Device for automatic cleaning of hard scale in heat exchange tubes

A technology for automatic cleaning and heat exchange tubes, applied in the direction of cleaning heat transfer devices, cleaning of rotating equipment, lighting and heating equipment, etc., can solve the problems of loss of hard scale cleaning ability, poor cleaning uniformity, and excessive residual dirt, and achieve a simple structure. , the effect of high uniformity and low fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

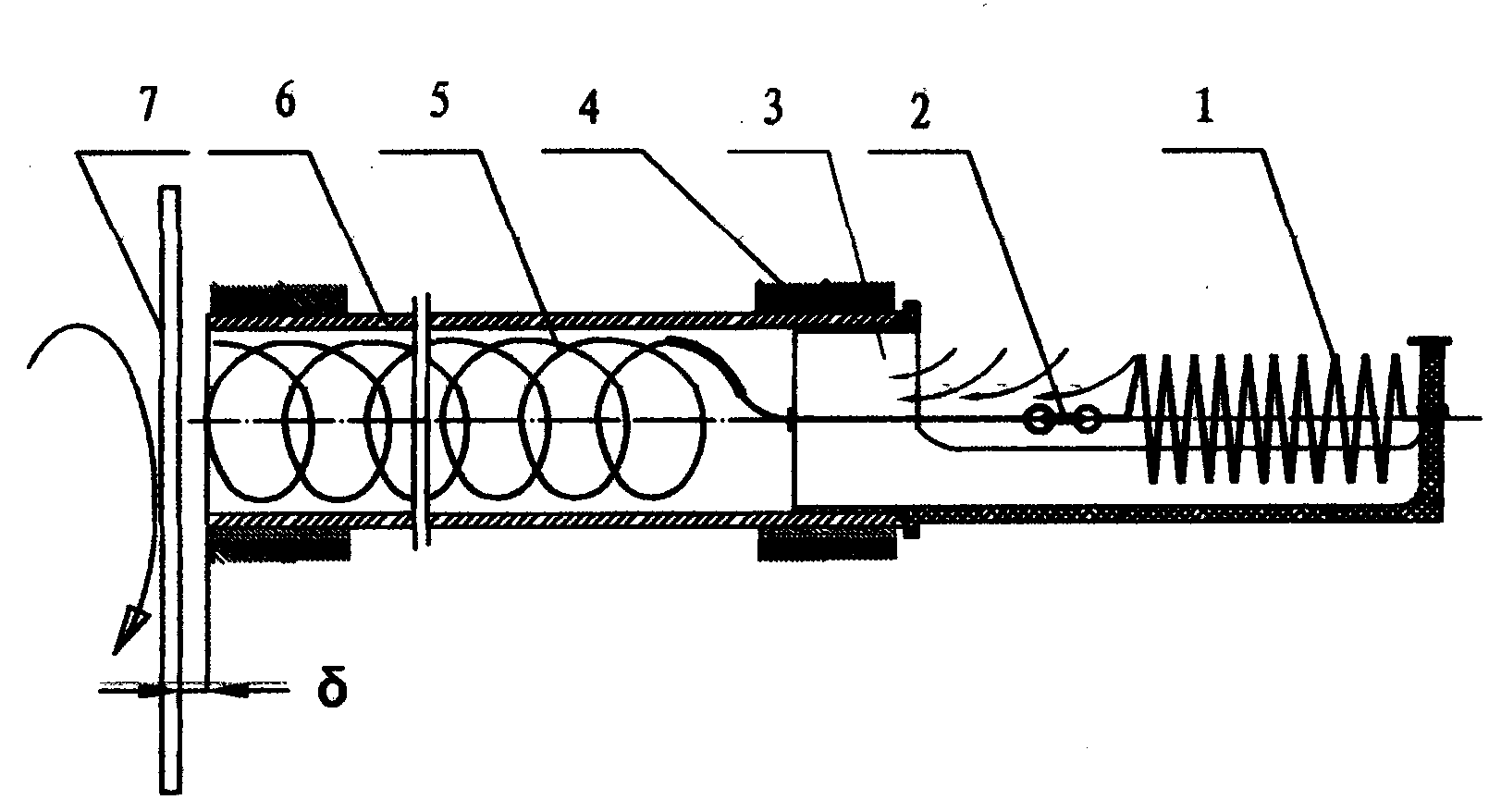

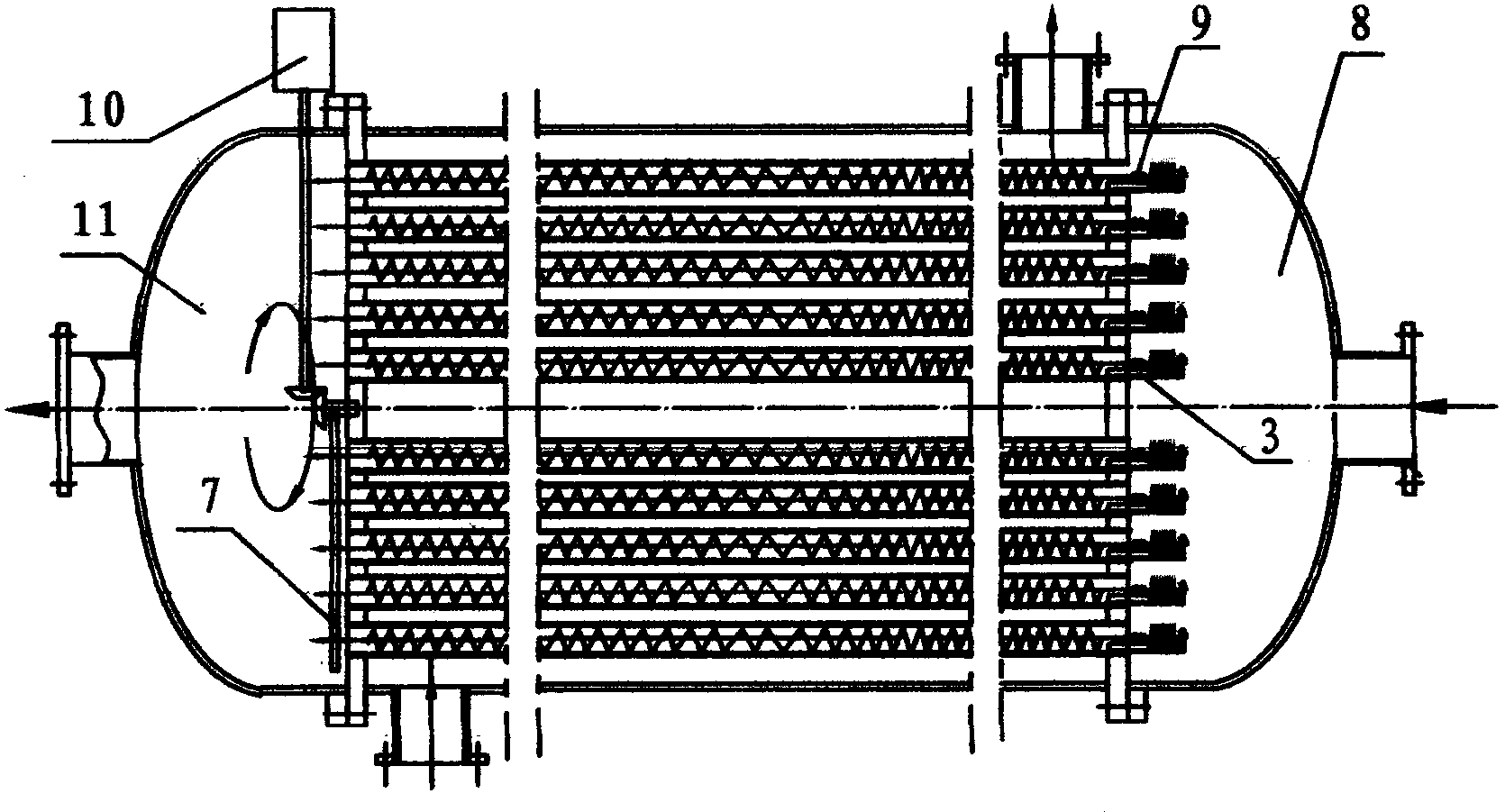

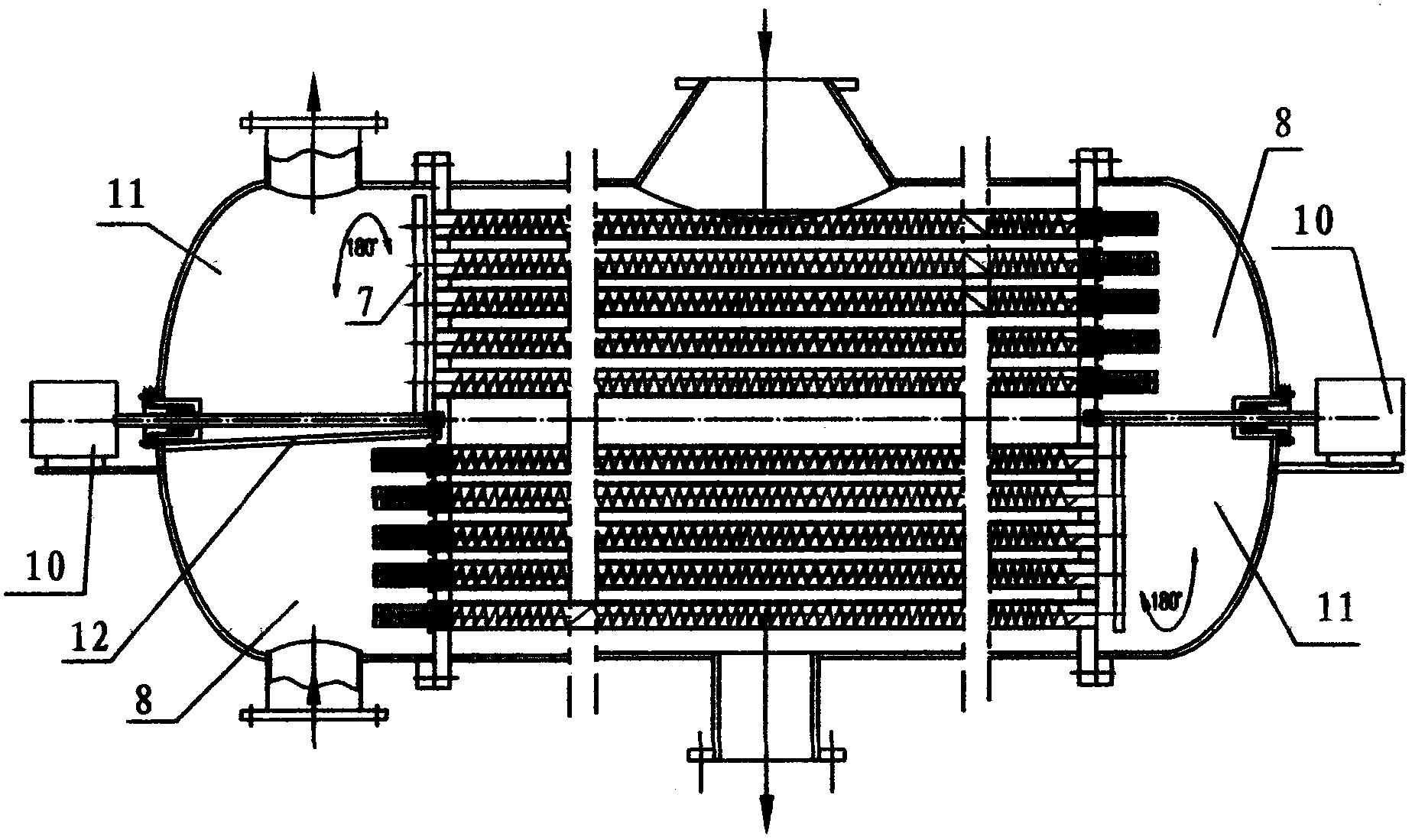

[0013] Attached below figure 1 , figure 2 , image 3 , the present invention is described in further detail.

[0014] In the figure: 1 parallel tight soft spring 2 plastic connecting ring 3 fixed frame 4 tube plate 5 steel wire cleaning spiral 6 heat exchange tube 7 baffle 8 inlet tube box 9 hook head 10 external power head 11 outlet tube box 12 tube side partition 13 fixed orifice plate 14 power vane

[0015] An automatic cleaning device for hard dirt in heat exchange tubes, the main components of which include parallel springs 1, steel wire cleaning spirals 5, heat exchange tubes 6, baffles 7, tube plates 4, inlet tube boxes 8, and outlet tube boxes 11. In the inlet pipe box 8 of the heat transfer equipment (evaporator, condenser, crystallizer, heat exchanger), the tight and soft spring 1 is installed on the inlet fixed frame 3 or the fixed orifice plate 13 . A steel wire cleaning spiral 5 is designed inside each heat exchange tube 6 . After the steel wire cleaning spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com