Gelatin-based papermaking sizing agent based on hydrogen-bond interaction and preparation method thereof

A technology of hydrogen bonding and sizing agent, applied in papermaking, textiles, papermaking, paper coating, etc., can solve the problems of low physical and mechanical properties, poor water resistance, high cost, etc., to reduce entanglement, improve gel condition, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

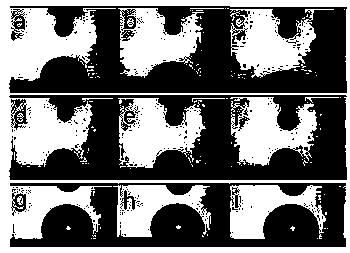

Image

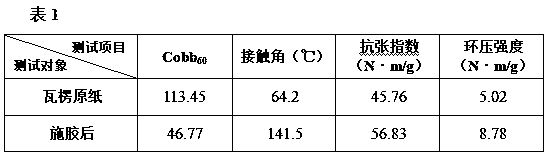

Examples

Embodiment 1

[0026] 1) Weigh 5g of gelatin into a beaker, add 20mL of deionized water, let it stand for 30 minutes, wait for it to swell fully, put it in a constant temperature water bath: adjust the temperature to 40°C, stir until it is completely dissolved to obtain a gelatin solution;

[0027] 2) Pour the gelatin solution obtained in step 1) into a 50mL silk bottle, add 2g of methacrylic acid monomer and an initiator of 0.1% of the monomer mass, and place it in a UV reaction box for 60min to obtain methacrylic acid modified gelatin emulsion;

[0028] 3) Add 3% sodium lauryl sulfate, 0.1g sodium bicarbonate, and 20mL distilled water into a 250mL three-neck flask, stirring at a speed of 250r / min to dissolve. When heating to 60°C, add a solution of 3% potassium persulfate and 5mL distilled water and 1g of polymerized monomer, and heat up to 80°C for reaction. After the reaction liquid shows obvious exotherm, control the reaction temperature at 80°C, slowly add 9g of polymerized monomer dr...

Embodiment 2

[0031] 1) Weigh 5g of gelatin into a beaker, add 20mL of deionized water, let it stand for 30 minutes, wait for it to swell fully, put it in a constant temperature water bath: adjust the temperature to 45°C, and stir until it is completely dissolved to obtain a gelatin solution;

[0032] 2) Pour the gelatin solution obtained in step 1) into a 50mL silk bottle, add 2g of acrylamide monomer and an initiator of 0.1% of the monomer mass, and place it in a UV reaction box for 60min to obtain an acrylamide-modified gelatin emulsion ;

[0033] 3) Add 3% sodium lauryl sulfate, 0.1g sodium bicarbonate, and 20mL distilled water into a 250mL three-neck flask, stirring at a speed of 250r / min to dissolve. When heating to 60°C, add a solution of 3% potassium persulfate and 5mL distilled water and 1g of polymerized monomer, and heat up to 80°C for reaction. After the reaction liquid shows obvious exotherm, control the reaction temperature at 80°C, slowly add 9g of polymerized monomer dropwi...

Embodiment 3

[0036] 1) Weigh 5g of gelatin into a beaker, add 20mL of deionized water, let it stand for 30 minutes, wait for it to swell fully, put it in a constant temperature water bath: adjust the temperature to 45°C, and stir until it is completely dissolved to obtain a gelatin solution;

[0037] 2) Pour the gelatin solution obtained in step 1) into a 50mL silk bottle, add 2g of methacrylic acid monomer and an initiator of 0.1% of the monomer mass, and place it in a UV reaction box for 45min to obtain methacrylic acid modified gelatin emulsion;

[0038] 3) Add 3% sodium lauryl sulfate, 0.1g sodium bicarbonate, and 20mL distilled water into a 250mL three-neck flask, stirring at a speed of 250r / min to dissolve. When heating to 60°C, add a solution of 3% potassium persulfate and 5mL distilled water and 1g of polymerized monomer, and heat up to 80°C for reaction. After the reaction liquid shows obvious exotherm, control the reaction temperature at 80°C, slowly add 9g of polymerized monome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com