Complete fuel gas combined cooling, heating and power device

A technology of combined cooling, heating and power, and gas, which is applied in the cooling of turbine/propulsion device, refrigerator, heating method, etc., can solve the problems of uncertainty of equipment quality and performance, increase of floor space, waste of flue gas waste heat, etc. Achieve the effect of improving energy utilization efficiency and equipment operation quality, reducing installation pipelines and elbows, and reducing equipment operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

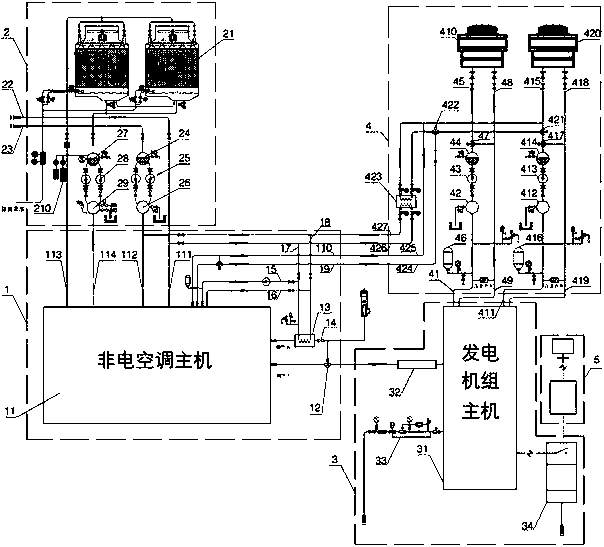

[0022] Such as figure 1 Shown: a complete set of gas cooling, heating and power cogeneration device, including generator set host 3, generator set integrated transmission and distribution device 4, lithium bromide unit (i.e. non-electric air conditioner) host 11, air conditioning integrated transmission and distribution device 2, energy control System 5.

[0023] In this embodiment, the integrated transmission and distribution device 4 of the generator set is a modular skid-mounted structure, the integrated transmission and distribution device 2 of the air conditioner is a modular skid-mounted structure, and the exhaust port of the high-temperature generator of the lithium bromide unit (hereinafter referred to as the high-temperature exhaust gas port) is integrated with a flue gas heat exchanger 13.

[0024] In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com