Full natural-circulating air cooling tower

A technology of circulating air and cooling towers, which is applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of not being able to meet cost requirements, increase equipment, and large volume of cooling towers, and achieve increased The effect of natural circulation ability, reduction of heat transfer, and improvement of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

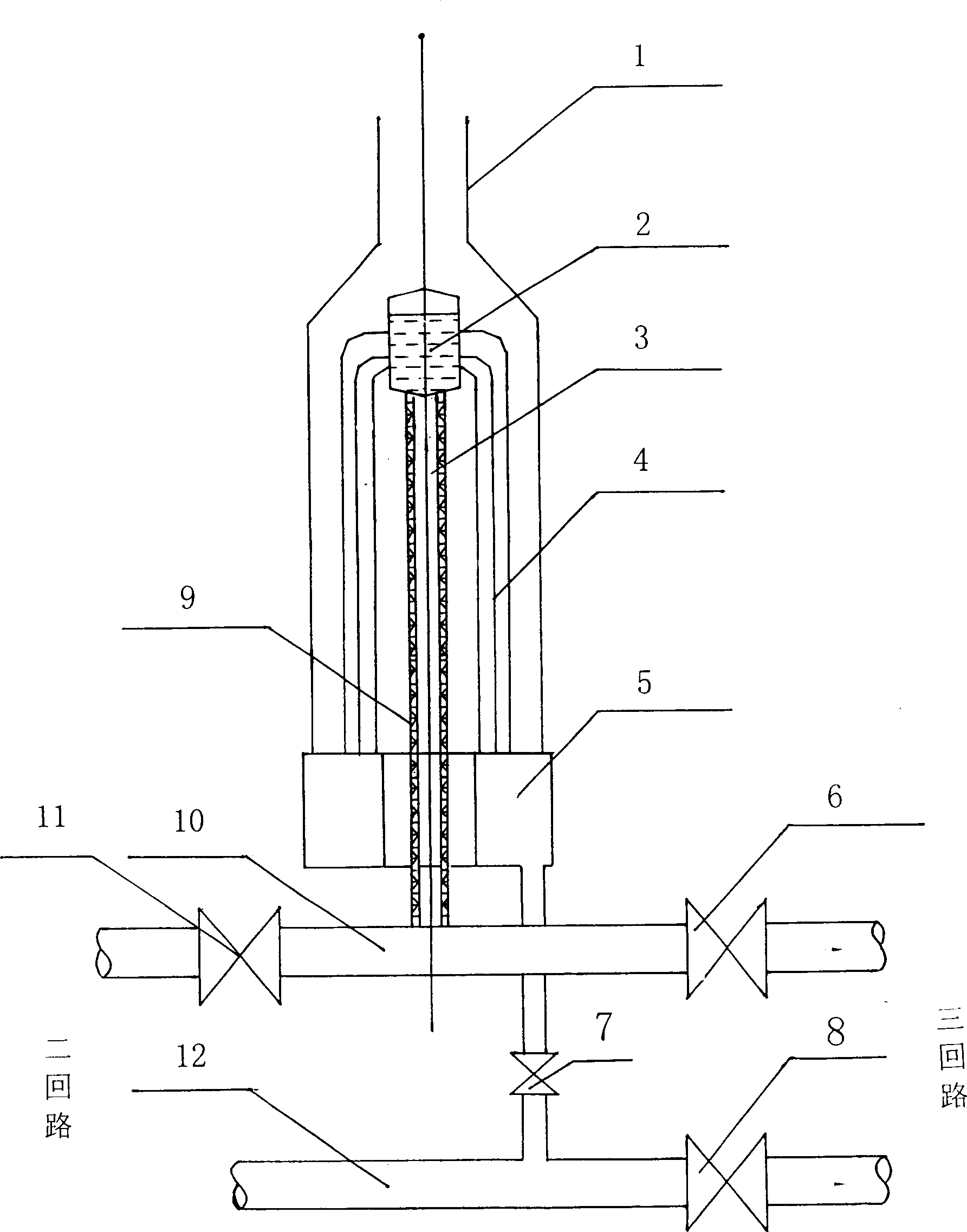

[0014] Such as figure 1 As shown, a full natural circulation air cooling tower includes a tower body and a rising pipe 3 connected to the heat pipe section 10 of the atmospheric pressure reactor secondary circuit arranged in the tower body. The rising pipe 3 is vertically arranged, and the outer side is covered with an insulating layer 9, the thermal insulation layer 9 generally can use thermal insulation cotton. An expansion tank 2 is provided at the top of the riser pipe 3, and the expansion tank 2 is connected to a vertically arranged heat transfer tube 4. The main function of the expansion tank 2 is to distribute water to the heat transfer tube 4 more evenly. In addition, there is a space for nitrogen pressure stabilization on the upper part of the expansion tank 2 to ensure that the pressure of the secondary circuit exceeds the pressure of the primary circuit under any working conditions. According to specific requirements, the pressure can be adjusted by charging and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com