A liquid heavy metal cooling natural circulation pool reactor internal auxiliary heating system

A liquid heavy metal, natural circulation technology, applied in reactors, cooling devices, greenhouse gas reduction and other directions, can solve problems such as system failure, unfavorable post-processing of reactor accidents, coolant solidification, etc., to improve the natural circulation capacity and reduce the system. Design complexity, the effect of reducing form resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention provides an auxiliary heating system in a liquid heavy metal cooling natural circulation pool reactor. The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings:

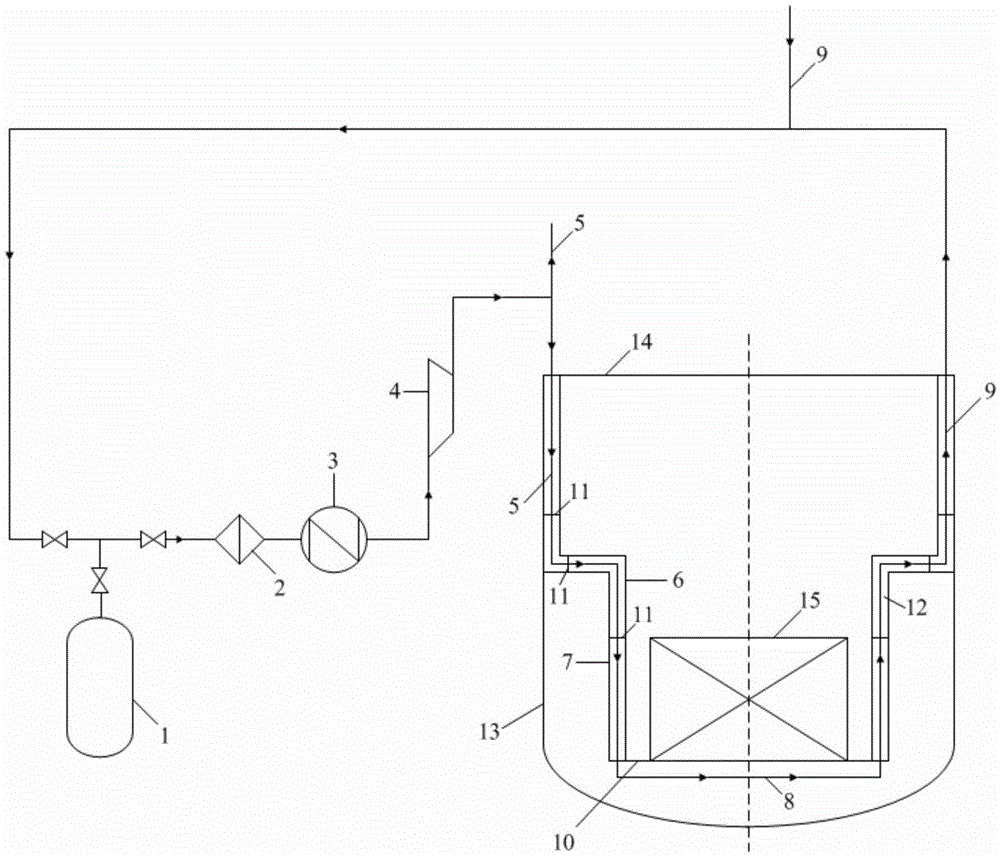

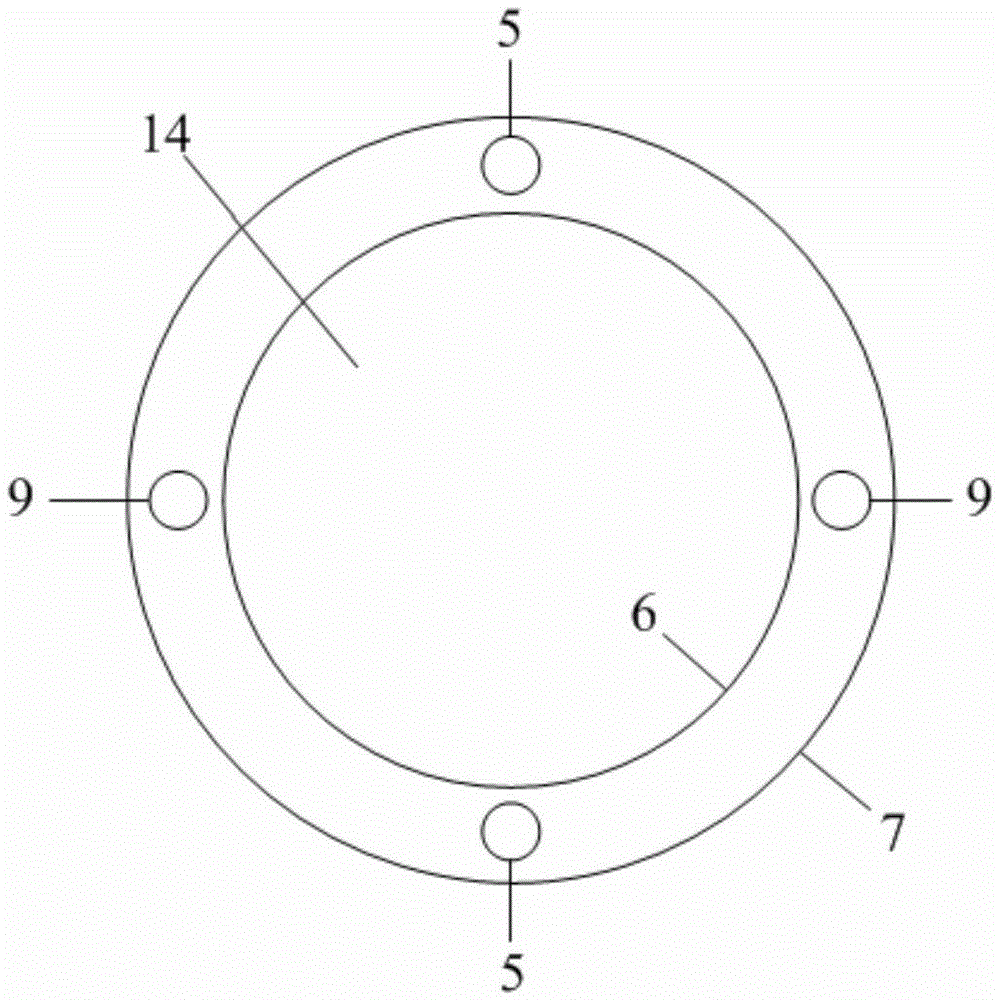

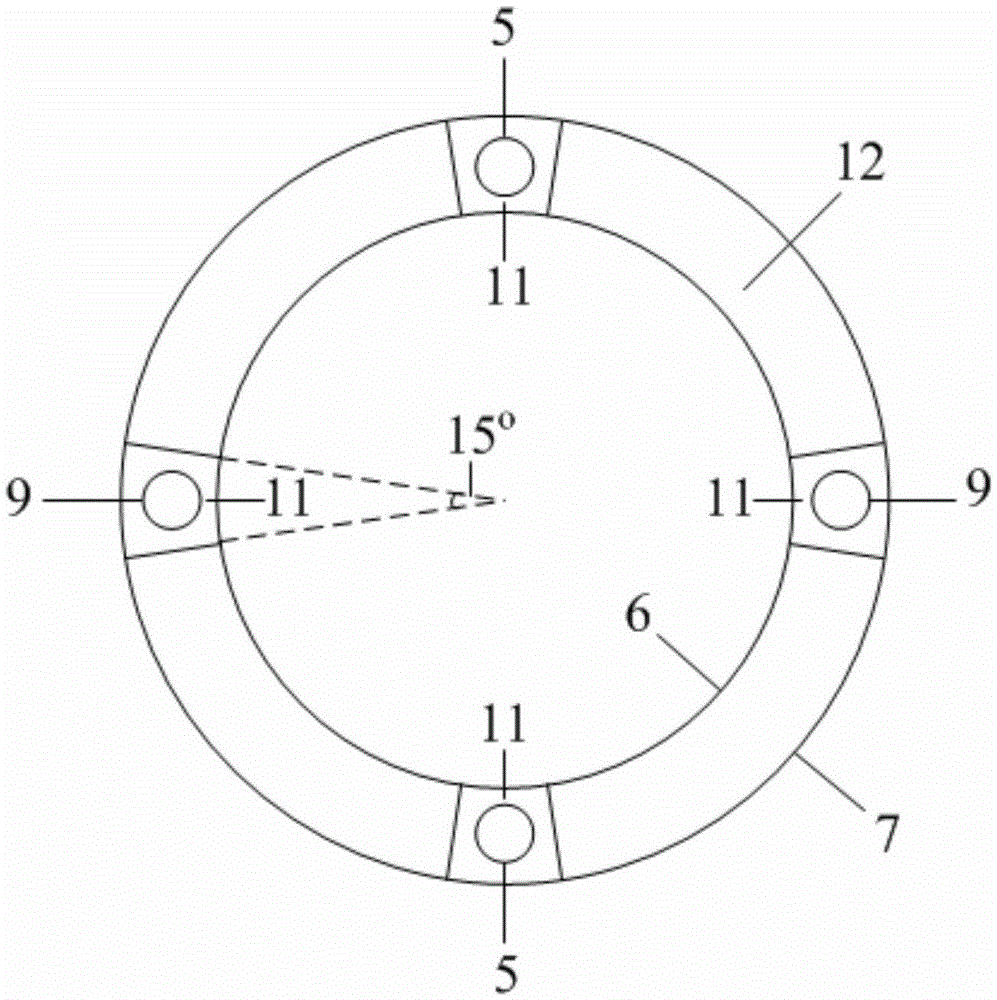

[0025] figure 1It is a schematic diagram of the system structure of the present invention. The present invention consists of a gas storage tank 1, a filter 2, a gas heater 3, a fan 4, a gas input pipe 5, an inner heat partition 6, an outer heat partition 7, a bottom heating ring 8, a gas output pipe 9, a stack The core coolant inlet baffle plate 10, the pipe fixing steel plate 11, and the pipes and valves connected between the above-mentioned components; wherein the inner thermal partition 6 and the outer thermal partition 7 are composed of an upper vertical section, a middle horizontal section, The lower vertical section is composed of a gap between the inner thermal partition 6 and the outer thermal partition 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com