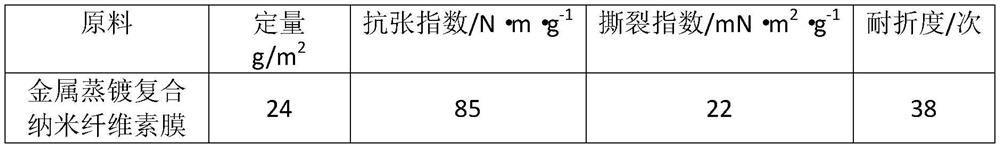

A technology of nanocellulose and nanofiber membranes, applied in vacuum evaporation plating, metal material coating process, sputtering plating, etc. Battery energy density and other issues, to achieve the effect of easy control of coating thickness, reduce the difficulty of evaporation, improve tensile performance and tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

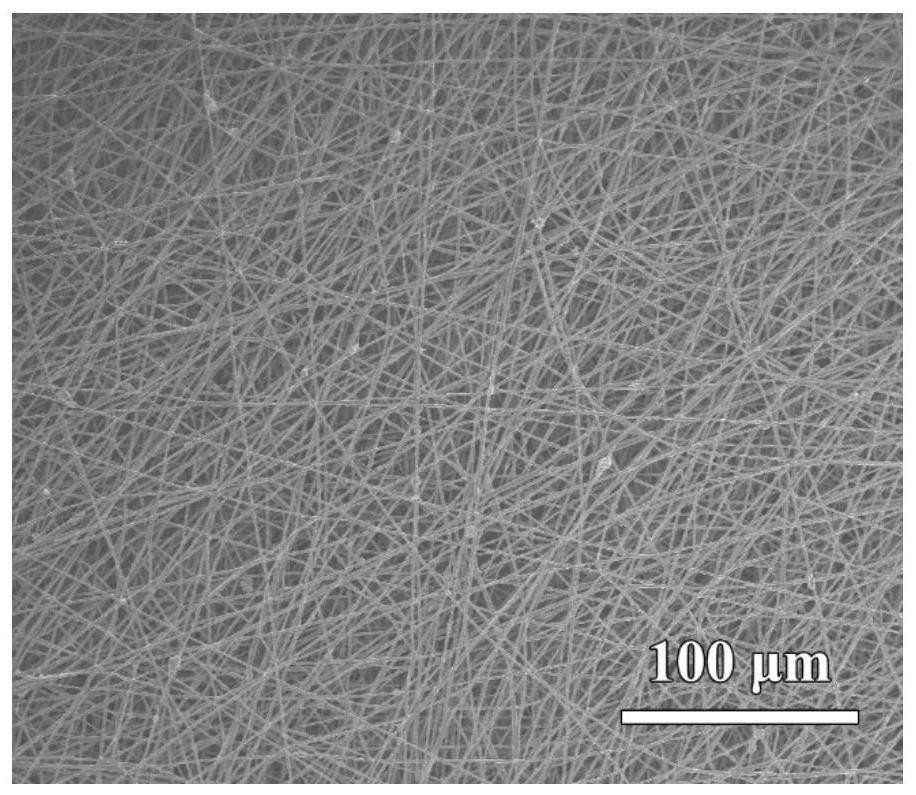

[0032] The nanocellulose membrane is prepared by the following steps:

[0033] (1) 20g microcrystalline cellulose is mixed with 300ml 64wt% sulfuric acid solution, and stirred at room temperature for 1h;

[0034] (2) add deionized water and dilute to 2wt%;

[0035] (3) Vacuum suction filtration, repeated washing until the pH value is neutral, and vacuum drying for about 10 minutes. The filter membrane used has a pore size of 0.5 μm to prepare a nanocellulose film of 8 μm.

[0036] After the nanocellulose membrane is prepared, the metal evaporation composite nanocellulose membrane current collector is prepared according to the following steps:

[0037] (1) nanocellulose membrane is placed on the fixed equipment;

[0038] (2) Vacuum the equipment to 8.0×10 -4 mba, then warm up the device;

[0039] (3) In the vacuum environment, the copper film material is pre-melted at a wire feeding speed of 250mm / min,

[0040] (4) After the pre-melting is completed, the copper target is e...

Embodiment 2

[0045] The nanocellulose membrane is prepared by the following steps:

[0046] (1) 20g microcrystalline cellulose was mixed with 300ml 55wt% sulfuric acid solution, and stirred at room temperature for 45min;

[0047] (2) add deionized water and dilute to 1.8wt%;

[0048] (3) Vacuum suction filtration, repeated washing until the pH value is neutral, and vacuum drying for 15 minutes. The filter membrane used has a pore size of 2 μm to prepare a 10 μm nanocellulose film.

[0049] After the nanocellulose membrane is prepared, the metal evaporation composite nanocellulose membrane current collector is prepared according to the following steps:

[0050] (1) nanocellulose membrane is placed on the fixed equipment;

[0051] (2) Vacuum the equipment to 1.0×10 -3 mba, then warm up the device;

[0052] (3) In the vacuum environment, the copper film material is pre-melted at a wire feeding speed of 200mm / min,

[0053] (4) After the pre-melting is completed, the copper target is evapo...

Embodiment 3

[0058] The nanocellulose membrane is prepared by the following steps:

[0059] (1) 20g microcrystalline cellulose was mixed with 300ml 65wt% sulfuric acid solution, and stirred at room temperature for 60min;

[0060] (2) add deionized water and dilute to 2wt%;

[0061] (3) Vacuum suction filtration, repeated washing until the pH value is neutral, and vacuum drying for 15 minutes. The filter membrane used has a pore size of 5 μm to prepare a 10 μm nanocellulose film.

[0062] After the nanocellulose membrane is prepared, the metal evaporation composite nanocellulose membrane current collector is prepared according to the following steps:

[0063] (1) nanocellulose membrane is placed on the fixed equipment;

[0064] (2) Vacuum the equipment to 8.0×10 -4 mba, then warm up the device;

[0065] (3) In the vacuum environment, the copper film material is pre-melted at a wire feeding speed of 180mm / min,

[0066] (4) After the pre-melting is completed, the copper target is evaporate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com