Accelerator-driven lead-bismuth cooled subcritical traveling wave reactor

An accelerator-driven, subcritical technology, applied in cooling devices, reactors, nuclear power generation, etc., can solve the problems of high fuel consumption of traveling wave reactors and reduce the practical feasibility of traveling wave reactors, and achieve high neutron economy and eliminate nuclear power generation. Possibility of criticality accidents, effect of good natural circulation capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

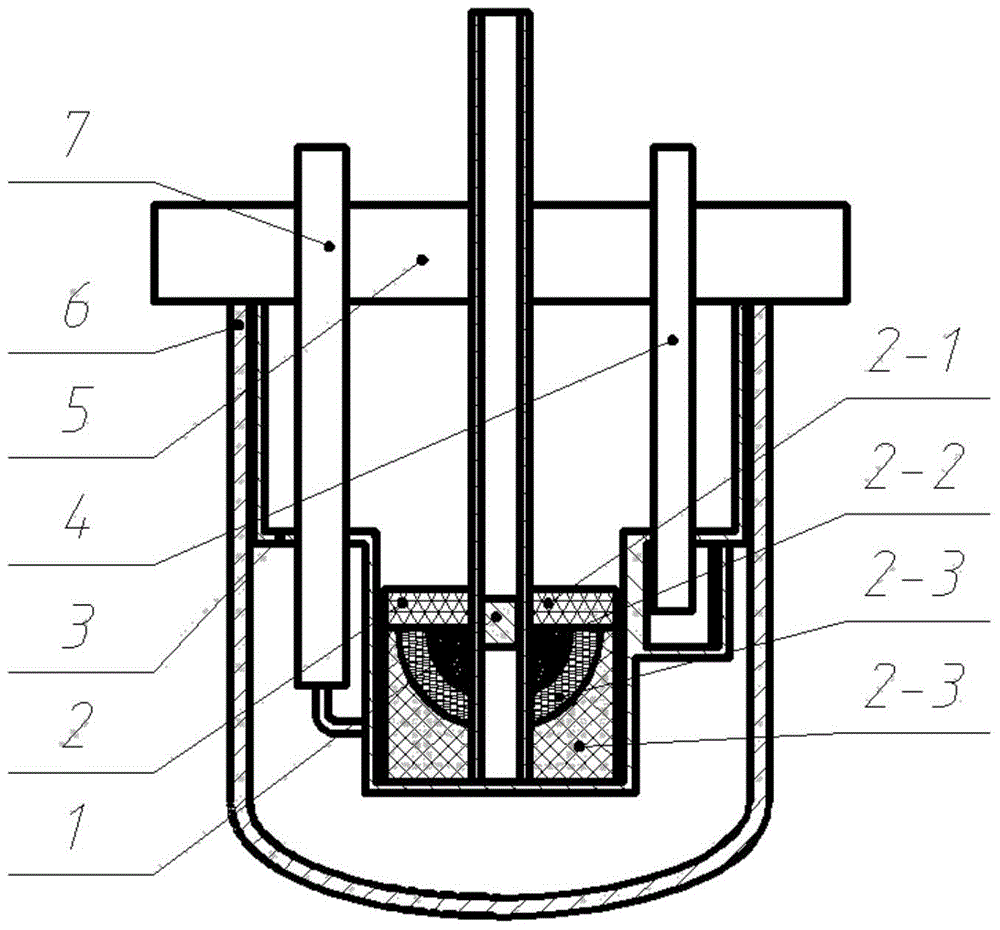

[0022] see figure 1 , the accelerator-driven lead-bismuth cooled subcritical traveling wave reactor disclosed in the present invention comprises a movable neutron source target 1, core fuel 2, reactor internals 3, main heat exchanger 4, stack top cover 5, stack container 6 and The main pump 7 and the core fuel 2 are divided into four areas: the spent fuel area 2-1, the burning wave area 2-2, the breeding wave area 2-3 and the new fuel area 2-4. The stack top cover 5 is in the form of a flat cover, installed on the upper edge of the stack container 6; the stack internals 3 are welded to the position above the bottom head of the stack container 6, and serve as core fuel 2, main heat exchanger 4, main pump 7, etc. Provide support and positioning and separate the cold pool and the hot pool. The upper part of the stack internals 3 is a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com