Horizontal activated carbon absorption tower

A technology of activated carbon adsorption and activated carbon, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient unloading, slow flow rate, and high floor space requirements, and achieve the reduction of elbows and pipes , reduce pressure loss and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

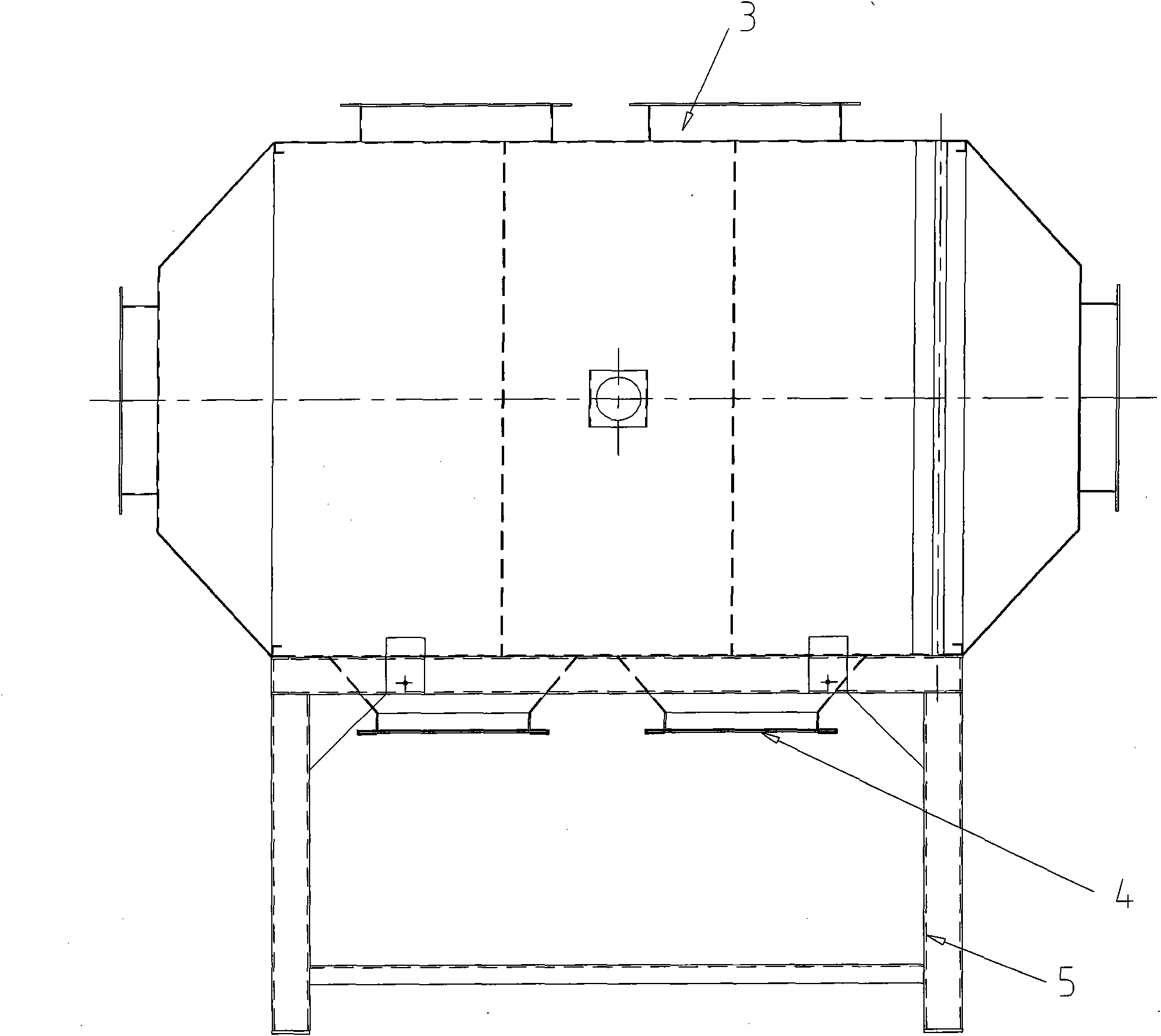

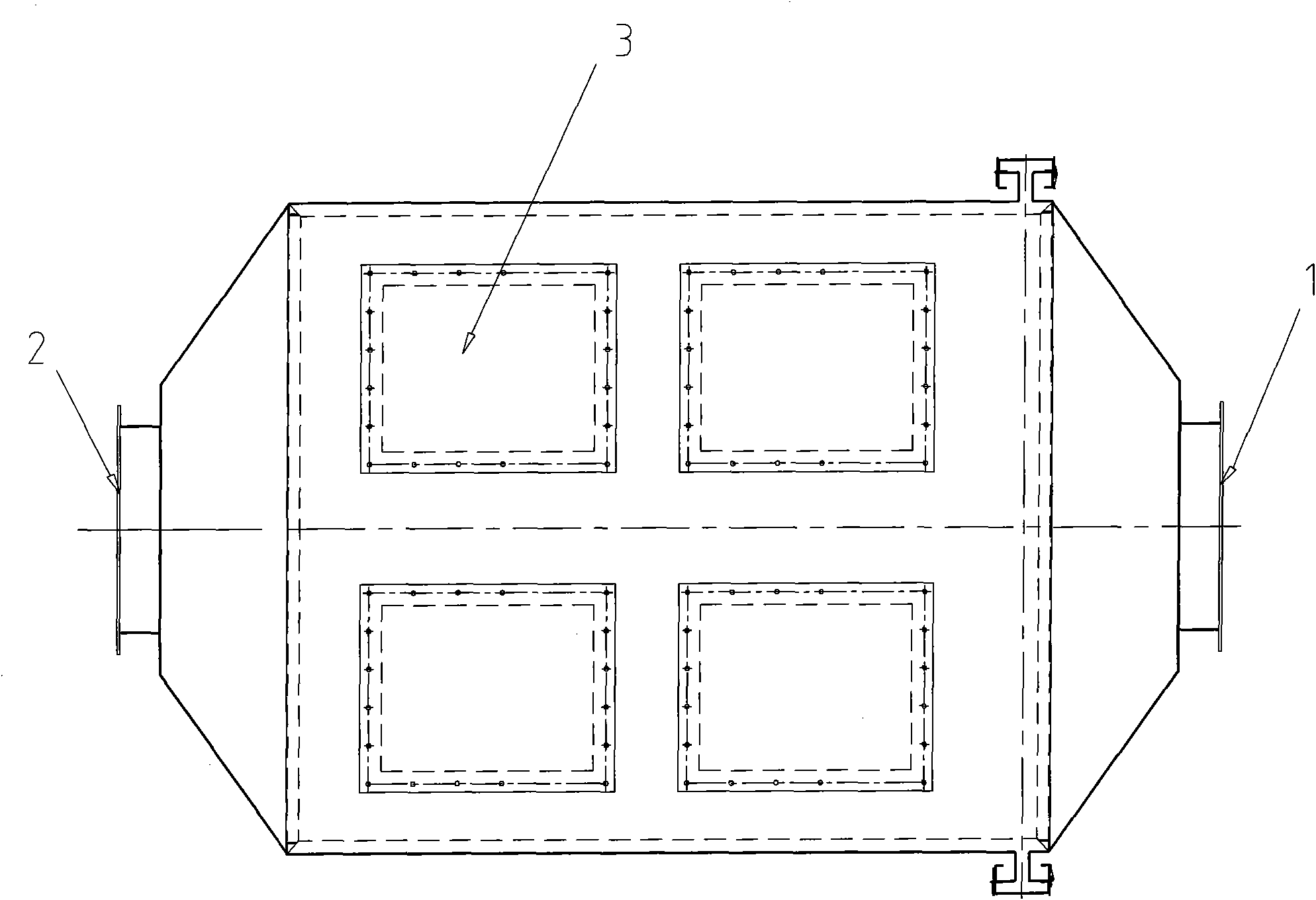

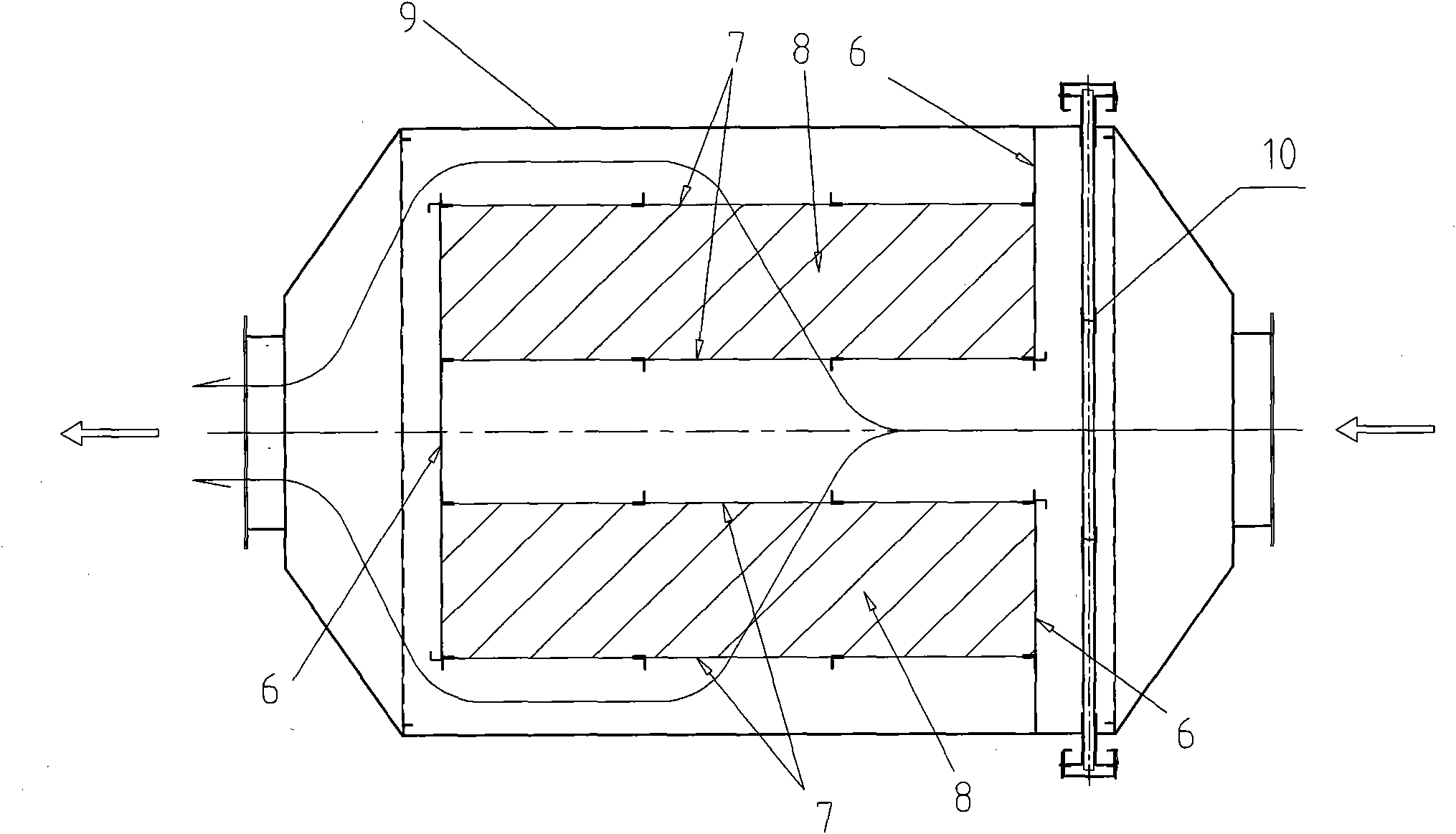

[0011] like figure 1 , figure 2 , image 3 As shown, a horizontal activated carbon adsorption tower includes an air inlet 1, an air outlet 2, a feed port 3, a discharge port 4, a base 5, a partition 6, a screen 7, activated carbon 8, and a carbon tower body 9 The two sides of the carbon tower body 9 supported on the base 5 are respectively provided with an air inlet 1 and an air outlet 2, the upper part of the carbon tower body 9 is provided with a feed inlet 3, and the bottom of the carbon tower body 9 is provided with a discharge outlet 4, which is located at the inlet. On the carbon tower body 9 between the tuyeres 1 and the air outlets 2, two groups of activated carbons 8 are horizontally arranged, and a partition net 7 is arranged along the periphery of each group of activated carbons 8 in the length direction. 7 vertical two partitions 6.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com