Valve element assembly and stop valve

A technology of spool components and stop valves, which is applied in the direction of lift valves, safety valves, balance valves, etc., can solve the problems of substandard sealing surface sealing performance, shortened service life, and affecting sealing effect, etc., and achieve simple structure and extended service life , long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (Example 1, spool assembly)

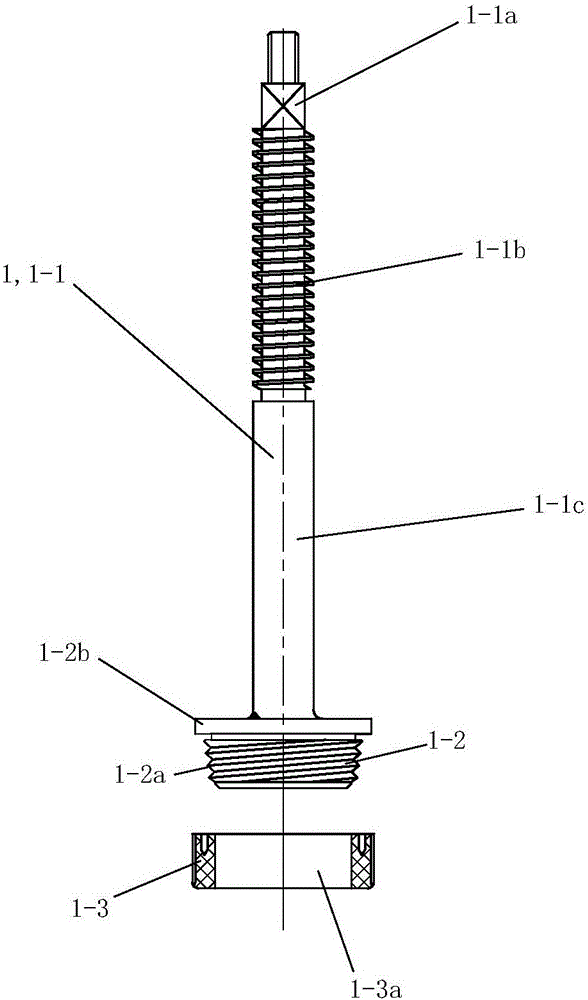

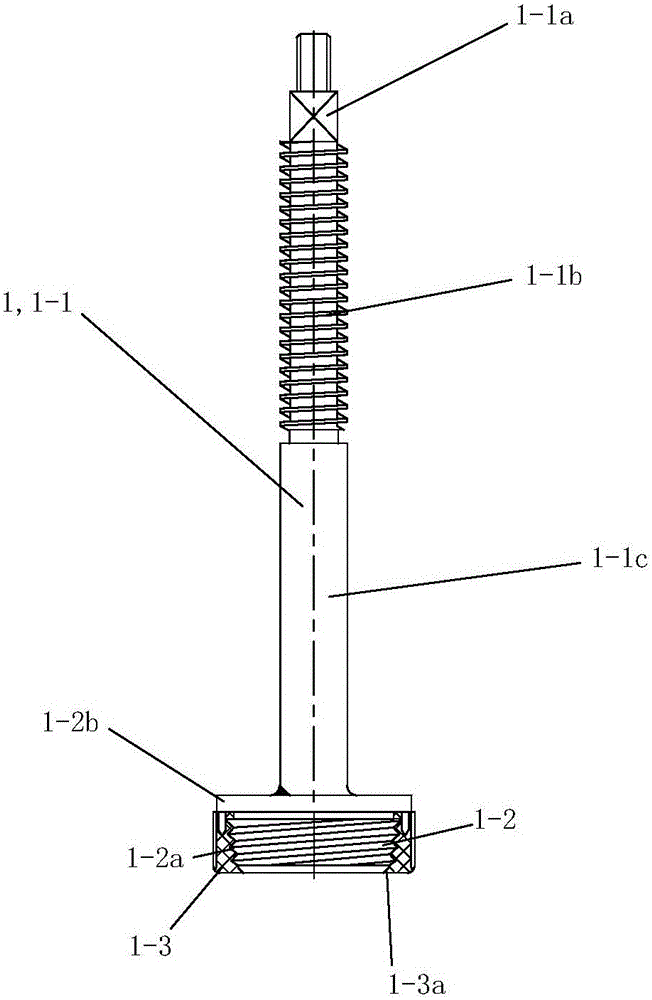

[0056] See figure 1 with figure 2 , The valve core assembly 1 of the present invention includes a valve stem 1-1, a valve flap 1-2 and a sealing packing 1-3.

[0057] See figure 1 with figure 2 The upper end of the valve stem 1-1 is provided with a connecting portion 1-1a, and the connecting portion 1-1a is used for fixed connection with a corresponding handwheel or wrench, so that the rotation of the valve stem 1-1 is controlled by the handwheel or wrench. An external thread section 1-1b is provided on the valve stem 1-1, and the external thread section 1-1b is located below the connecting portion 1-1a, and the length of the external thread section 1-1b can be determined according to actual needs. The lower part of the valve stem 1-1 is a cylindrical sealing connection part 1-1c. The valve clack 1-2 is coaxially fixedly connected and arranged on the lower end of the valve stem 1-1. Conical threads 1-2a are distributed on the outer ...

Embodiment 2

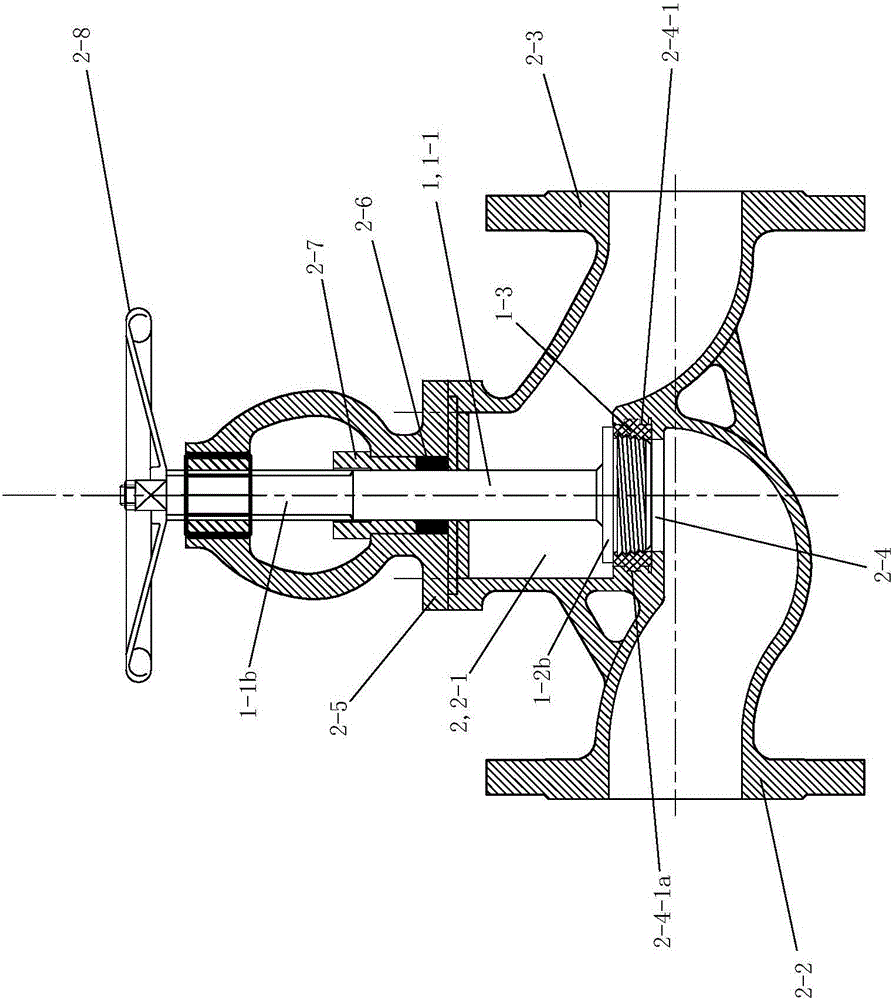

[0060] (Example 2, globe valve)

[0061] Such as image 3 , the shut-off valve 2 of this embodiment includes a valve core assembly, and the valve core assembly adopts the valve core assembly 1 described in Embodiment 1. The rest of the stop valve 2 includes: a valve chamber 2-1, the side wall of the valve chamber 2-1 is symmetrically provided with an inlet joint 2-2 and an outlet joint 2-3; the outlet 2-4 of the inlet joint 2-2 extends to The valve cavity 2-1 is set upwards; the outlet 2-4 of the inlet joint 2-2 is provided with an assembly groove 2-4-1, and the assembly groove 2-4-1 is provided with an internal thread. The sealing packing part 1-3 of the valve core assembly 1 is screwed and fixedly arranged in the assembly groove 2-4-1, and the inner wall of the assembly groove 2-4-1 is provided with a groove 2-4- 1a. When the valve disc 1-2 is screwed on the sealing packing part 1-3 for the first time, the taper thread 1-2a of the valve disc 1-2 generates a corresponding ...

Embodiment 3

[0063] (Example 3, cut-off valve)

[0064] Such as Figure 4 , the cut-off valve in this embodiment is the angle cut-off valve 3, and the angle cut-off valve 3 includes a valve core assembly, and the valve core assembly adopts the valve core assembly 1 described in Embodiment 1. The rest of the angle cut-off valve 3 includes: a second valve chamber 3-1, and a second inlet joint 3-2 and a second outlet joint 3 are respectively provided on the adjacent side walls perpendicular to each other of the second valve chamber 3-1. -3; the axis of the second inlet joint 3-2 is set coaxially with the valve stem 1-1 of the valve core assembly 1 . The outlet 3-4 of the second inlet joint 3-2 extends into the second valve chamber 3-1 and is set upward; the outlet 3-4 of the second inlet joint 3-2 is provided with a second assembly groove 3-4- 1. The second assembly groove 3-4-1 is provided with an internal thread, and the sealing packing part 1-3 of the valve core assembly 1 described in E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com