Preparation method of polycarboxylic acid high-performance cement water reducing agent

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of cement water reducing agent preparation, to achieve high water reducing rate, increase strength, and improve market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

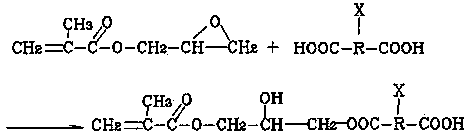

Method used

Image

Examples

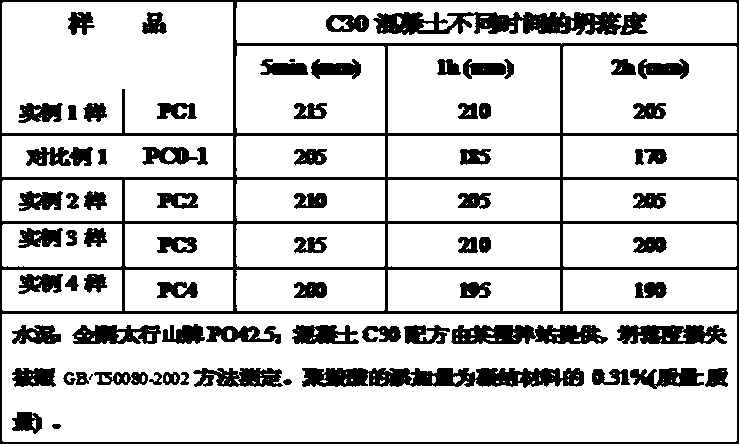

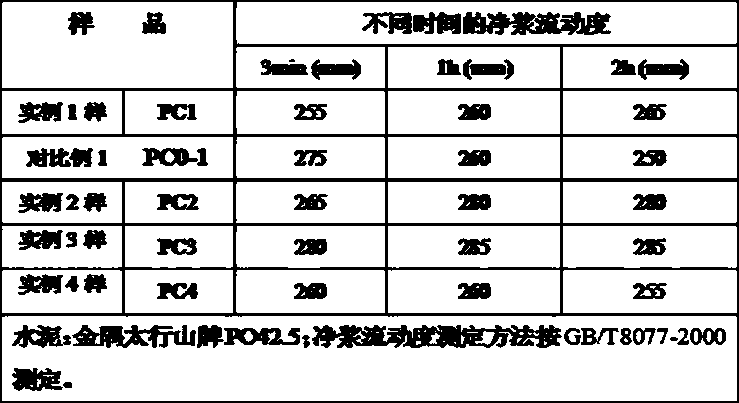

Embodiment 1

[0019] Glycidyl methacrylate and anhydrous citric acid have a molar ratio of 1.0:1.05 (mol:mol), add an appropriate amount of polymerization inhibitor and ring-opening esterification catalyst, the reaction temperature is 90~110°C, react for 2 hours, and cool down to Below 40°C, the reaction product is made into an aqueous solution with a concentration of 40% (weight) for the next polymerization reaction, and the molar concentration of the reaction product is calculated based on glycidyl methacrylate. The reactant (40% (weight) aqueous solution) of methallyl polyglycol ether (molecular weight 2400), acrylic acid, glycidyl methacrylate prepared above and anhydrous citric acid is molar The ratio is 1.0:3.0:1.5, and then mixed with the calculated amount of deionized water to obtain the mixed monomer for the drop reaction; the solid content of the polycarboxylic acid (the weight concentration of the contained solid) is based on 40% ( weight) design, the polymerization reaction is b...

Embodiment 2

[0023]Glycidyl methacrylate and anhydrous tartaric acid have a molar ratio of 1.0:1.3 (mol:mol), add an appropriate amount of polymerization inhibitor and ring-opening esterification catalyst, the reaction temperature is 85~100°C, react for 3 hours, and cool down to 40°C Below ℃, the reaction product is made into an aqueous solution with a concentration of 40% (weight) for the next polymerization reaction, and the molar concentration of the reaction product is calculated based on glycidyl methacrylate. Three monomers of methallyl polyglycol ether (molecular weight 2400), methacrylic acid, the reaction product of glycidyl methacrylate prepared above and anhydrous tartaric acid (aqueous solution with a concentration of 40% (by weight)) Mix according to the molar ratio of 1.0:3.5:0.75, and then add the calculated amount of deionized water to obtain the mixed monomer for the drop reaction; the solid content of polycarboxylic acid (the weight concentration of the contained solid) is...

Embodiment 3

[0025] The molar ratio of glycidyl methacrylate to malonic acid is 1.0:1.1 (mol:mol), the reaction temperature is 105~110°C, the reaction is 2h, the temperature is lowered to below 40°C, and the concentration of the reaction product is 40% (weight). The aqueous solution is used for the polymerization reaction of the next step, and the molar concentration calculation of the reaction product is based on glycidyl methacrylate. The reaction product of methoxy-terminated methallyl polyglycol ether (molecular weight 2400), acrylic acid, glycidyl methacrylate prepared above and malonic acid (the reaction product has a concentration of 40% (by weight) Aqueous solution) three kinds of monomers are mixed according to molar ratio 1:3.7:0.5, then add the calculated amount of deionized water to obtain the mixed monomers for drop reaction; the solid content of polycarboxylic acid is 40% (weight ) design, the polymerization reaction is based on deionized water, the polymerization temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com