Thermoplastic rubber particles and preparation method thereof

A thermoplastic rubber and particle technology, used in the field of cable materials, can solve the problems of high use cost, high density, and plastic materials that do not have environmental protection effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0014] According to the recipe listed in Table 1, the preparation steps were used:

[0015] S1. Ingredients: mix TPS-SEBS, white oil, dibutyl ester, calcium powder, stabilizer, and antioxidant according to the corresponding parts;

[0016] S2. Premixing: put the above-mentioned raw materials with configured parts into the ribbon mixer for premixing;

[0017] S3. Pelletizing: put the above-mentioned premixed raw materials into a twin-screw extruder for extruding and hot-cutting into pellets.

[0018] The prepared samples were tested for performance, and the results are shown in Table 1

[0019] Table 1

[0020]

[0021] As can be seen from the results of the examples in Table 1, appropriately increasing the TPS-SEBS content helps to improve the performance of thermoplastic rubber particles, and can reduce the compression set of thermoplastic rubber particles, but with the continuous increase of TPS-SEBS, The compression set performance of thermoplastic rubber particles re...

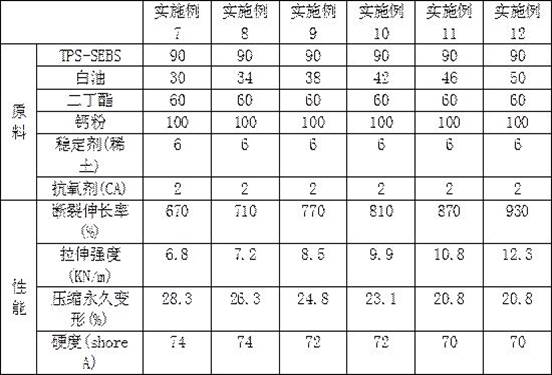

Embodiment 7-12

[0023] According to the formula listed in Table 2, use the same preparation steps as in Example 1-6

[0024] The prepared samples were tested for performance, and the results are shown in Table 2

[0025] Table 2

[0026]

[0027] As can be seen from the results of the examples in Table 2, properly increasing the white oil content helps to improve the performance of thermoplastic rubber particles, and can reduce the compression set of thermoplastic rubber particles, but with the continuous increase of white oil, thermoplastic rubber The compression set performance of the particles remains basically unchanged, but the processing performance gradually deteriorates, and the processing cost gradually increases. Therefore, the white oil content should not be too high.

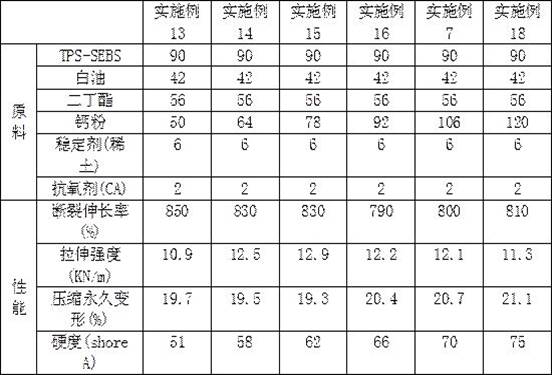

Embodiment 12-18

[0029] According to the formula listed in table 3, use the same preparation steps as in Example 1-6

[0030] The prepared samples were tested for performance, and the results are shown in Table 3

[0031] table 3

[0032]

[0033] From the results of the examples in Table 3, it can be seen that appropriately increasing the white oil content helps to improve the performance of thermoplastic rubber particles, and can reduce the compression set of thermoplastic rubber particles, but with the continuous increase of white oil, thermoplastic rubber The compression set performance of the particles begins to rebound, and the hardness also begins to rebound, so that the processing performance gradually deteriorates, and the processing cost gradually increases. Therefore, the white oil content should not be too high or too low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com