Preparing method of depleted-uranium magnetron sputtering target slices

A technology of magnetron sputtering and depleted uranium, which is applied in the field of preparation of depleted uranium magnetron sputtering targets, and can solve the problems that the preparation method is difficult to meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

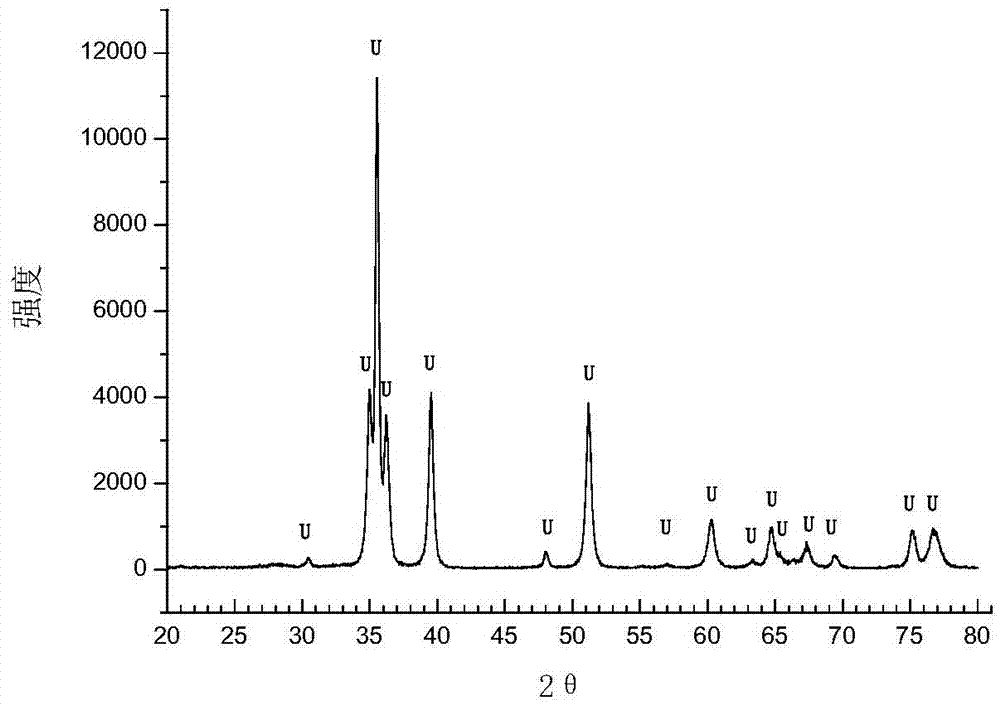

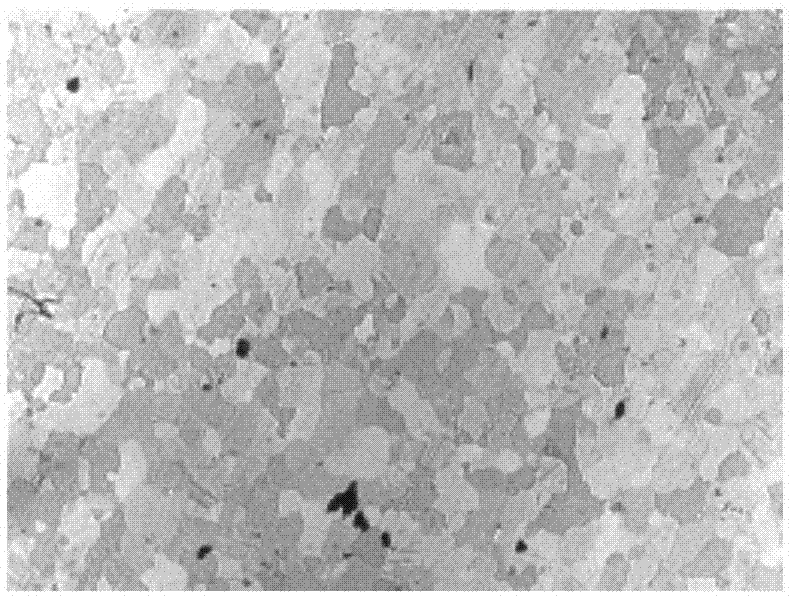

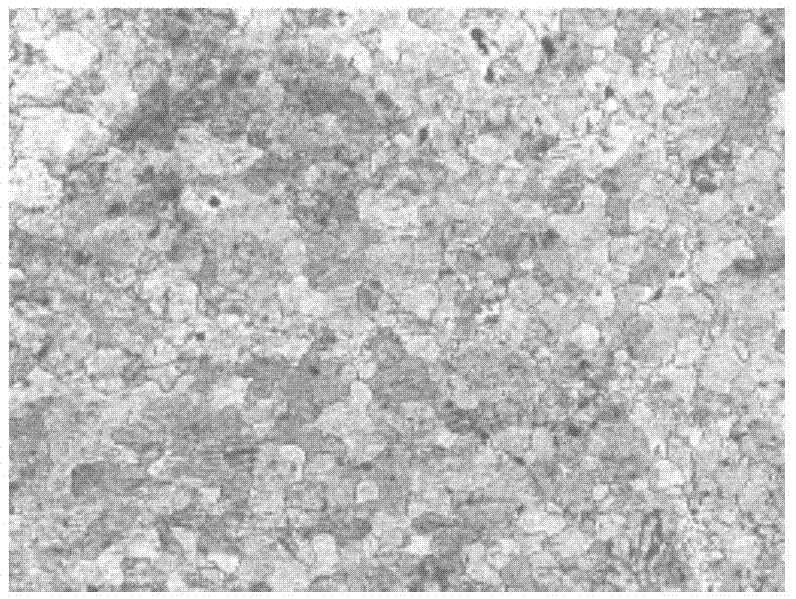

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below through specific examples.

[0027] A method for preparing a depleted uranium magnetron sputtering target of the present invention comprises the following steps;

[0028] (1) Refining and purification

[0029] Due to the active chemical properties of metallic uranium, it is easy to react with H during the reduction process. 2 O, O 2 , C and other media reactions to produce hydrides, oxides and carbides, etc., so the calcithermal reduction of UF 4 The obtained uranium ingots are vacuum refined, and in a vacuum atmosphere, the impurity elements in the metal uranium can be effectively removed through high-temperature volatilization, vacuum degassing, slagging, etc., so as to achieve the purpose of purification.

[0030] The specific method is to carry out vacuum refining three times in a vacuum induction furnace, a vacuum consumable electric arc furnace, and a vacuum induction fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com