Preparation method of marine microorganism antifouling coating

A technology of marine microorganisms and antifouling coatings, applied in biochemical equipment and methods, antifouling/underwater coatings, microorganisms, etc., can solve problems such as genetic variation of marine organisms, death of seaweed and other organisms, and destruction of ecological balance, and achieve production Low cost, good anti-fouling effect, no environmental pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

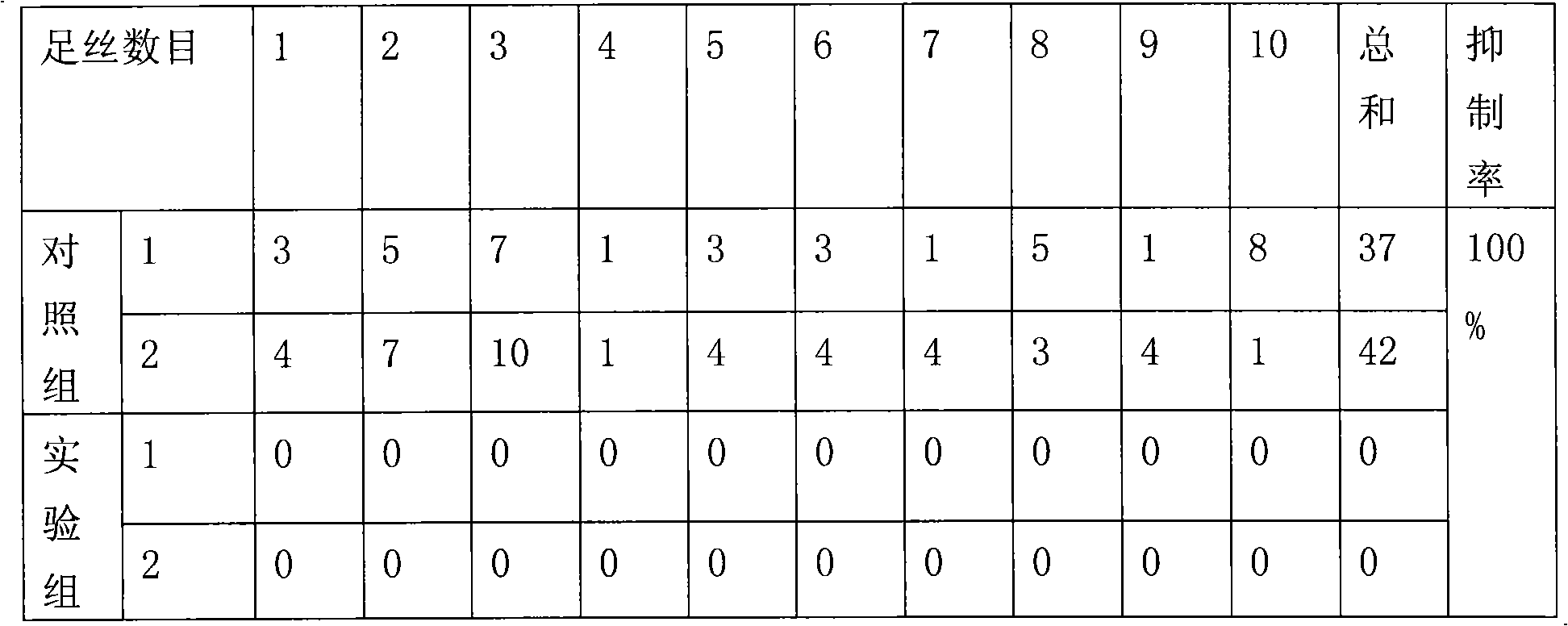

Examples

Embodiment 1

[0011] Embodiment 1: the preparation of antifouling microorganism

[0012] Pick a loop of the preserved antifouling microbial strains with an inoculation needle and inoculate them into the seed medium (3g of beef extract, 10g of peptone, 5g of sodium chloride, 1L of seawater, pH 7.0-7.2), and after 24 hours of cultivation, press Inoculate 5% of the inoculum into a 250ml Erlenmeyer flask containing 100ml of fermentation medium, incubate at 150 rpm at 20°C for 48 hours; filter the fermentation broth with gauze; filter the mother liquor and centrifuge at 8000rpm / min for 30 minutes, and the sediment is antifouling microorganism.

Embodiment 2

[0013] Embodiment 2: the preparation of antifouling protease

[0014] Centrifuge the anti-fouling microbial fermentation broth prepared in Example 1 at a speed of 6000rpm for 15 minutes, take the supernatant and use ammonium sulfate with a saturation of 60% to carry out salting out, and after standing overnight, 8000rpm / min for 30 minutes After centrifugation, the precipitate was collected and then chromatographed on a sephadex G-75 chromatographic column. After the same components were collected, they were freeze-dried. The samples were subjected to SDS-polyacrylamide gel electrophoresis, and the molecular weight of the antifouling protease was about 65Kd.

Embodiment 3

[0015] Embodiment 3: the preparation of microbial antifouling paint

[0016] Weigh the antifouling microorganism 3.5g among the embodiment 1, add 15g rosin and add 1.2g bentonite in the xylene (40 / 100, W / W) solution of 80g chlorinated rubber, after stirring 10 minutes with electric stirrer, Add 3.5 g of filtered and centrifuged sediment (target active microorganism) and stir evenly to obtain microbial antifouling coating; apply the above-mentioned prepared coating on A3 steel, hang the board in sea area for 40 days after the coating is completely dry , no marine organisms were found on the surface of the hanging board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com