Burner for pulverized coal gasifier

A technology of gasifier and pulverized coal, which is applied in the field of burners, can solve the problems of inconvenient disassembly and maintenance, high processing and manufacturing costs, and complicated manufacturing processes, so as to avoid burning loss, reduce the contact area and protect the burners Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

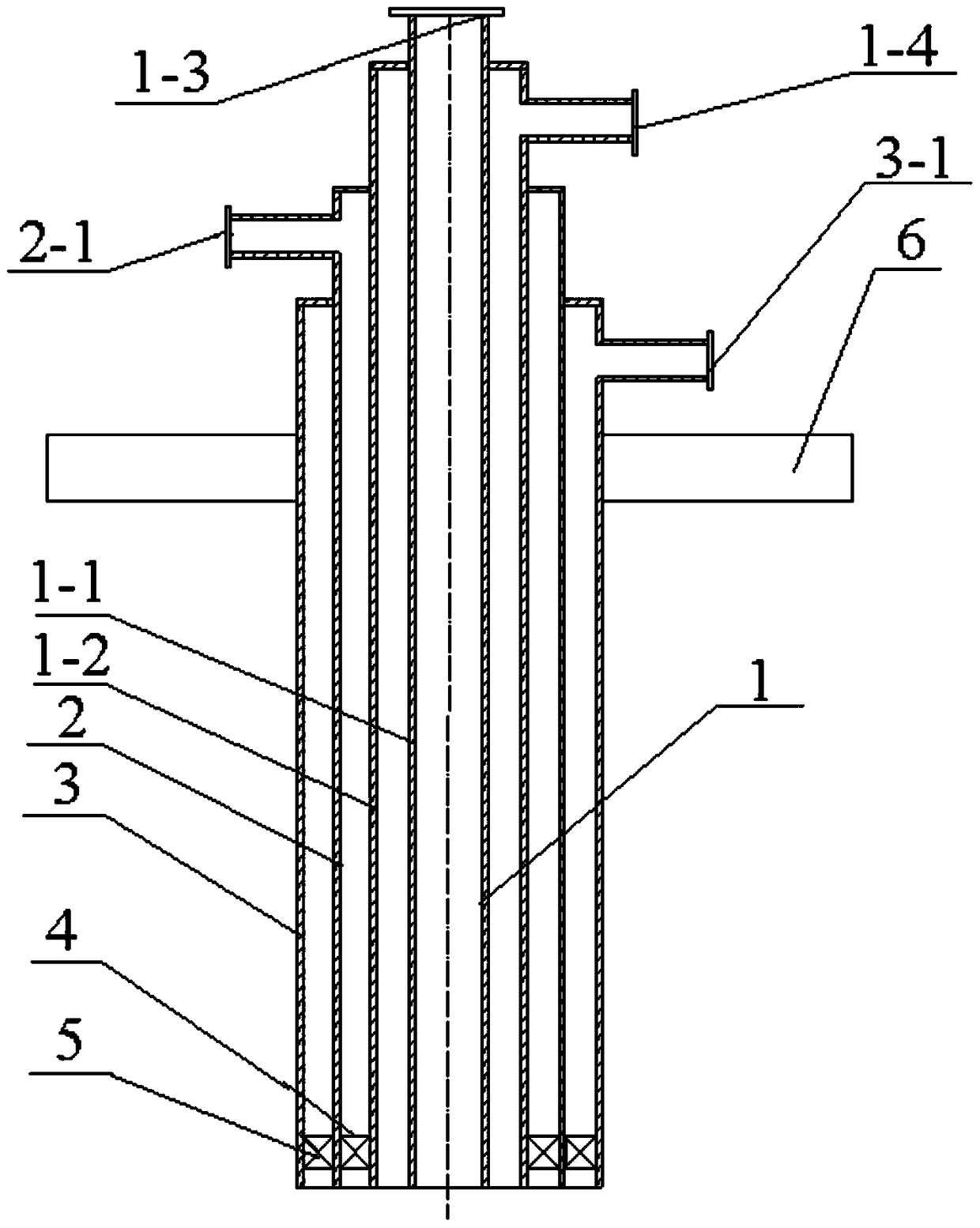

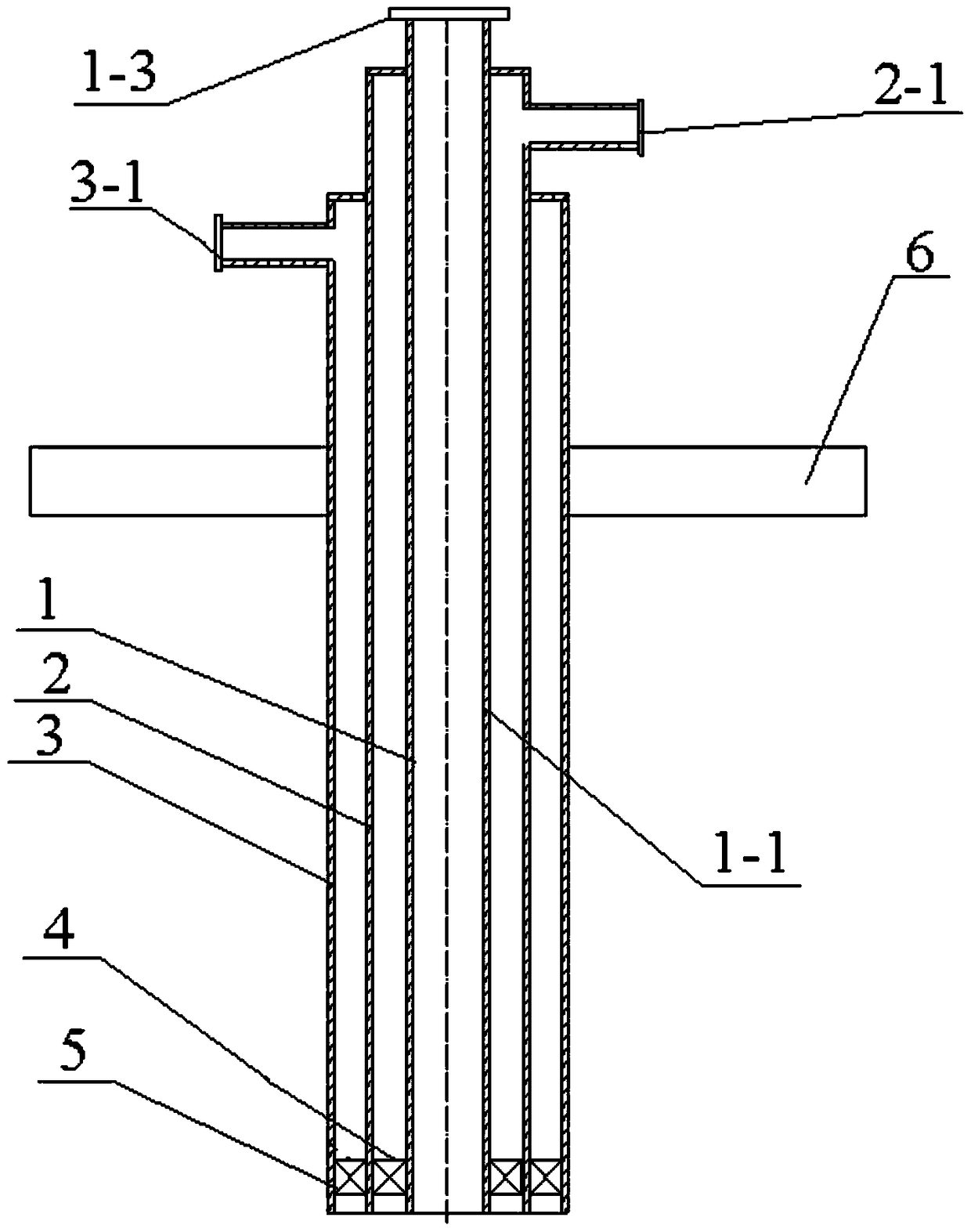

[0014] Specific implementation mode one: combine Figure 1-Figure 2 Description of this embodiment, a pulverized coal gasifier burner, which includes at least one layer of protective gas pipeline 1, gasification agent pipeline 2, pulverized coal pipeline 3, first swirl blade 4, second swirl blade 5 and Flange 6; the gasification agent pipeline 2 is set on the outside of at least one layer of protective gas pipeline 1, the pulverized coal pipeline 3 is set on the outside of the gasification agent pipeline 2, and the flange 6 is set on the outer wall of the pulverized coal pipeline 3, The first swirl blade 4 is arranged between the outer wall of at least one layer of shielding gas pipeline 1 and the inner wall of gasification agent pipeline 2, and the second swirl blade 5 is arranged between the outer wall of gasification agent pipeline 2 and the pulverized coal pipeline 3 between the inner sidewalls, and the first swirl vane 4 and the second swirl vane 5 are set close to the bo...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 2 Describe this embodiment, a pulverized coal gasifier burner of this embodiment, the protective gas pipeline of the at least one layer of protective gas pipeline 1 is the first protective gas pipeline 1-1 of one layer, other structures and specific implementation Method 1 is the same.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Describe this embodiment, a pulverized coal gasifier burner of this embodiment, the protective gas pipeline of the at least one layer of protective gas pipeline 1 is two layers of the first protective gas pipeline 1-1 and the second protective gas pipeline 1-2, the second protective gas pipeline 1-2 is sleeved on the first protective gas pipeline 1-1, and the top of the second protective gas pipeline 1-2 is sealed with the outer wall of the first protective gas pipeline 1-1, The top of the first shielding gas pipeline 1-1 is processed with a first shielding gas inlet 1-3, and the side wall of the second shielding gas pipeline 1-2 is processed with a second shielding gas inlet 1-4 near the top. Other structures and specific embodiments One is the same.

[0018] Specific implementation mode four: combination figure 1 Describe this embodiment, a pulverized coal gasifier burner of this embodiment, the first protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com