In-pile heat separation system of liquid heavy metal cooling natural circulating pool type reactor

A technology of liquid heavy metals and natural circulation, applied in reactors, cooling devices, reducing greenhouse gases, etc., can solve problems affecting the thermal efficiency and stability of the primary loop coolant cycle, reduce the natural circulation capacity of the whole stack, etc., and achieve the increase of natural circulation capability, increased reliability and safety, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

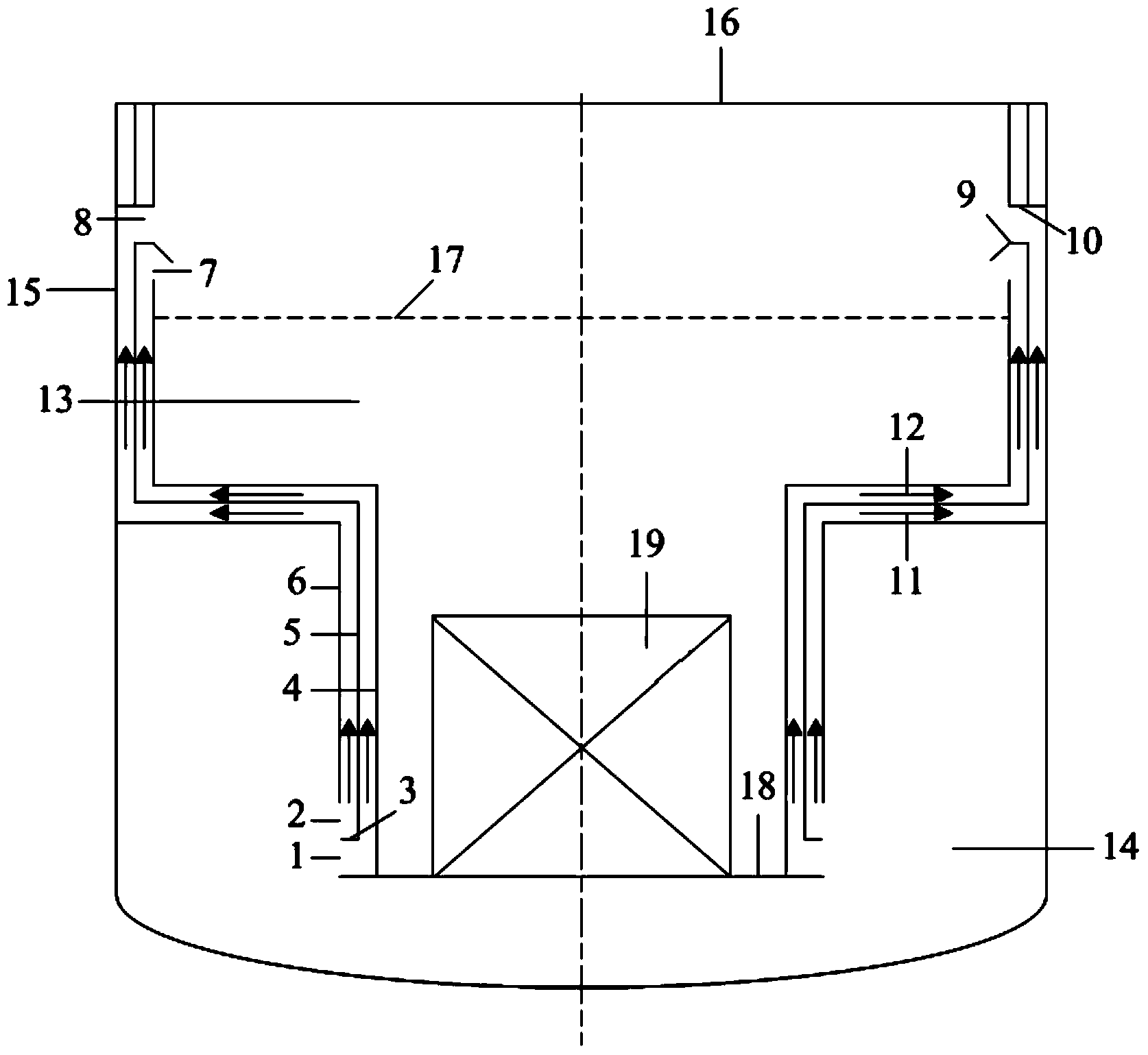

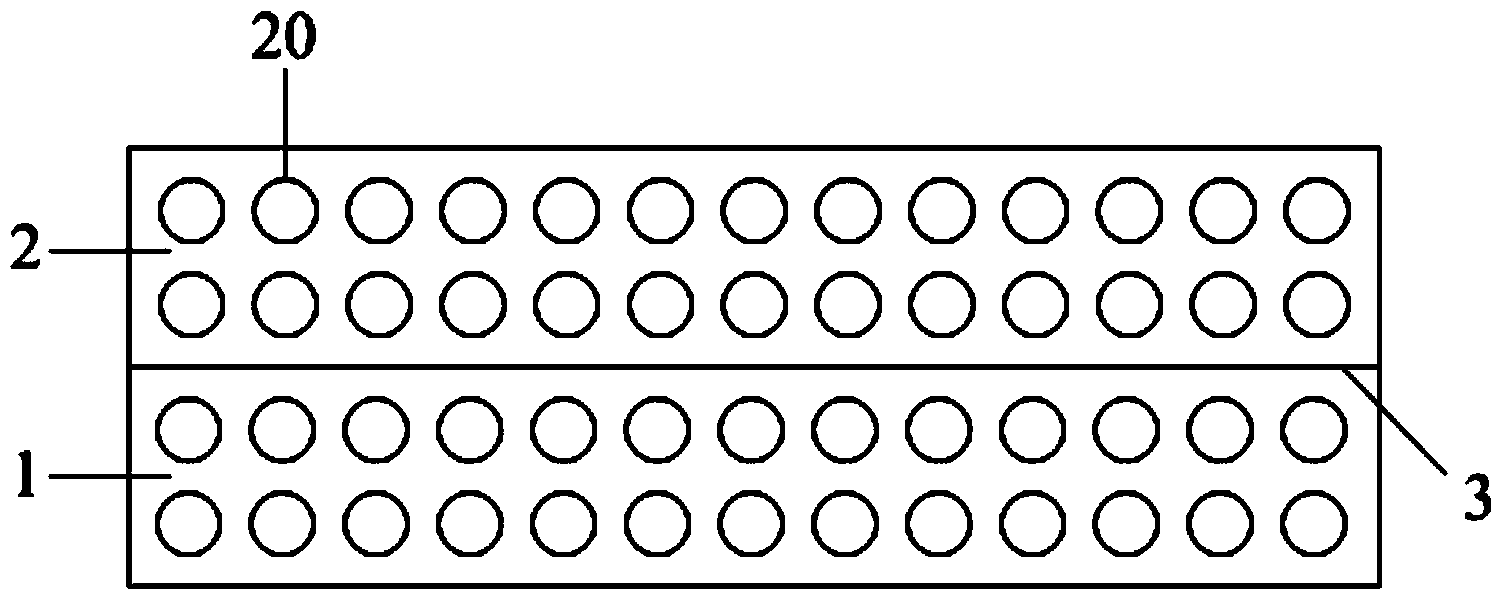

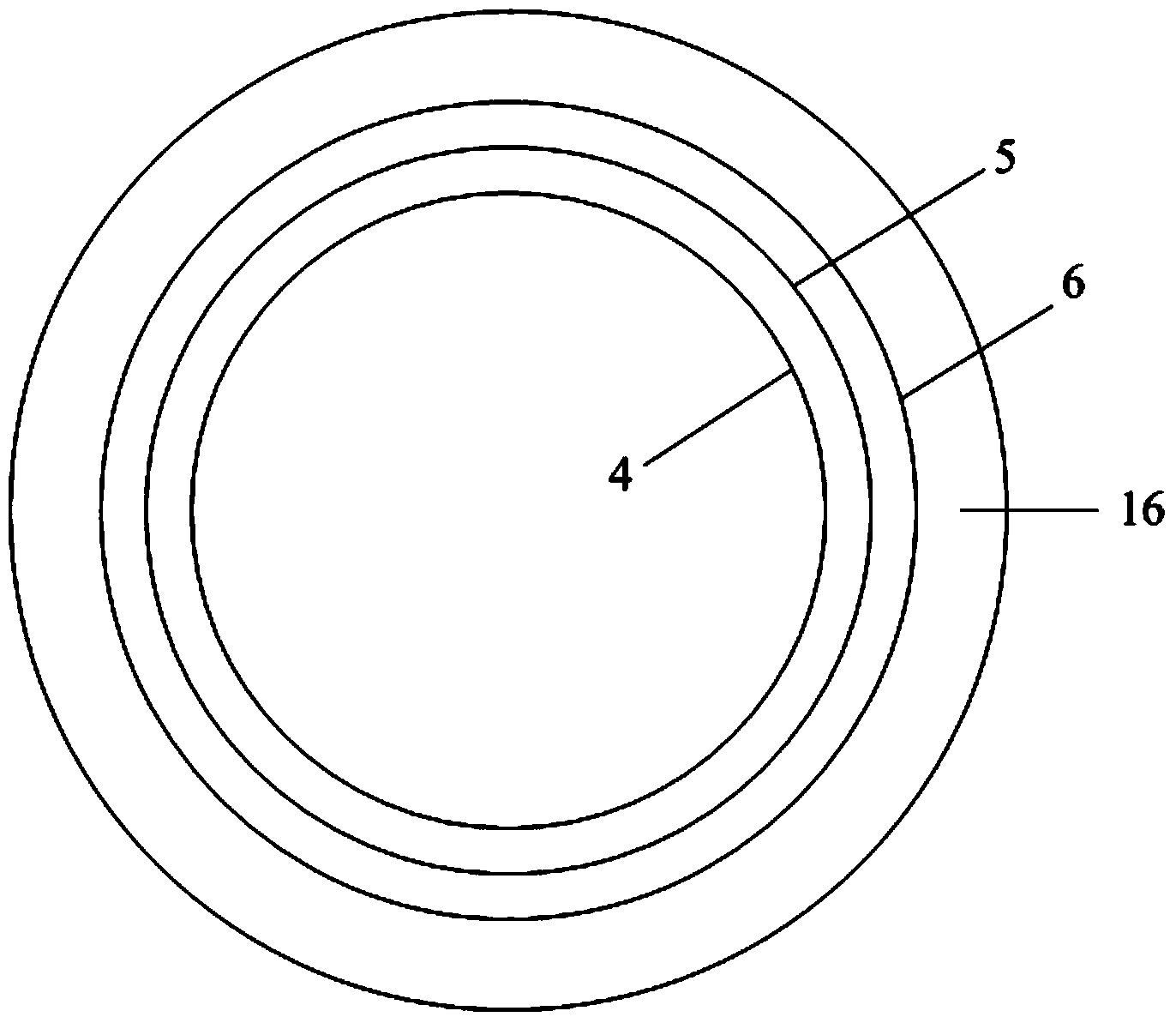

[0018] Such as figure 1As shown, the cold and hot pool separation system in a liquid heavy metal cooling natural circulation pool reactor reactor provided by the present invention is composed of an inner layer coolant inlet 1, an outer layer coolant inlet 2, a coolant inlet baffle plate 3, and an inner layer heat sink. Separator 4, middle thermal partition 5, outer thermal partition 6, inner coolant outlet 7, outer coolant outlet 8, inner coolant outlet baffle 9 and outer coolant outlet baffle 10. Wherein the hot pool 13 and the cold pool 14 are all located inside the main container 15, and the hot pool 13 is positioned above the cold pool 14; the inner layer thermal partition 4, the middle layer thermal partition 5 and the outer layer thermal partition 6 are all vertically formed by the upper part. section, the middle horizontal section, and the lower vertical section, the inner thermal partition 4 is in contact with the hot pool 13, the lower vertical section and the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com