Anti-scale method and device of filter used in ship ballast water management system

A technology of ship ballast water management system, which is applied in the anti-scaling field of filters used in ship ballast water management system, can solve problems such as filter fouling and clogging, and achieve easy clogging, high intelligence, and improved filtration efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

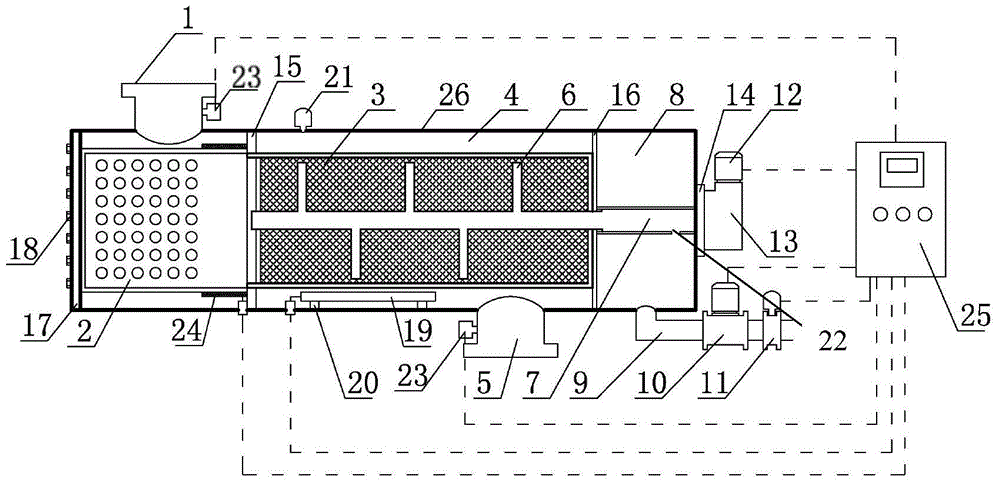

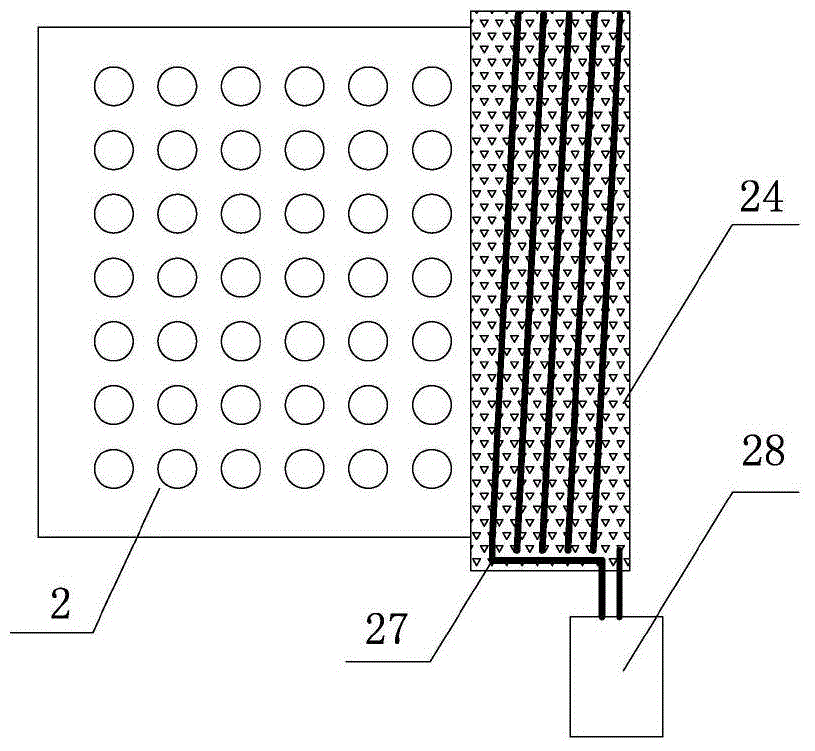

[0038] see figure 1 and figure 2, the anti-scaling technology and device of the filter used in the ship's ballast water management system of the present invention include a coarse filter screen 2, a fine filter screen 3, a backwash unit, a sewage discharge unit and a control system 25, which are installed horizontally in the filter cavity Coarse filter 2, first partition 15, fine filter 3, another partition 16, sewage unit; control unit is part of the main control equipment; first partition between fine filter 3 and coarse filter 2 15 and the filter chamber form a filter chamber 4, the water inlet 1 is installed on the filter housing 26 above the coarse filter 2 and communicates with the filter chamber, and the water outlet 5 is installed on the filter housing 26 and communicates with the filter chamber 4 ; Also includes a frequency conversion electromagnetic processing unit, the frequency conversion electromagnetic processing unit is composed of a signal generator controlle...

Embodiment 2

[0070] The method for filtering using the anti-scaling device of the filter for the ship ballast water management system of embodiment 1 of the present embodiment includes:

[0071] 1) The step of carrying out two-stage filtration to the ballast water: the ballast water is firstly filtered through the coarse filter screen, and then flows into the fine filter screen for the second-stage filtration;

[0072] 2) The step of flushing the fine filter: using the sewage nozzle and the sewage cavity to flush the fine filter;

[0073] 3) The step of using the sewage unit to discharge the sludge in the device;

[0074] Also includes:

[0075] 4) The step of using the frequency conversion electromagnetic treatment unit to perform electromagnetic treatment on the water in the fine filter: changing the arrangement of water molecules to prevent scaling;

[0076] 5) The step of using the ultrasonic unit to perform sonic treatment on the whole set of equipment: remove the dirt on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com