Armor-piercing head

A technology of armor-piercing warheads and bullet cores, which is applied in the field of bullets and can solve problems such as environmental pollution, non-environmental protection, and failure to attack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

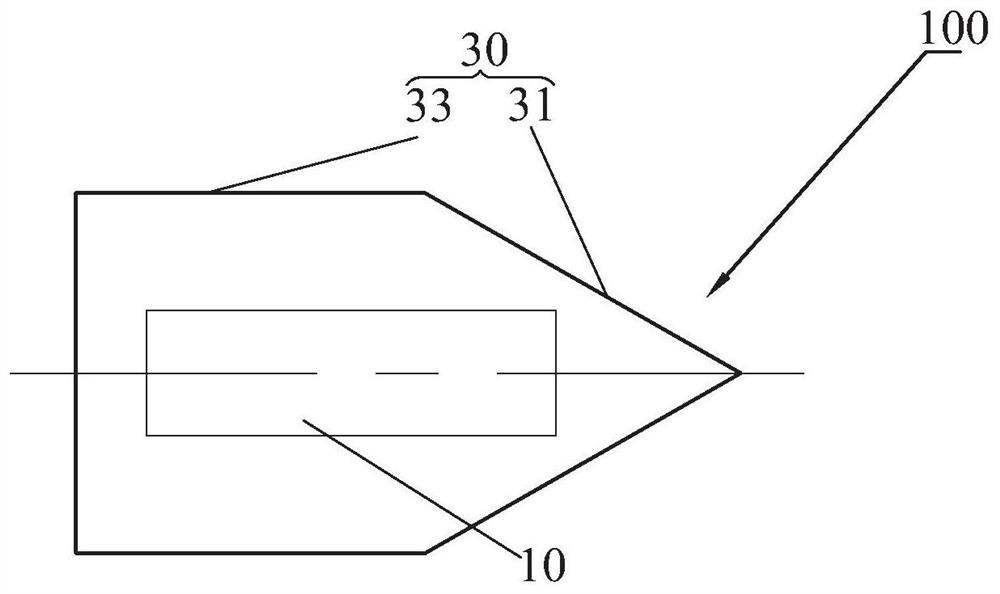

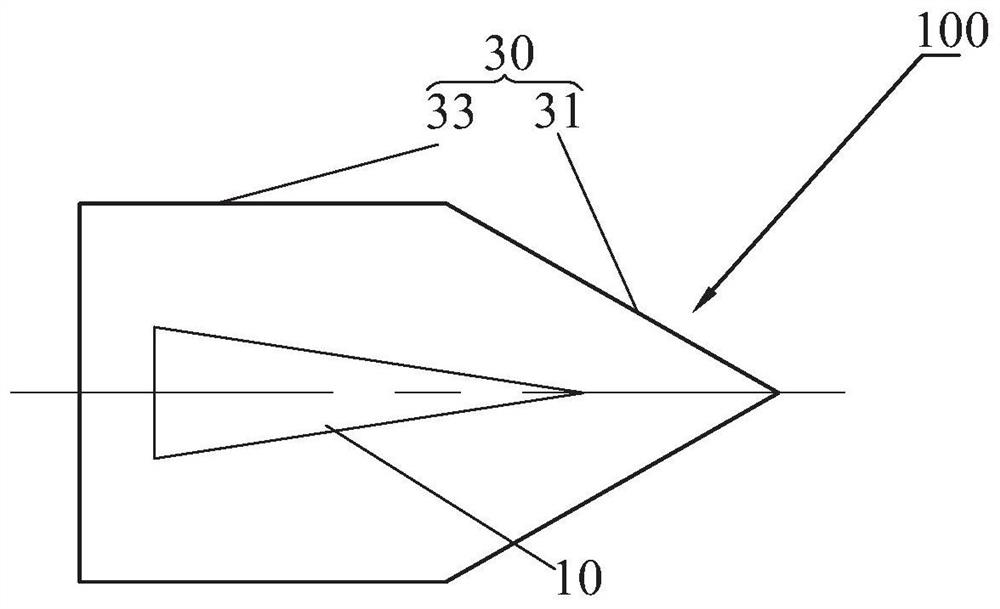

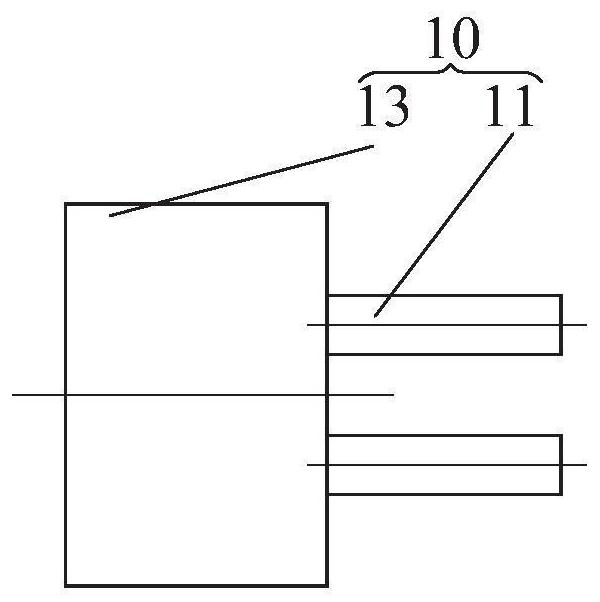

[0046] use as Figure 3-5 For the armor-piercing warhead of the shown structure, the shape of the armor-piercing warhead 100 is composed of a conical top cone 31 and a platform 33 connected to the bottom of the top cone 31. The platform 33 is a cylinder with the same diameter as the cone, including the bullet core 10 and the bullet core. 10 is an integrated shell 30, and the shell 30 wraps all the bullet cores 10. The bullet core 10 includes a base body 13 and a protrusion 11 connected to the base body 13. The base body 13 is wrapped by the shell 30 located on the platform 33, and part of the protrusion 11 is wrapped by the shell 10 located at the top cone 31. The protrusion 11 is interposed between the base body 13 and the top. Between the cones 31 , four protrusions 11 are evenly distributed around the centerline of the top cone 31 , the protrusions 11 and the base 13 are both cuboid structures, and a / (a+b) is 0.5.

[0047] Wherein, the bullet core 10 is made of tungsten ma...

Embodiment 2

[0049] An armor-piercing projectile with the same structure as in Example 1 is used, wherein the projectile core 10 is made of tungsten-molybdenum alloy obtained by investment casting and is sandblasted, and the shell 30 is made of zirconium-based amorphous alloy. The zirconium-based amorphous alloy is deposited on the surface of the tungsten core by magnetron sputtering to obtain an integrated armor-piercing bullet, and the armor-piercing bullet is surface-treated by micro-arc oxidation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com