Lignite gasification-reduction three-stage dust removal cooling and automatic air lock device

An automatic, lignite technology, applied in gasification process, combined device, manufacture of combustible gas, etc., can solve the problem of low dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

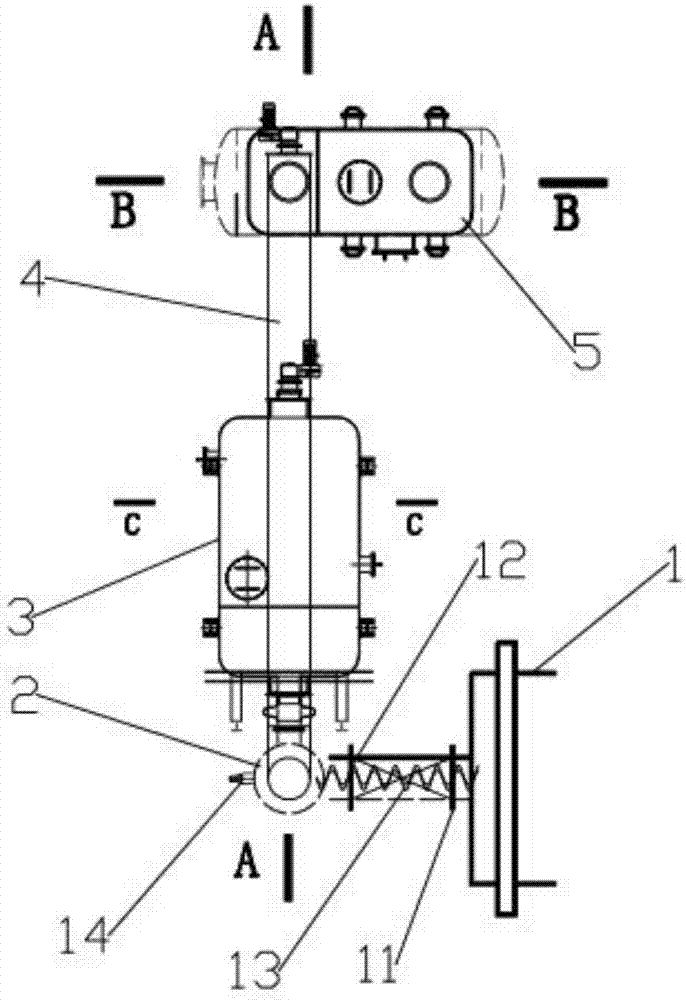

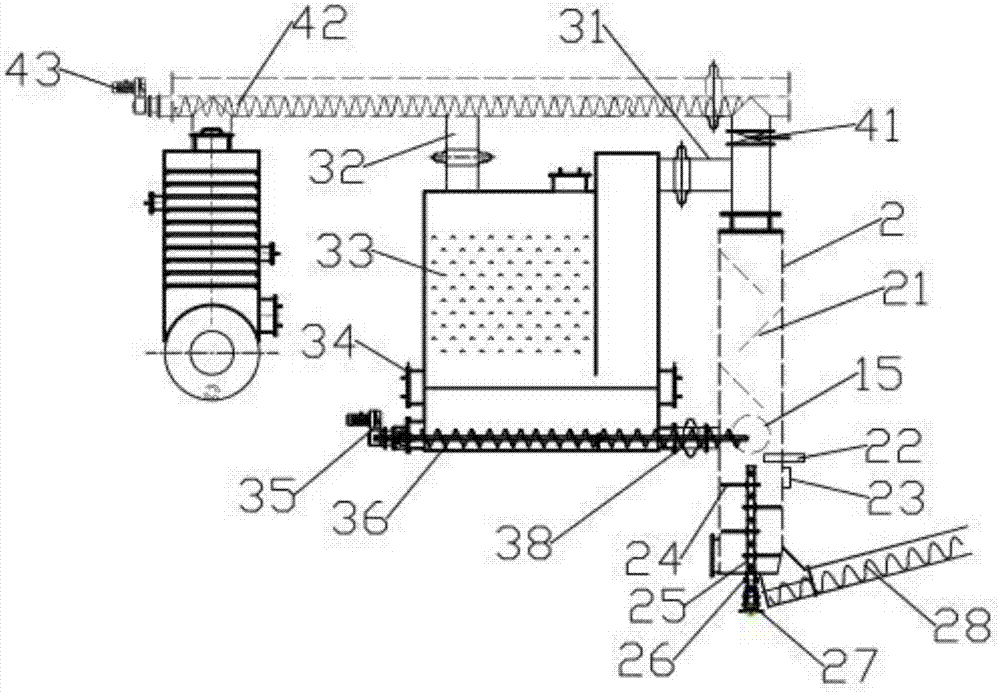

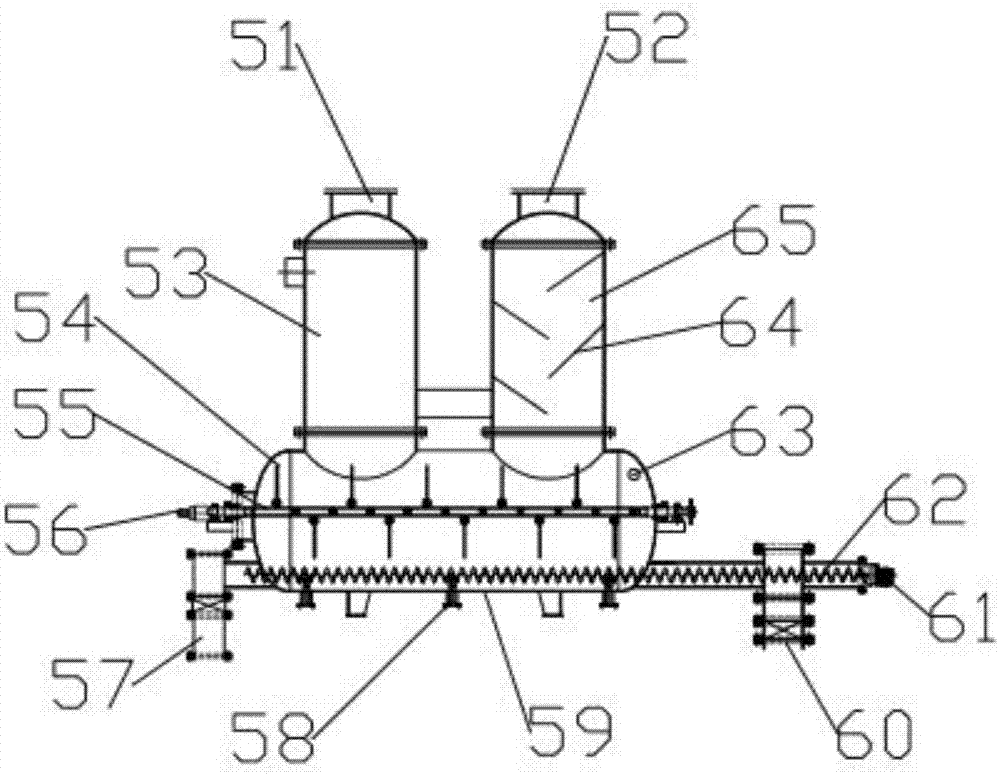

[0060] Such as figure 1 , figure 2 , image 3 , Figure 4 A three-stage dedusting cooling and automatic gas lock device for lignite gasification reduction shown includes a first filter 2 which is sequentially connected to the first gas outlet 15 of the reactor 1, and is used to receive the The dusty high-temperature oil and gas discharged from the air port 15; the first baffle 21 is installed above the first filter 2, the second rotating shaft 25 with the stirring blade 24 and the second motor 26 are installed below, and the bottom is provided for discharge. The third shaftless screw 28 driven by the third motor 27 of the material. The second filter 3 is used to remove a large amount of dust and heavy tar from the high-temperature oil and gas at the first air inlet 31; the L-shaped angle steel 33 for dust removal is installed inside, and the fourth shaft driven by the fourth motor 35 for separating materials The spiral 36 is sealed and connected with a rectangular baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com