Preparation method of covalent organic framework/carbon nitride composite material and application thereof

A technology of covalent organic framework and composite material, which is applied in the field of preparation of covalent organic framework/carbon nitride composite material, can solve the problems of complicated preparation process of covalent organic framework material, incapability of large-scale production, harsh experimental conditions and the like, Achieve the effects of excellent electron transfer ability, short synthesis time and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of covalent organic framework / carbon nitride composites

[0032] The preparation method of the covalent organic framework / carbon nitride composite material in this example is as follows:

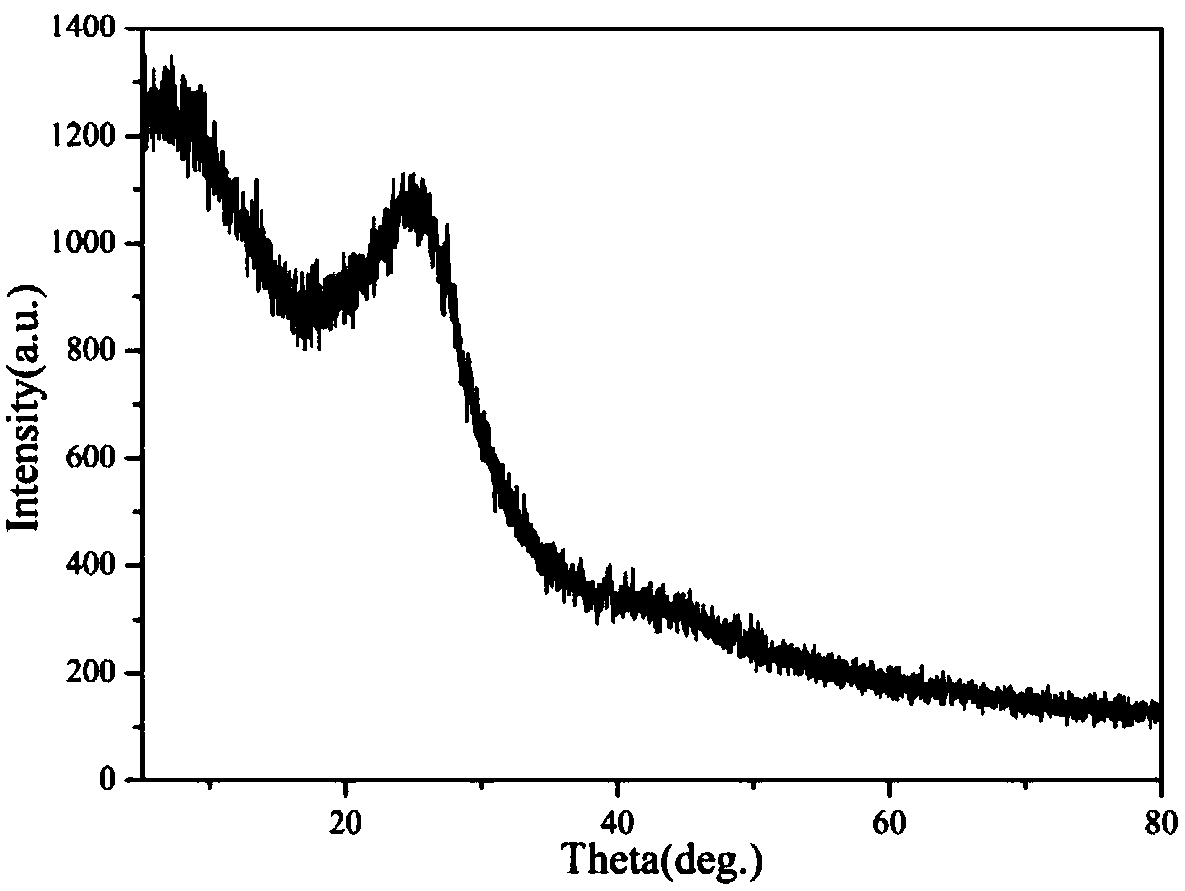

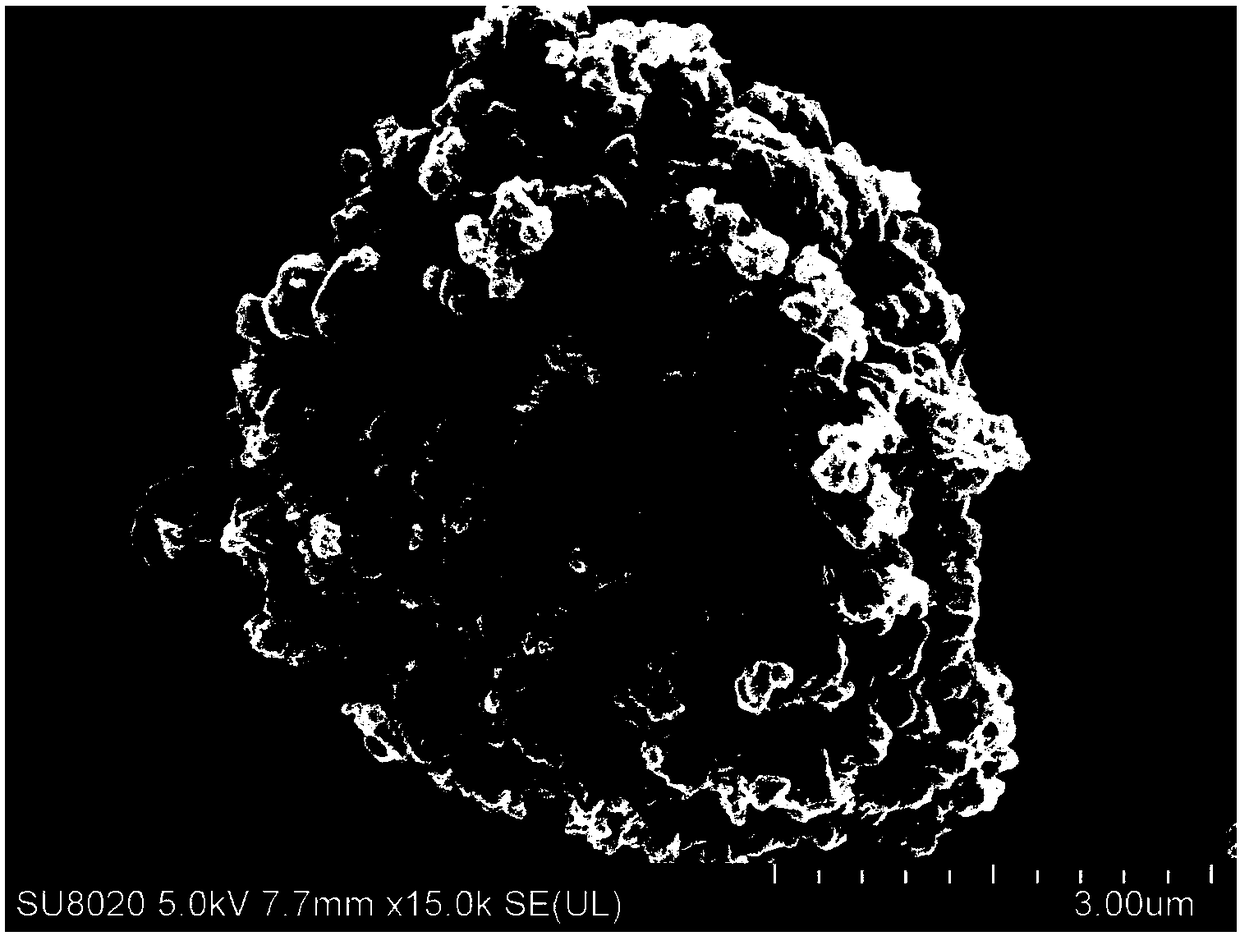

[0033] 1. Calcining urea at 550°C to obtain carbon nitride powder;

[0034] 2. Mix p-phenylenediamine and triformylphloroglucinol in a molar ratio of 2:3 and stir for 45 minutes. During the stirring process, add a mixture of 1,3,5-trimethylbenzene, dioxane and acetic acid. Collect the red powder with methanol, centrifuge and wash with dichloromethane, dry and calcinate at 180°C for 24 hours under the protection of high-purity nitrogen or argon to obtain a covalent organic framework material as a dark red product;

[0035]In step 2, the volume ratio of 1,3,5-trimethylbenzene, dioxane and acetic acid in the mixture of 1,3,5-trimethylbenzene, dioxane and acetic acid is 1:1:0.01.

[0036] 3. Disperse 150 mg of the carbon nitride powder obtained in step 1 and 50 mg of the...

Embodiment 2

[0042] (1) Preparation of covalent organic framework / carbon nitride composites

[0043] The preparation method of the covalent organic framework / carbon nitride composite material in this example is the same as that in Example 1.

[0044] (2) Degradation of toxic organic pollutants

[0045] Prepare 20mg / L methylene blue solution to simulate toxic organic wastewater (V=100mL), add 20mg oxidant permonomonosulfate (PMS) and 10mg covalent organic framework / carbon nitride composite material prepared in this embodiment at the same time, at 25 It reacts at ℃ for 90 minutes. After testing, the removal rate of toxic organic pollutants is as high as 100%.

Embodiment 3

[0047] (1) Preparation of covalent organic framework / carbon nitride composites

[0048] The preparation method of the covalent organic framework / carbon nitride composite material in this example is the same as that in Example 1.

[0049] (2) Degradation of toxic organic pollutants

[0050] Prepare 20mg / L methyl violet solution to simulate toxic organic wastewater (V=100mL), and add 20mg oxidant permonomonosulfate (PMS) and 10mg covalent organic framework / carbon nitride composite material prepared in this example at the same time, After reacting at 25°C for 90 minutes, the removal rate of toxic organic pollutants is as high as 97.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com