High Quality Calcium Hydroxide Slurries

a high-quality, stable technology, applied in water softening, water/sludge/sewage treatment, chemistry apparatus and processes, etc., can solve the problems of serious chemical burns, dangerous handling, and indefinite stability of magnesium hydroxide, and achieves anti-scaling properties, easy redisperation, and resistance to hard packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

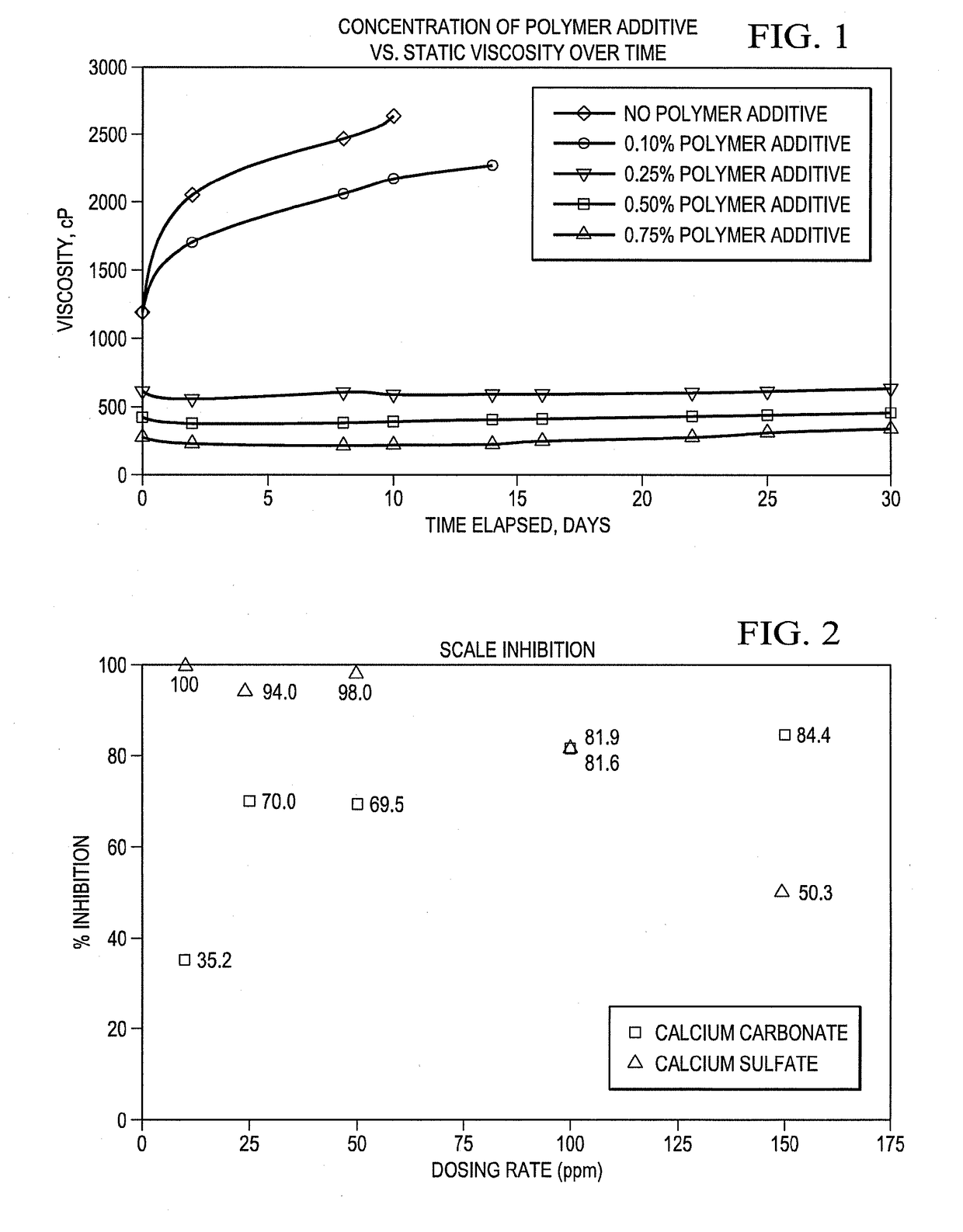

[0021]As described in the Background portion of the application, fluid calcium hydroxide slurries prepared in a conventional manner from quicklime and water, or from simple mixing of calcium hydroxide with water, will increase in viscosity over time, will settle and can be difficult to redisperse after storage or transport. Additionally calcium hydroxide slurries can form scale in pipes, tanks and other storage and handling equipment.

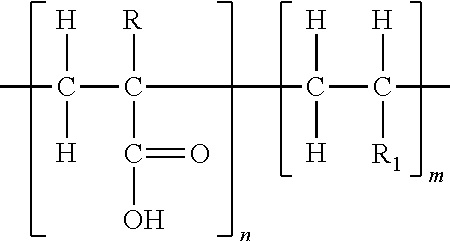

[0022]To produce the desired stable, high solids lime slurry it is necessary to provide a low viscosity so that the slurry can be easily pumped. Slurries having a viscosity of less than 2000 cps and preferably less than 1000 cps as measured at 100 RPM on a Brookfield™ or Labline™ viscometer are generally required to be usable as a replacement for caustic solutions. A pumpable lime slurry with high solids content is formulated by first adding a polymer additive to the initial slurry water and then adding the required amount of lime. Alternatively, the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com