Preparation method and application of solvent-type hydrophobic and oleophobic fluoroalkyl silicone resin

The technology of fluorocarbon-based silicone resin and fluorocarbon-based halosilane is applied in the preparation field of solvent-based hydrophobic and oleophobic fluorocarbon-based silicone resin, which can solve the problems of complicated steps and the like, and achieve the effect of good antifouling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

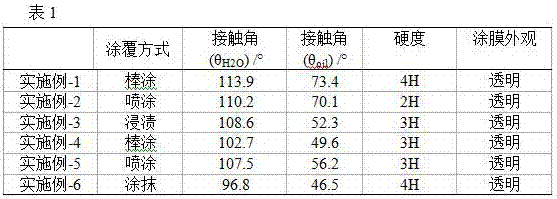

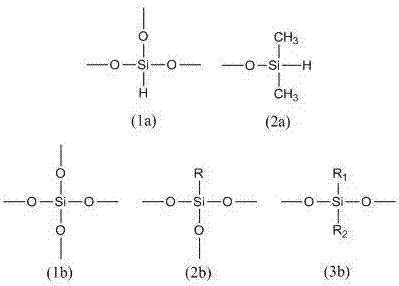

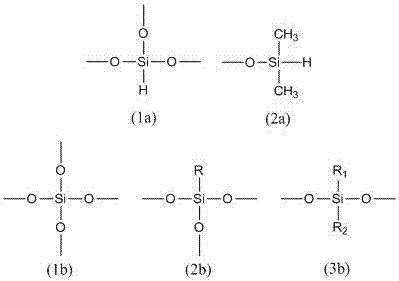

[0028] In a 100mL three-necked flask equipped with a reflux condenser, a thermometer, and a stirrer, add 10g (containing Si-H bond 0.09mol) in sequence (1a), (2a), (1b), (3b), R 1 =R 2 =-CH 3, Si-H content of 0.9mmol / g, methyl hydrogen-containing silicone resin (HSR-1) with a viscosity of 143mPa.s, 32.1g (0.072mol) heptadecafluoro-1-decene (R f17 V), 0.051g (0.00045mol) allyl glycidyl ether (AGE), 4.28g (0.0225mol) vinyltriethoxysilane (VTES), Si-H:R in HSR-1 f17 V:AGE:VTES molar ratio is 1:0.8:0.005:0.25, stir and mix to obtain mixture A; then, mix A with 23.2g (accounting for 50% of the mass of A) co-solvent trifluoroethanol and heat to 80 °C, then add 500ppm complex platinum catalyst KP22 and carry out the hydrosilylation addition reaction at 80°C for 10 hours; after the reaction is over, recover the co-solvent under normal pressure at 85°C, and then decompress and remove the low boiling point for 10min under the condition of 50mmHg , to obtain a total amount of about 46...

Embodiment 2

[0031] In a 100mL three-necked flask equipped with a reflux condenser, a thermometer, and a stirrer, add 20g (containing Si-H bond 0.02mol) in sequence (2a), (2b), (3b), R=-C 12 h 25 , R 1 =R 2 =-CH 3 , Si-H content of 0.1mmol / g, viscosity of 2000mPa.s dodecyl methyl hydrogen-containing silicone resin, 2.77g (0.008mol) tridecafluoro-1-octene (R f13 V), 0.51g (0.004mol) glycidyl acrylate (GA), 0.74g (0.005mol) vinyltrimethoxysilane (VTMS), Si-H in HSR-2: R f13 V: GA: VTMS molar ratio is 1: 0.4: 0.2: 0.25, stir and mix to obtain mixture A; then, A is heated to 80°C, then 250ppm complex platinum catalyst KP23 is added and the temperature is controlled at 100°C for silicon The hydrogenation addition reaction was 2 hours; the reaction was completed, and the low boiling was removed under reduced pressure at 100°C and 260mmHg for 5 minutes to obtain a total amount of about 24.02g tridecafluorooctyl / trimethoxysilyl ethyl co-modified silicone resin (FR- 2) Intermediates.

[0032]...

Embodiment 3

[0034] In a 100mL three-necked flask equipped with a reflux condenser, thermometer, and stirrer, add 12.0g (containing Si-H bond 0.036mol) in sequence (1a), (2a), (2b), (3b), R=-CH 3 , R 1 =R 2 =-ph, Si-H content of 0.3%, viscosity of 1200mPa.s methyl phenyl hydrogen-containing silicone resin (HSR-3, Jiangxi Lvtai Technology Co., Ltd.), 10.08g (0.0252mol) dodecyl methacrylate Fluoroheptyl ester (DFMA), 0.76g (0.0053mol) glycidyl methacrylate (GMA), 0.44g (0.0018mol) 3-(methacryloyloxy)propyltrimethoxysilane (KH-570), Si-H: DFMA: GMA: KH-570 molar ratio in HSR-3 is 1: 0.7: 0.15: 0.05, stir and mix well to obtain mixture A; then, heat A to 80°C, and then add 100ppm platinum catalyst KP22 And the temperature was controlled at 90°C to carry out the hydrosilylation addition reaction for 4 hours; after the reaction was completed, under the condition of 210mmHg, the low boiling was removed for 7 minutes, and the total amount was about 23.28g of dodecafluoroheptoxyacylpropyl / trimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com