Low-cost modified amino-sulfonic acid-based high-efficiency water reducer and preparation method thereof

A sulfamic acid-based, high-efficiency water-reducing agent technology is applied in the field of building materials to achieve the effects of wide range of raw materials, good application prospects and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Add 990 kg of water to the reaction kettle and heat it to 65-70°C, add 375 kg of crude p-aminobenzenesulfonic acid, 313 kg of refined bisphenol A waste phenol residue and 100 kg of caustic soda, and heat up to 85-90°C while stirring ; Add 584 kg of formaldehyde dropwise, finish dropping within 20-30 minutes, and keep the temperature between 90°C-95°C, keep warm for 4 hours; then add 605 kg of remaining grass pulp black liquor and 33 kg of caustic soda, Keep warm at ~90°C for 3 hours; cool to room temperature to prepare liquid product.

Embodiment 2

[0046] Add 1010 kg of water to the reaction kettle and heat it to 65-70°C, add 370 kg of crude p-aminobenzenesulfonic acid, 330 kg of refinery waste phenol residue and 100 kg of caustic soda, and heat up to 85-90°C while stirring; Add 598 kg of formaldehyde, drop it in 20-30 minutes, keep the temperature between 90-95°C, and keep warm for 3 hours; then add 552 kg of remaining grass pulp black liquor, 30 kg of caustic soda and 10 kg of calcium hydroxide, Keep the temperature between 85° C. and 90° C. for 3 hours; cool to room temperature, and then prepare the liquid product.

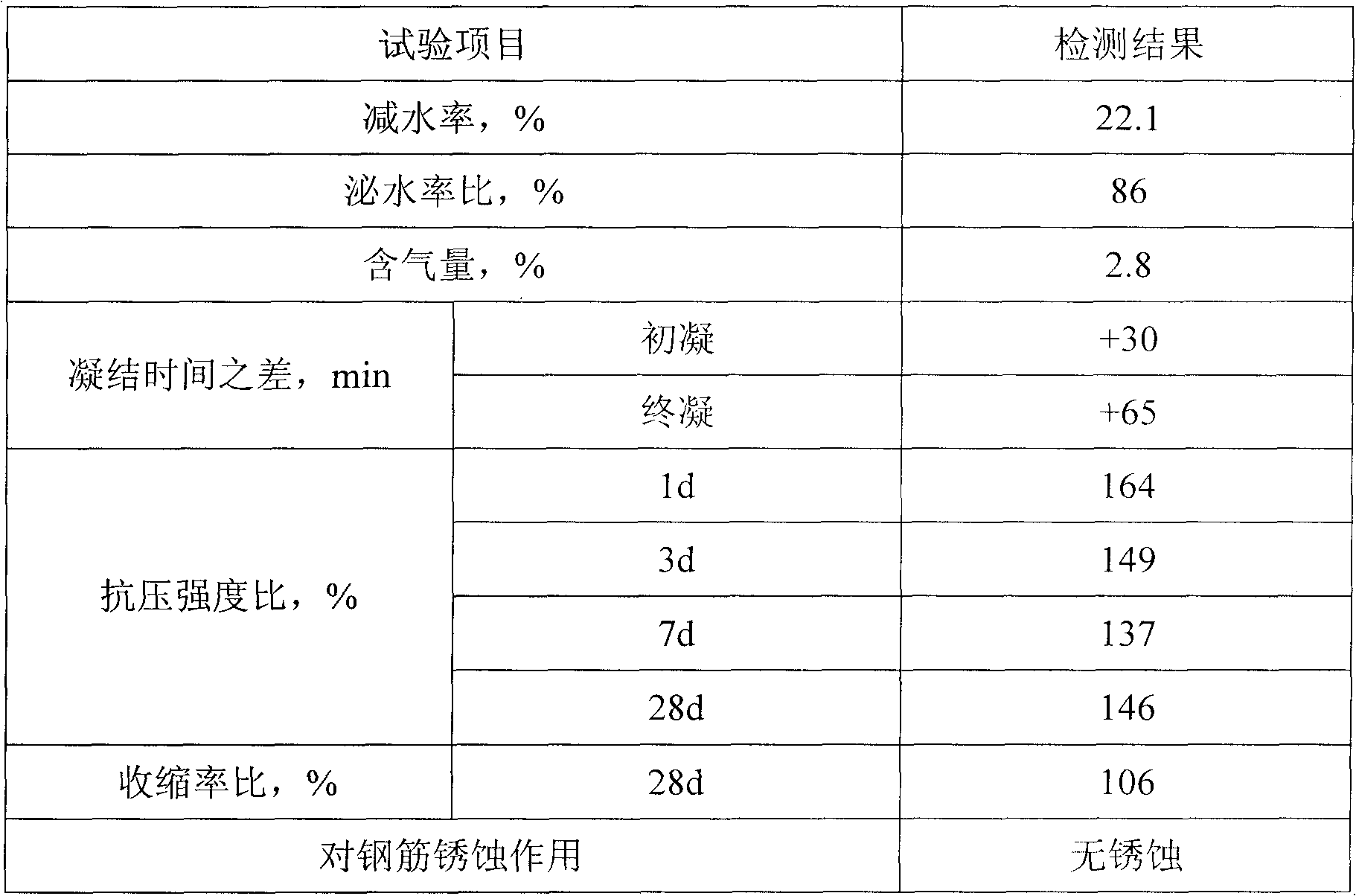

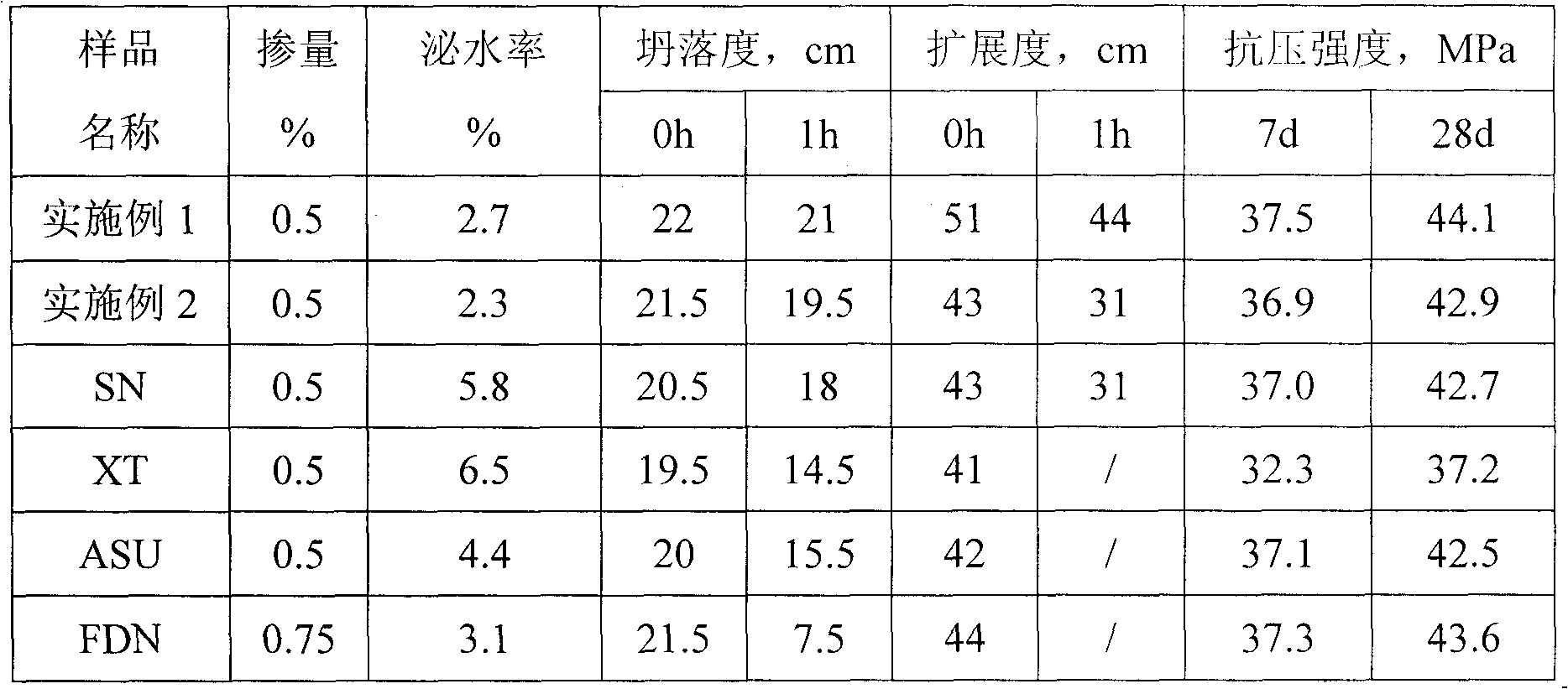

[0047] The following is the performance situation of the present invention and its performance comparison with similar products:

[0048] Main raw materials, concrete mix ratio and test method Raw materials:

[0049] Cement: Jinning Yang P·II42.5 cement produced by Jiangnan Cement Plant

[0050] Sand: medium sand with a fineness modulus of 2.6.

[0051] Stone: basalt produced in Jiangning, Nanjing, cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com