Multi-station forming device for producing paper pulp seedling cup

A molding device and multi-station technology, which is applied in textiles and papermaking, can solve the problems of low production efficiency, complicated pipeline structure, and large workshop area, and achieve low efficiency, save equipment investment, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, and the structure and principle of this device are very clear to those skilled in the art. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

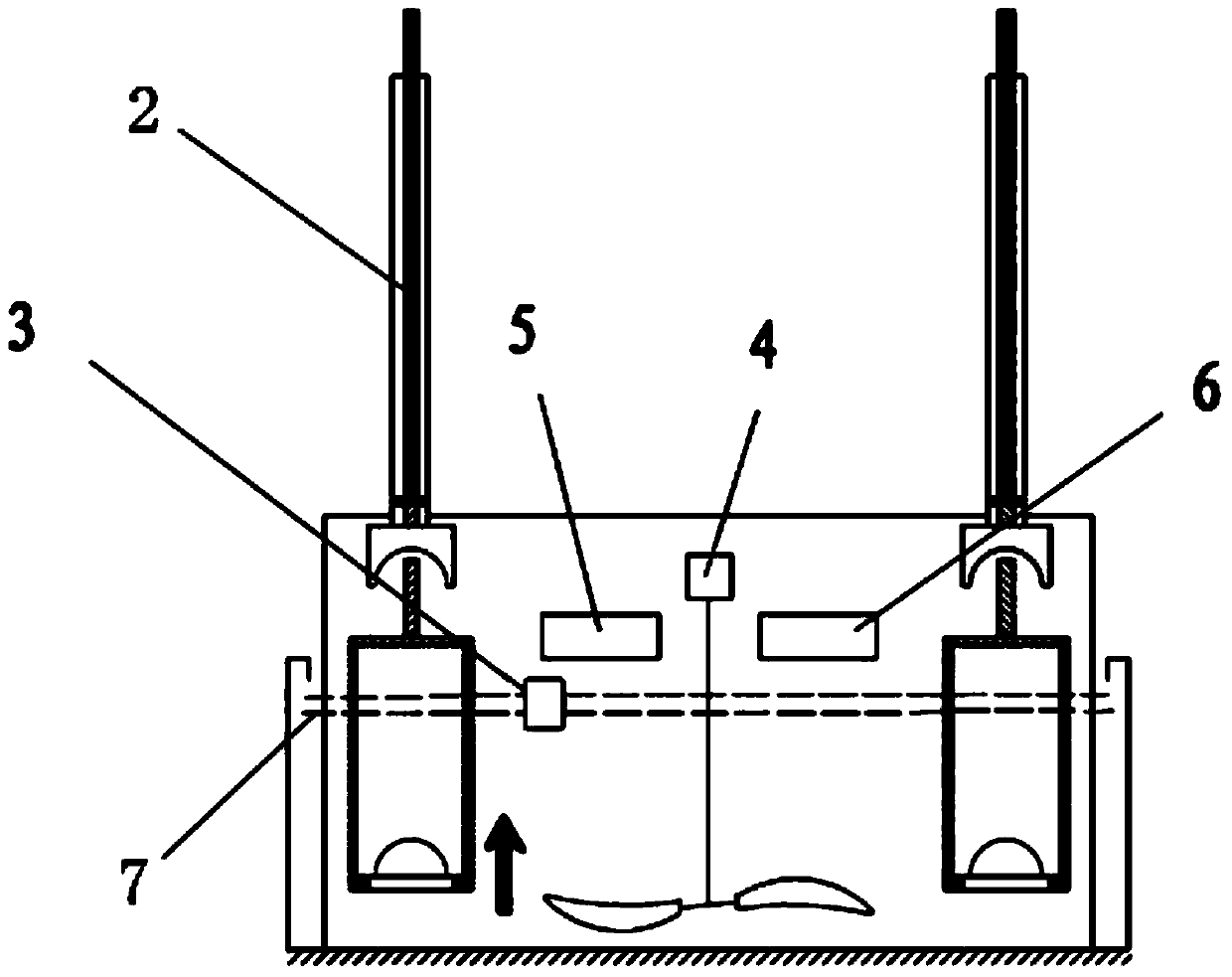

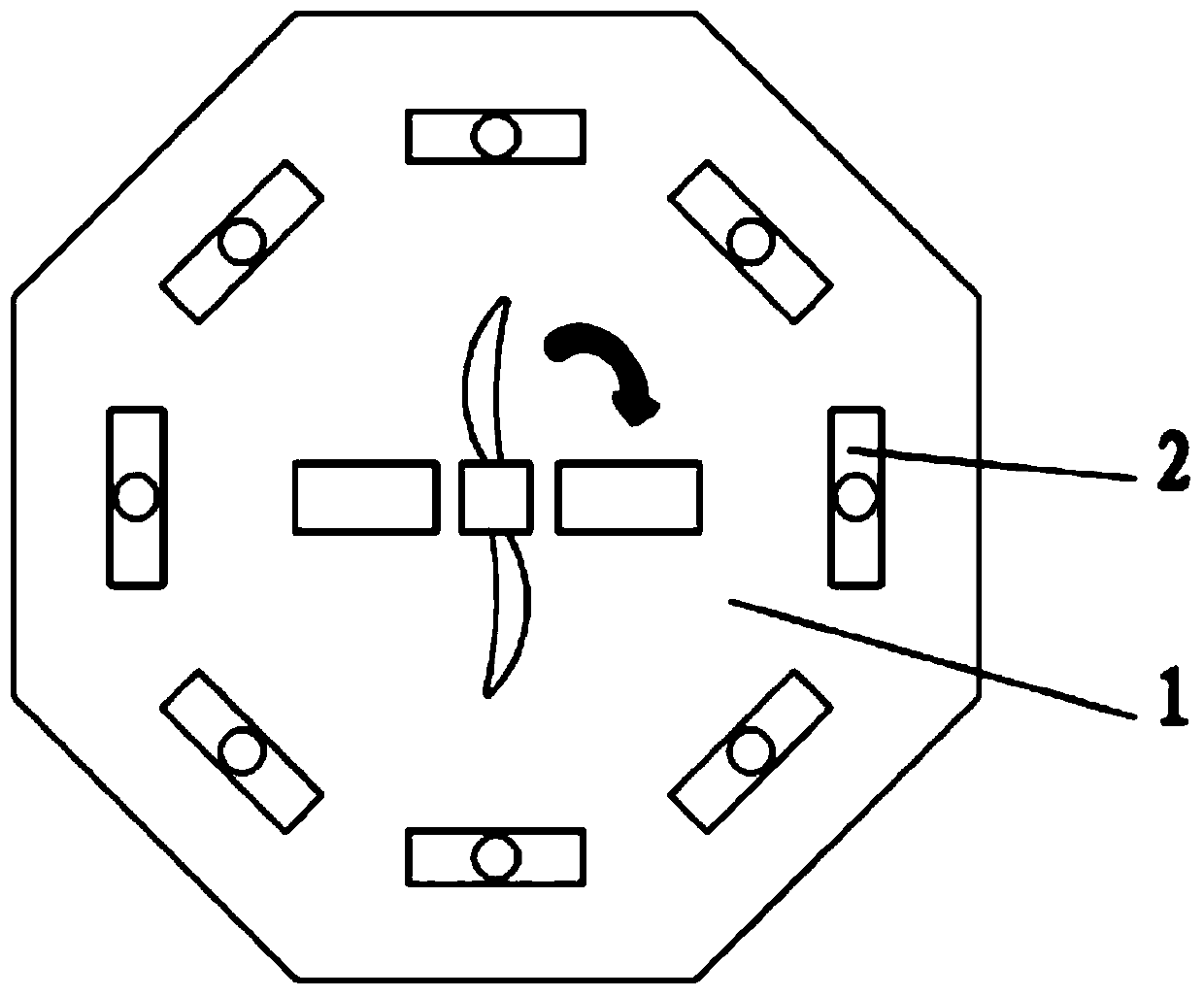

[0017] The present invention is a multi-station molding device for producing pulp seedling cups, which adopts the design of one pool and multiple stations, and only uses one slurry delivery pipe to connect the stations, and the stations are all arranged on the periphery of the pulp pool. The pulp tank is polygonal, one station corresponds to one side, and one station is a multi-station forming machine, and the length of each side of the pulp tank is ≥1m. The multi-station molding machine is set in the frame, and the frame is fixed by the embedded parts arranged at the bottom of the pulp pool. The frame is made of stainless steel, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com