Patents

Literature

30results about How to "Reduce elbow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

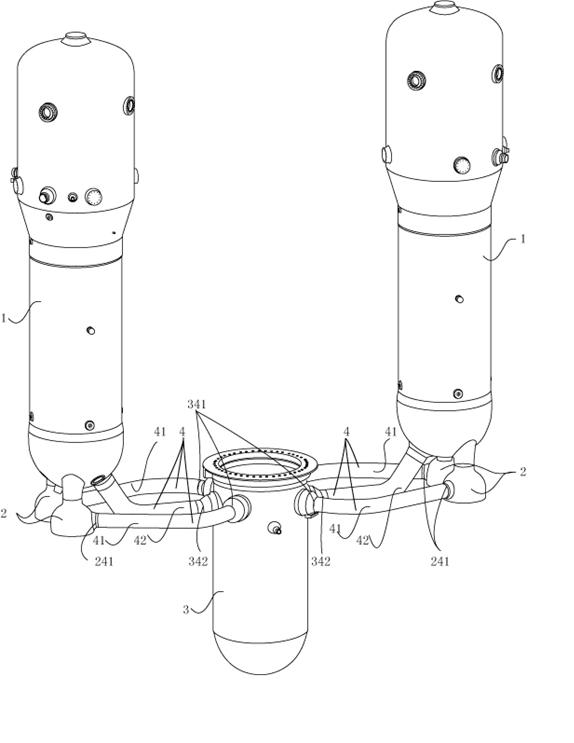

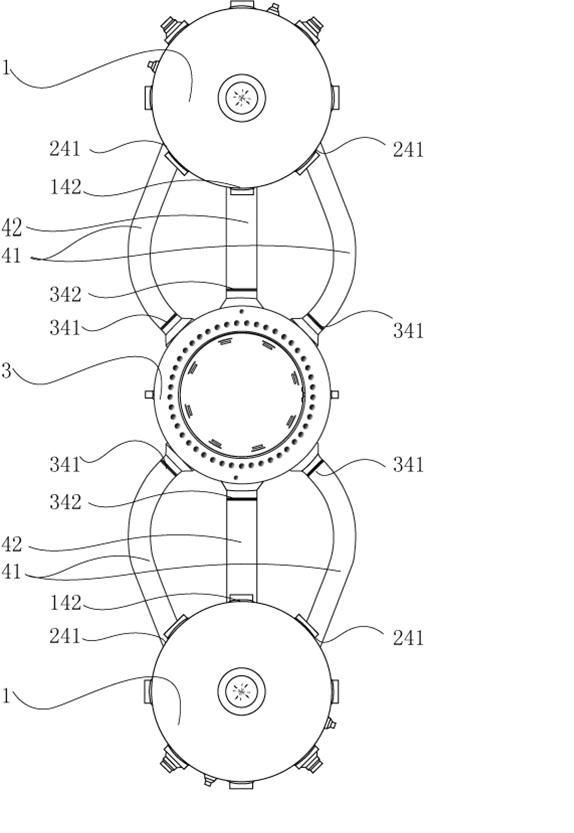

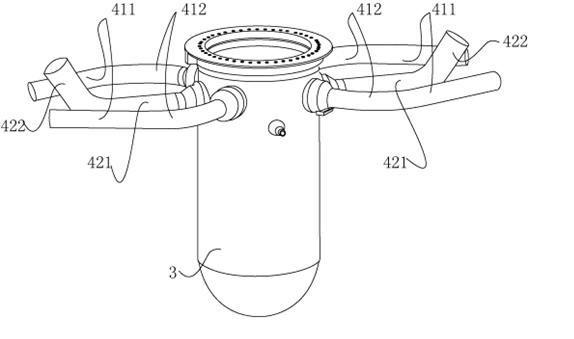

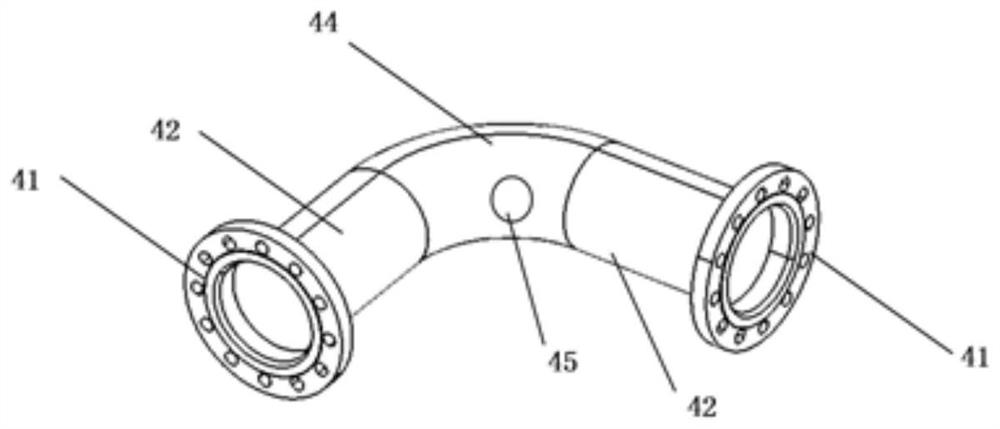

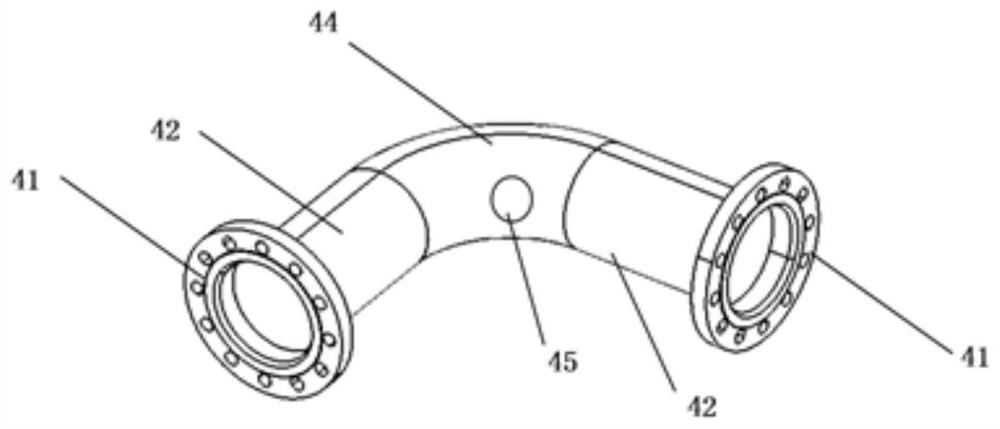

Installing method for main pipeline of coolant system of nuclear power station

ActiveCN102169736ASimple structureReduce elbowNuclear energy generationReactors manufactureNumerical controlPressurized water reactor

The invention relates to an installing method for a main pipeline of a coolant system of a nuclear power station, which is characterized in that the main pipeline of the coolant system of a reactor of the pressurized water reactor nuclear power station comprises a cool section (41) and a hot section (42), and a steam generator is directly connected with a main pump. According to the invention, the problem that the main pipeline is installed and welded by only a pressure container or steam generator in place by adopting the installing method of the main pipeline without a transition section issolved, and technical limit that the main pipeline is installed after the pressure container is in place and the steam generator or main pump is in place in the traditional main pipeline constructiontechnology is eliminated. A main pipeline groove is processed by adopting a site numerical control machining technology, the main pipeline and equipment connected with the main pipeline are subjectedto measurement, modeling and process monitoring by adopting a laser tracking measuring and 3D modeling technology, the main pipeline is regulated to meet the assembly welding requirement and is installed by using a narrow TIG (argon tungsten-arc welding) automatic welding technology, thus a feasible method is provided for shortening the construction period of the nuclear power station.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

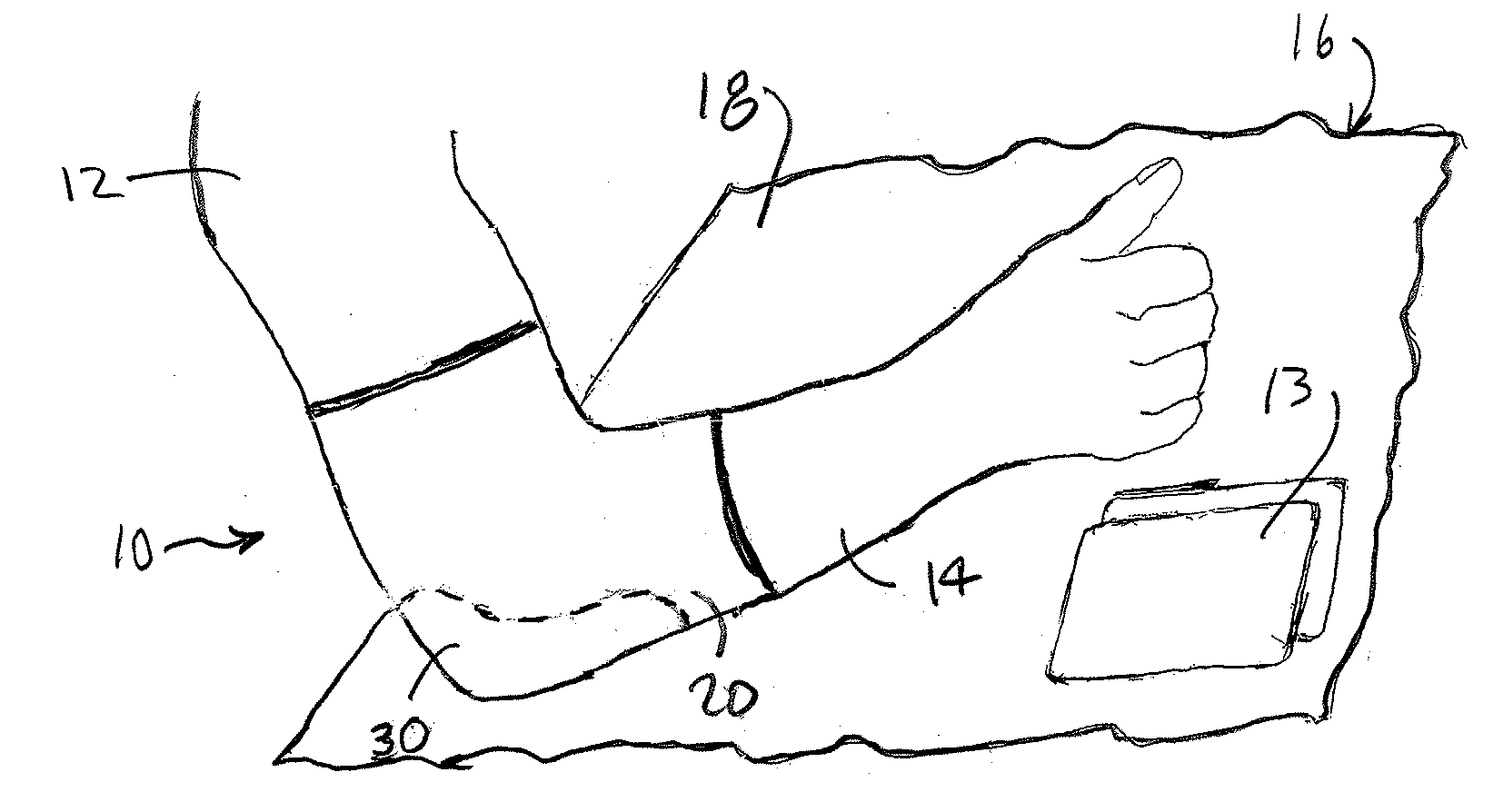

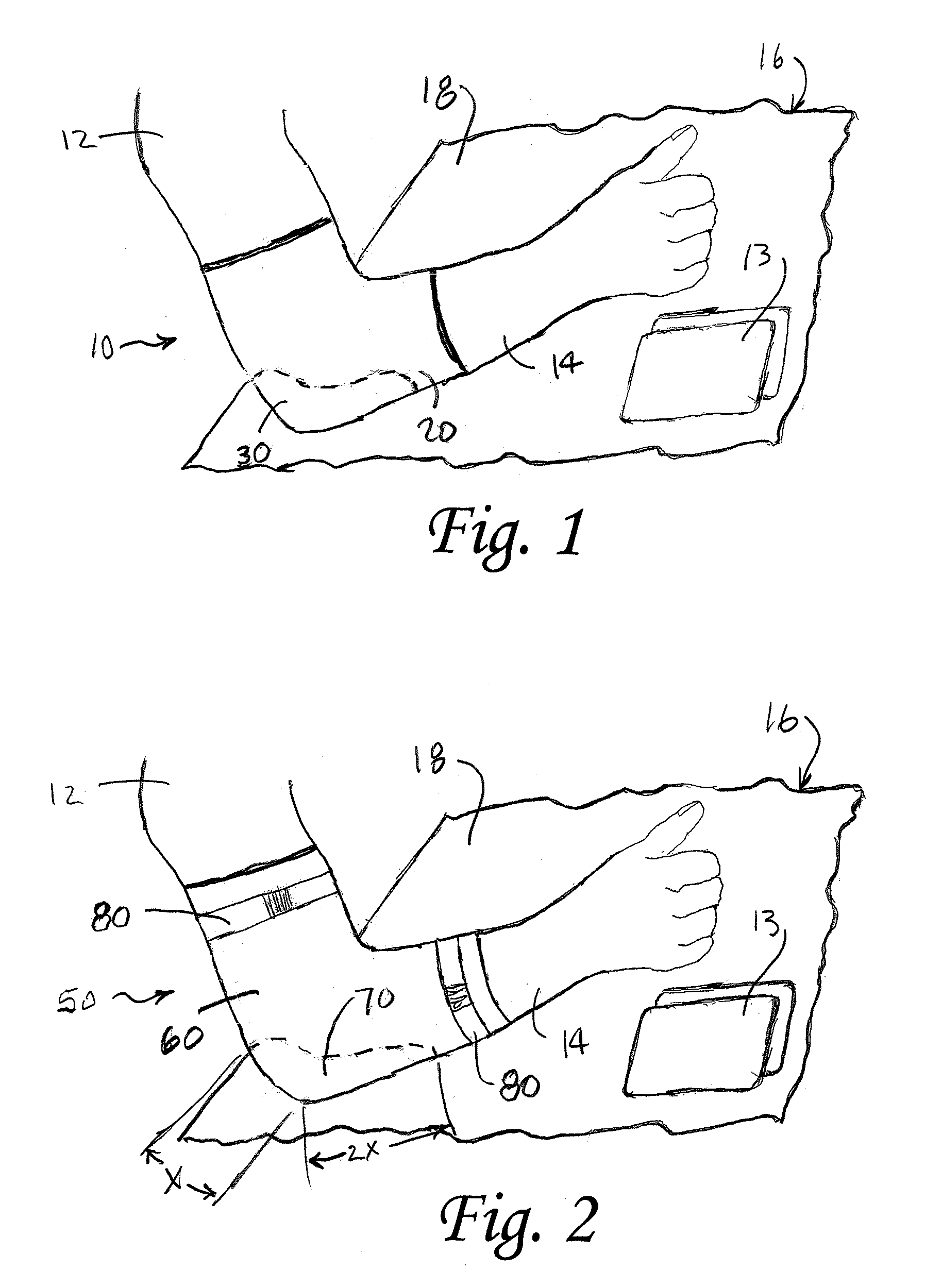

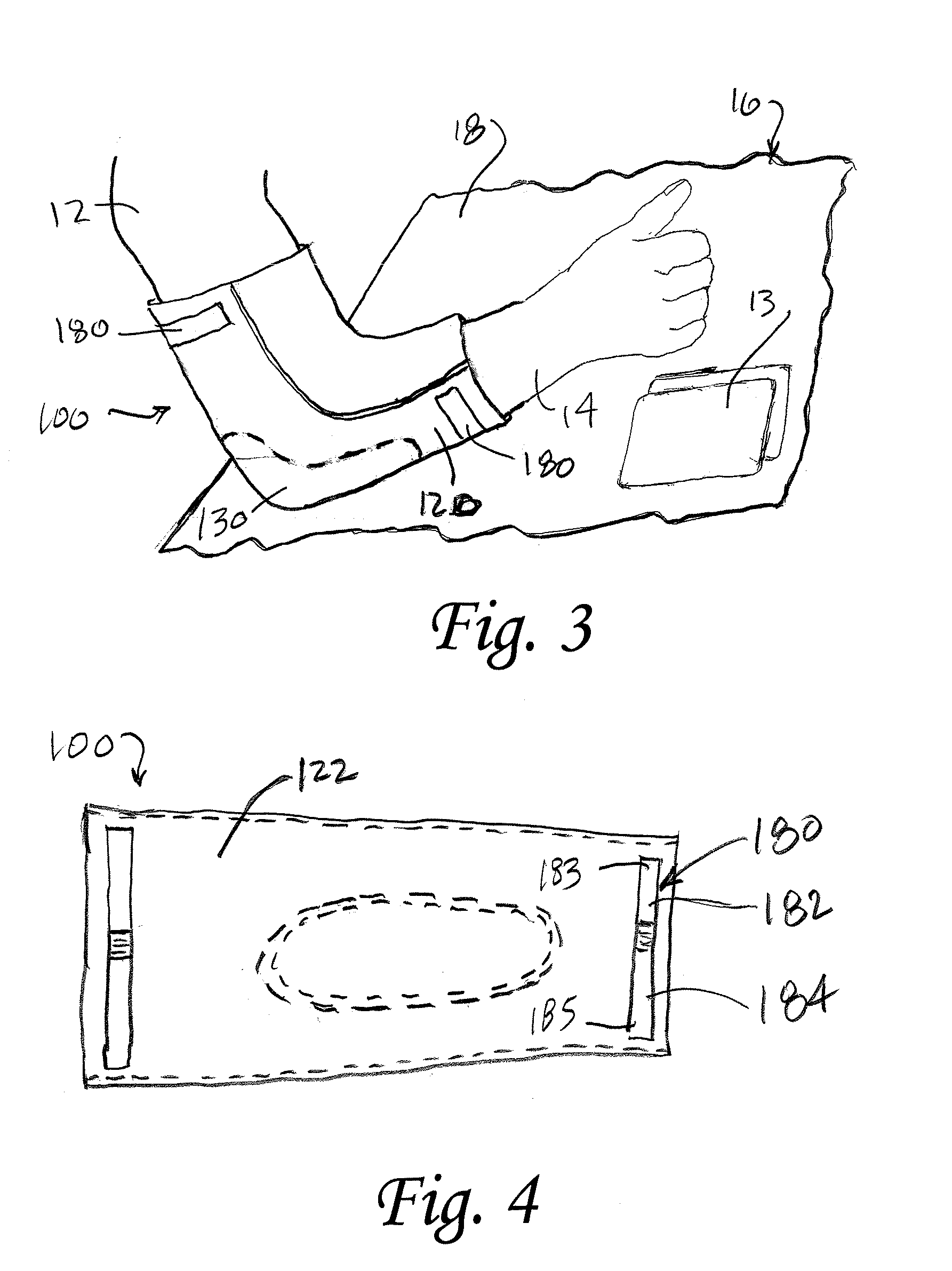

Methods and devices for reducing elbow pain and arm fatigue for poker players when playing poker

A method includes in one embodiment wearing a first resilient sleeve having a first elbow pad on a first arm of the poker player, positioning the elbow pad between a surface of a poker table and the poker player's elbow of the first arm, and compressing a portion of the first resilient elbow pad between a surface of a poker table and the poker player's first elbow of the first arm to resiliently support the weight of the poker player's first arm on the first elbow pad during play of a plurality of poker games. The method may further include positioning a hot pack or a cold pack in a pocket attached to the sleeve on the first arm during play of the plurality of poker games.

Owner:SCOTT MICHAEL A +1

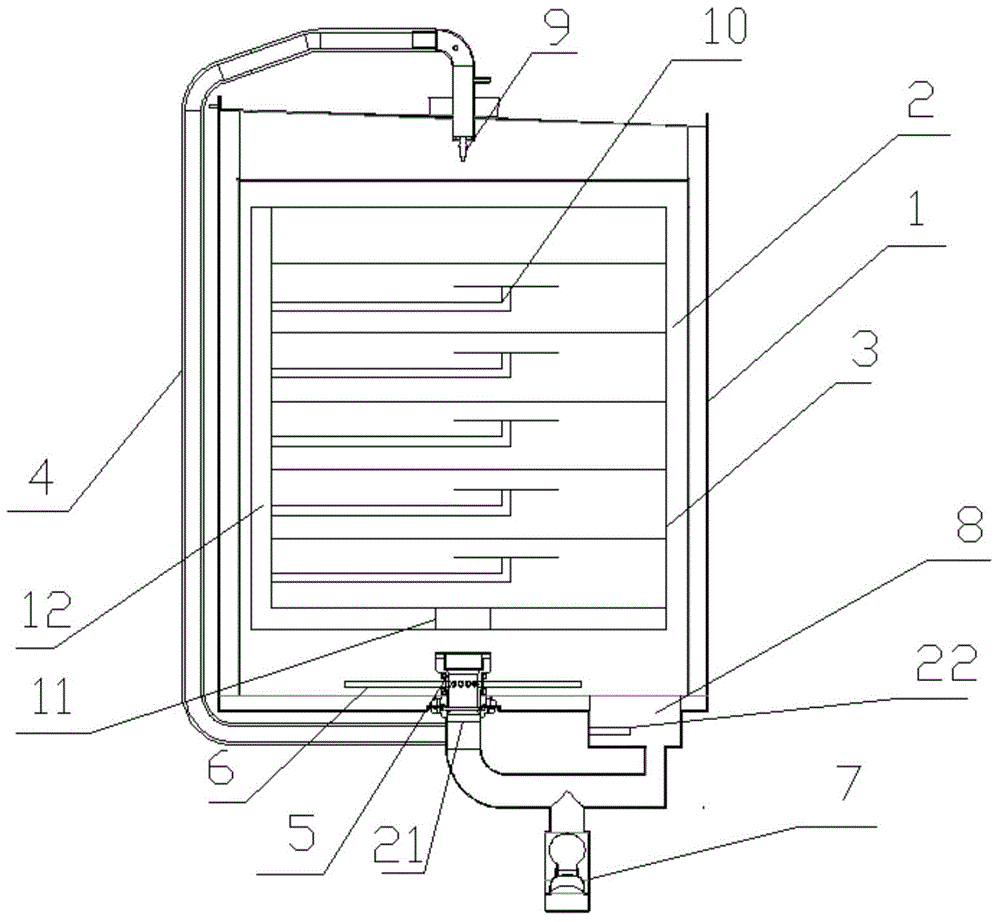

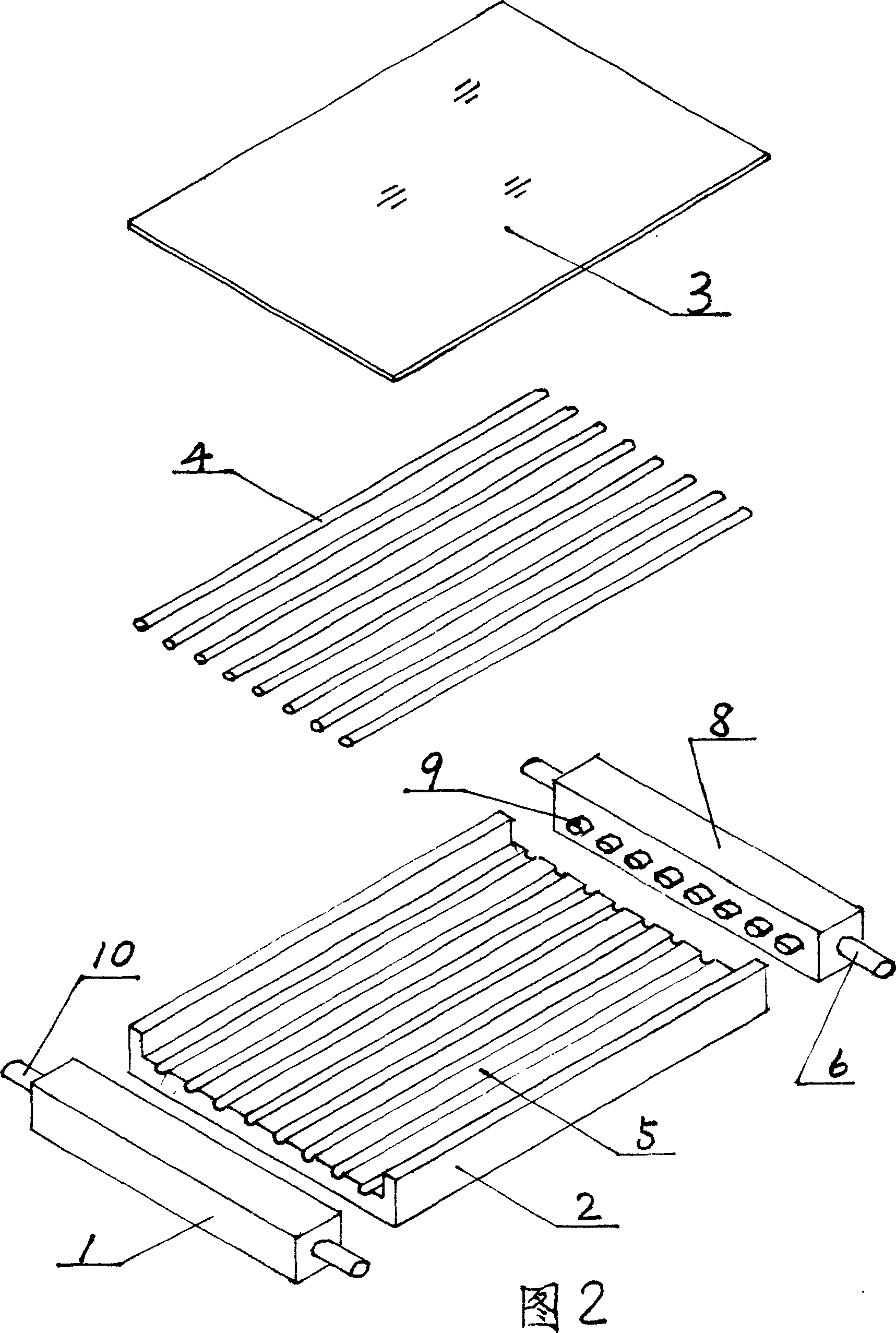

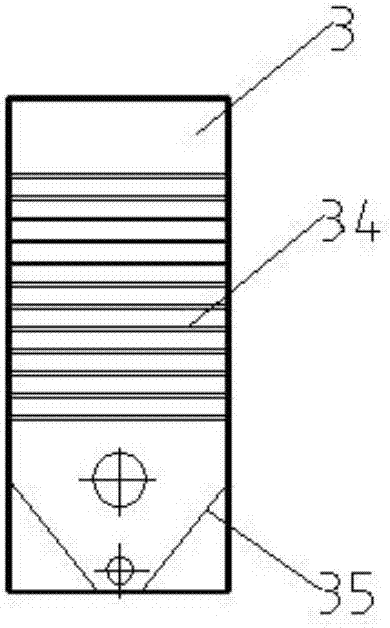

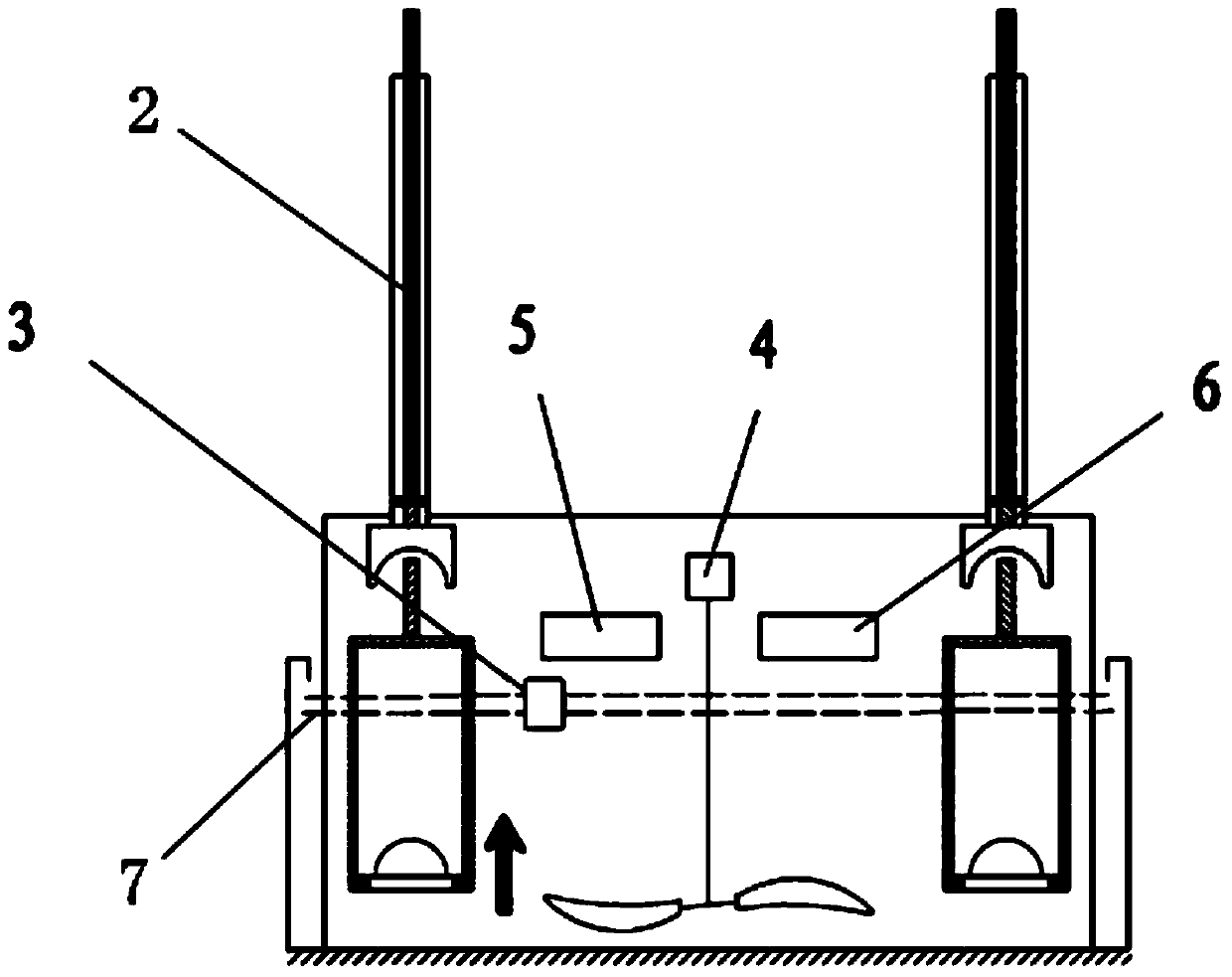

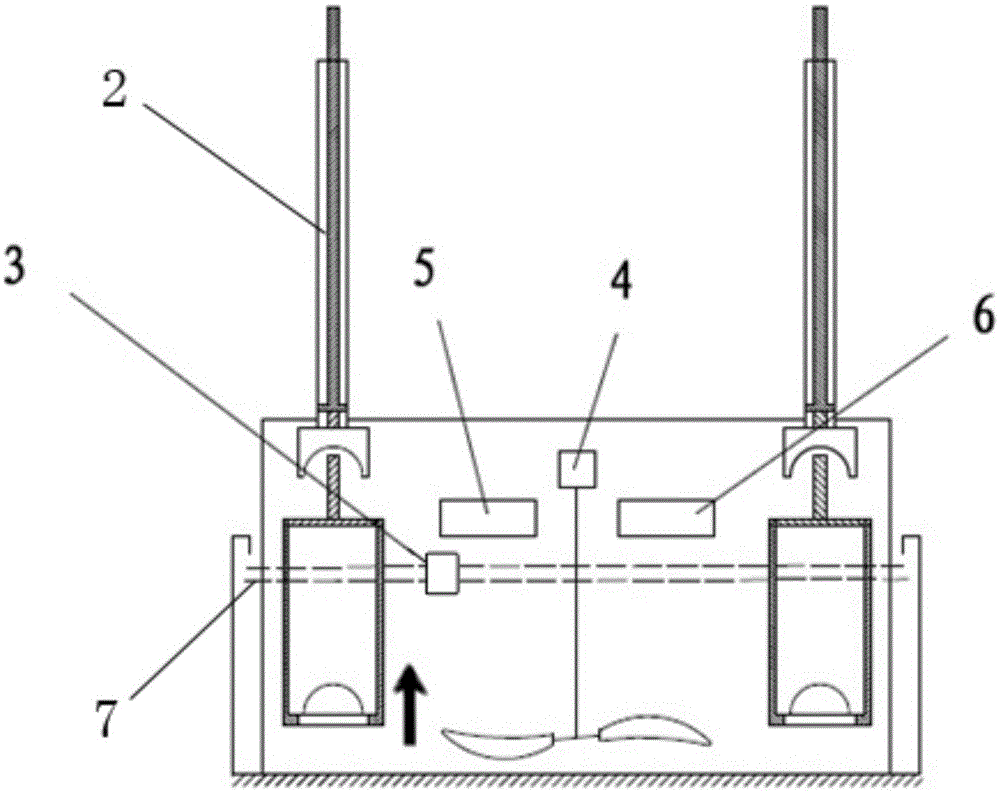

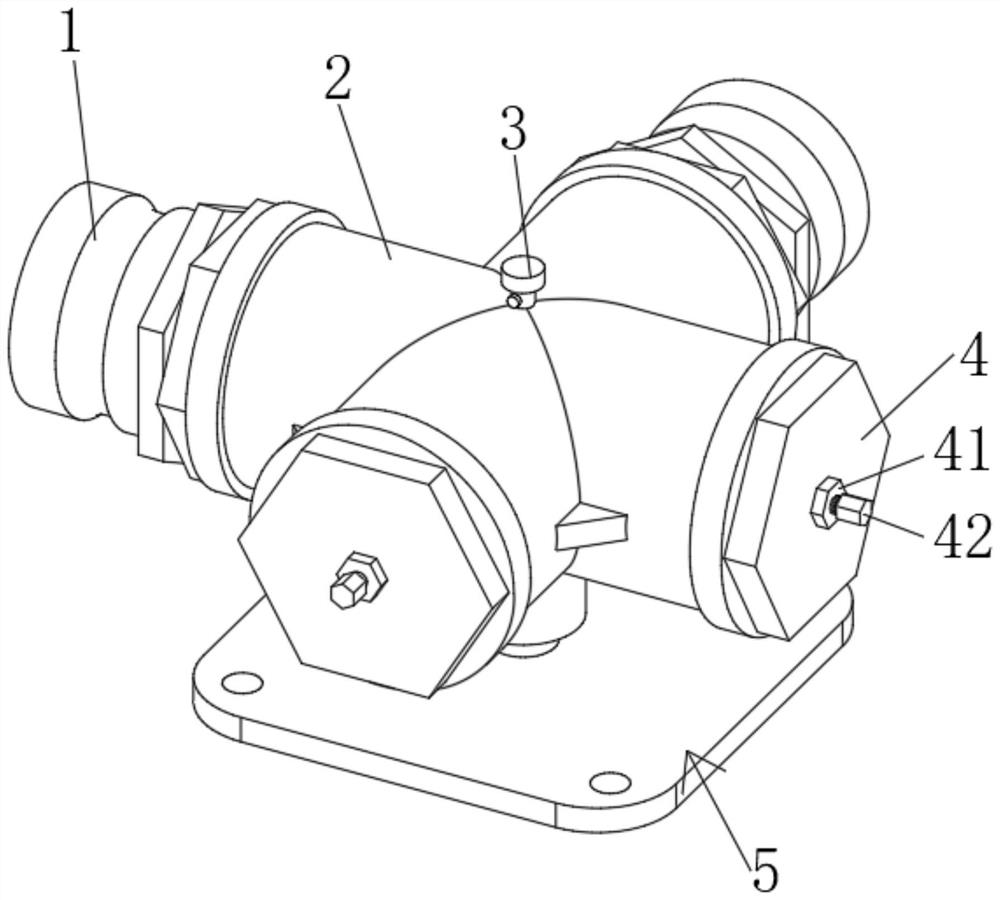

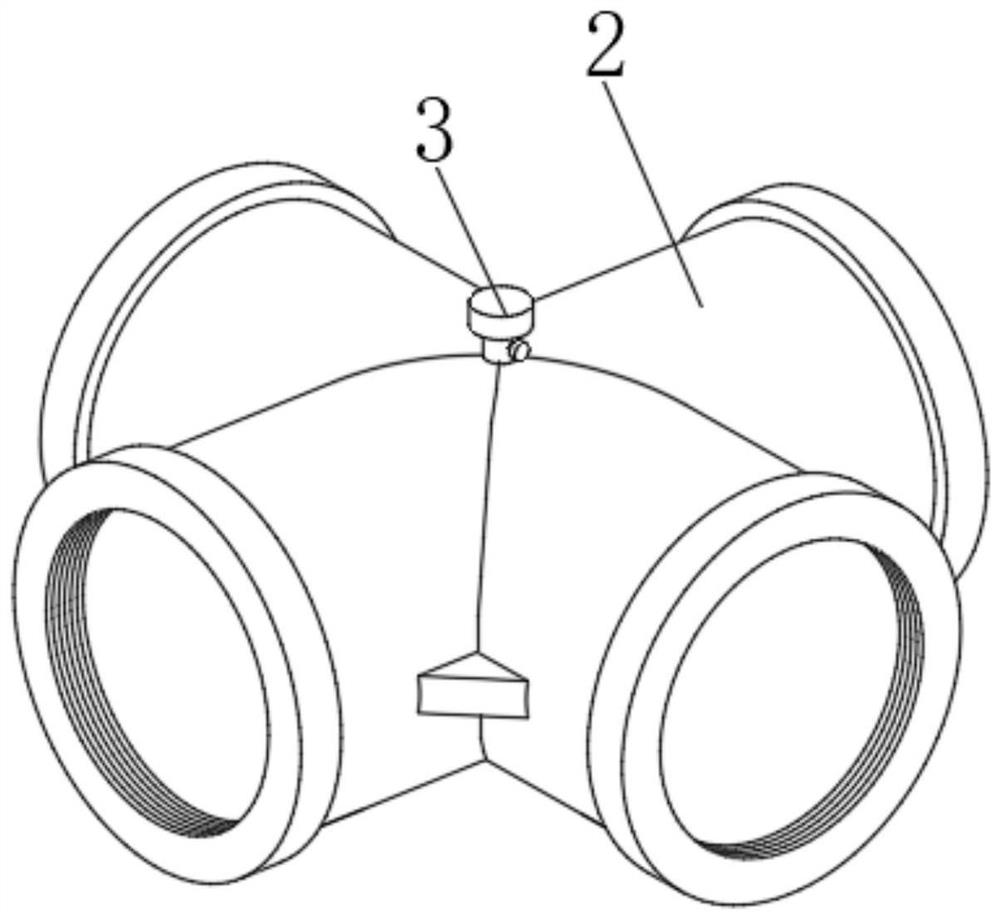

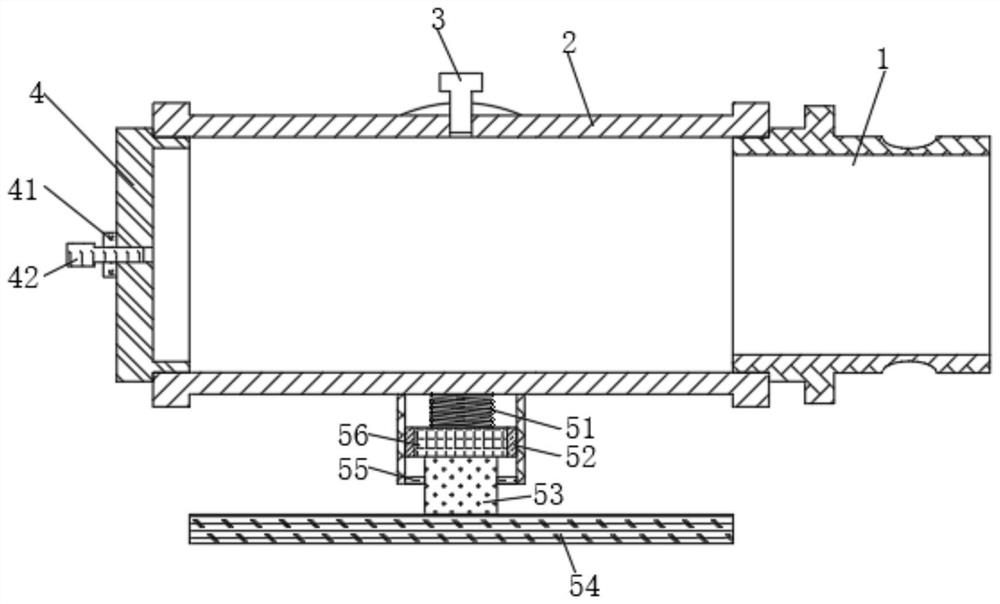

Full-automatic medical cleaning machine

ActiveCN104525513AReduce elbowReduction of recycled water consumptionCleaning using liquidsButt jointWater resources

The invention discloses a full-automatic medical cleaning machine. The full-automatic medical cleaning machine comprises a frame, a cleaning bin and a water pump, wherein a cleaning frame is positioned in the cleaning bin; a water inlet is formed in the lower end of the cleaning frame; a water inlet main pipe is arranged at one side of the cleaning frame, and is connected with the water inlet; a main water pipe is arranged at the bottom of the cleaning bin; a joint device is arranged at a water outlet end of the main water pipe; a butt joint ring is arranged in a pipe hole in the upper end of the joint device; a water inlet end of the main water pipe is connected with the water pump; when water is supplied into the cleaning bin, the water pump is started, and the butt joint ring in the joint device is upwards flushed by water pressure under water pressure impact provided by the water pump, so that the top surface of the butt joint ring is tightly butted to the periphery of the water inlet in the bottom surface of the cleaning frame; and when the water is stopped being supplied into the cleaning bin, the butt joint ring in the joint device downwards drops to reset under the effect of self gravity. The full-automatic medical cleaning machine adopts the novel joint device, so that the use level of water pipes is reduced, the water resource is saved, the space in the cleaning bin is enlarged, and the cleaning capacity is improved.

Owner:LAOKEN MEDICAL TECH

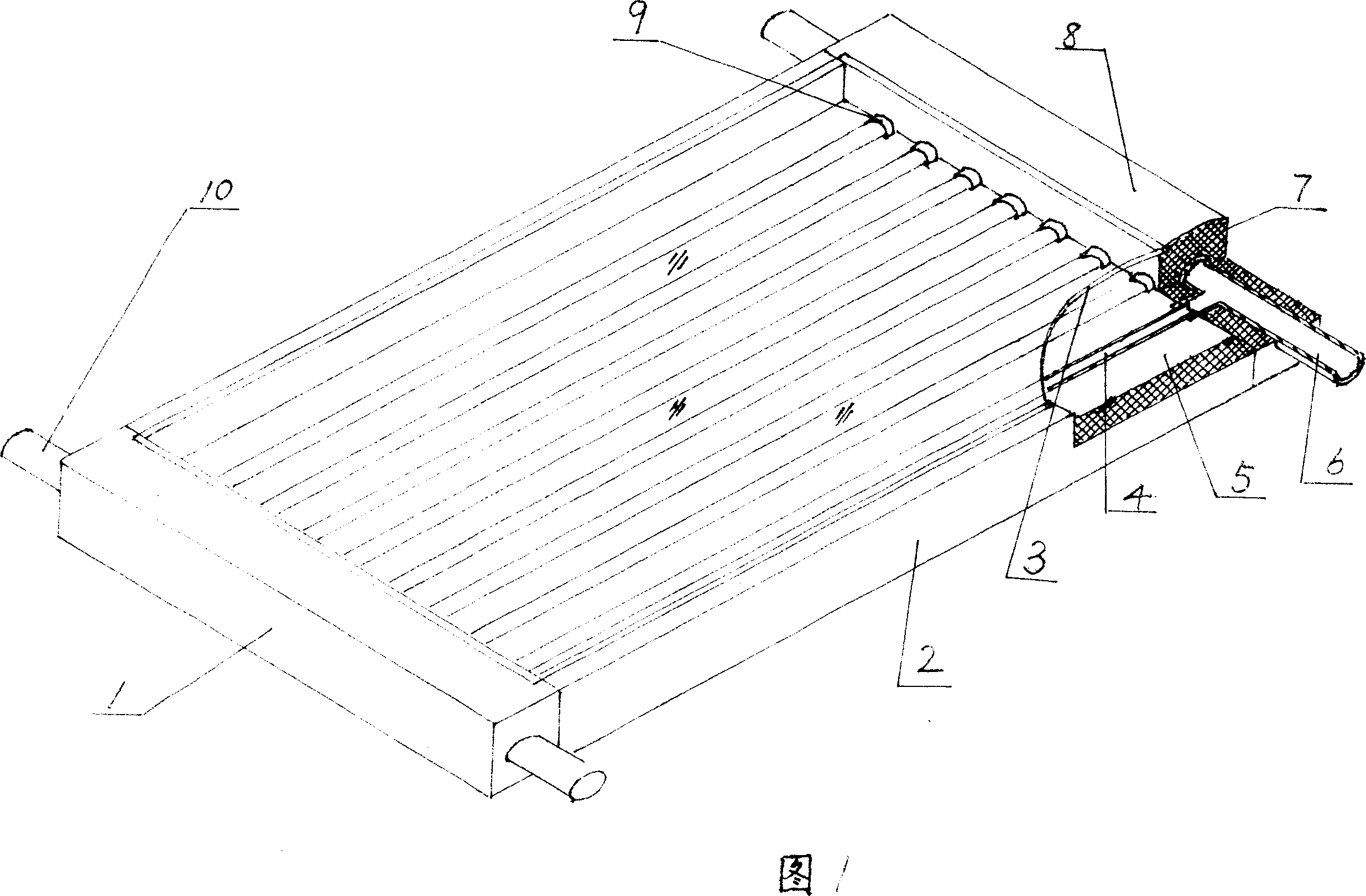

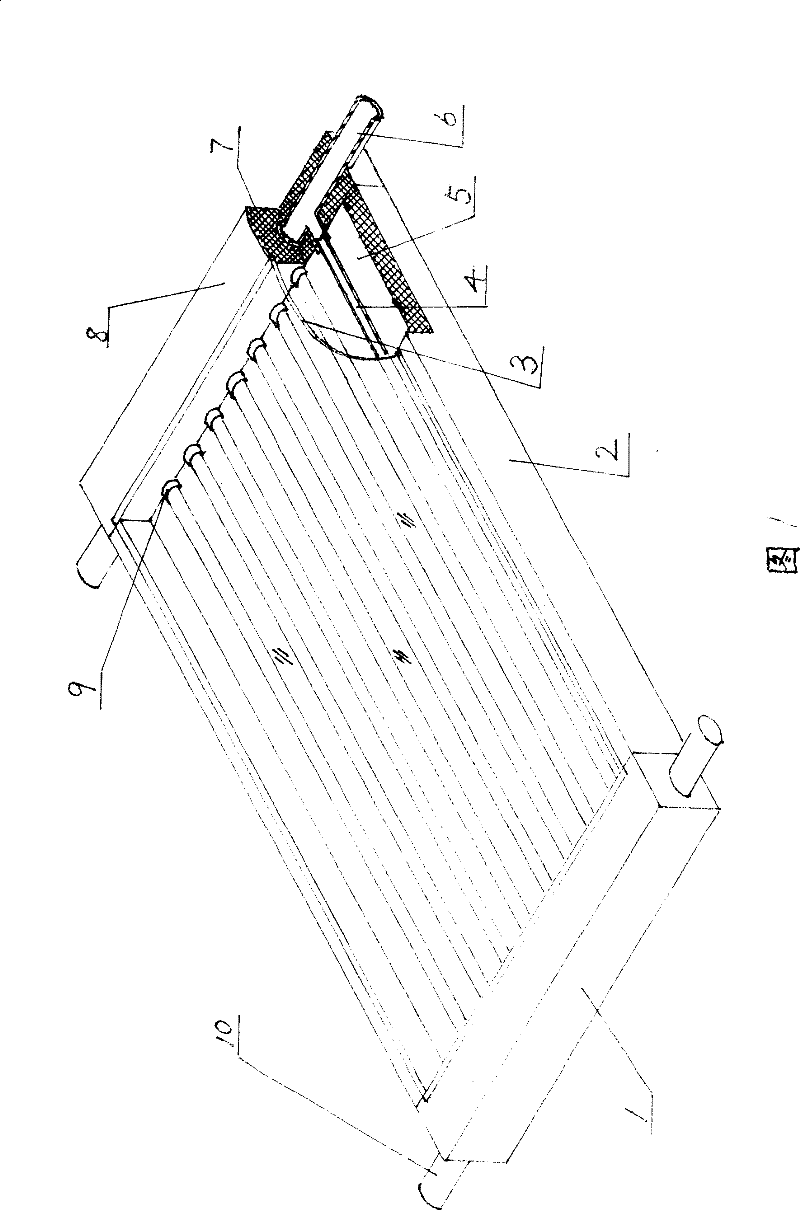

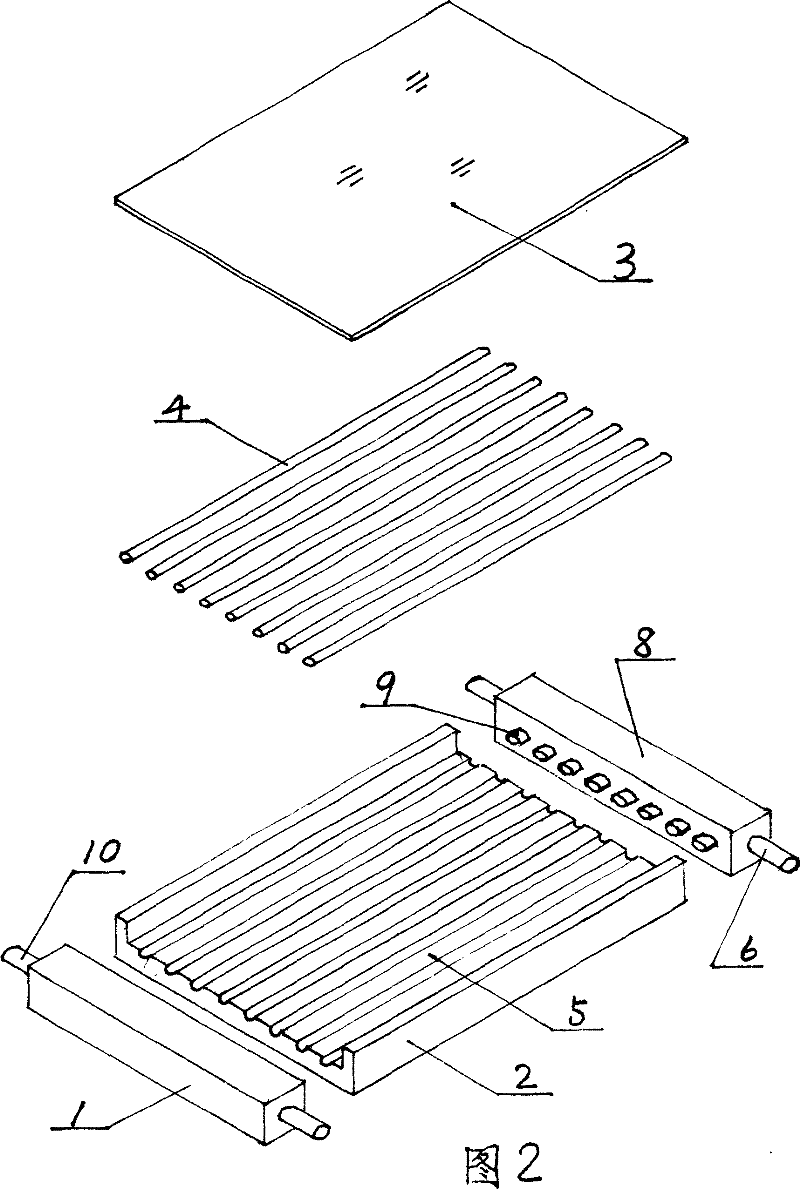

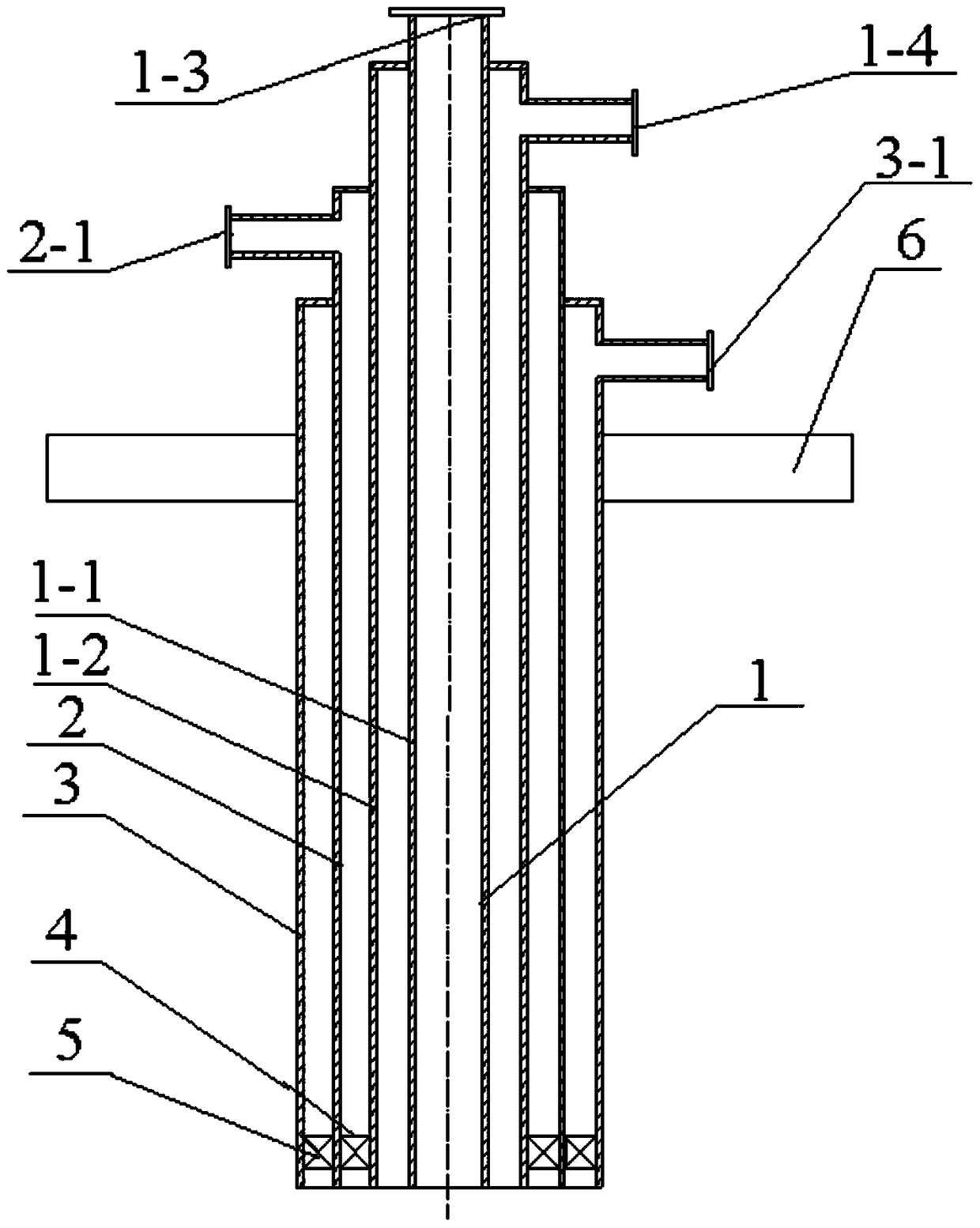

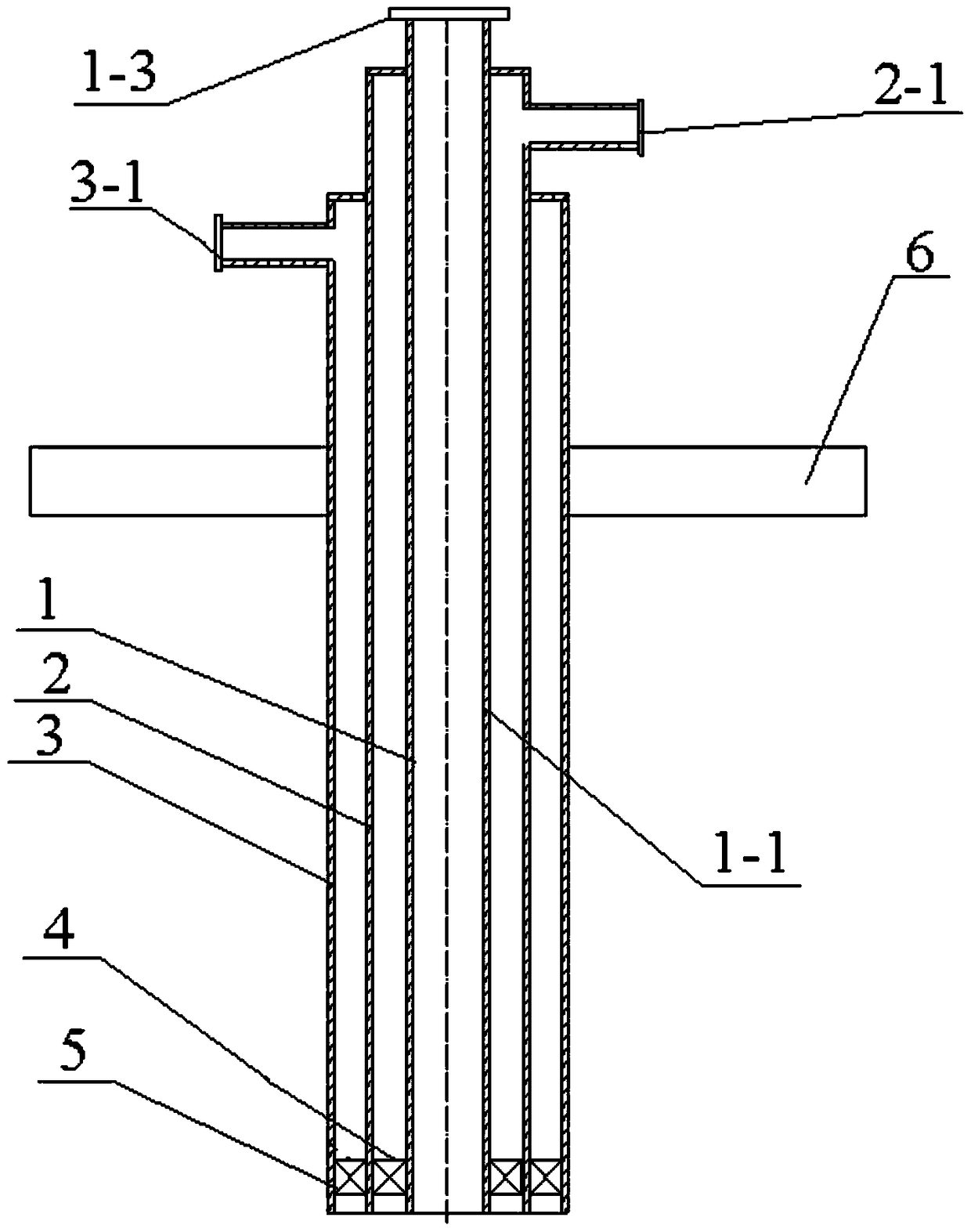

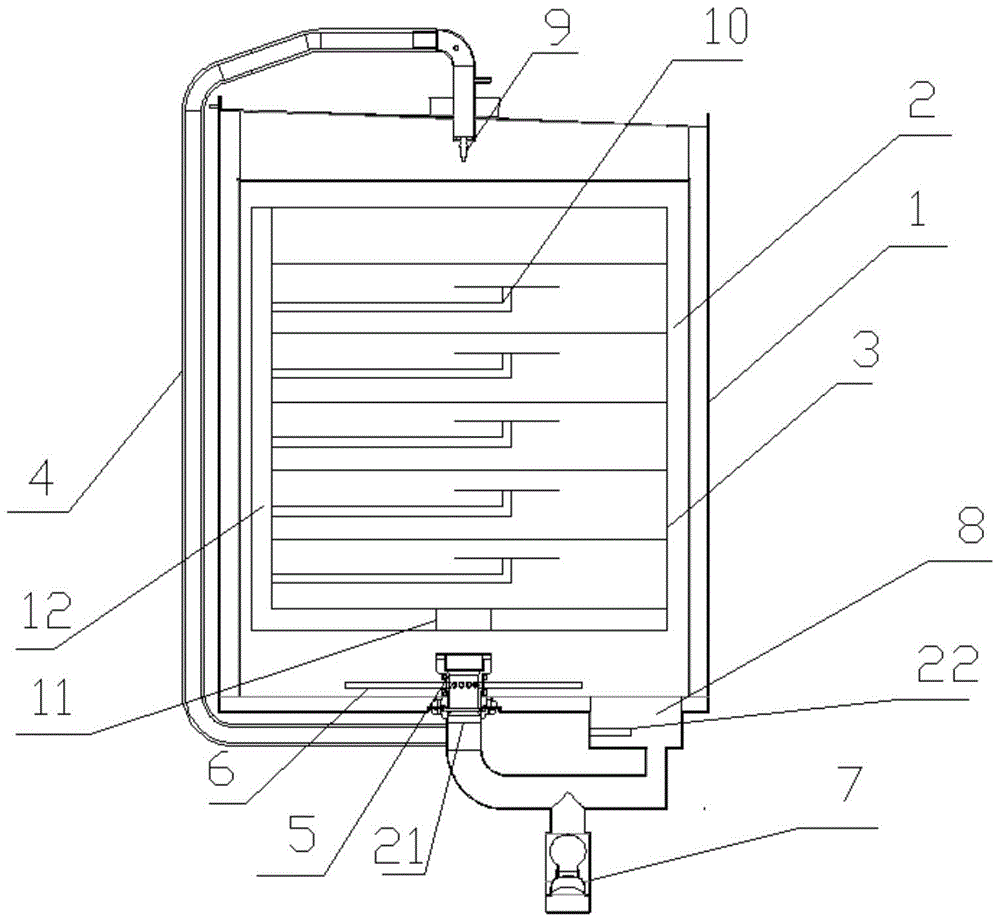

Solar heat collector, its production and usage

InactiveCN1982805ASimple materialSimple processSolar heating energySolar heat devicesEngineeringWater tanks

A solar heat-collector comprises a heat-absorbing plate, a heat-absorbing pipe, a water intake main pipe and a discharge main pipe. On the heat-absorbing plate and pipe is disposed heat-absorbing material. Its manufacture method includes the following steps: processing and laying the foam sandwich board with the heat-absorbing plate; setting the heat-absorbing pipe; connecting two ends of the heat-absorbing pipe with the water intake and discharge main pipes separately with a quick connector; coating the heat-absorbing material; setting a supporting method including the following steps: mounting the solar heat collector and a insulated water tank; connecting one end of water intake and discharge main pipes with the insulated water tank separately and connecting a water supply pipe for supplying hot-water to all the users by using a hot-water main pipe and hot water branch pipes.

Owner:宋惠军

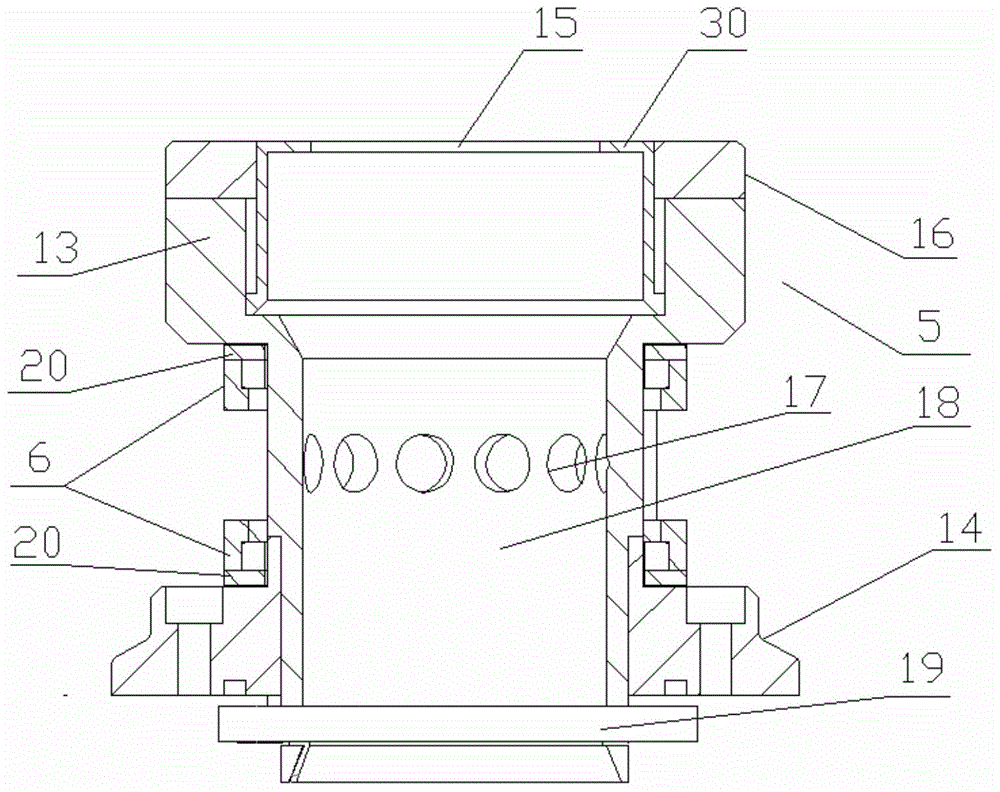

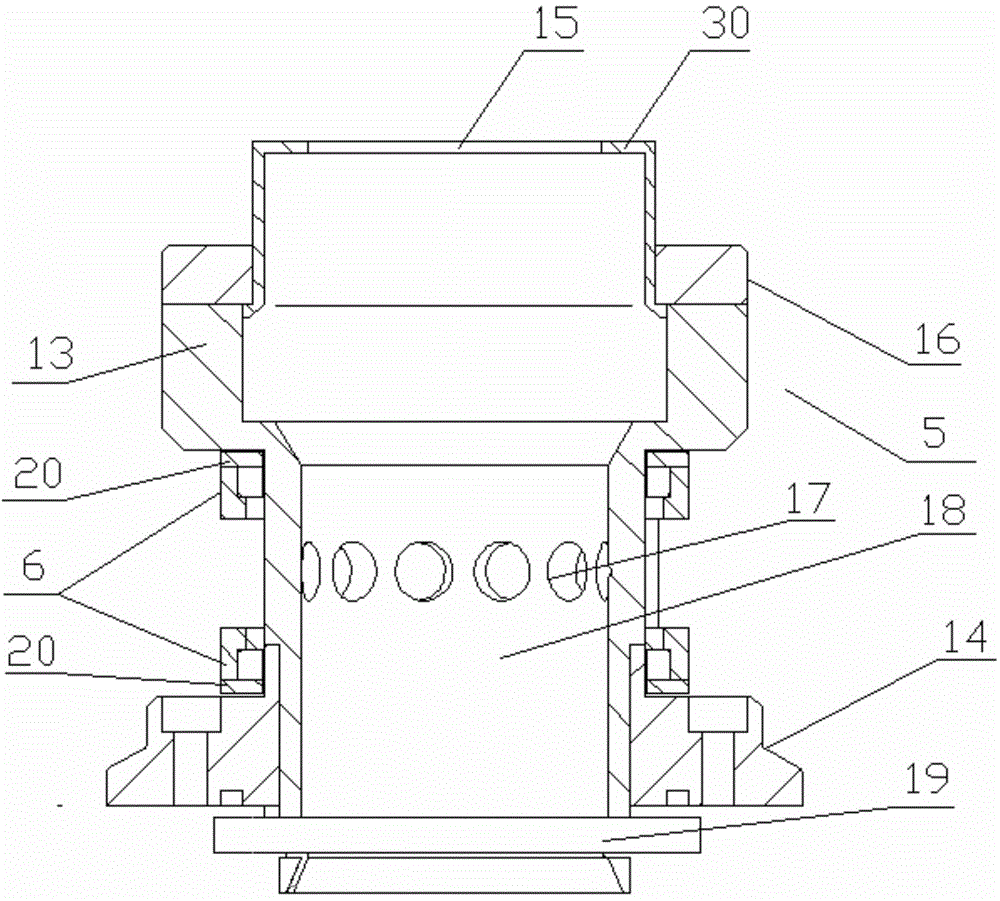

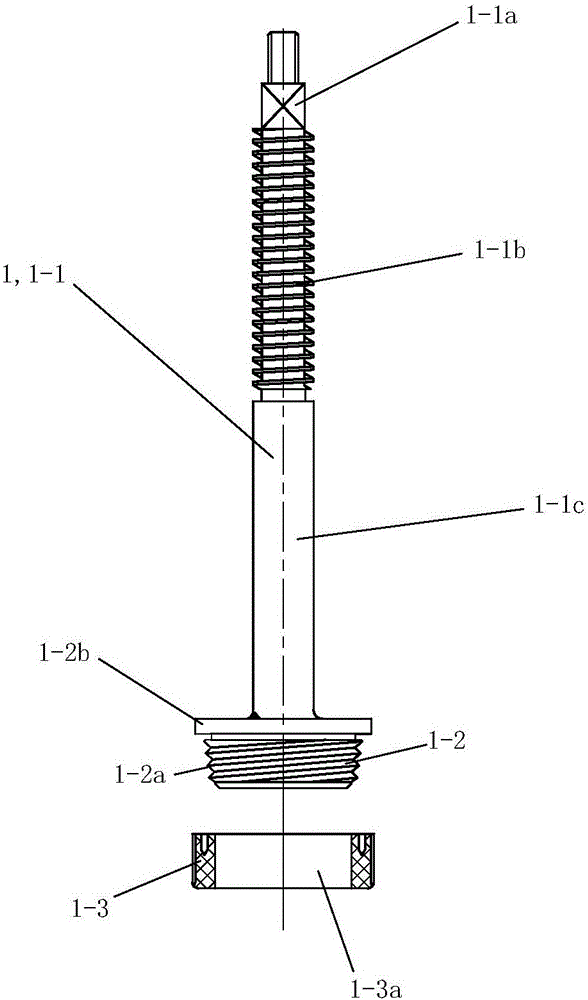

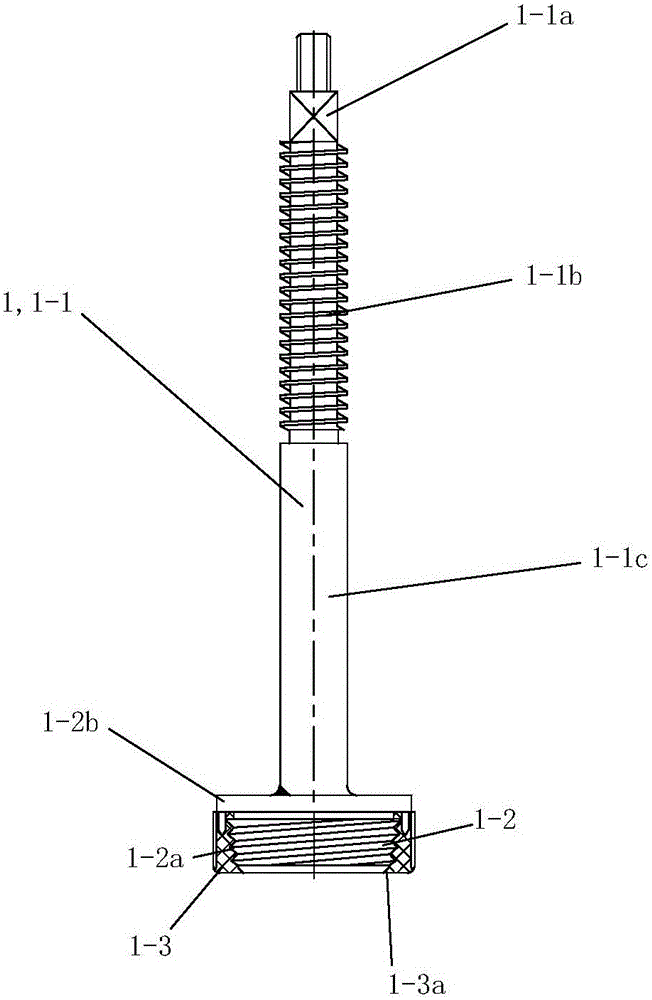

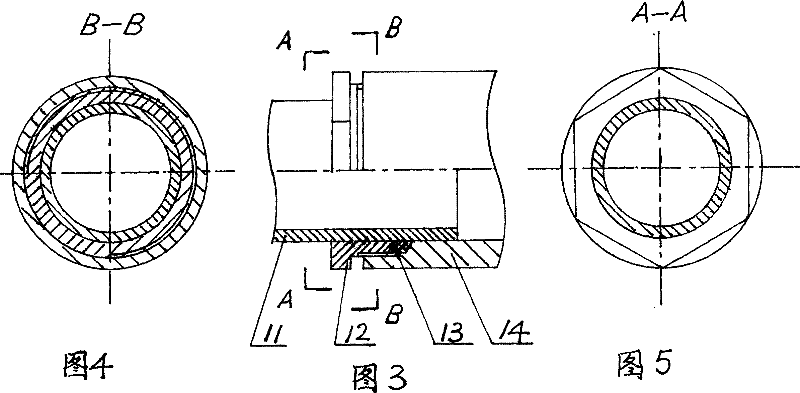

Valve element assembly and stop valve

InactiveCN105736713ASimple structureEasy to installEqualizing valvesSafety valvesEngineeringGlobe valve

The invention discloses a valve element assembly and a stop valve. The valve element assembly is characterized by comprising a valve rod, a valve clack and a sealing filler piece; the valve clack is coaxially and fixedly connected to the lower end of the valve rod; taper threads are distributed on the outer circumferential wall of the valve clack; a center through hole is formed in the sealing filler piece; and the sealing filler piece is made of plastic, and during using, a corresponding inner thread matched with the taper threads is generated in the center through hole of the sealing filler piece through the taper threads of the valve clack. After the valve element assembly is adopted in the stop valve, the stop valve is simple in structure and convenient to use, during using, only the sealing filler piece needs to be fixed in an installing groove of the stop valve firstly, the inner thread on the sealing filler piece is generated through the corresponding taper threads of the valve clack, the positioning problem does not need to be considered, and matching is reliable.

Owner:JIANGSU SHUANGHU ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP TECH CO LTD

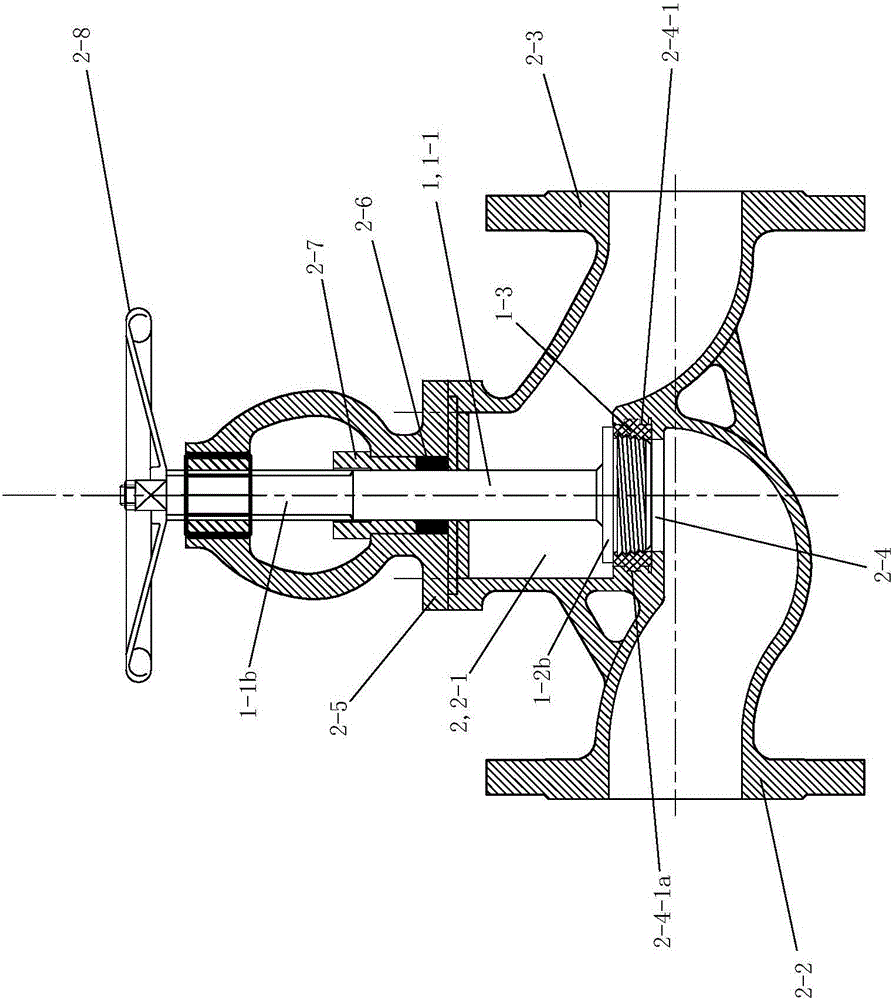

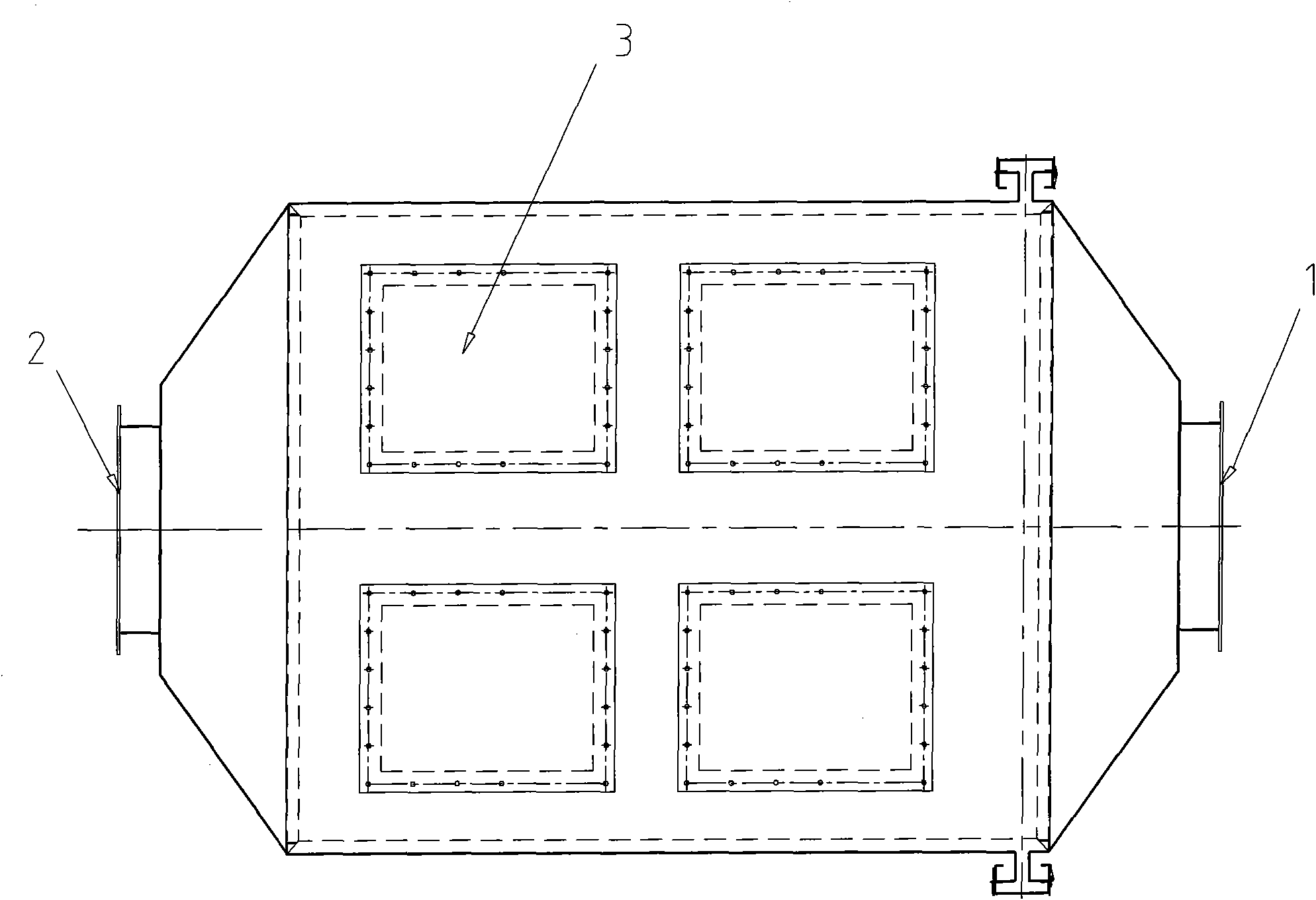

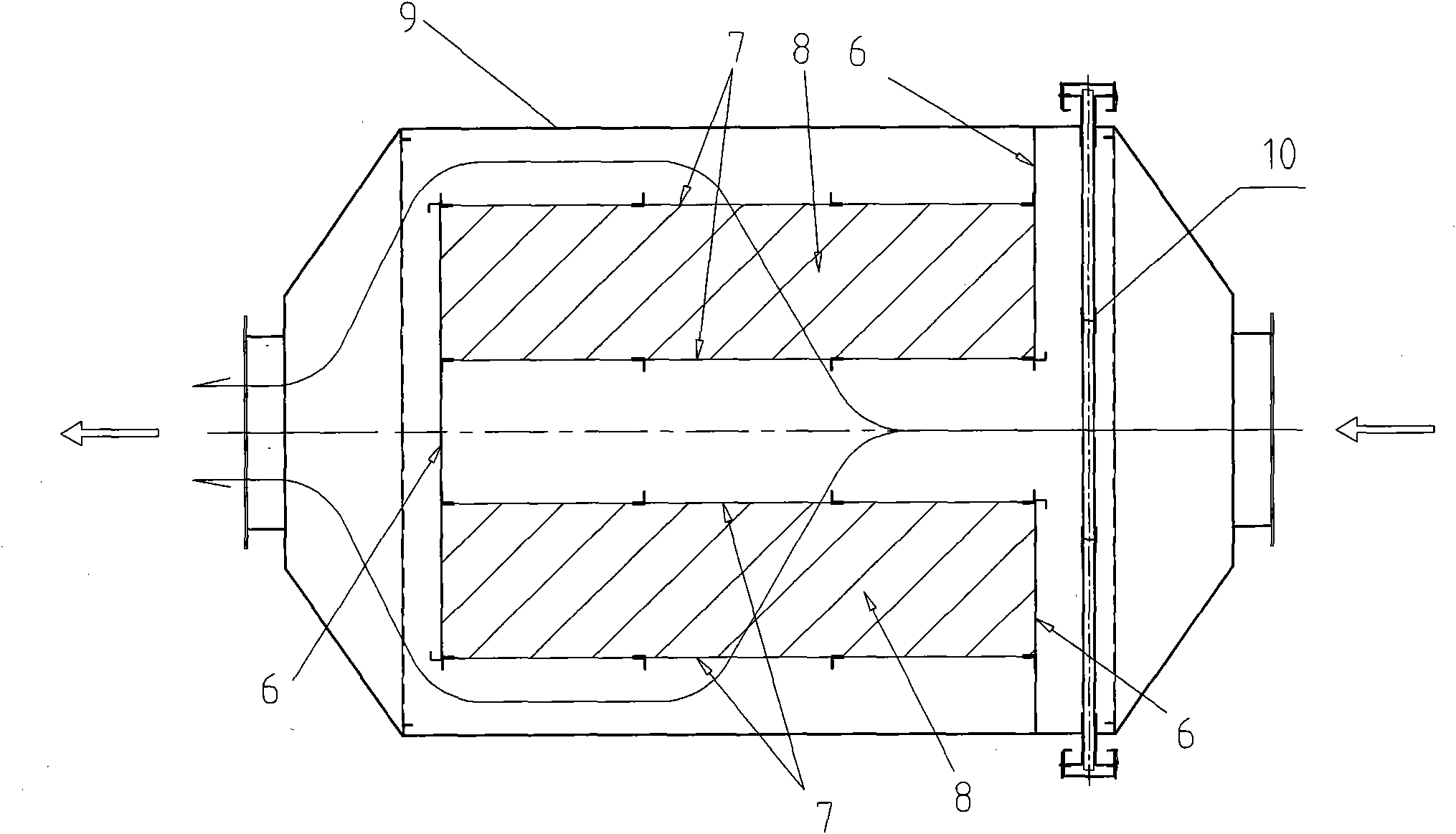

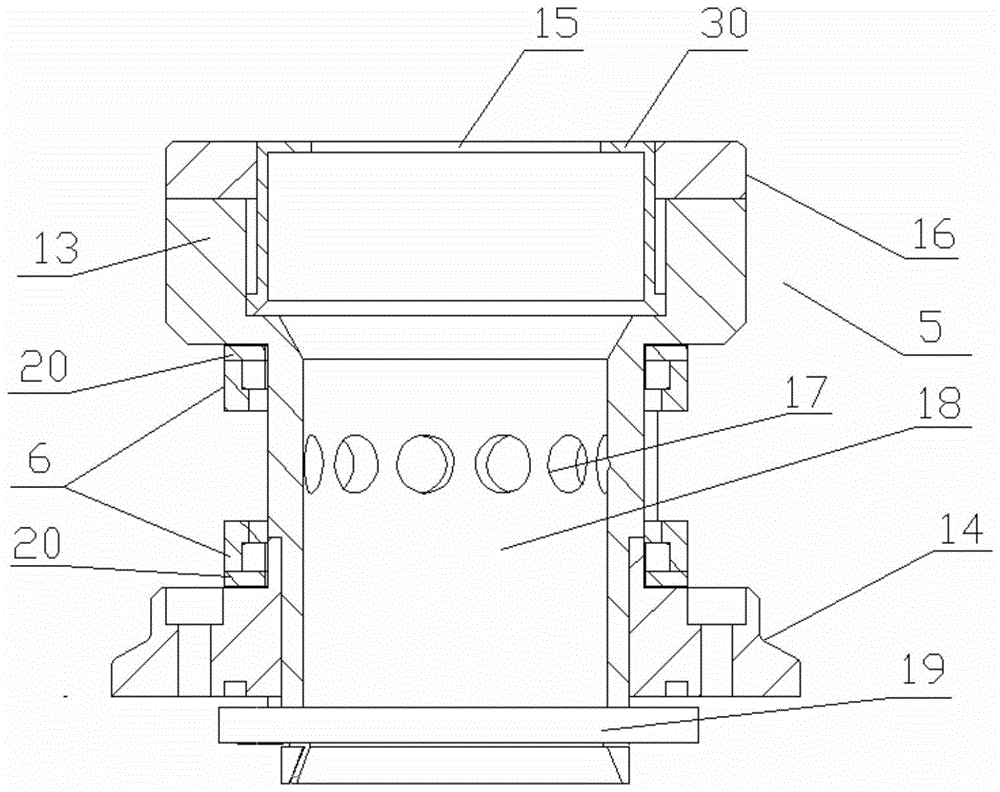

Horizontal activated carbon absorption tower

InactiveCN101987276AReduce sizeSmall pressure lossDispersed particle separationActivated carbonEngineering

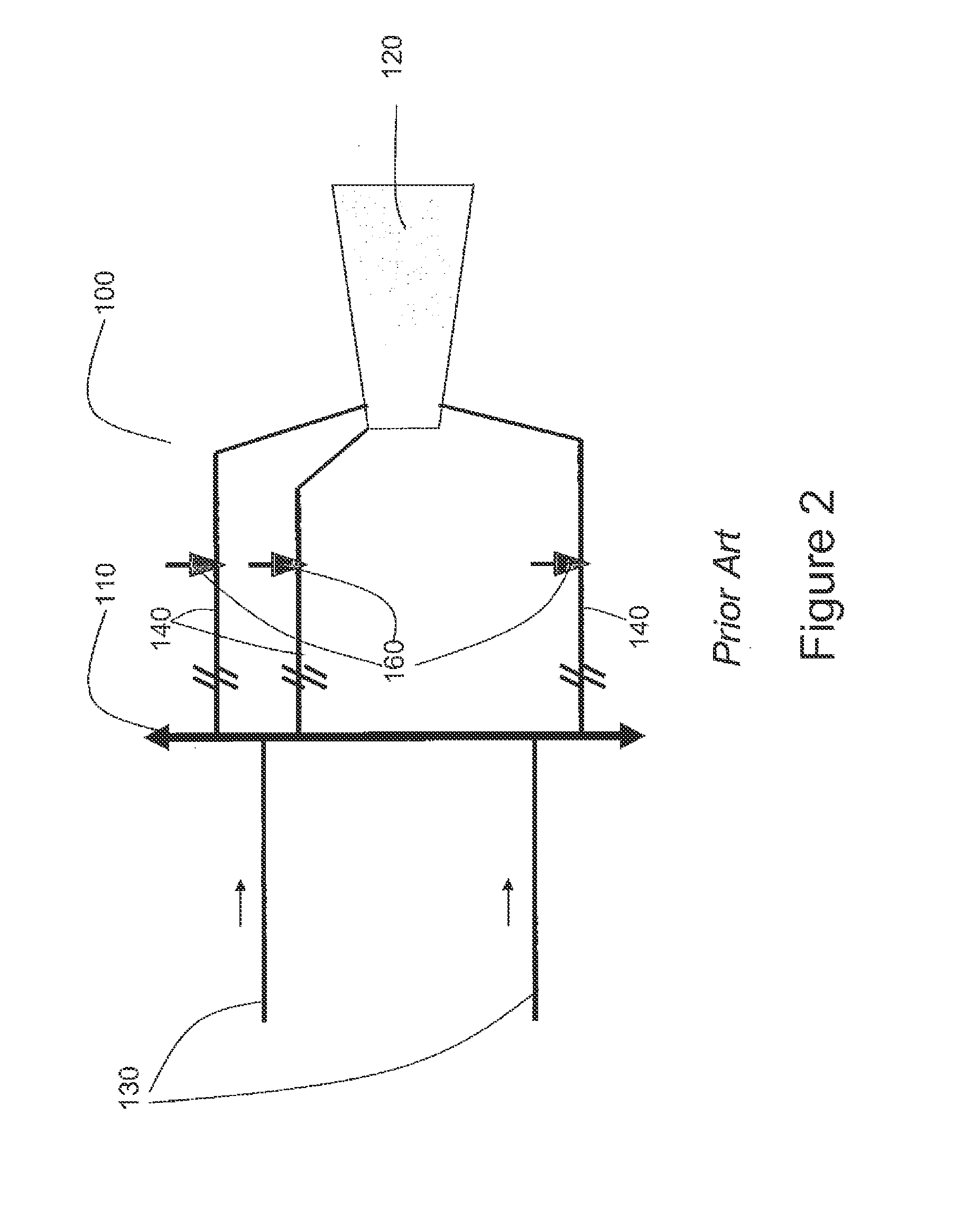

The invention relates to a horizontal activated carbon absorption tower, which relates to the technical field of horizontal activated carbon absorption tower devices in an aspect for carrying out organic waste gas control. The horizontal activated carbon absorption tower comprises an air inlet, an air outlet, a material inlet, a material outlet, a base, separation plates, separation screens, activated carbon and a carbon tower body, wherein both sides of the carbon tower body supported on the base are respectively provided with the air inlet and the air outlet, the upper part of the carbon tower body is provided with the material inlet, the lower part of the carbon tower body is provided with the material outlet, two groups of activated carbon are transversely arranged on the carbon tower body between the air inlet and the air outlet, the separation screens are distributed on the outer periphery of the length direction of each group of activated carbon, and the side wall of each group of activated carbon is vertically provided with two separation plates vertical to the separation screens. The invention achieves the goals of simple structure, convenient installation, easy material discharge and cost saving.

Owner:SUZHOU DINGYU ENERGY EFFICIENT EQUIP

Solar heat collector, its production and usage

InactiveCN1982805BEnhanced convective heat transferReduce designSolar heating energySolar heat devicesThermodynamicsEngineering

Owner:宋惠军

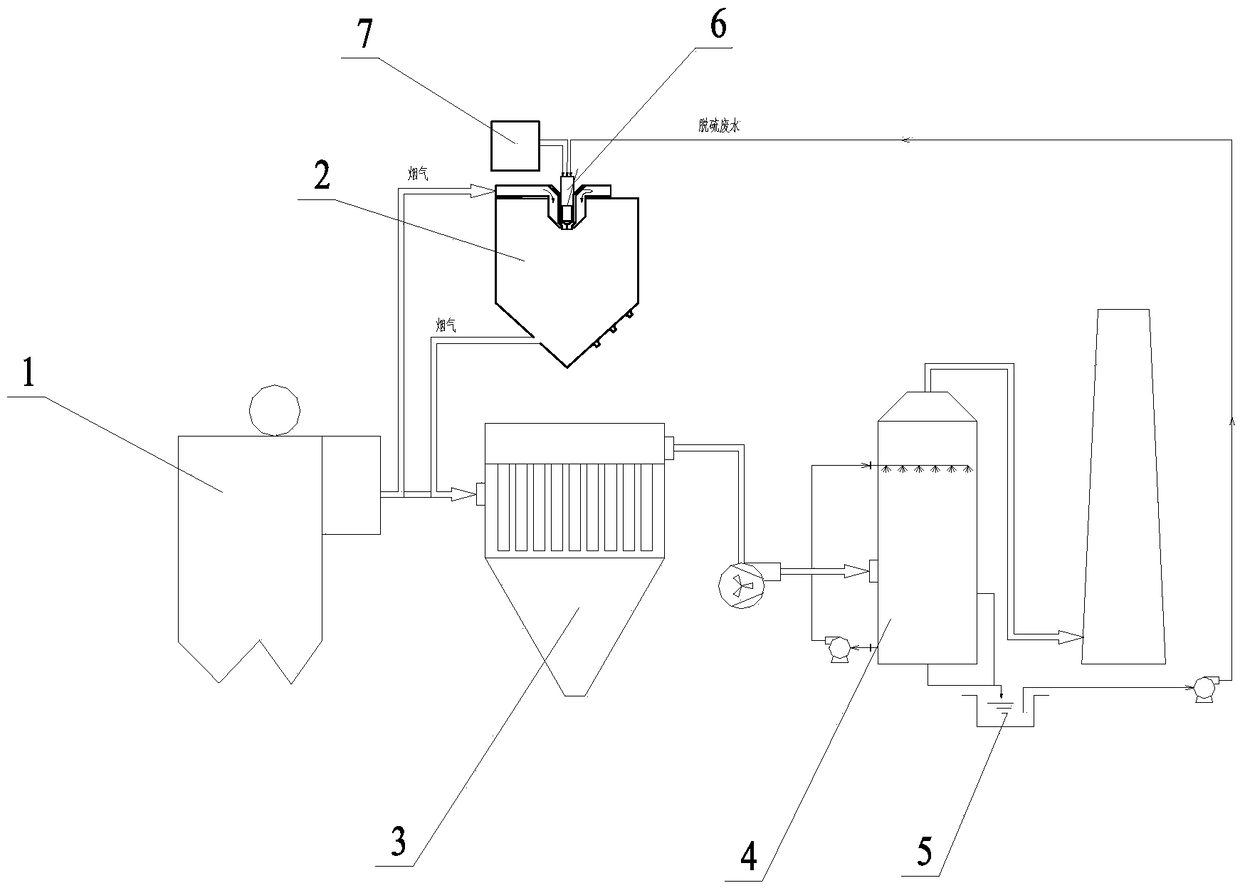

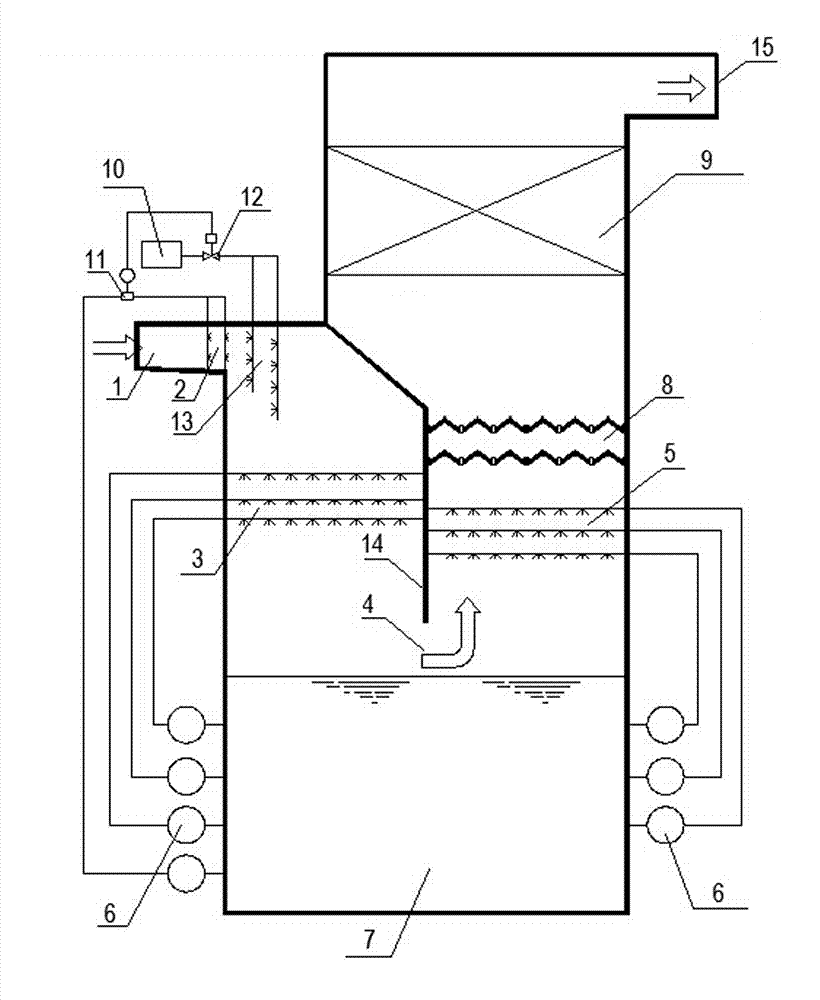

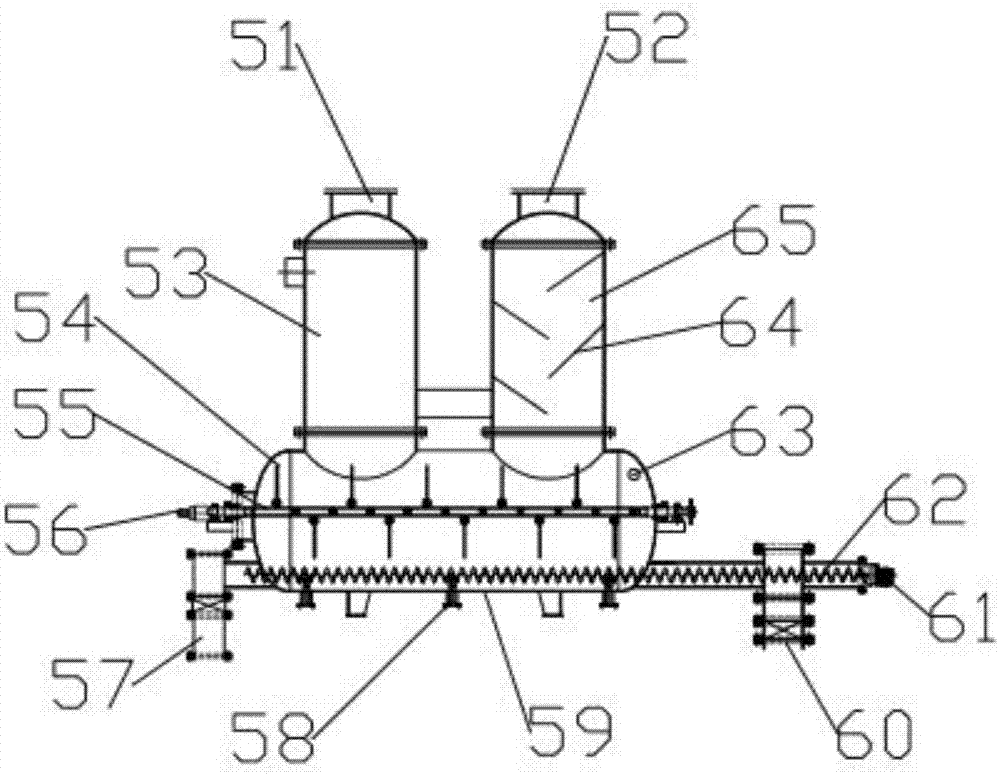

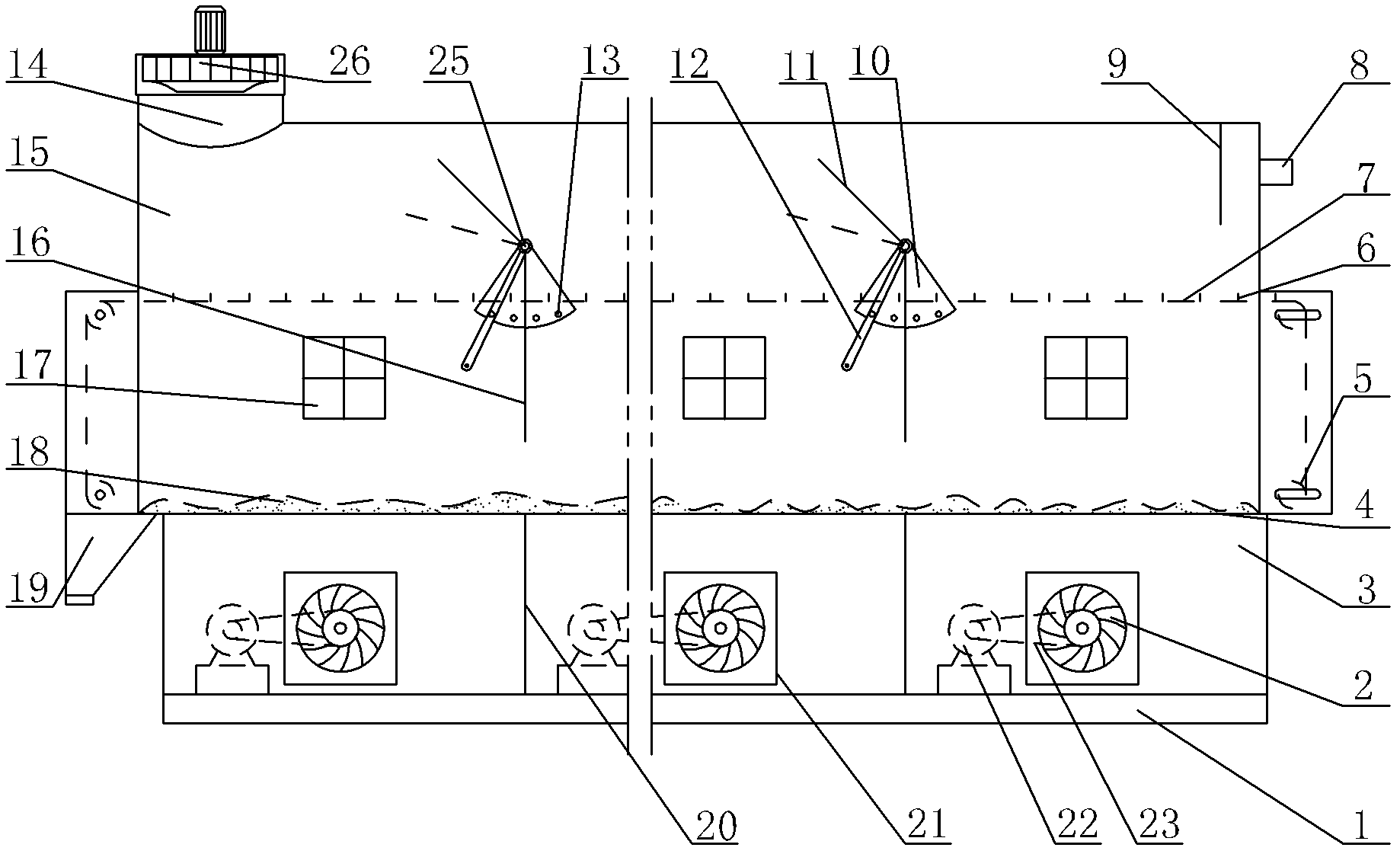

Zero-discharge system for desulfurization wastewater

PendingCN109133234AShort processLess process equipmentWater contaminantsWaste water treatment from gaseous effluentsSludgeProcess engineering

The invention discloses a zero-discharge system for desulfurization wastewater. The zero-discharge system comprises a boiler, a dust remover and a desulfurization tower, which are arranged in sequence; a drying tower is arranged between the boiler and the dust remover; and a rotary atomizer is arranged on the tower top of the drying tower. The rotary atomizer rotates at a high speed and wastewatergenerated by the desulfurization tower is sprayed into the drying tower by the rotary atomizer; and an air flow diversion device is arranged in the drying tower, exhaust gas generated by the boiler enters the drying tower through an exhaust gas inlet and forms a downwards rotating air flow under the diversion of the air flow diversion device, and the rotating direction of the air flow is oppositeto the rotating direction of the rotary atomizer. The zero-discharge system for the desulfurization wastewater provided by the invention is used for wastewater treatment, in which the desulfurizationwastewater is directly atomized by the rotary atomizer and instantaneously evaporated by the hot exhaust gas in the drying tower, therefore no sludge is produced and no heating is needed in the process, so that the construction cost and the running cost of the zero-discharge system for the desulfurization wastewater are greatly reduced.

Owner:江苏海澜正和环境科技有限公司

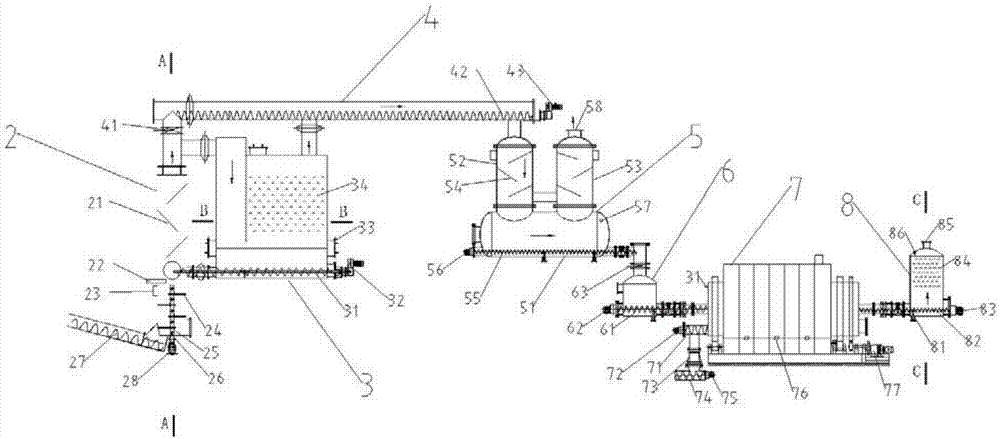

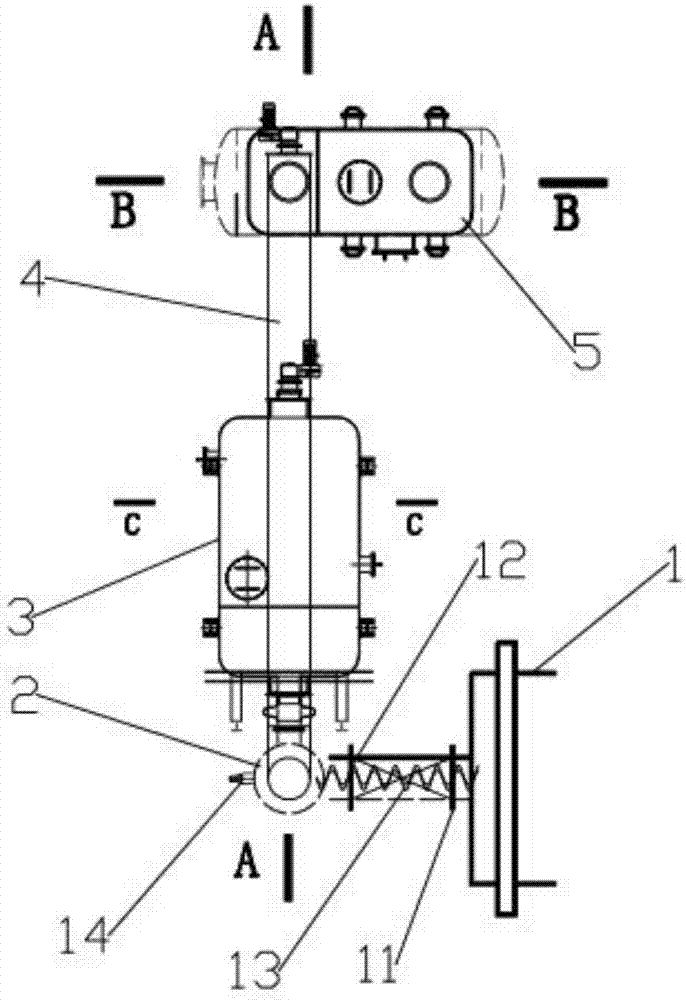

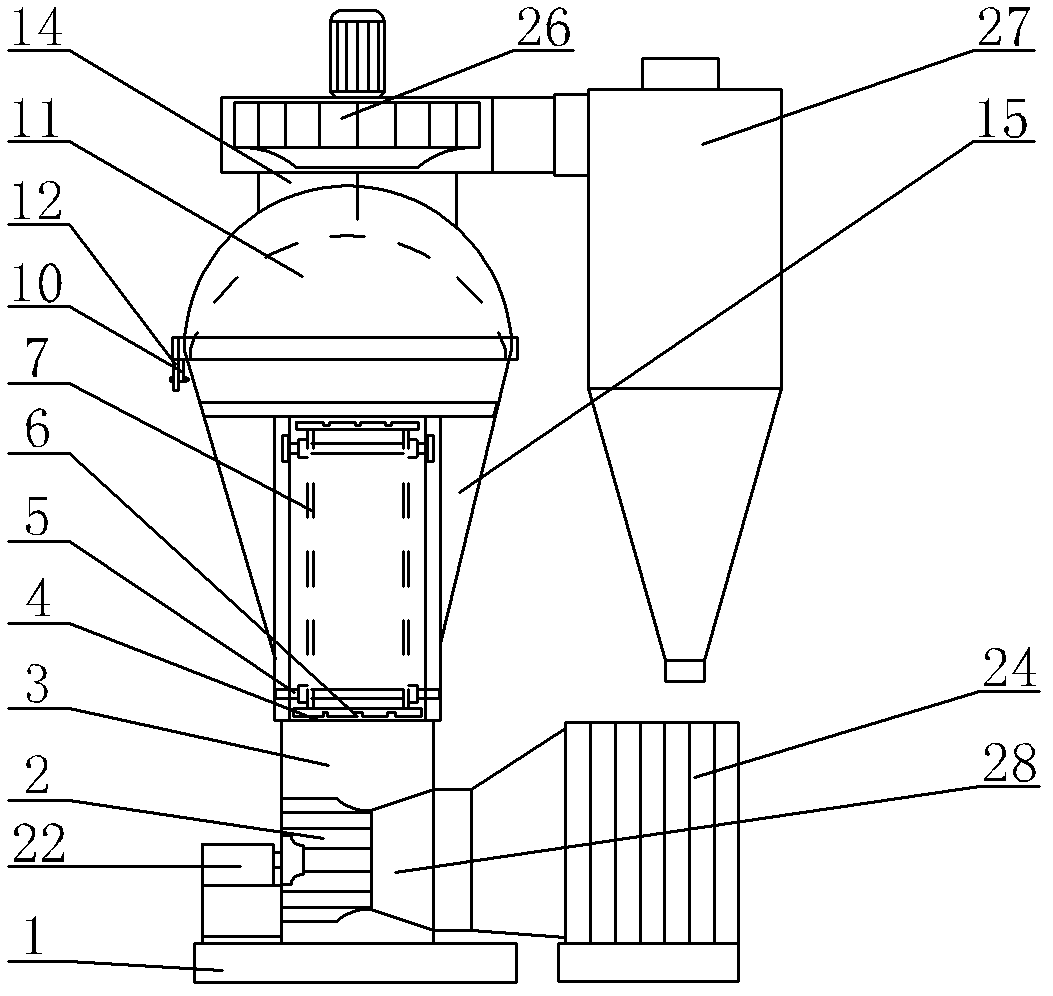

Device for gasifying and reducing high-temperature oil gas, removing dust, cooling, reducing tar, refining and separating

PendingCN107974302ASimple structureReduce wearCatalytic crackingSpecial form destructive distillationTarCoal dust

The invention discloses a device for gasifying and reducing high-temperature oil gas, removing dust, cooling, reducing tar, refining and separating. The device comprises a reaction kettle, a first dust remover, a primary filter, a secondary filter, a refining kettle and a second dust remover which are connected sequentially, wherein the reaction kettle is used for performing dry distillation and gasification reduction on coal; the first dust remover is used for removing a large amount of the dust entrained by the high-temperature oil gas; the primary filter is used for continuously removing the dust from the high-temperature oil gas and reducing heavy tar content; the secondary filter is used for continuously cooling the heavy tar and removing coal dust from the oil gas; the refining kettle is used for further performing gasification and reduction on fatlute through heating catalysis; and the second dust remover is used for performing heating catalysis and gasification-reduction on thegenerated oil gas to further remove the dust. The device has high removal rate of the dust and the heavy tar, can automatically lock gas, can continuously discharge materials, further utilizes the fatlute, increases the additional value of products, improves the quality of products, simplifies the subsequent separation equipment, can realize continuous operation and truly realizes industrializedmass production.

Owner:浙江天禄环境科技有限公司

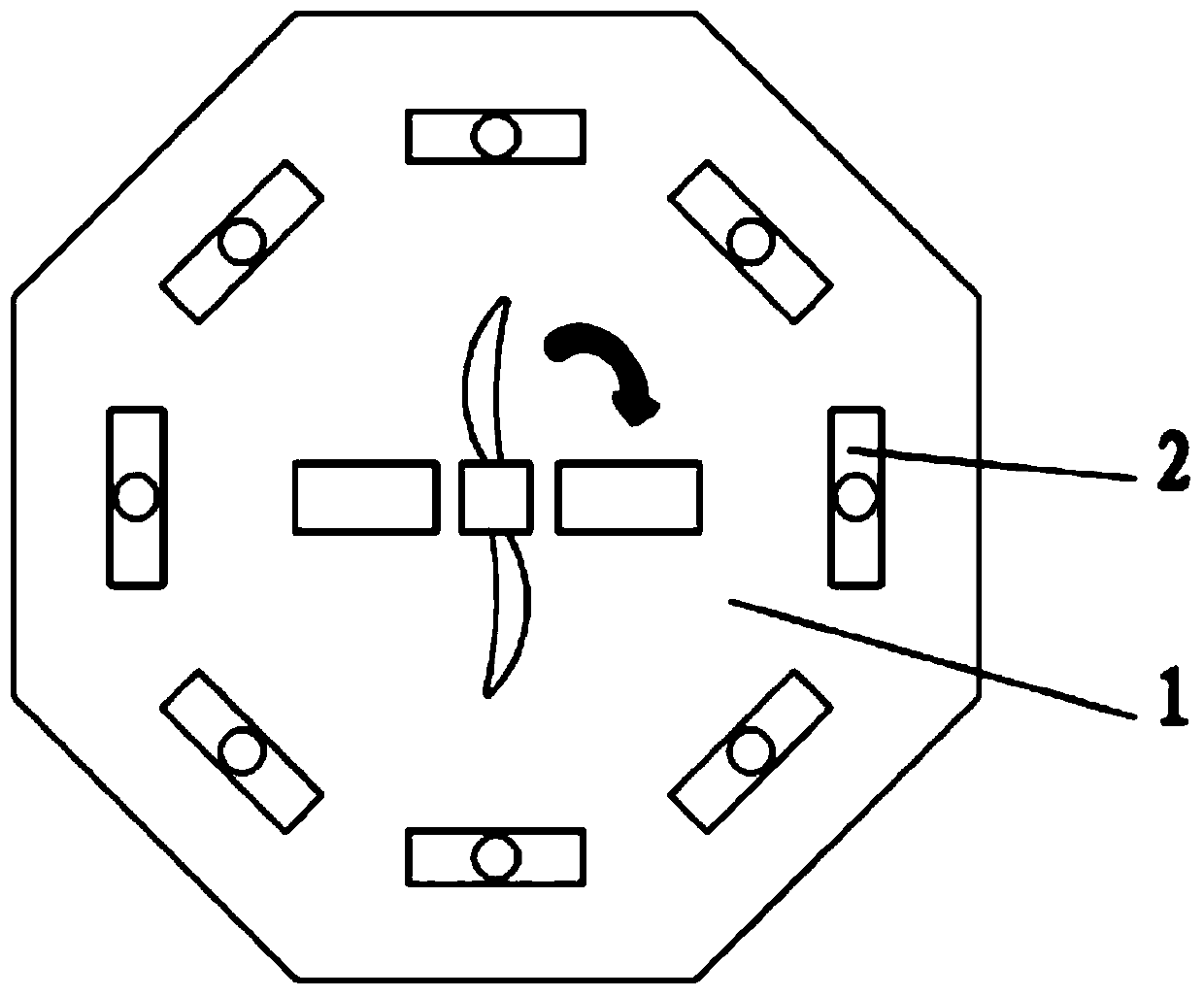

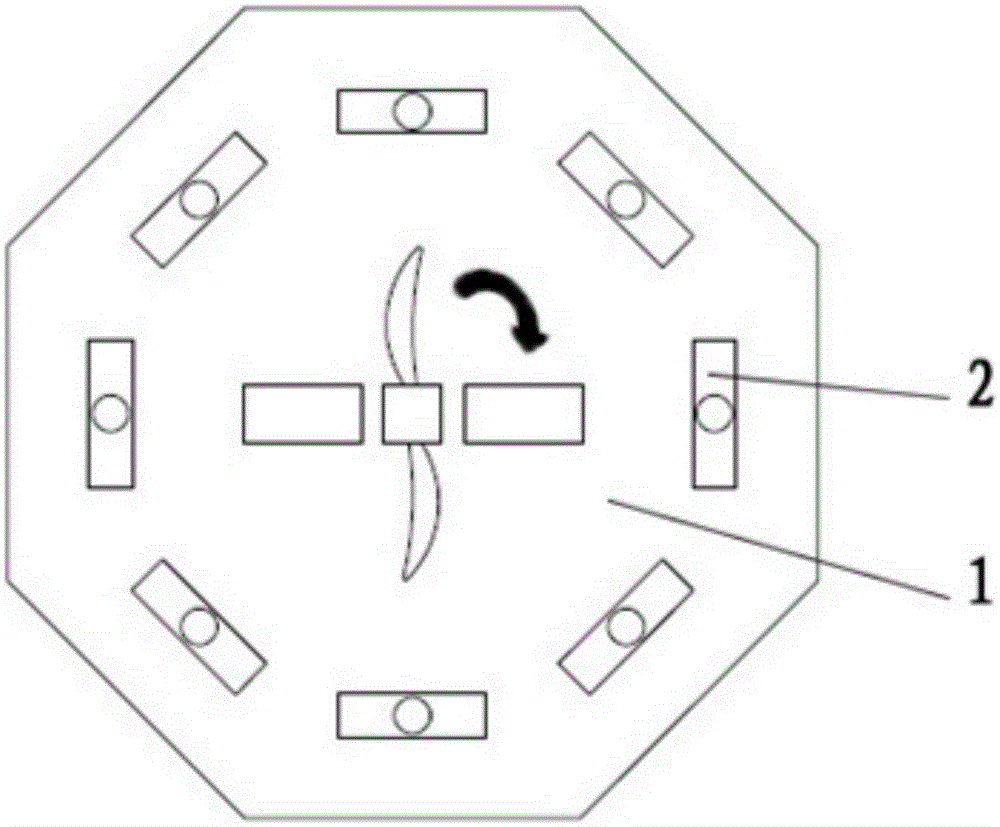

Multi-station forming device for producing paper pulp seedling cup

The invention relates to the technical field of squeezing fiber paper pulp or paper stock producing articles in models during a paper making period, in particular to a multi-station forming device for producing a paper pulp seedling cup. One or more multi-station forming machines are arranged at the inner periphery of a pulp chest; automatic flow control valves are arranged on the multi-station forming machines and are connected with a pulp conveying pipe; a metering pump is arranged on the pulp conveying pipe; a small-size stirrer is further arranged at the center of the pulp chest; an compressed air cylinder and a vacuum cylinder are respectively arranged on the left side and the right side of the small-size stirrer. According to the multi-station forming device disclosed by the invention, multiple stations existing in one chest can be realized; only one pulp conveying pipe is needed even if the number of the work stations is more; pipeline interfaces and pipeline elbows are reduced; the resistances of compressed air and vacuum in a pipeline are also reduced, and the leakage probability is reduced. No excessive pulp, overflow port, overflow groove, pulp reflowing pipe, pulp storage chest for reflowing pulp or pulp returning pump is needed. The investment of equipment is saved, the occupied space of a workshop is reduced, and the energy consumption of multiple circulating pipelines is reduced. The multi-station forming device has the advantages of high efficiency, small occupied area and low energy consumption.

Owner:上海同孚纸制品厂

Deep flue gas purification device for efficient desulphurization and dust removal

The invention relates to a deep flue gas purification device for efficient desulphurization and dust removal. The deep flue gas purification device for efficient desulphurization and dust removal comprises an absorption tower, wherein a slurry pool and a flue gas absorption area located above the slurry pool are arranged in the absorption tower; a circulating slurry spray device is arranged at a flue gas inlet; the flue gas absorption area is partitioned into a first absorption area and a second absorption area located at one side of the first absorption area by a partition plate; a flue gas turn-round channel enabling a flue gas to flow to the second absorption area from the first absorption area is arranged between the partition plate and the slurry pool; the first absorption plate is provided with a first slurry spray layer, and the second absorption area is provided with a second slurry spray layer; the first slurry spray layer, the second slurry spray layer and the circulating slurry spray device are all connected with the slurry pool through a slurry circulation pump; a demister, a dust remover and a flue gas outlet are sequentially arranged above the second slurry spray layer from bottom to top. The device synchronously realizes deep purification in flue gas desulphurization and dust removal in one piece of equipment, thus reducing the height of the absorption tower, reducing the flowing resistance of the flue gas, saving the building expense, and reducing the running cost.

Owner:YONKER ENVIRONMENTAL PROTECTION

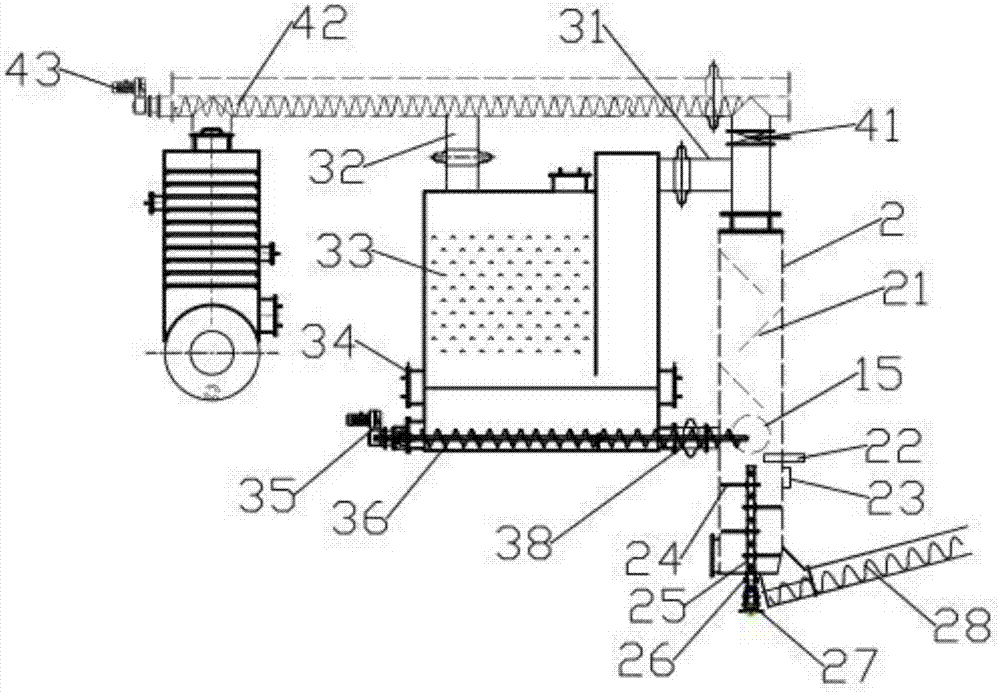

Lignite gasification-reduction three-stage dust removal cooling and automatic air lock device

PendingCN107880944APrevent bridgingSolve the high temperature semi-coke bridging phenomenonCombination devicesGasification processes detailsThree stageTar

The invention discloses a lignite gasification-reduction three-stage dust removal cooling and automatic air lock device, which is characterized by comprising a first filter, a second filter, a round pipe and a third filter which are sequentially connected with a first air outlet of a reaction kettle, wherein the first filter is used for receiving dust-containing high-temperature oil gas exhaustedfrom the first air outlet; the second filter is used for removing a large amount of dust and heavy tar in the high-temperature oil gas from the first gas inlet; L-shaped angle steel for dust removal is arranged at the inside; a reverse-eight-shaped rectangular baffle plate is connected in a sealed way; the round pipe is connected with three filters; a valve is arranged at a part connected with thefirst filter; the third filter is used for cooling the tar and dust-containing particles. The device provided by the invention has the advantages that automatic gas lock and continuous material discharging are realized; the content removal rate of the dust-containing particles and the heavy tar is high; the product quality is greatly improved; equipment is simplified for subsequent coke oven gasand light tar separation; the quality is improved; the continuous operation can be realized; the industrial mass production is really realized.

Owner:浙江天禄环境科技有限公司

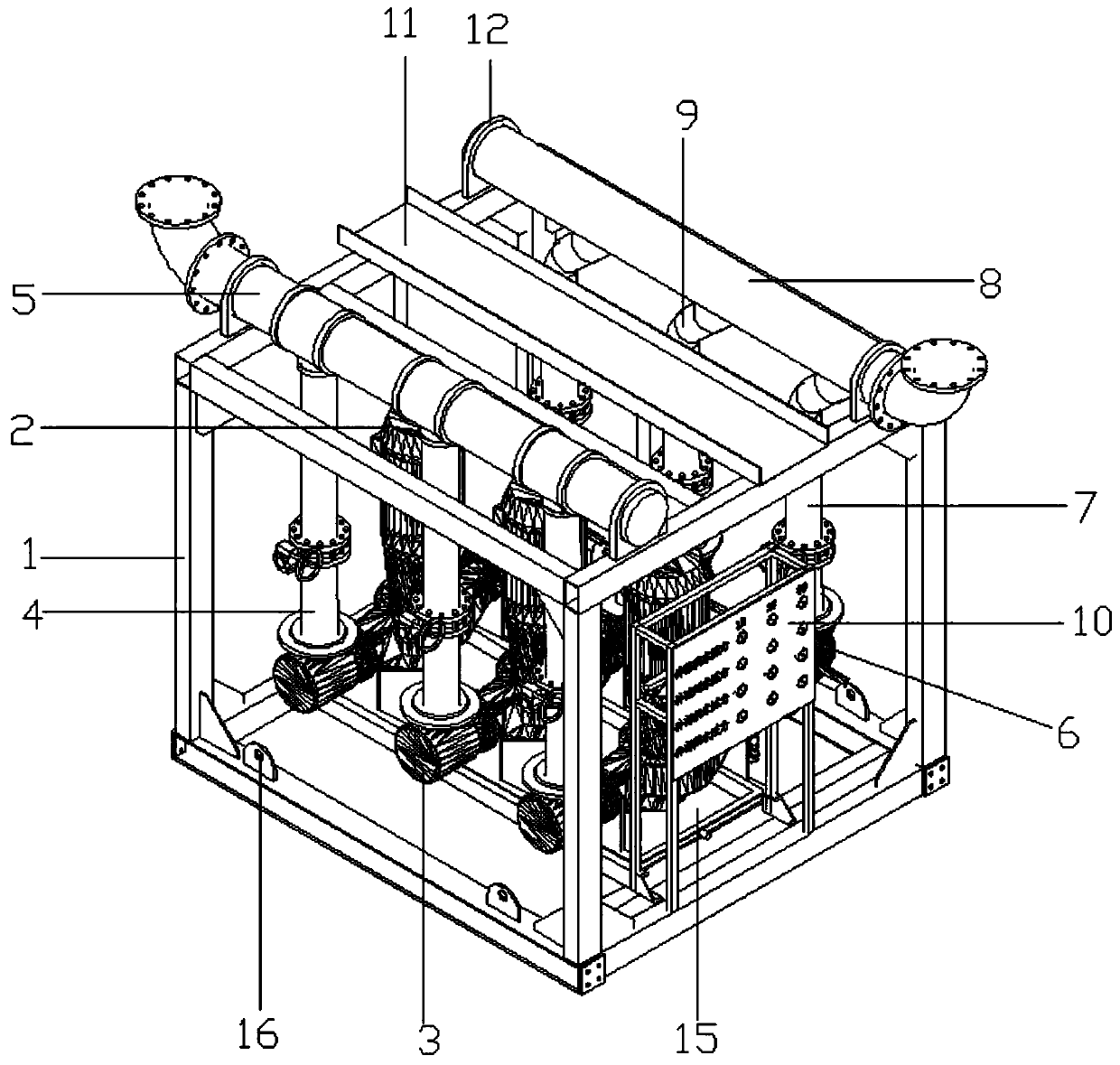

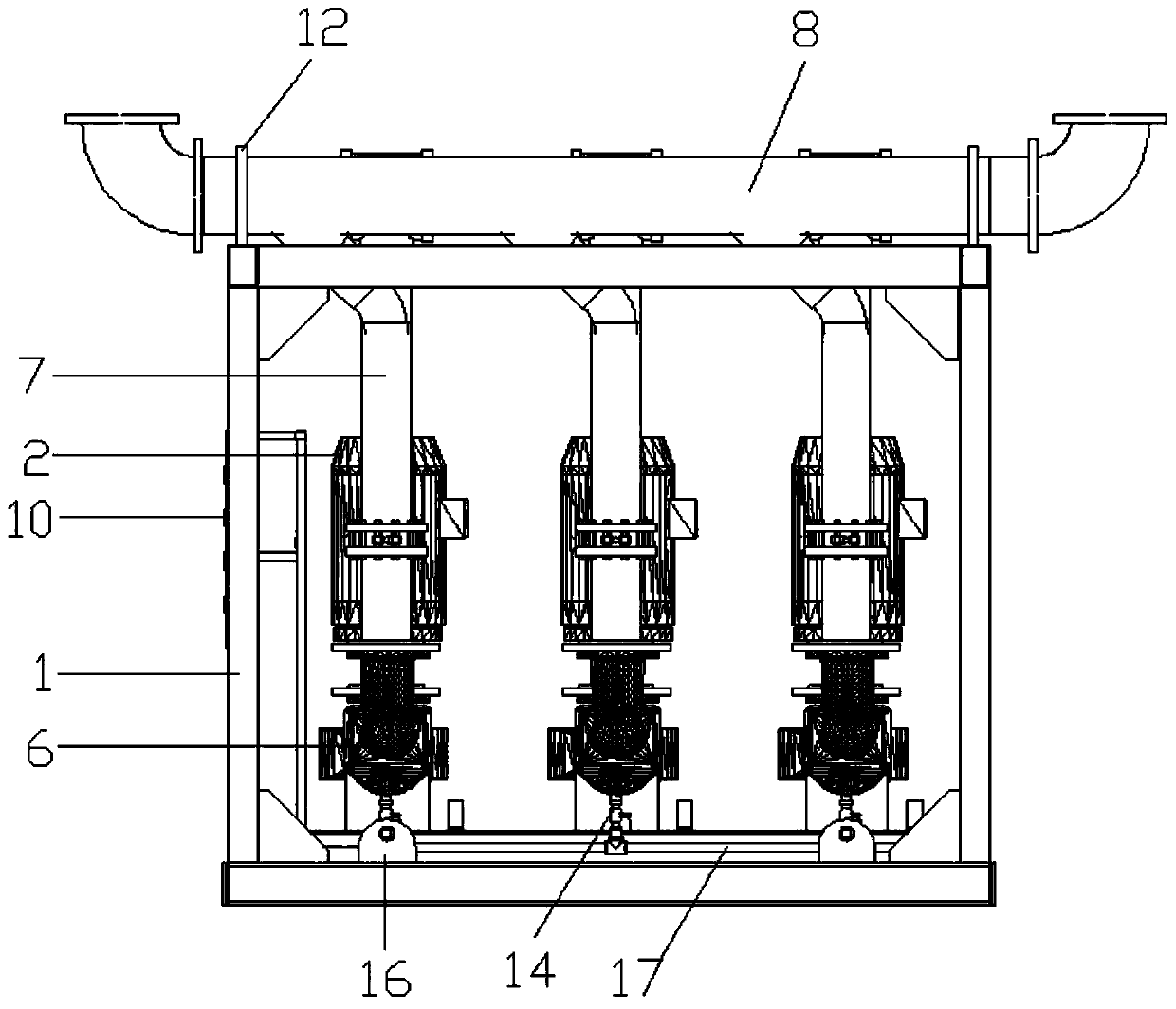

Intelligent fluid pump group

PendingCN110425152AHigh concentricitySimple designSubstation/switching arrangement detailsPump componentsImpellerDynamic balance

The invention provides an intelligent fluid pump group. The intelligent fluid pump group comprises an H steel frame, and at least two intelligent variable-frequency pumps are installed at the bottom of the H steel frame; water inlets of the intelligent variable-frequency pumps are connected with suction fluid directors, and the suction fluid directors are connected with a first water collection pipe installed at the top end of the H steel frame through first vertical pipes; and water outlets of the intelligent variable-frequency pumps are connected with connecting pipes, the connecting pipes are connected with multifunctional valves, and the multifunctional valves are connected with a second water collection pipe installed at the top end of the H steel frame through second vertical pipes.According to the intelligent fluid pump group, noise and vibration are low in the running process, the occupied area and space are small, the intelligent fluid pump group does not need to depend on anexternal sensor, and therefore the pumping efficiency is improved to the maximum limit; and the concentricity of the intelligent variable-frequency pumps is high, pump shafts and motor shafts are positioned by adopting machining connecting steel frames and connected through rigid couplers, impellers achieve dynamic balance design, and flow channels achieve optimization design.

Owner:济南金孚瑞供热工程技术有限公司

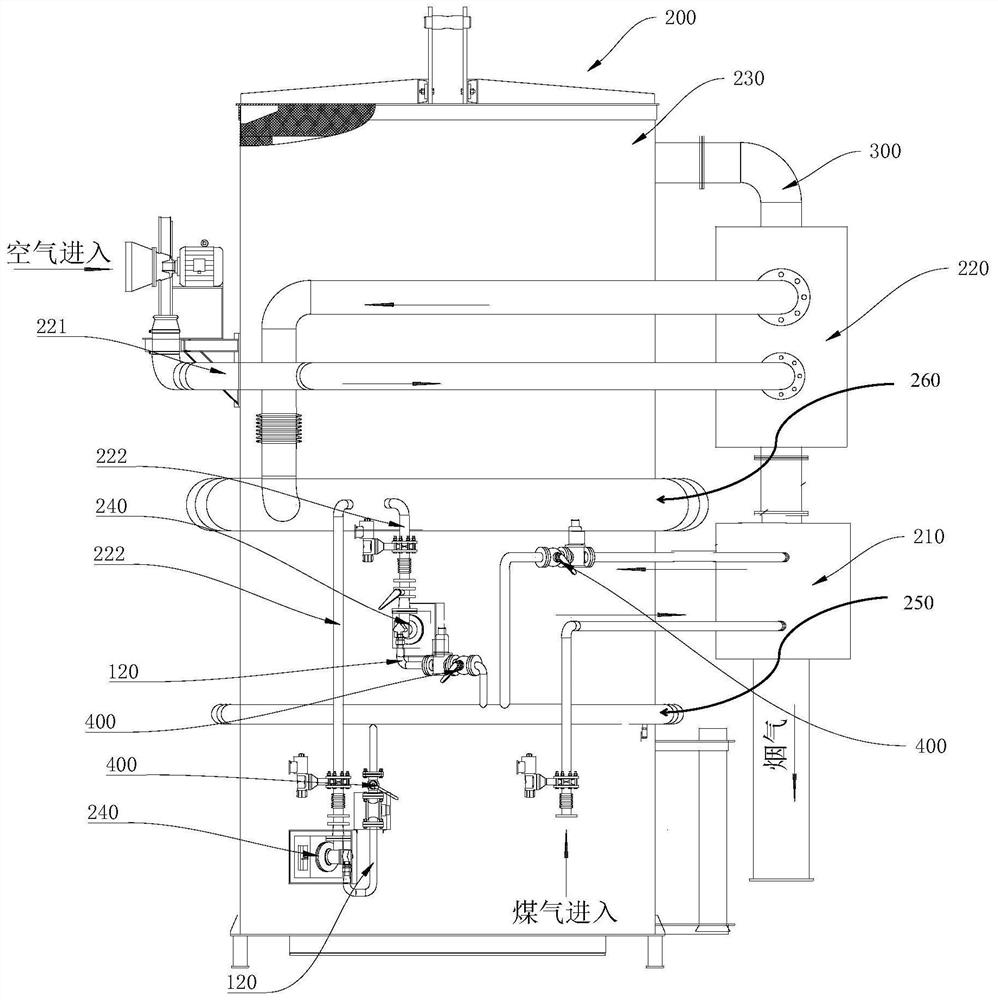

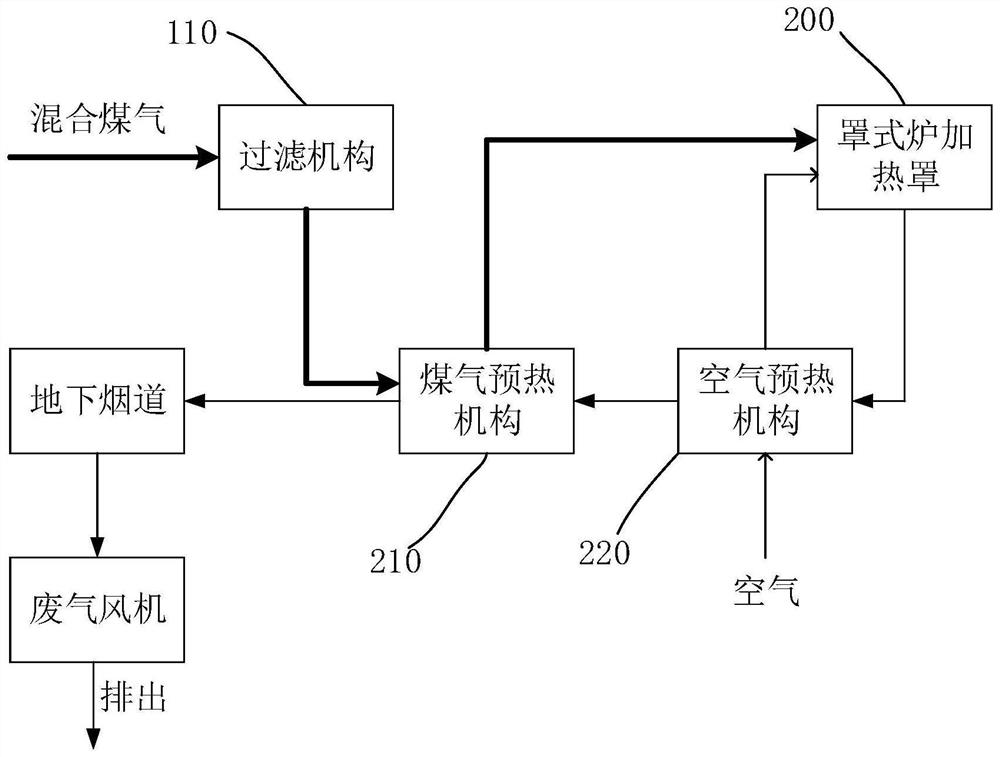

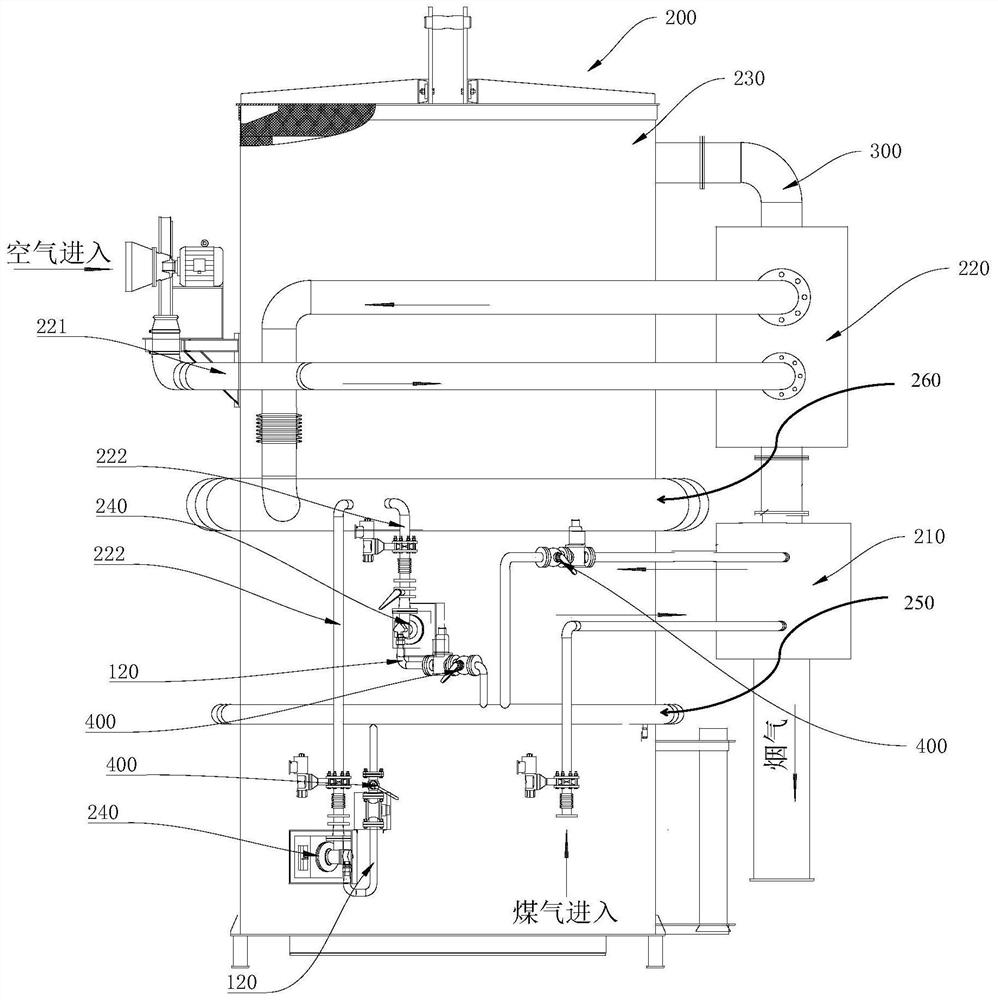

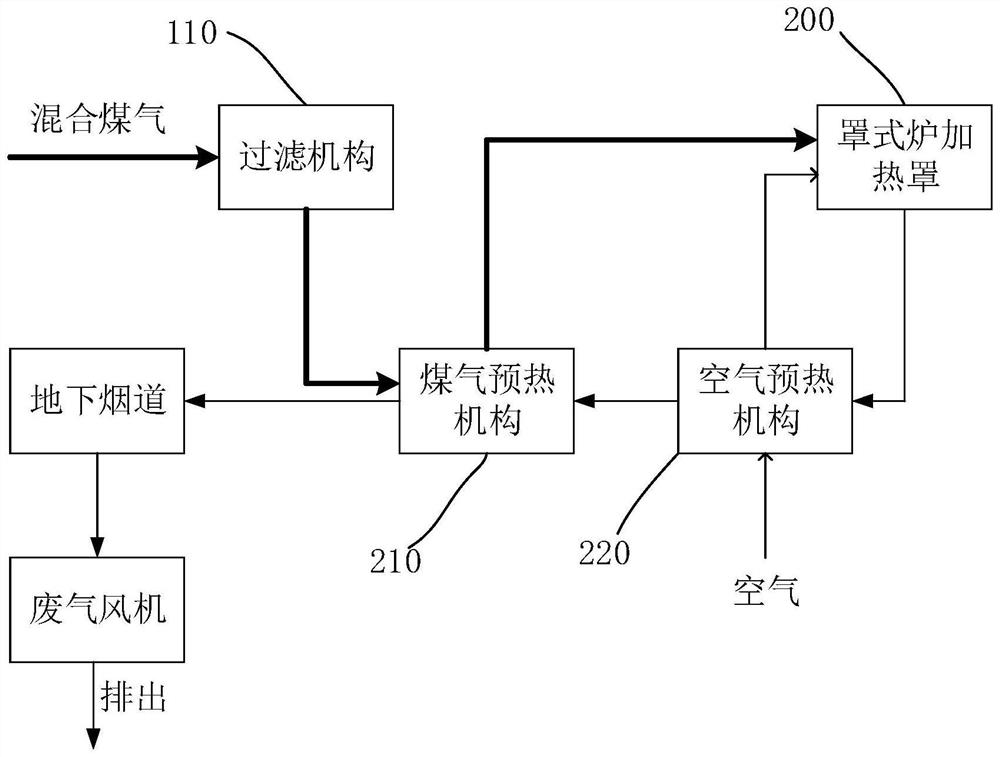

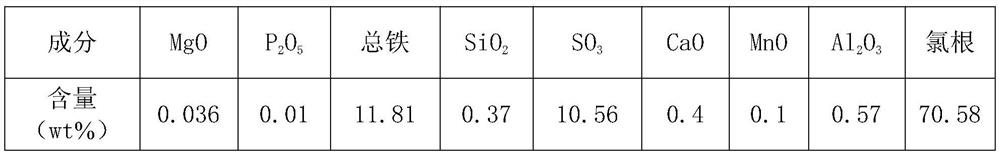

Bell-type furnace heating mantle and operation method thereof

PendingCN112460987ASimple structureImprove reliabilityIndirect carbon-dioxide mitigationBell type furnacesThermodynamicsGas supply

The invention provides a bell-type furnace heating mantle and an operation method thereof. The bell-type furnace heating mantle comprises a body, a burner arranged in the body and a gas inlet pipelinearranged outside the body; and the gas inlet pipeline communicates with the burner to supply gas, and the gas inlet pipeline is provided with a gas preheating mechanism for preheating mixed gas in the pipeline of the gas inlet pipeline. According to the bell-type furnace heating mantle, by preheating the mixed gas received by the gas inlet pipeline, salt substances in the mixed gas can be in an aerosol state, and the probability that the salt substances crystallize at places such as elbows, reducing parts and valves on the gas pipeline and the bell-type furnace heating mantle, which cause theconductance change of the mixed gas, to form blockage can be reduced; and meanwhile, naphthalene and tar are in an aerosol state, and the viscosity is reduced, so that the probability of blockage caused by adhesion at the gas conductance change places is reduced, and therefore, a bell-type furnace heating mantle pipeline and accessory equipment are not prone to blockage.

Owner:湖南华菱涟源钢铁有限公司

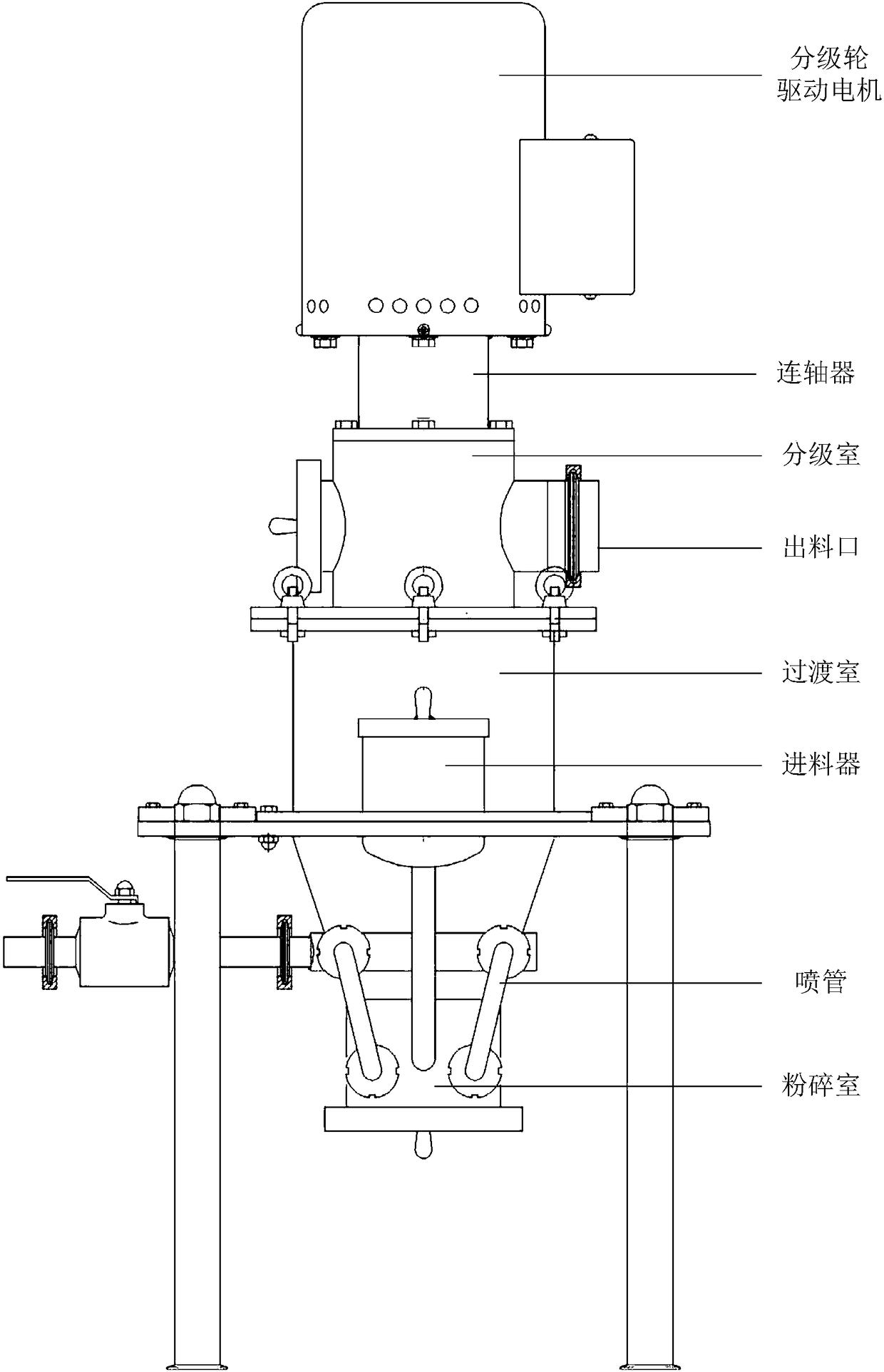

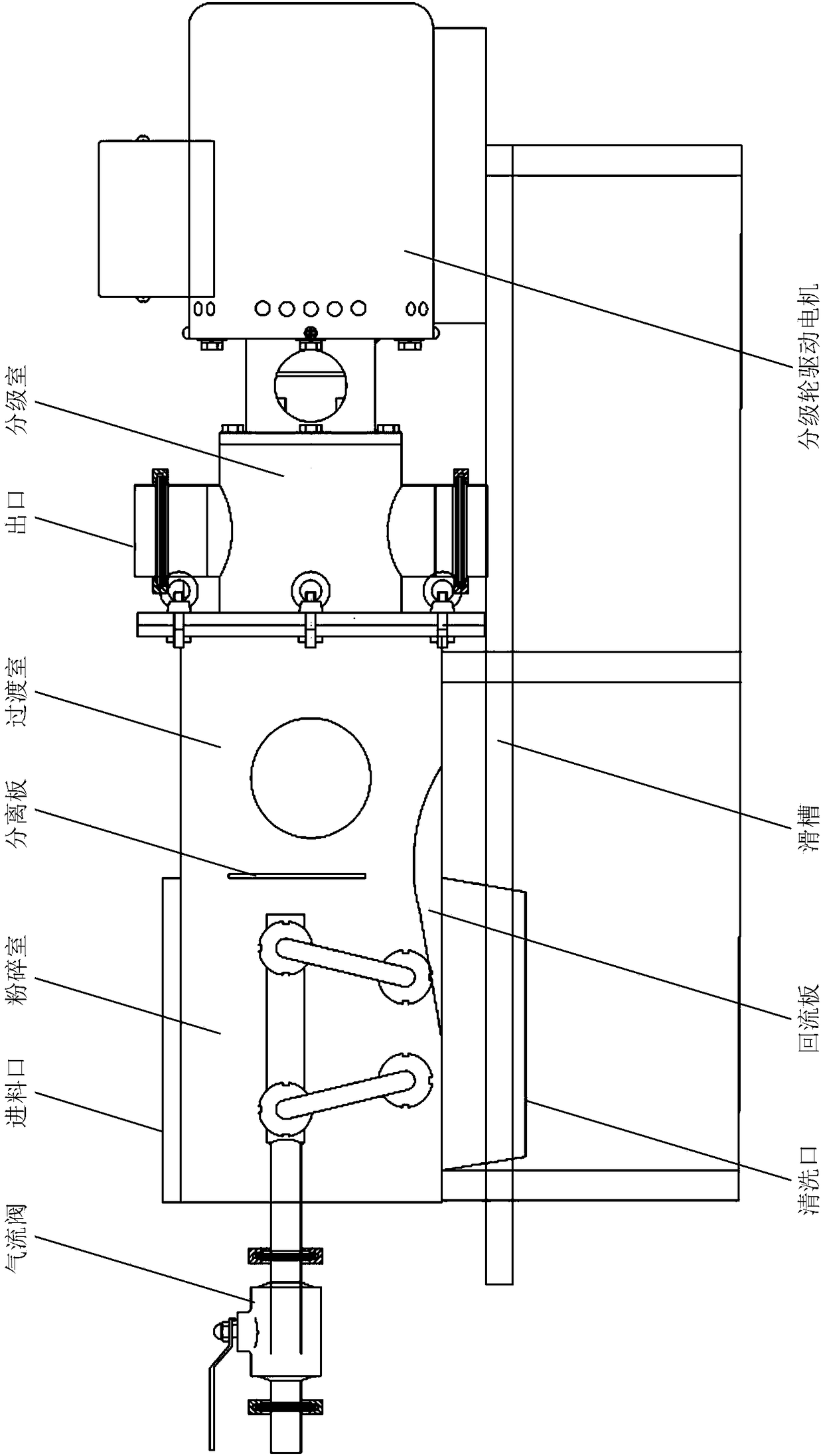

Horizontal fluidized bed jet mill

ActiveCN108114793ALower the altitudeObvious advantagesGrain treatmentsPlastic recyclingFluidized bedEngineering

The invention discloses a horizontal fluidized bed jet mill which comprises a crushing chamber, a transition chamber, a grading chamber as well as a separation plate and a backflow plate, wherein a grading wheel is arranged inside the grading chamber; the crushing chamber, the transition chamber and the grading chamber are communicated in a horizontal direction; the separation plate is positionedbetween the crushing chamber and the transition chamber and is used for partitioning the crushing chamber from the transition chamber; and the separation plate is of a porous structure. The inventionaims to improve equipment efficiency and solve the problems that a conventional fluidized bed jet mill is cumbersome and hard to operate.

Owner:廊坊新龙立机械制造有限公司

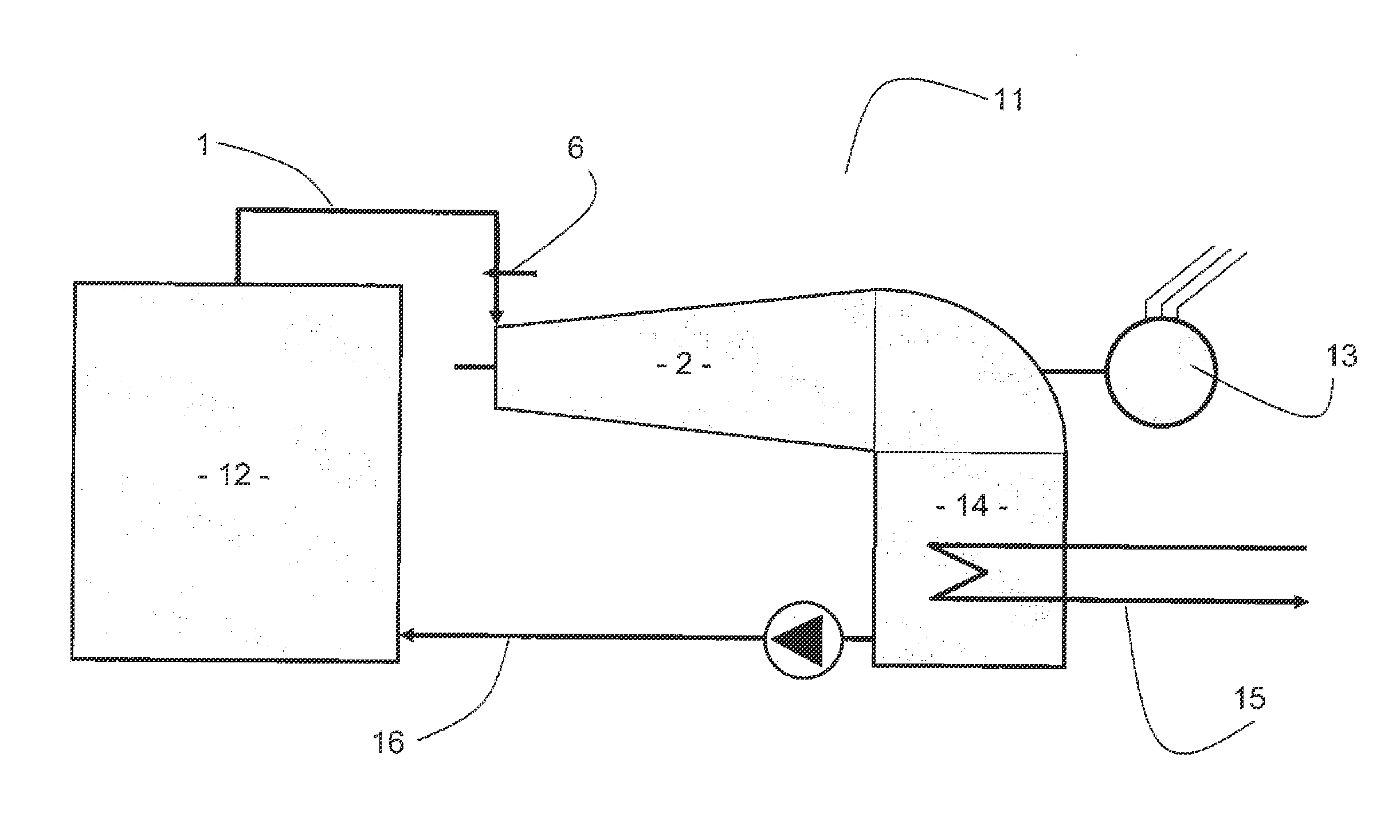

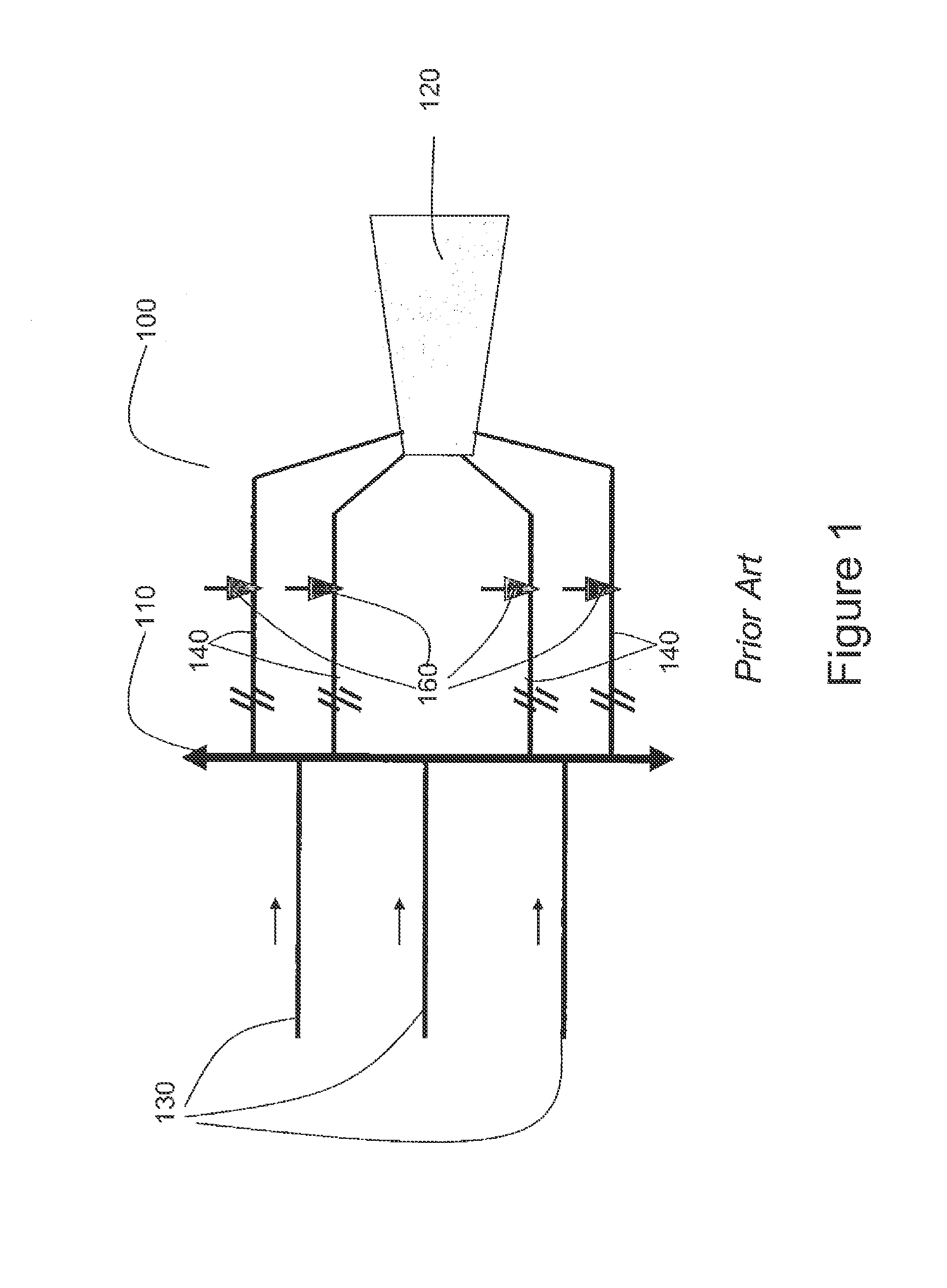

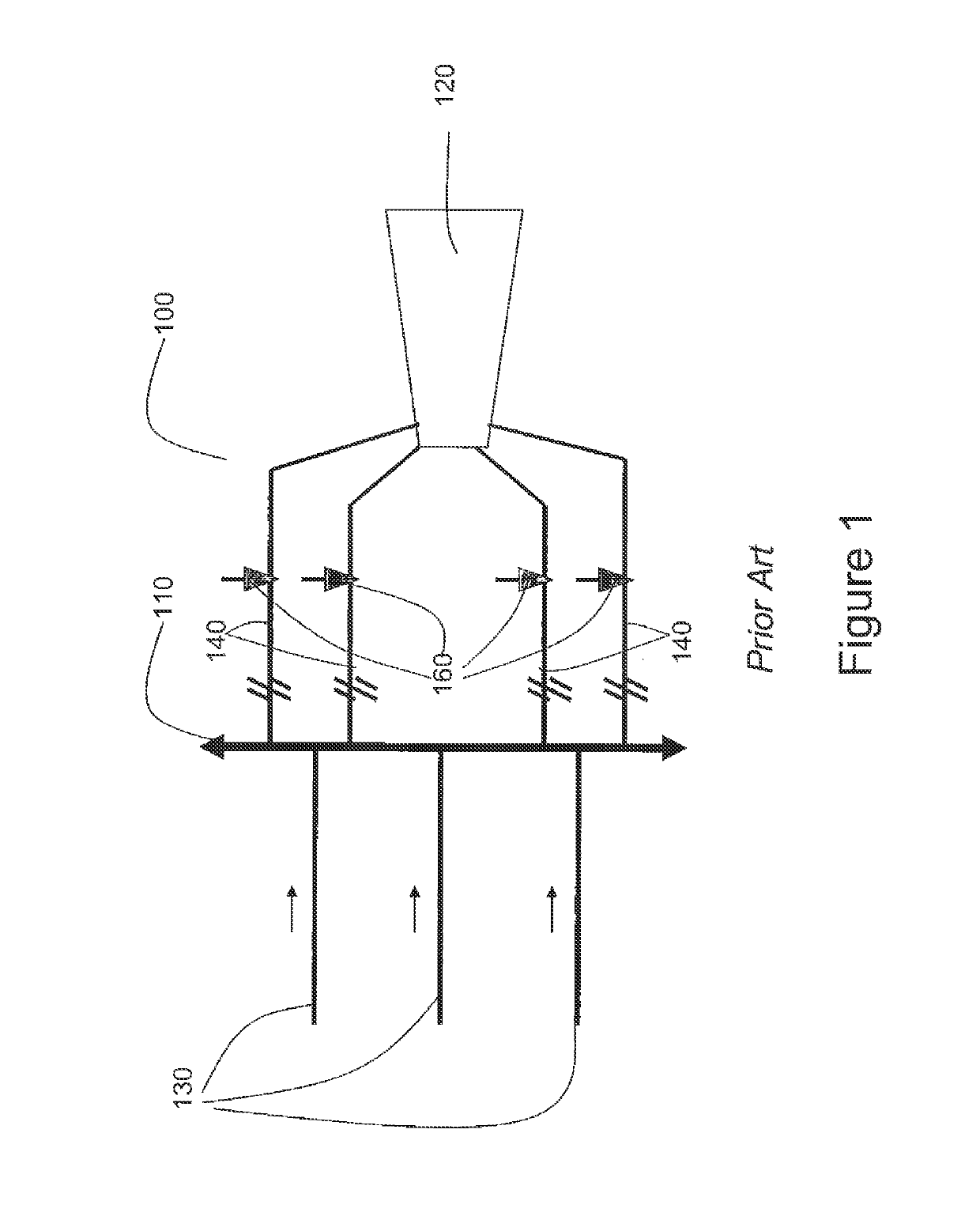

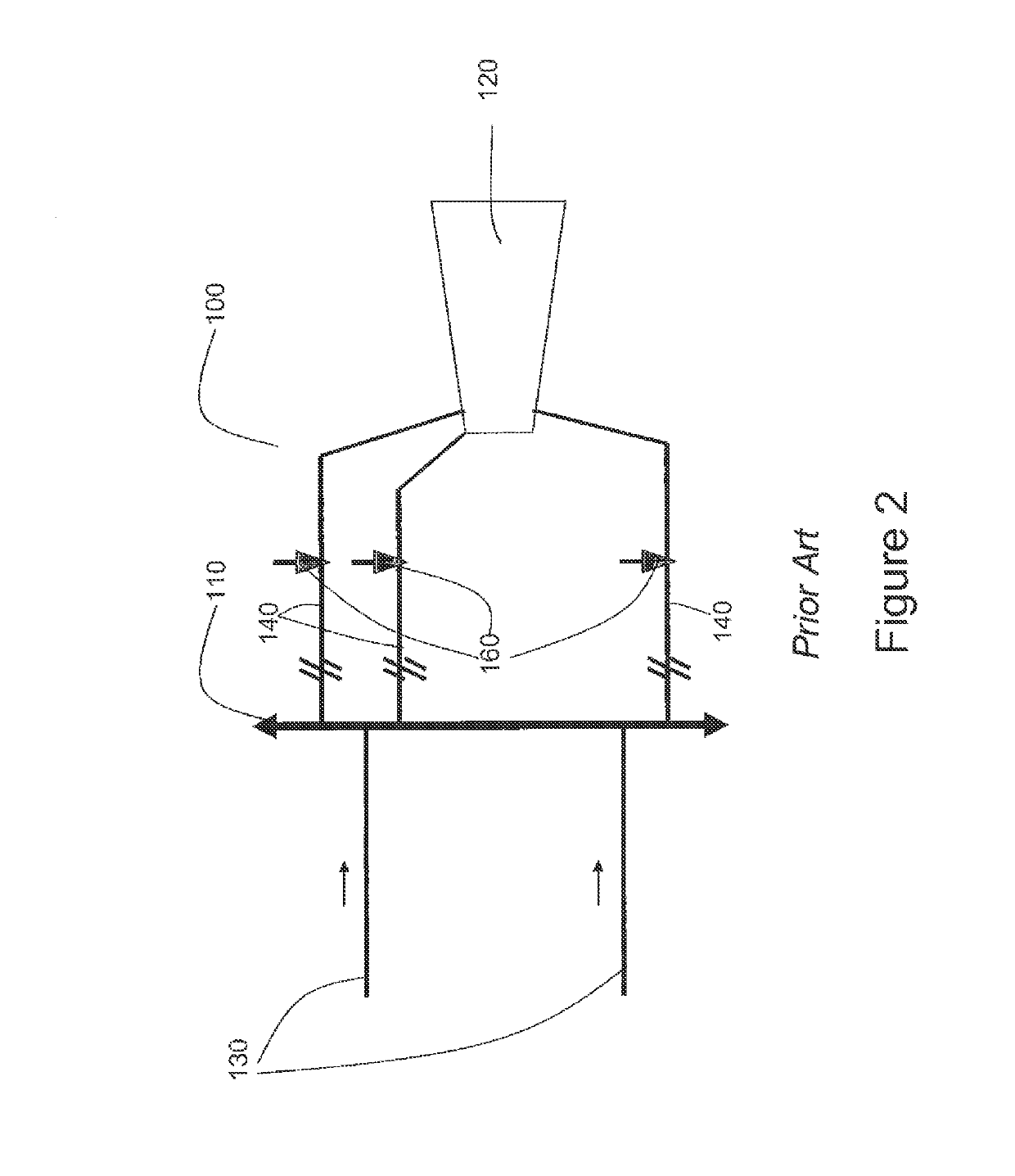

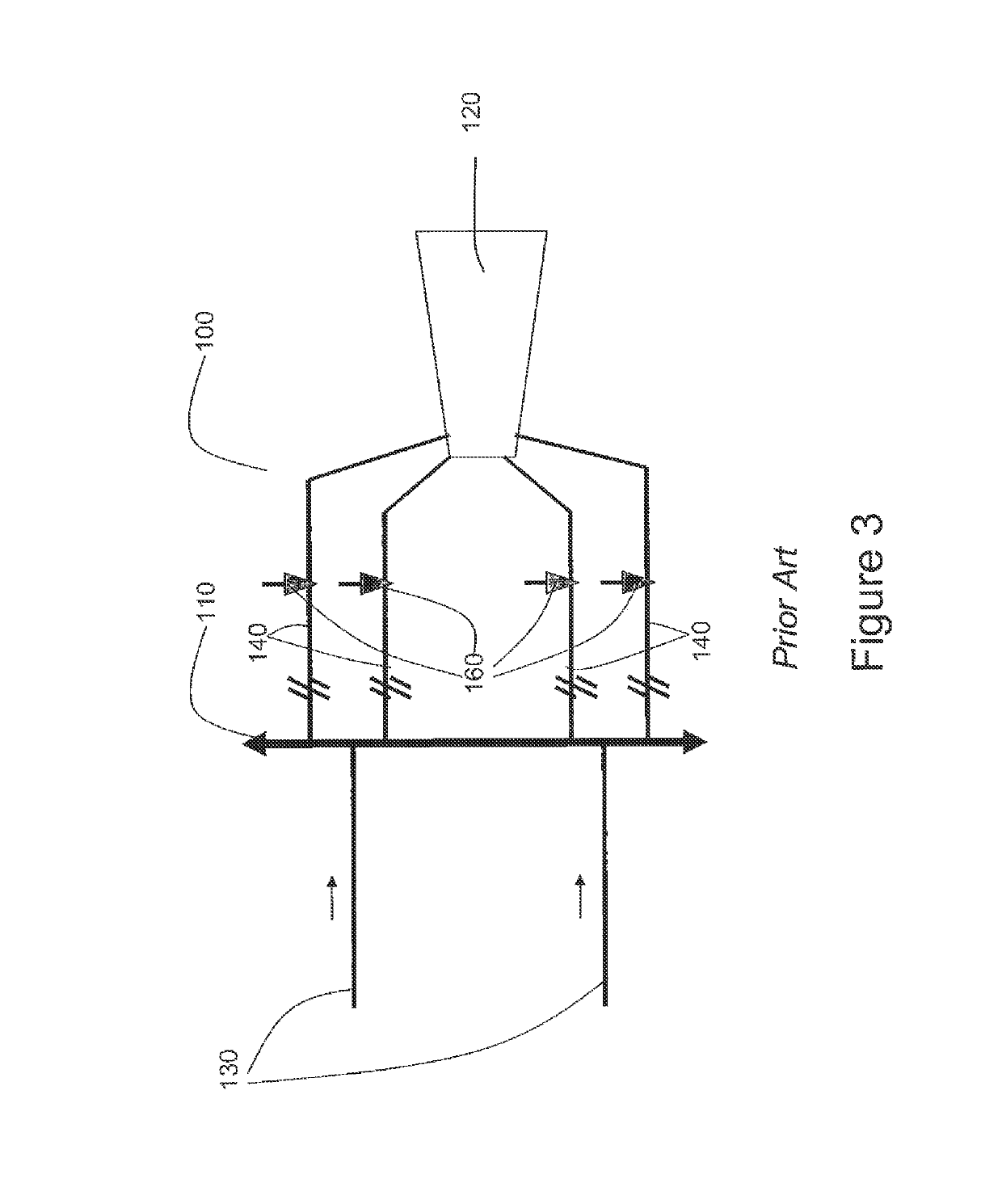

Steam supply circuit from a turbine

ActiveUS20140030068A1Reduce elbowLower overall pressure dropGas turbine plantsEngine componentsEngineeringTurbine

The technical field of the invention is steam turbines including a steam feed circuit based on a functional steam generator set that may be nuclear- or fossil-fuel powered, and in particular a steam feed circuit (1) of a turbine (2), comprising n main steam lines (3) and n′ steam admission lines (4) to the turbine, the number n′ of steam admission lines (4) to the turbine being strictly greater than the number n of main steam lines (3), characterized in that there are n direct steam admission lines (5) to the turbine linking the as main steam lines (3) directly to the steam admission lines (4) to the turbine.

Owner:GENERAL ELECTRIC TECH GMBH

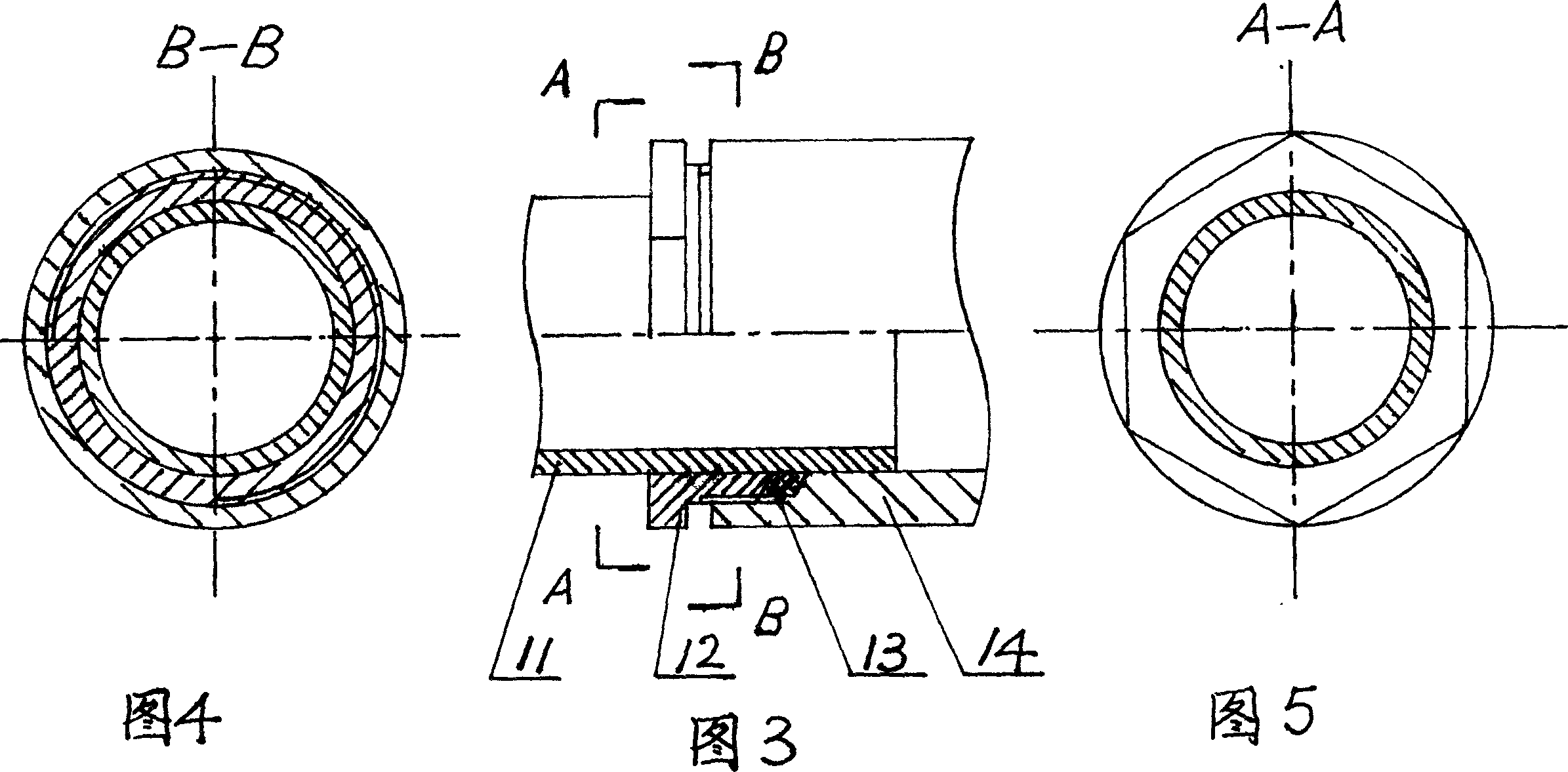

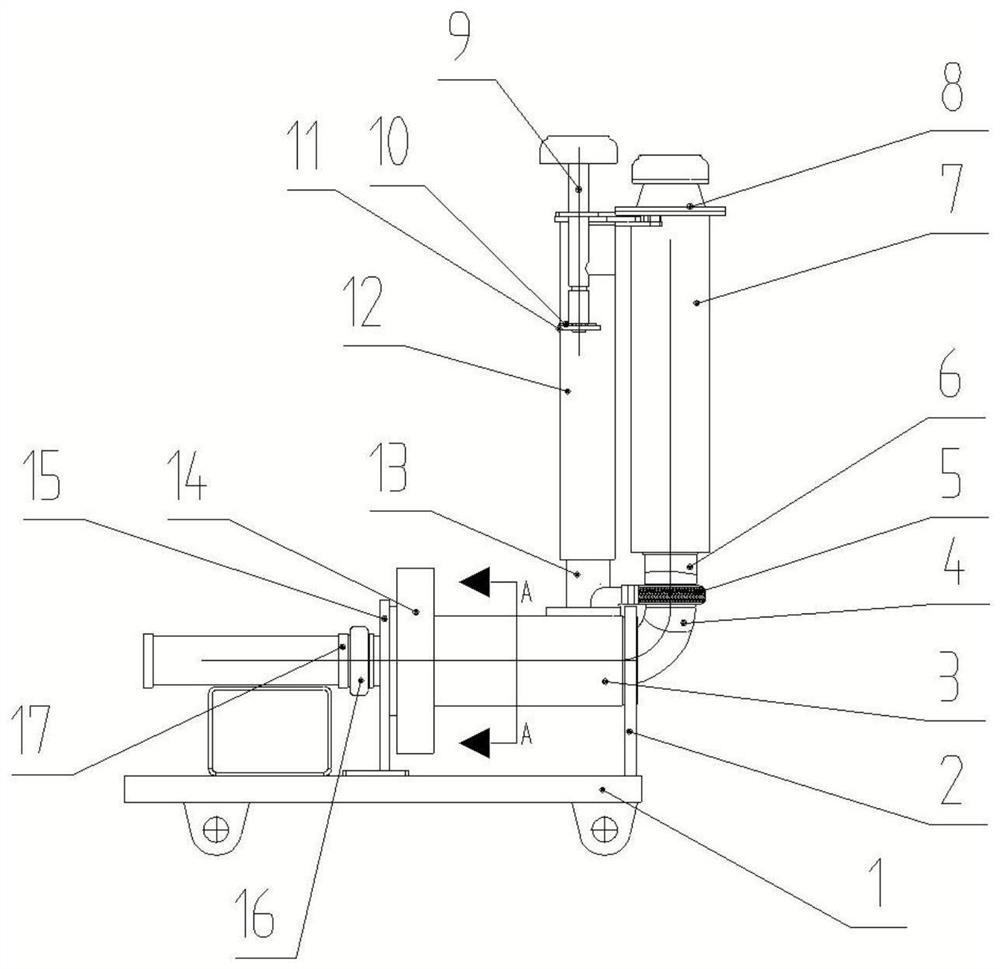

Burner for pulverized coal gasifier

ActiveCN105132037BAvoid burnsSolve high temperature oxidationGranular/pulverulent flues gasificationCoal pipelineEngineering

A burner for a pulverized coal gasifier. The present invention relates to a burner. The present invention solves the problem of complex manufacturing process, high manufacturing cost, inconvenient disassembly and maintenance, and The problem of short service life, which includes at least one layer of shielding gas pipeline, gasification agent pipeline, pulverized coal pipeline, first swirl blade, second swirl blade and flange; gasification agent pipeline is sleeved on at least one layer of protection Outside the gas pipeline, the pulverized coal pipeline is sleeved outside the gasification agent pipeline, the flange is sleeved on the outer wall of the pulverized coal pipeline, and the first swirl vane is set on at least one layer of the outer wall of the protective gas pipeline and the inner side of the gasification agent pipeline Between the walls, the second swirl vane is set between the outer wall of the gasification agent pipeline and the inner wall of the pulverized coal pipeline, and the top of the pulverized coal pipeline is provided with a pulverized coal airflow inlet, and the top of the gasification agent pipeline is provided with a gas flow inlet. The inlet of the protective gas is provided at the top of at least one layer of the protective gas pipeline. The invention is used in a coal gasification device.

Owner:HARBIN INST OF TECH

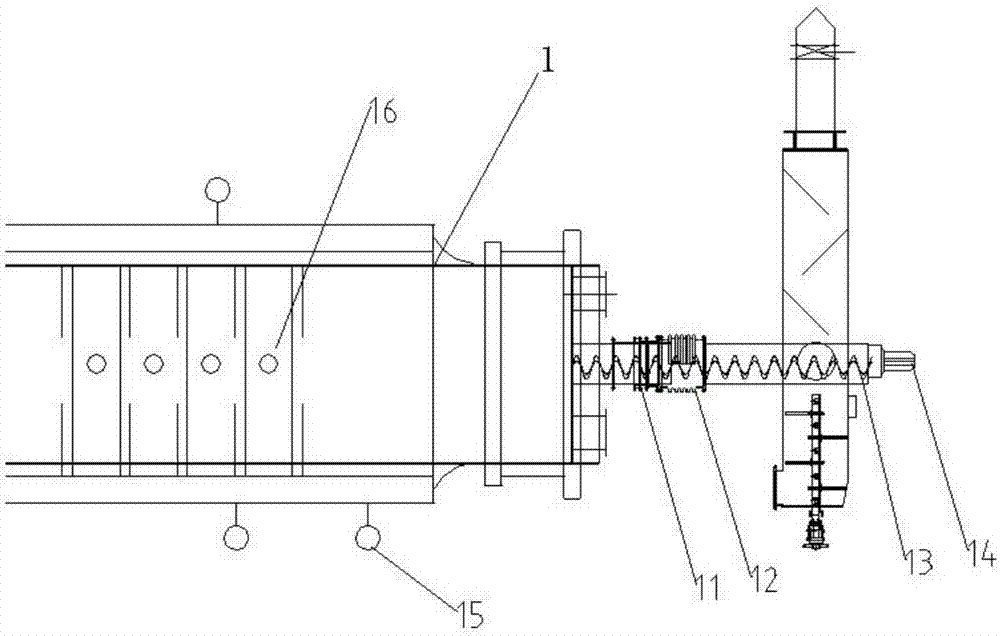

Telescopic material distributing machine

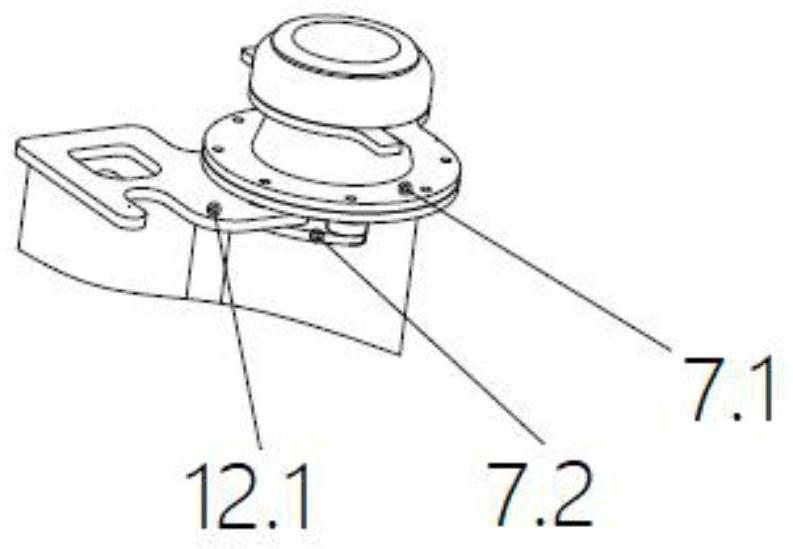

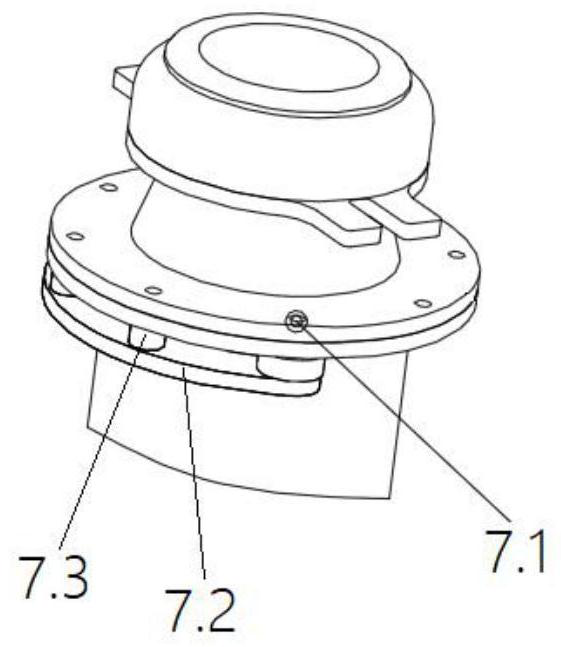

PendingCN112963176AReduce connecting pipesReduce elbowUnderground chambersTunnel liningStructural engineeringMechanical engineering

The invention provides a telescopic material distributing machine. The telescopic material distributing machine comprises a small rail car, a rotating mechanism, a pouring opening assembly and a cleaning opening assembly, wherein the cleaning opening assembly comprises a telescopic assembly and a cleaning pipe set; the cleaning pipe set is arranged on the rotating mechanism through the telescopic assembly; the pouring opening assembly comprises a telescopic casing pipe; the telescopic casing pipe is movably connected with the telescopic assembly; the telescopic assembly is used for driving the cleaning pipe set and the telescopic casing pipe to move; and the rotating mechanism is arranged on the small rail car and used for driving the pouring opening assembly and the cleaning opening assembly to rotate. According to the telescopic material distributing machine, the cleaning opening assembly and the pouring opening assembly are driven to rotate through the rotating mechanism, and vertical movement of the cleaning pipe set and the telescopic casing pipe is achieved through the telescopic assembly, so that the rotary material distributing function is achieved; and the telescopic casing pipe is movably connected with the telescopic assembly, so that small-range self-adaptive adjustment of an outer pipe of the telescopic assembly can be achieved when the outer pipe is stressed, and lateral force caused by the telescopic assembly can be eliminated.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

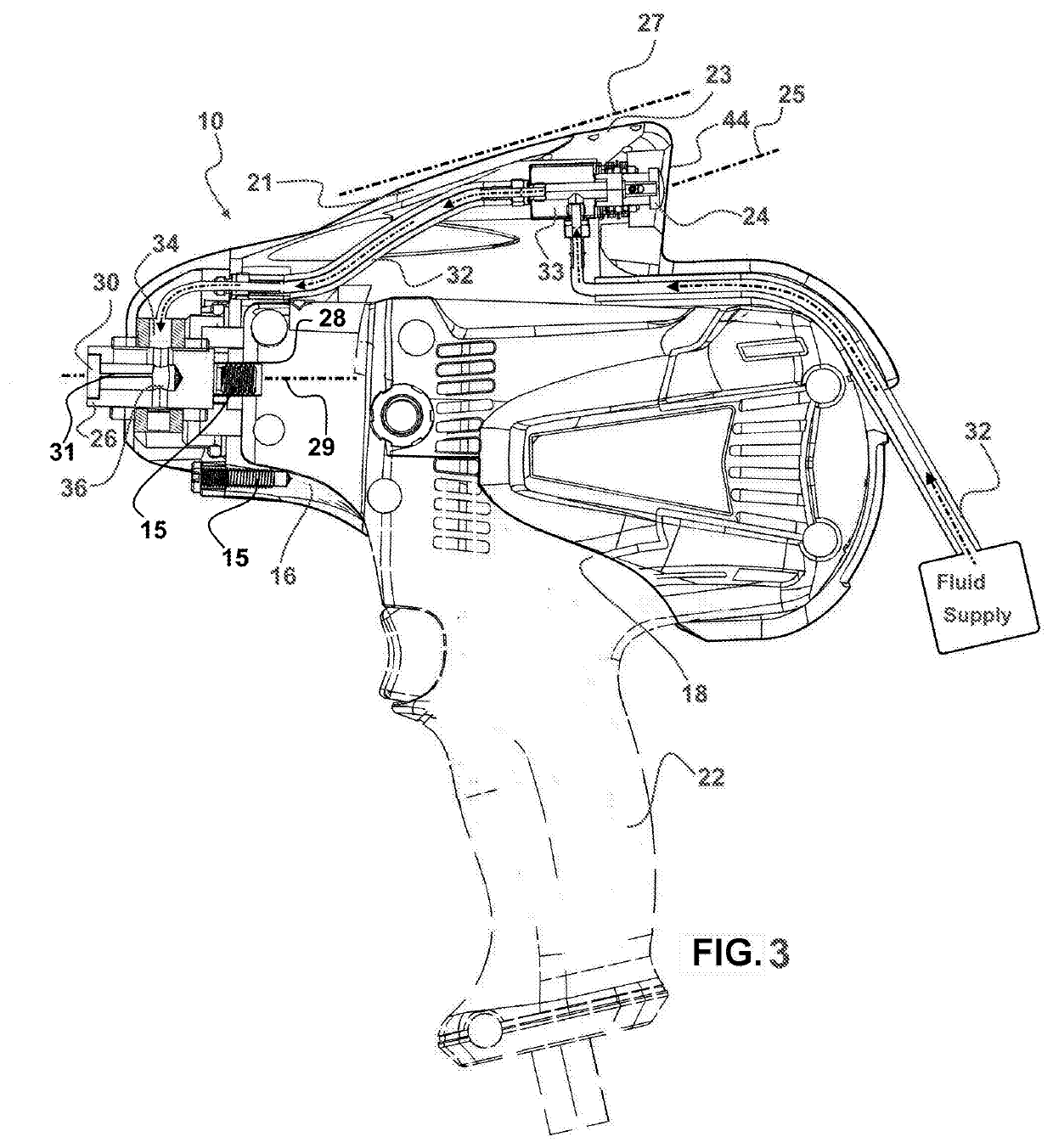

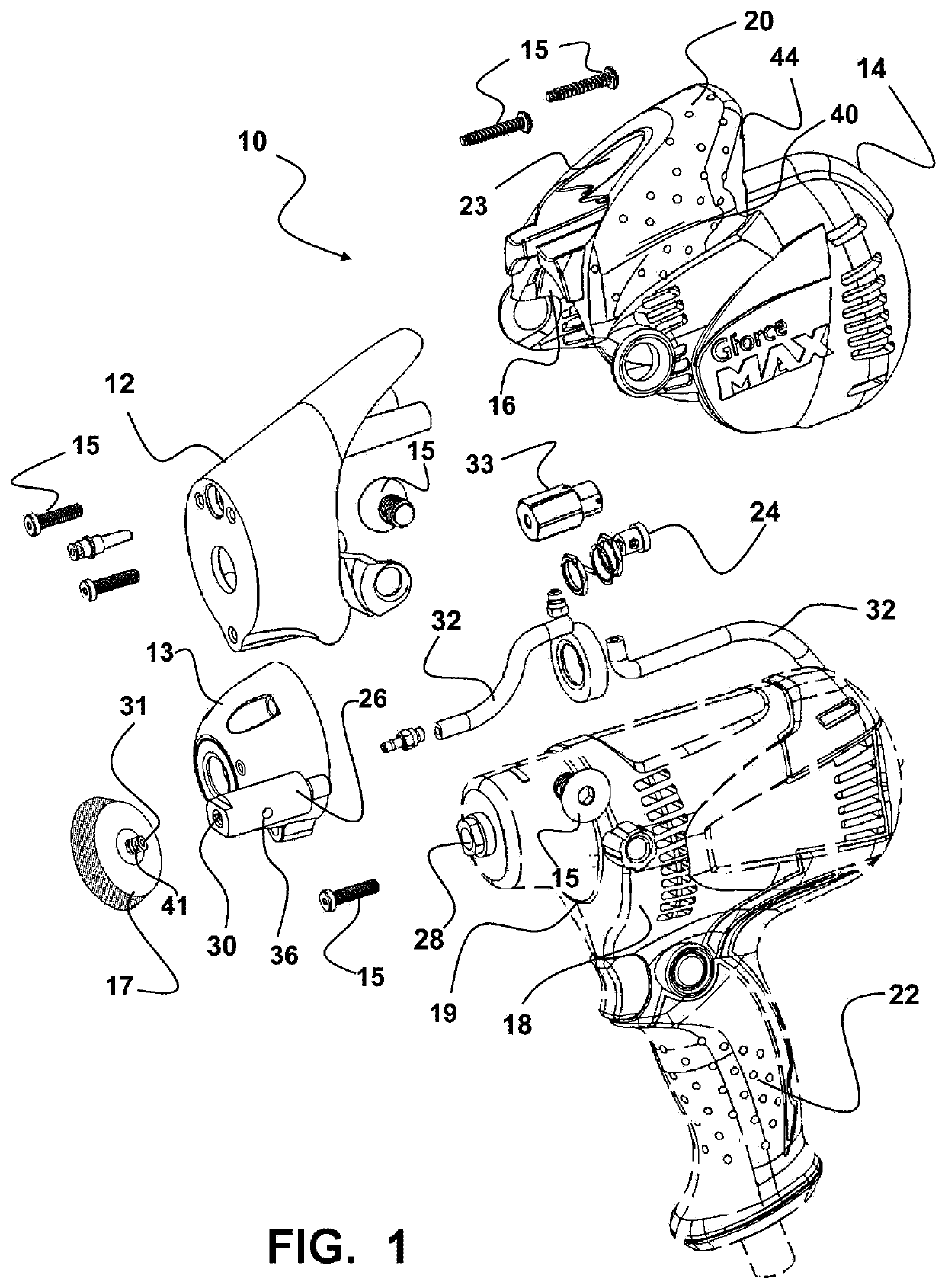

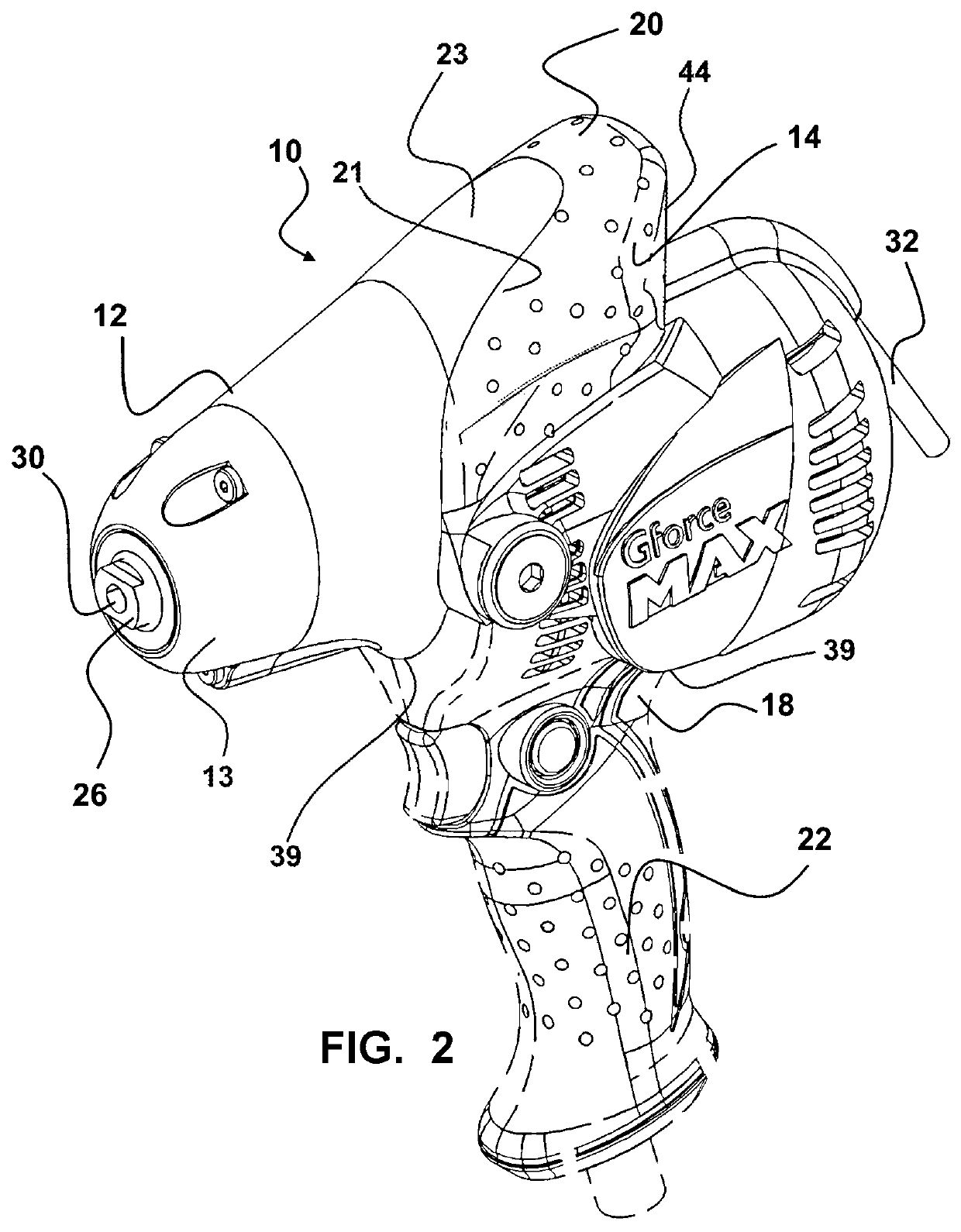

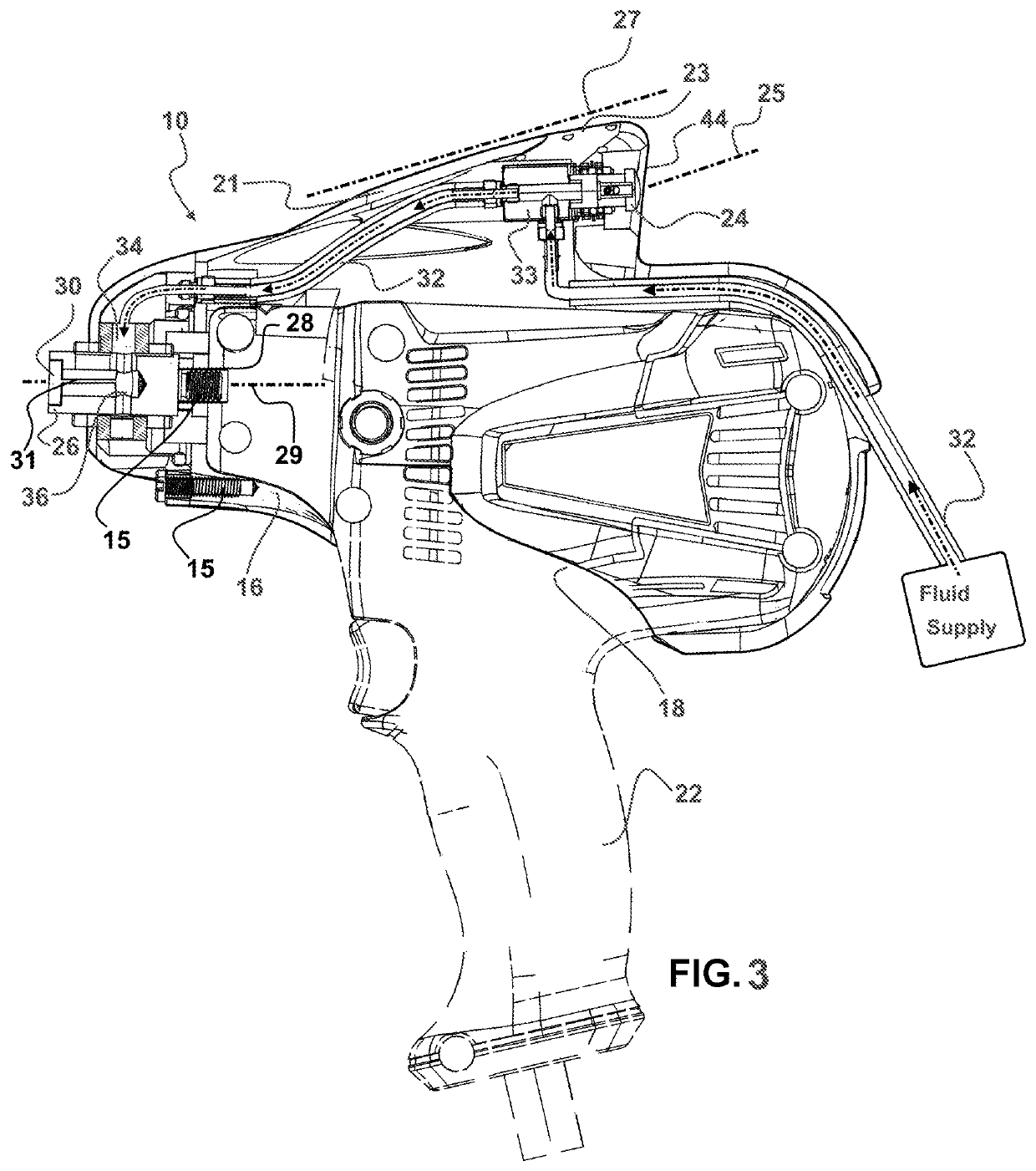

Glass Polishing Device

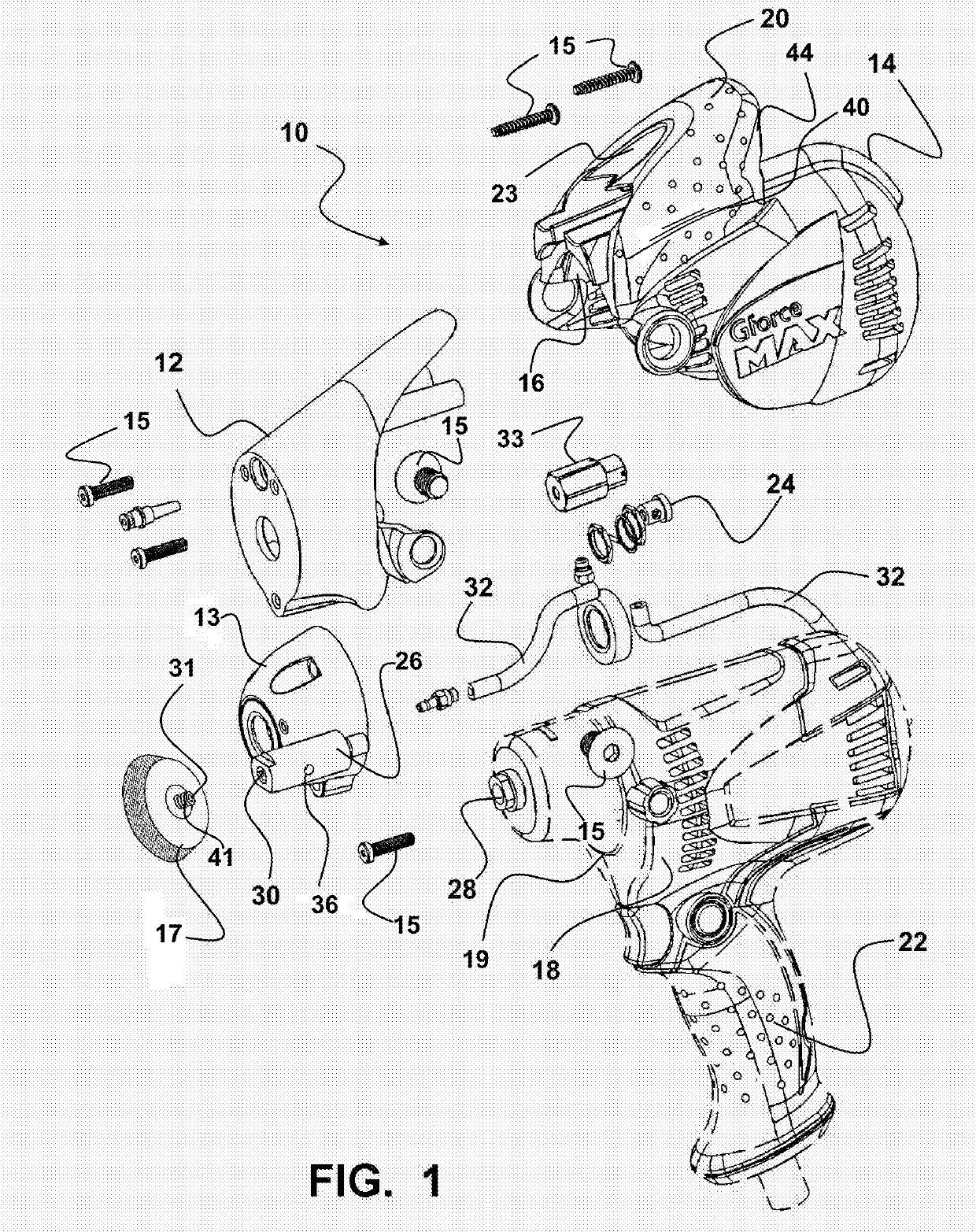

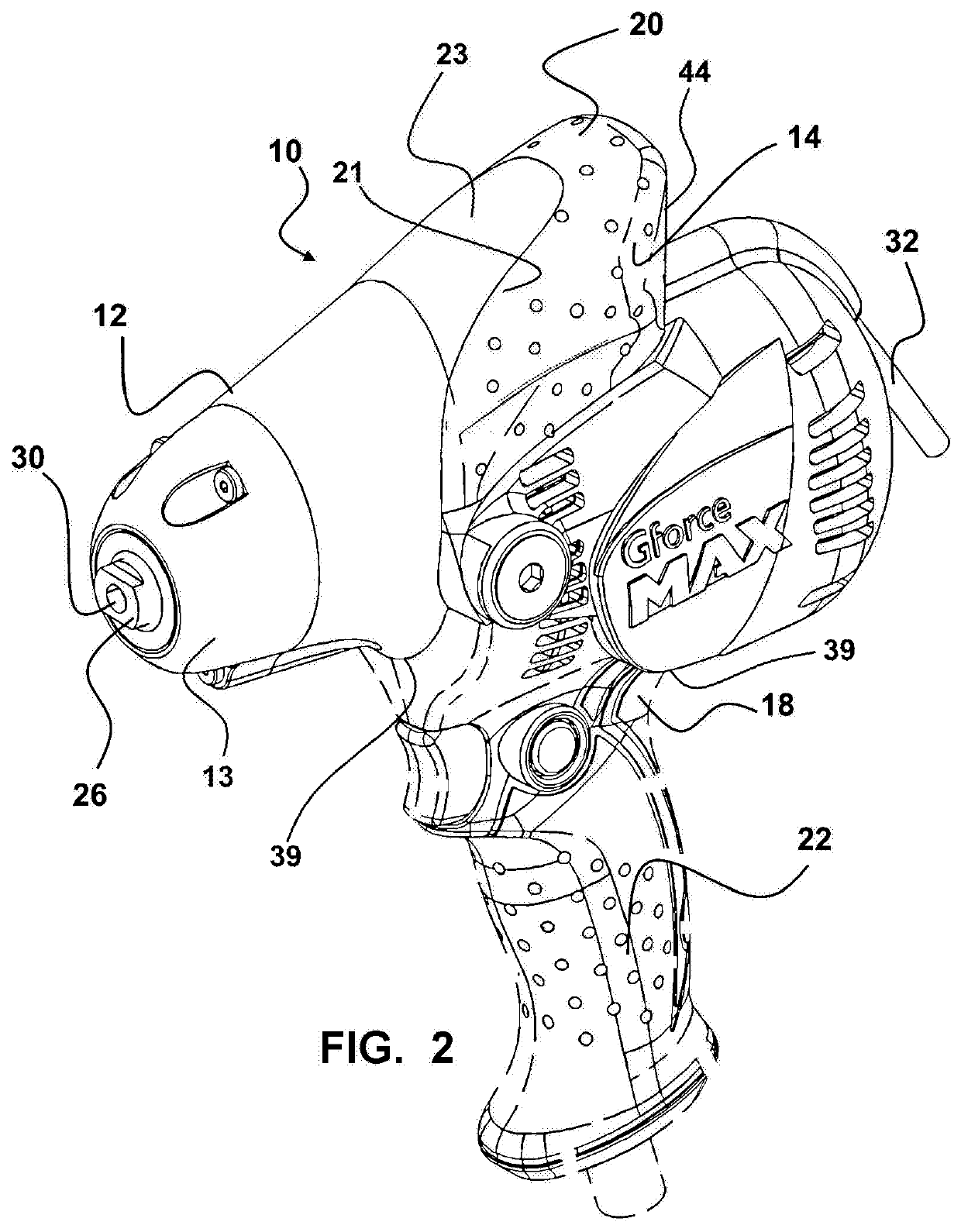

ActiveUS20200139509A1Easy to engageImprove stabilityPortable grinding machinesPortable power-driven toolsPolishingDrill

A glass polishing device has a casing adapted for operative engagement with the exterior surface of a powered drill motor. The casing includes a handle extending from a second side opposite an opening in an opposite first side thereof from which a handle of the engaged drill motor projects. A triggerable fluid supply is coupled to the casing and projects fluid to a tool or a section of glass being resurfaced by the tool.

Owner:GLAS WELD SYST

A multi-station forming device for producing pulp seedling cups

The invention relates to the technical field of squeezing fiber paper pulp or paper stock producing articles in models during a paper making period, in particular to a multi-station forming device for producing a paper pulp seedling cup. One or more multi-station forming machines are arranged at the inner periphery of a pulp chest; automatic flow control valves are arranged on the multi-station forming machines and are connected with a pulp conveying pipe; a metering pump is arranged on the pulp conveying pipe; a small-size stirrer is further arranged at the center of the pulp chest; an compressed air cylinder and a vacuum cylinder are respectively arranged on the left side and the right side of the small-size stirrer. According to the multi-station forming device disclosed by the invention, multiple stations existing in one chest can be realized; only one pulp conveying pipe is needed even if the number of the work stations is more; pipeline interfaces and pipeline elbows are reduced; the resistances of compressed air and vacuum in a pipeline are also reduced, and the leakage probability is reduced. No excessive pulp, overflow port, overflow groove, pulp reflowing pipe, pulp storage chest for reflowing pulp or pulp returning pump is needed. The investment of equipment is saved, the occupied space of a workshop is reduced, and the energy consumption of multiple circulating pipelines is reduced. The multi-station forming device has the advantages of high efficiency, small occupied area and low energy consumption.

Owner:上海同孚纸制品厂

Heavy caliber pipe fitting method

InactiveCN101338839BSimplified installation stepsReduce spendingFluid pressure sealed jointsRandom materialsPipe fitting

The invention provides an installation method of a large diameter pipeline, which has the advantages of simple and easy implementation, time saving and labor saving during the installation at the over-bent area. The installation method of the large diameter pipeline adopts a rubber gasket type mouthing pipe and a rubber gasket matching with the mouthing pipe. The invention is characterized in that the rubber gasket type mouthing pipe is 1 to 2 meters in length and is connected with the rubber gasket by a sealing way. The rubber gasket is of the well-known and common random model, and the preferable model is a R type rubber gasket. The rubber gasket type mouthing pipe is the well-known and common random material, and the preferable material is the PVC-U pipe. The diameter of the rubber gasket type mouthing pipe is Phi 250 to Phi 315 millimeter. Due to adopting the rubber gasket type mouthing pipe with 1 to 2 meters of length, the length is greatly decreased by compared with 6 meter of the original length, therefore, when the rubber gasket type mouthing pipe is put into the over-bent area after direct connecting with the rubber gasket, the pipeline can be naturally shaped according to the excavation direction, and any auxiliary facility is not required. The installation procedure has the advantages of simple and easy implementation, time saving and labor saving, greatly decreasing the installation cost, enabling water to flow smoothly and not being easily leaked and lost.

Owner:卞顺舟

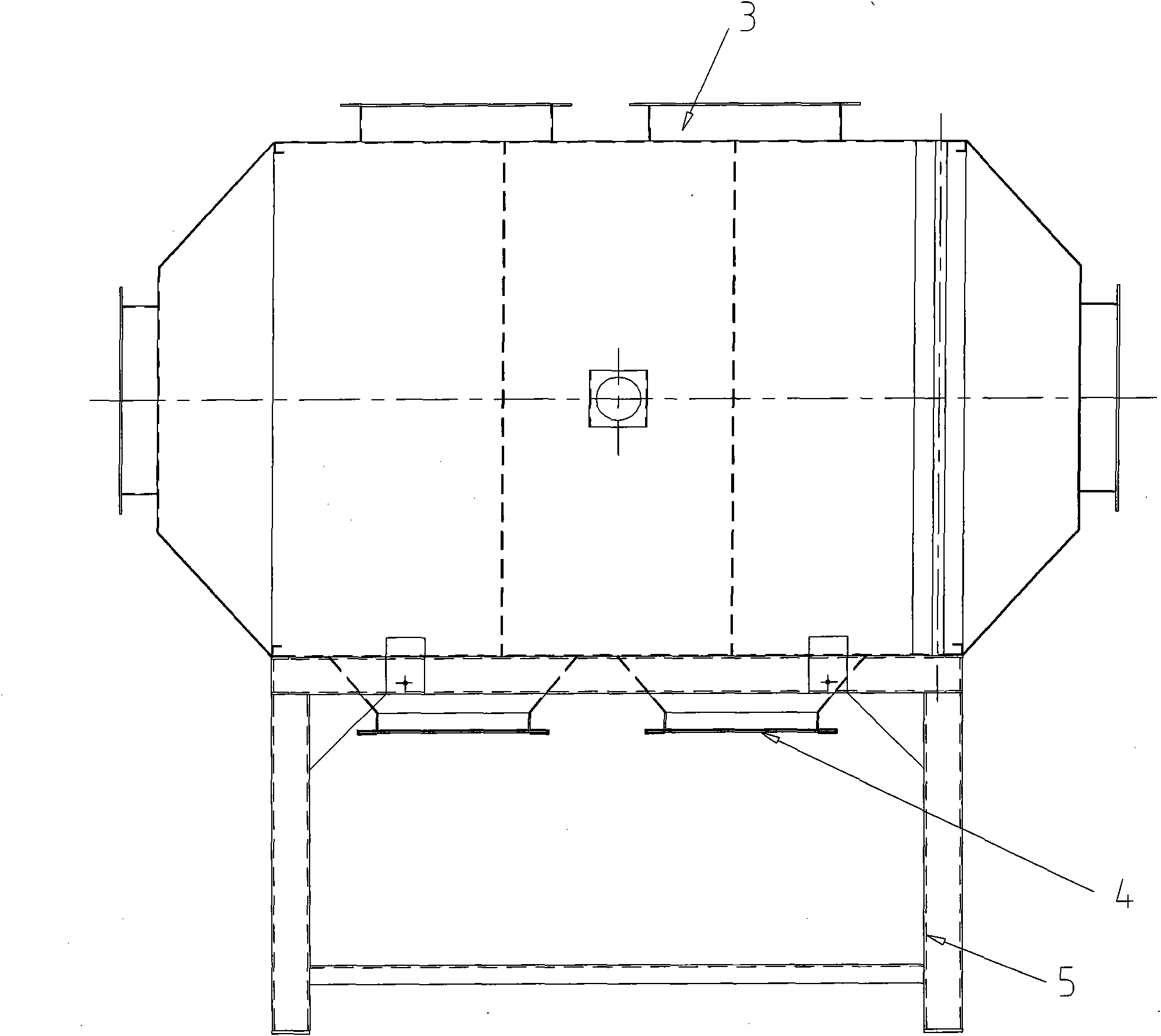

Vibrationless fluidized bed drying machine

ActiveCN102331158BExtend your lifeBalanced discharge effectDrying solid materials with heatDrying gas arrangementsFluidized bed dryingEngineering

The invention relates to a vibrationless fluidized bed drying machine, which belongs to the field of mechanical equipment and comprises a base, a box body, a heat exchanger, a draught fan and a deduster, wherein the box body is arranged on the base, an air outlet of the box body is connected with the draught fan, the draught fan is connected with the deduster, an air distribution plate is arranged in the box body, the box body is partitioned into an upper box body and a lower box body by the air distribution plate, lower partition boards are arranged in the lower box body, the lower box body is partitioned into a plurality of air chambers by the lower partition boards, upper partition boards are arranged in the upper box body corresponding to the lower partition boards, the top of the upper box body is provided with an upper ventilation duct, a blast device is arranged between two adjacent lower partition boards, and the blast device is connected with the heat exchanger. A duct is divided into the upper ventilation duct and a lower ventilation duct by the upper partition boards of the upper box body, air quantity of the upper ventilation duct and the lower ventilation duct can be adjusted by an adjusting plate so as to achieve an uniform discharge effect; the blast device is arranged between the two adjacent lower partition boards in the lower box body, energy is saved, the air quantity can be respectively adjusted according to different moisture contents of materials to obtain qualified materials; and the original vibration device is replaced by a material poking device to avoid the phenomenon of bed blocking.

Owner:山东宾利环保科技有限公司

Bell-type furnace heating mantle gas system and operation method thereof

PendingCN112460593ASimple structureImprove reliabilityIndirect carbon-dioxide mitigationBell type furnacesThermodynamicsEngineering

The embodiment of the invention provides a bell-type furnace heating mantle gas system and an operation method thereof. The bell-type furnace heating mantle gas system comprises a gas pipeline and a bell-type furnace heating mantle, wherein the gas pipeline is communicated with the bell-type furnace heating mantle; and in the conveying direction of mixed gas, the gas pipeline is sequentially provided with a filtering device and a gas preheating mechanism, the filtering device is used for filtering dust in the mixed gas, and the gas preheating mechanism is used for preheating the filtered mixedgas. Dust in the mixed gas is filtered through the filtering device on the gas pipeline, and then the filtered mixed gas is preheated through the gas preheating mechanism, so that salt substances inthe mixed gas are in an aerosol state, and the probability of blockage caused by crystallization of the salt substances at places such as elbows, reducing parts and valves on the gas pipeline and thebell-type furnace heating cover, which cause the conductance change of the mixed gas, can be reduced. Meanwhile, naphthalene and tar are in an aerosol state, and the viscosity is reduced, so that theprobability of blockage caused by adhesion at a gas conductance change place can be reduced.

Owner:湖南华菱涟源钢铁有限公司

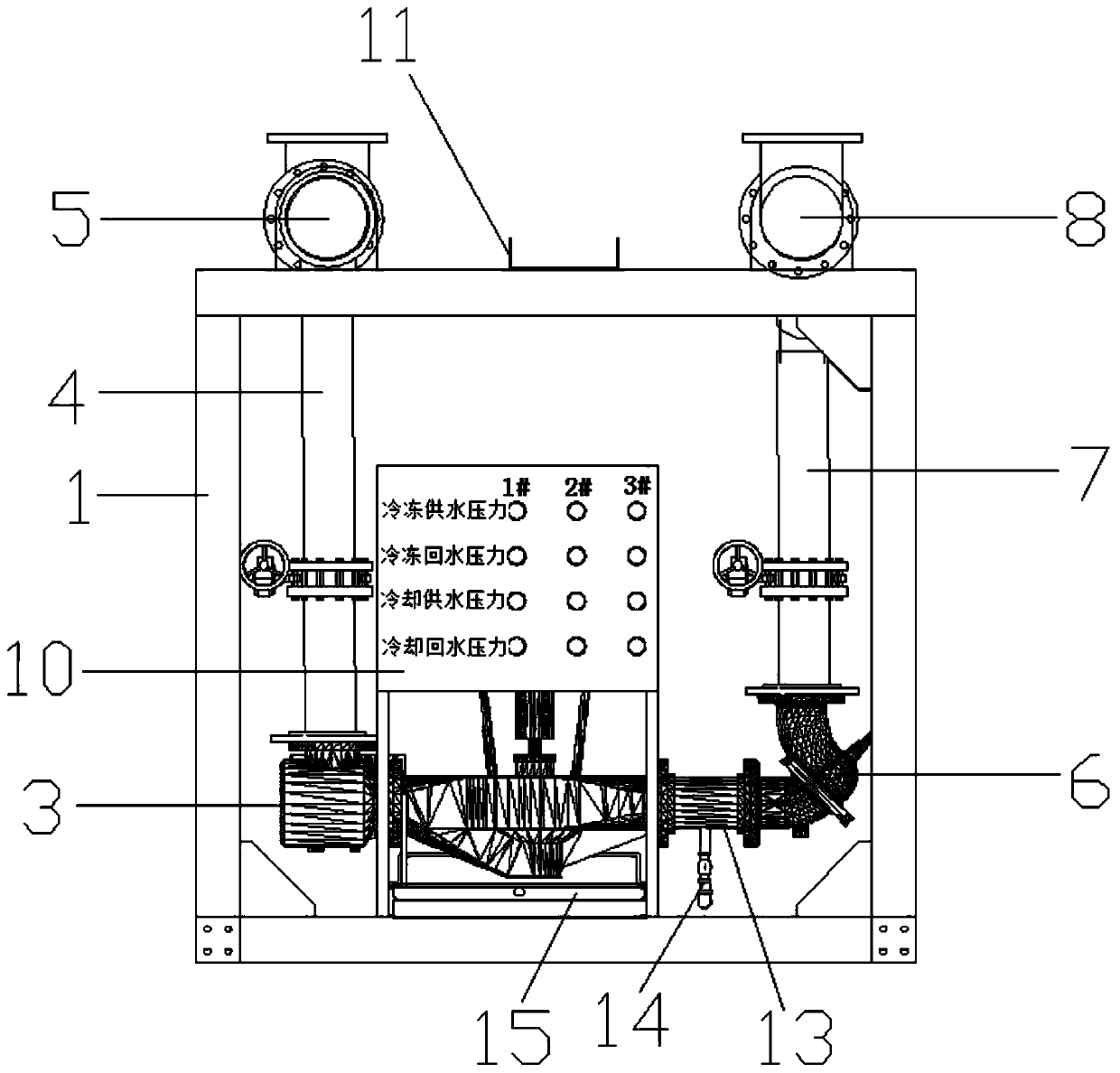

A laboratory multifunctional cold and hot water unit test tool

ActiveCN110926839BReduce typesReduce elbowStructural/machines measurementExhaust valveExperimental laboratory

Owner:GUANGDONG NEW ENERGY TECH DEV

A medical automatic washing machine

ActiveCN104525513BReduce elbowReduction of recycled water consumptionCleaning using liquidsButt jointPore water pressure

The invention discloses a full-automatic medical cleaning machine. The full-automatic medical cleaning machine comprises a frame, a cleaning bin and a water pump, wherein a cleaning frame is positioned in the cleaning bin; a water inlet is formed in the lower end of the cleaning frame; a water inlet main pipe is arranged at one side of the cleaning frame, and is connected with the water inlet; a main water pipe is arranged at the bottom of the cleaning bin; a joint device is arranged at a water outlet end of the main water pipe; a butt joint ring is arranged in a pipe hole in the upper end of the joint device; a water inlet end of the main water pipe is connected with the water pump; when water is supplied into the cleaning bin, the water pump is started, and the butt joint ring in the joint device is upwards flushed by water pressure under water pressure impact provided by the water pump, so that the top surface of the butt joint ring is tightly butted to the periphery of the water inlet in the bottom surface of the cleaning frame; and when the water is stopped being supplied into the cleaning bin, the butt joint ring in the joint device downwards drops to reset under the effect of self gravity. The full-automatic medical cleaning machine adopts the novel joint device, so that the use level of water pipes is reduced, the water resource is saved, the space in the cleaning bin is enlarged, and the cleaning capacity is improved.

Owner:LAOKEN MEDICAL TECH

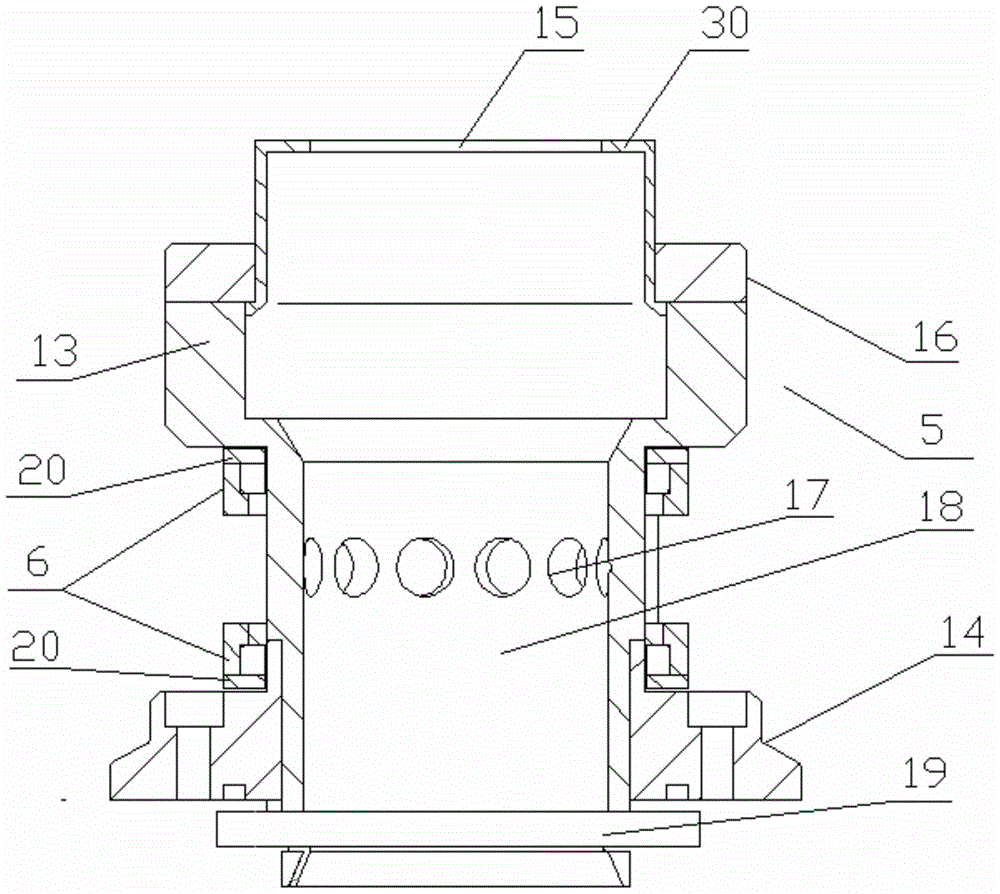

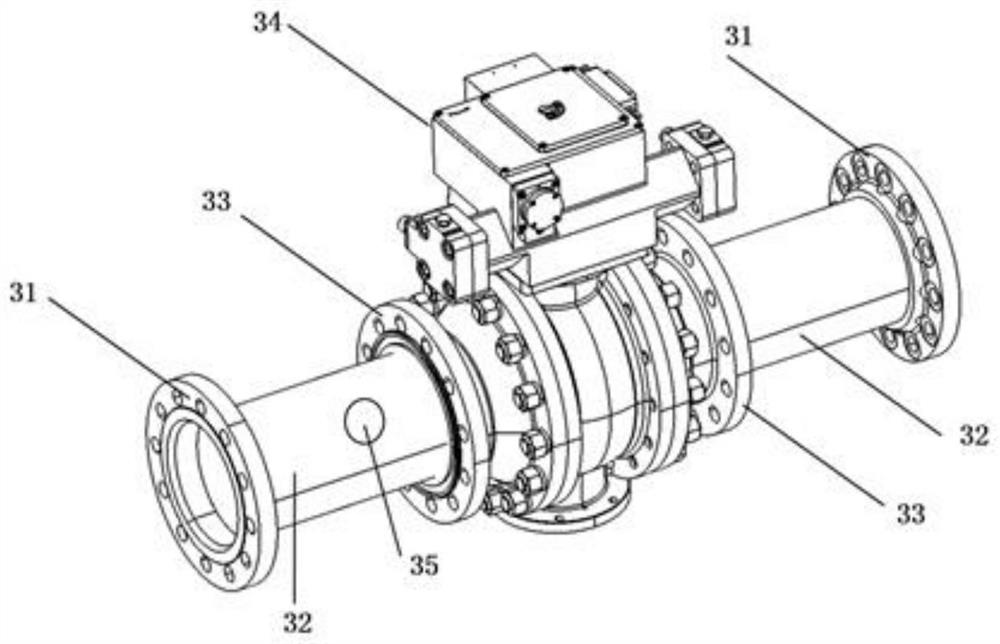

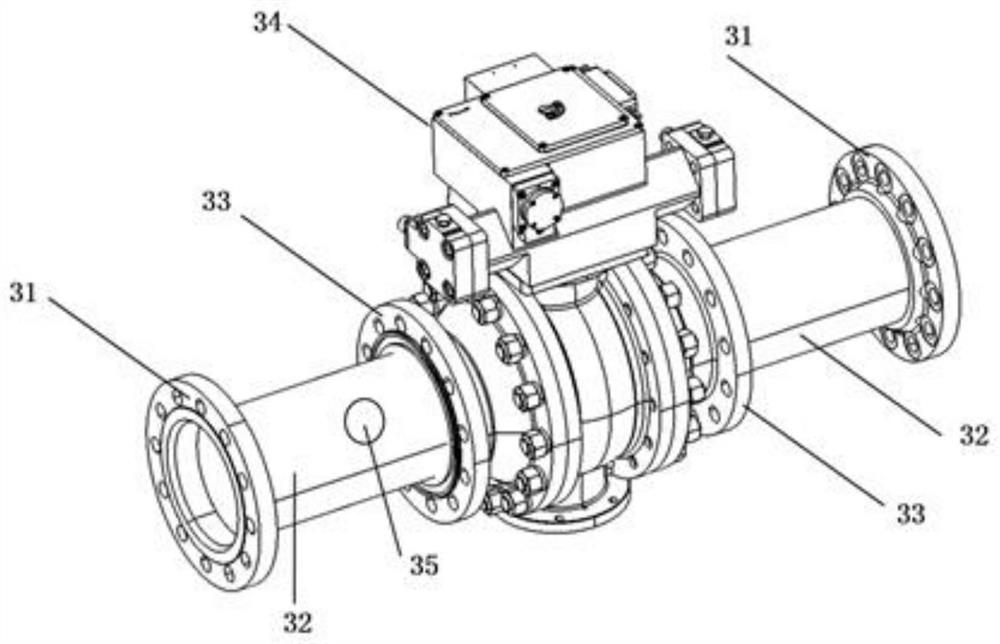

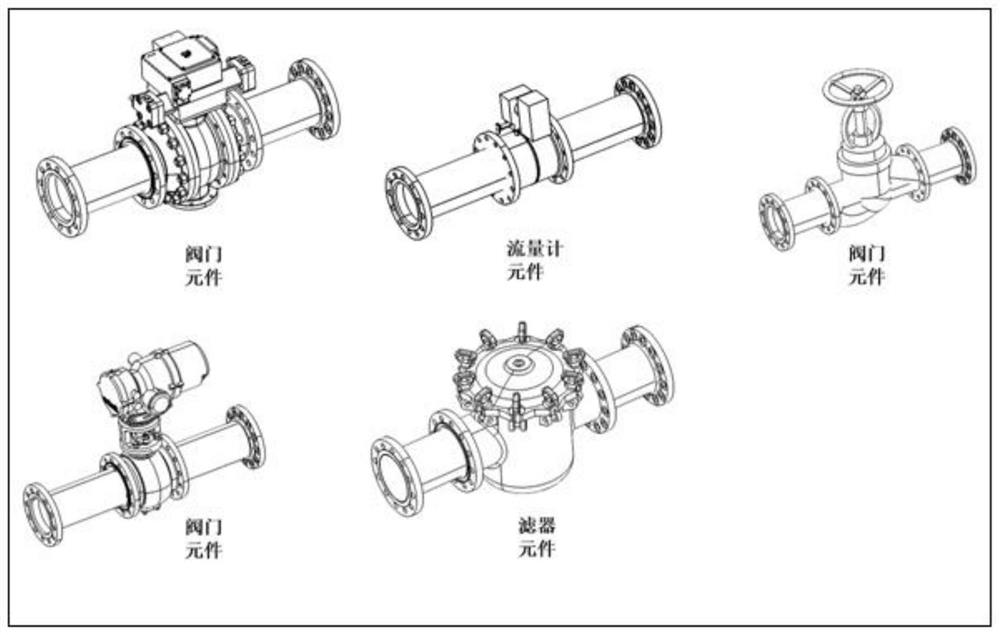

A fast-build water system pipeline test platform and its working method

ActiveCN112507744BAvoid randomnessReduce stakeCo-operative working arrangementsSensing by electromagnetic radiationExperimental laboratorySoftware system

The invention relates to the field of design and construction of water system test pipelines, and provides a rapidly built water system pipeline test platform and its working method and working method, especially suitable for testing the characteristics of water system pipeline components, The pipeline configuration, pipeline direction and performance are tested and studied. This platform comprises basic element, basic platform mounting board, and computer software system; Said basic element comprises the basic functional element of standardized production and the basic connecting element of standardized production, and said computer software system comprises basic library module, design module, auxiliary module , warehouse management module. The test platform of the invention has the characteristics of multiple research functions, short construction time, simple transformation and high reuse rate of pipeline components.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

Quickly-built water system pipeline test platform and working method thereof

ActiveCN112507744AAvoid randomnessShorten construction timeCo-operative working arrangementsSensing by electromagnetic radiationProcess engineeringTest platform

The invention relates to the field of design and construction of water system test pipelines, provides a quickly-built water system pipeline test platform and a working method thereof, which are particularly suitable for laboratory building and used for test research on water system pipeline element characteristics, pipeline configuration, pipeline trend, performance and the like. The platform comprises a basic element, a basic platform mounting plate and a computer software system, wherein the basic elements comprise basic functional elements manufactured in a standardized mode and basic connecting elements manufactured in a standardized mode, and the computer software system comprises a basic library module, a design module, an auxiliary module and a warehouse management module. The testplatform provided by the invention has the characteristics of multiple research functions, short construction time, simple transformation and high reuse rate of pipeline components.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

Steam supply circuit from a turbine

ActiveUS10260347B2Reduce elbowLower overall pressure dropGas turbine plantsEngine componentsSteam lineEngineering

The technical field of the invention is steam turbines including a steam feed circuit based on a functional steam generator set that may be nuclear- or fossil-fuel powered, and in particular a steam feed circuit (1) of a turbine (2), comprising n main steam lines (3) and n′ steam admission lines (4) to the turbine, the number n′ of steam admission lines (4) to the turbine being strictly greater than the number n of main steam lines (3), characterized in that there are n direct steam admission lines (5) to the turbine linking the as main steam lines (3) directly to the steam admission lines (4) to the turbine.

Owner:GENERAL ELECTRIC TECH GMBH

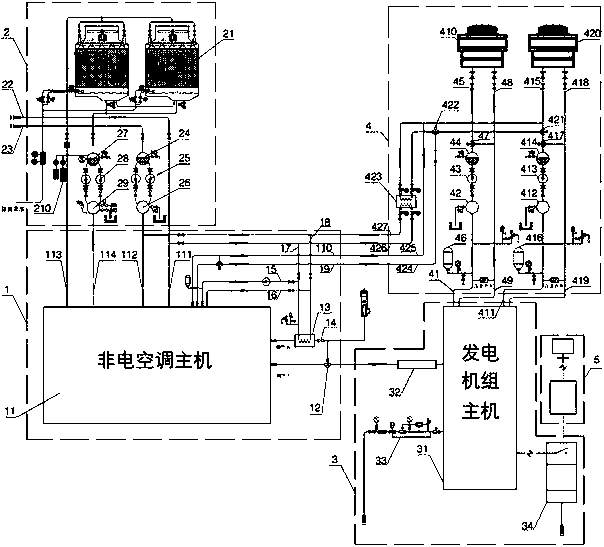

Complete fuel gas combined cooling, heating and power device

PendingCN108489140ACompact structureHigh degree of modular integrationTurbine/propulsion engine coolingGas turbine plantsLithium bromideCogeneration

A complete fuel gas combined cooling, heating and power device comprises a generator set host, a generator set integrated transmission and distribution device, a lithium bromide unit host, an air conditioner integrated transmission and distribution device and a control system; the generator set integrated transmission and distribution device and the air conditioner integrated transmission and distribution device are both modular skid-mounted structures; the generator set host is provided with an intercooling water outlet port, an intercooling water return port, a cylinder sleeve water outlet port and a cylinder sleeve water return port; the lithium bromide unit host is provided with an air conditioner cooling water outlet port, an air conditioner cooling water return port, an air conditioner cold / warm water outlet port and an air conditioner cold / warm water return port; and a smoke heat exchanger is integrated at a high exhaust opening in the lithium bromide unit host, and a heat exchange water pipeline of the smoke heat exchanger is connected with the lithium bromide unit host. According to the complete fuel gas combined cooling, heating and power device, on the one hand, the structure is compact, the degree of modular integration is high, and the process that users install pipelines and elbows on site can be omitted; and on the other hand, the system running resistance and equipment running energy consumption can be reduced, and time, cost and space are saved.

Owner:BROAD AIR CONDITIONING CO LTD

Glass polishing device

ActiveUS11465257B2Easy to engageImprove stabilityPortable grinding machinesPortable power-driven toolsPolishingEngineering

A glass polishing device has a casing adapted for operative engagement with the exterior surface of a powered drill motor. The casing includes a handle extending from a second side opposite an opening in an opposite first side thereof from which a handle of the engaged drill motor projects. A triggerable fluid supply is coupled to the casing and projects fluid to a tool or a section of glass being resurfaced by the tool.

Owner:GLAS WELD SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com