Patents

Literature

36 results about "Pool-type reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pool-type reactors, also called swimming pool reactors, are a type of nuclear reactor that has a core (consisting of the fuel elements and the control rods) immersed in an open pool of usually water. Some sodium-cooled reactors like the BN-600 have sodium pools instead. The rest of this article will assume that water is being used.

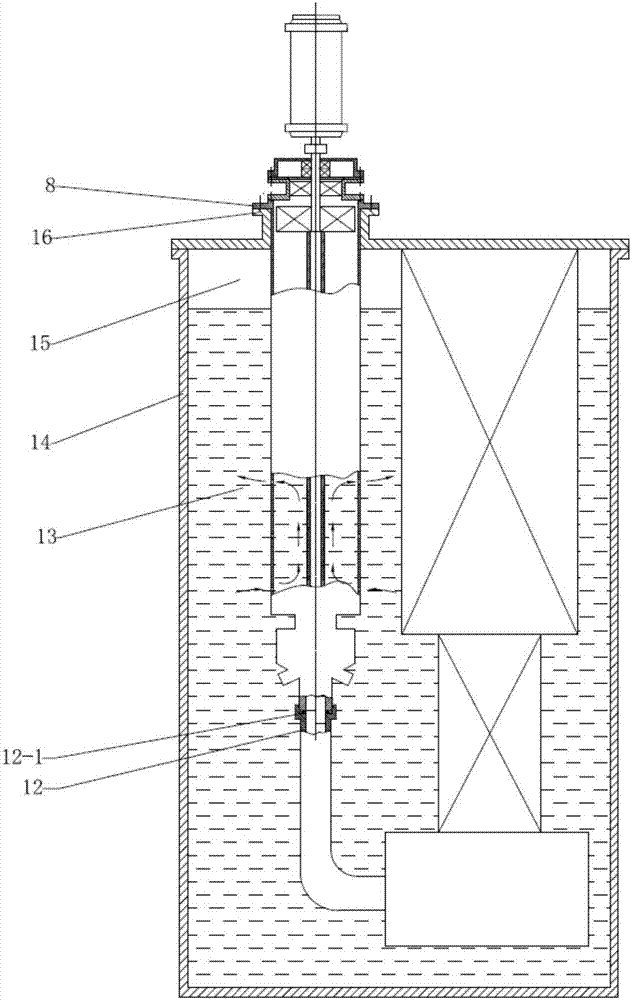

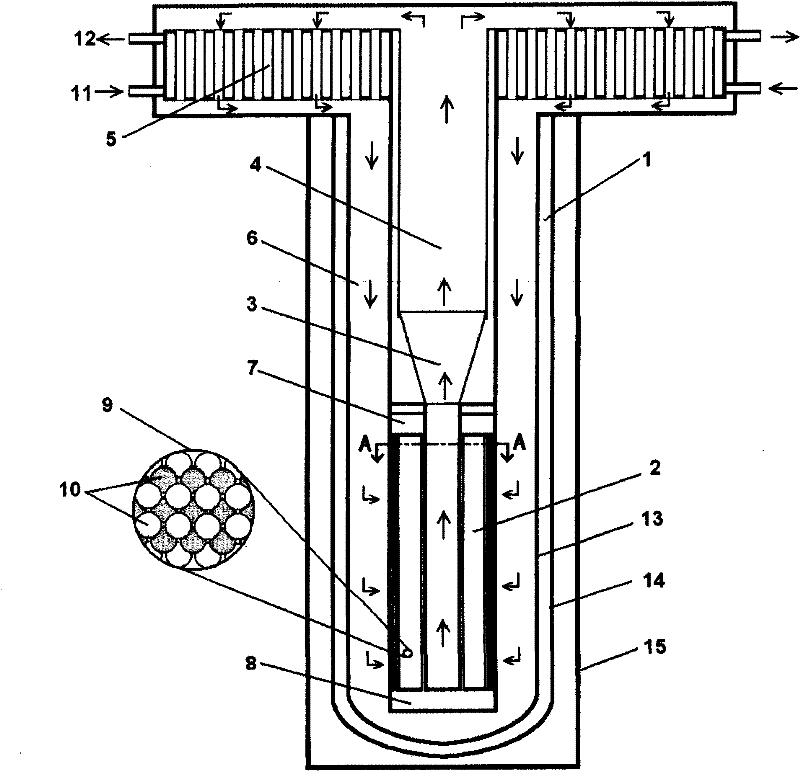

Non-kinetic inherently safe tube-pool type reactor

ActiveCN101149990AReliable passive safety systemSafeNuclear energy generationCooling arrangementInherent safetyNuclear reactor

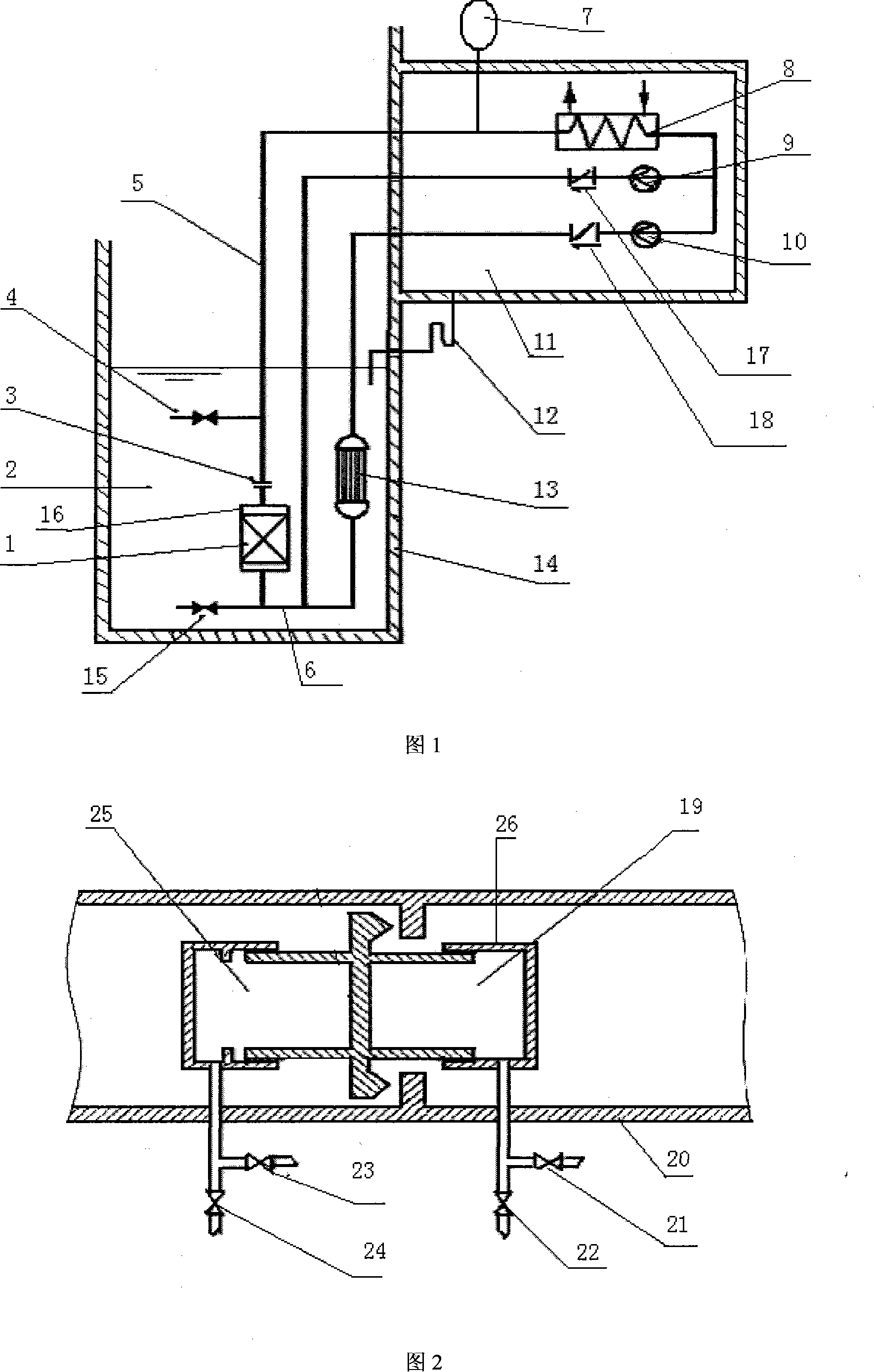

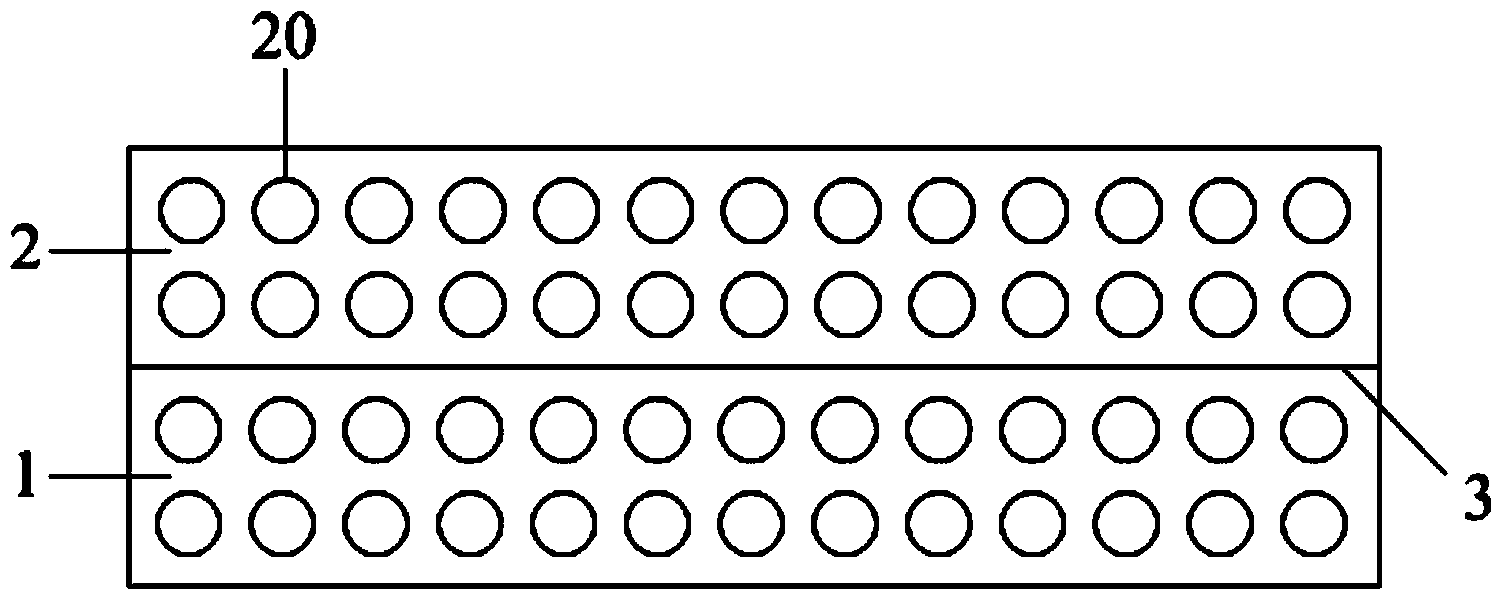

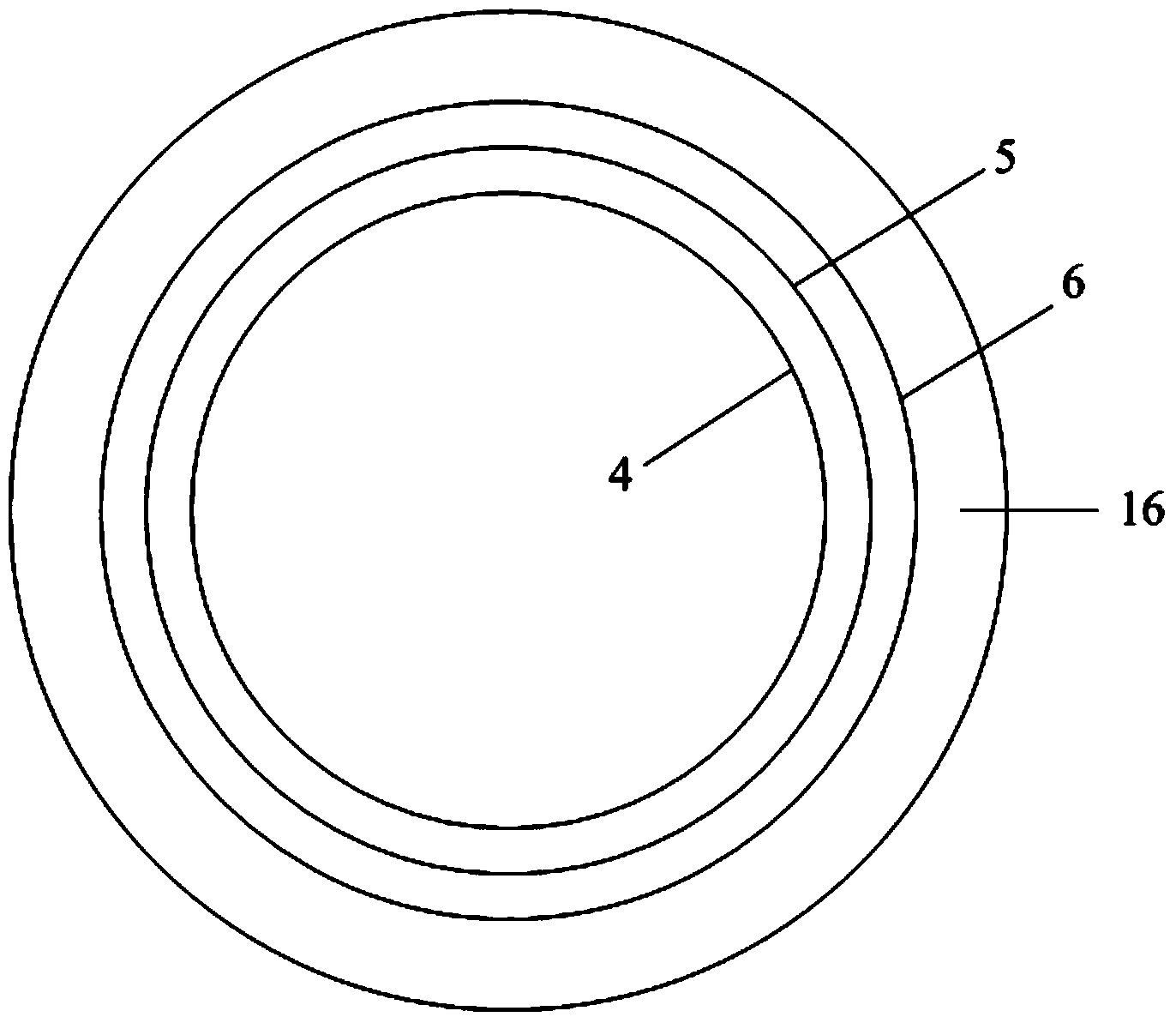

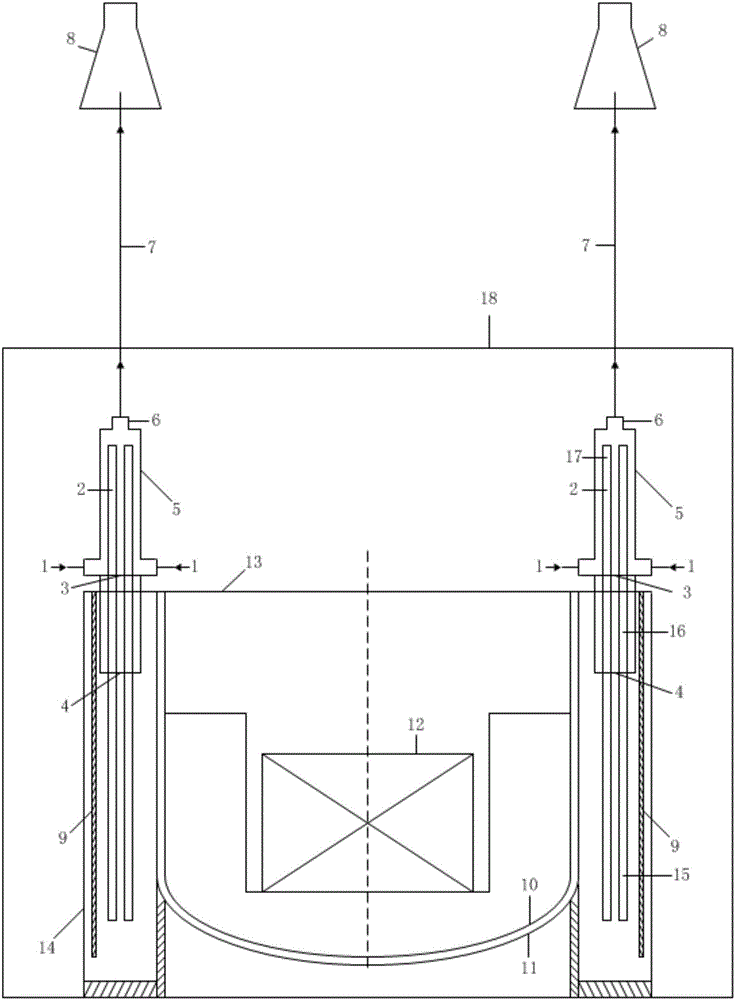

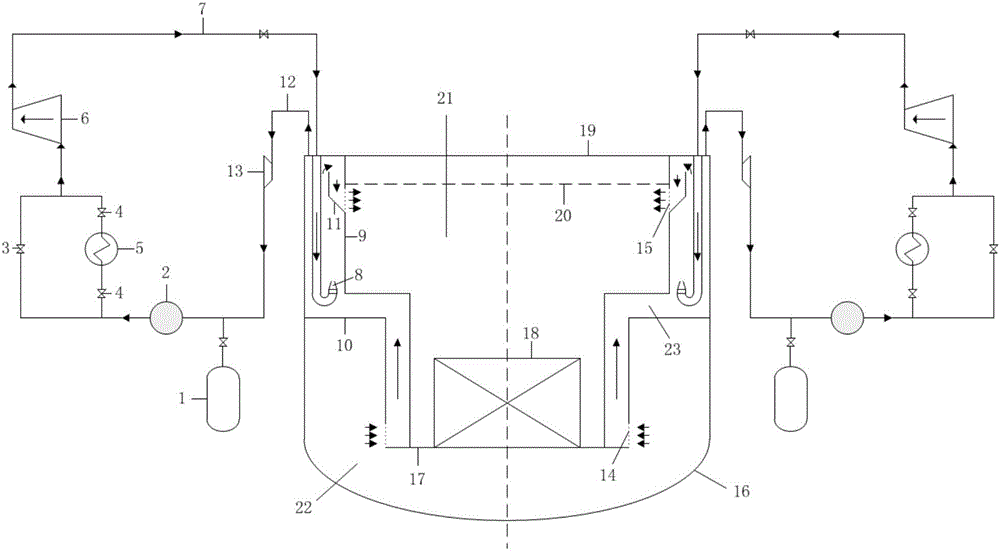

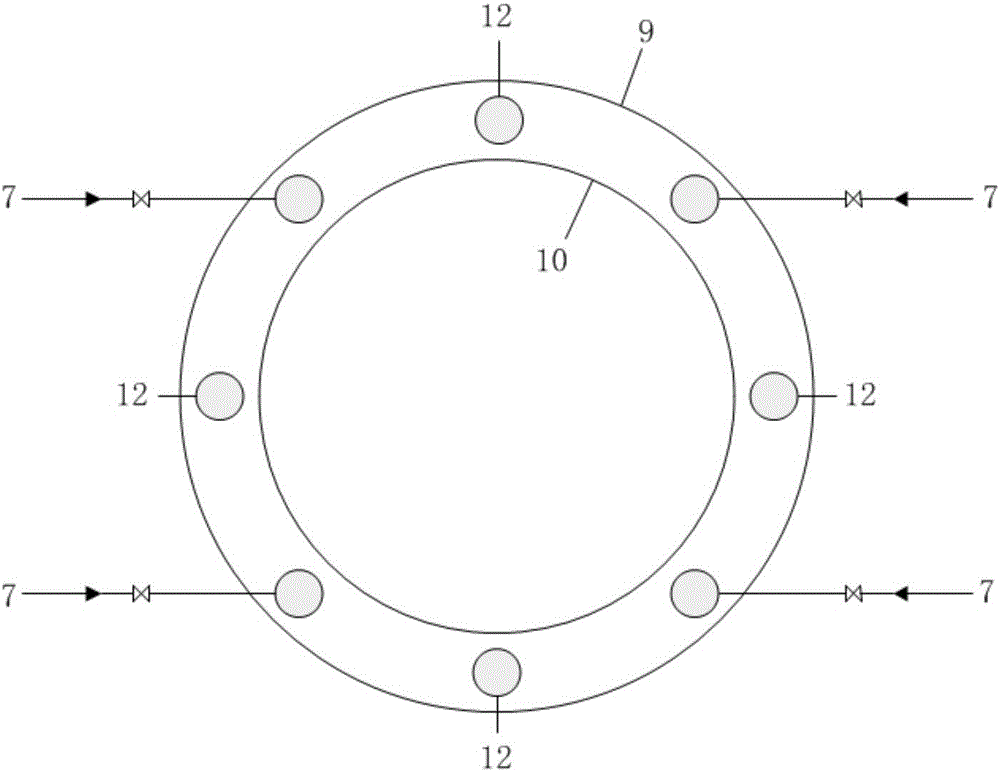

The invention relates to an inherent safety tube-pool type nuclear reactor for research. The cooling-water main pump and the after-heat deriving pump of the reactor are set at back of the main heat-exchanger and connected in parallel in the main circuit room. The after-heat heat-exchanger is fitted in the water pool of the reactor. The main circuit room is provided at upper part of the water pool and at the bottom of the main circuit room there is a pipeline communicated to the under-water part of the water pool. At the inlet and the outlet of the reactor core is respectively provided with a hydraulic control open-close valve communicated with the water pool of the reactor. When the main pipeline occurs water-loss fault, water in the main circuit room can return to the water pool. At same time, as the pressure in the reactor container is low, the hydraulic control open-close valves at inlet and outlet of the reactor core automatically opens. When the after-heat deriving pump occurs fault, the inlet-outlet hydraulic control open-close valve is opened by a signal of high reactor-core temperature to make the reactor core and the water pool form a natural circulation to derive the after heat of reactor core into the water pool of the reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

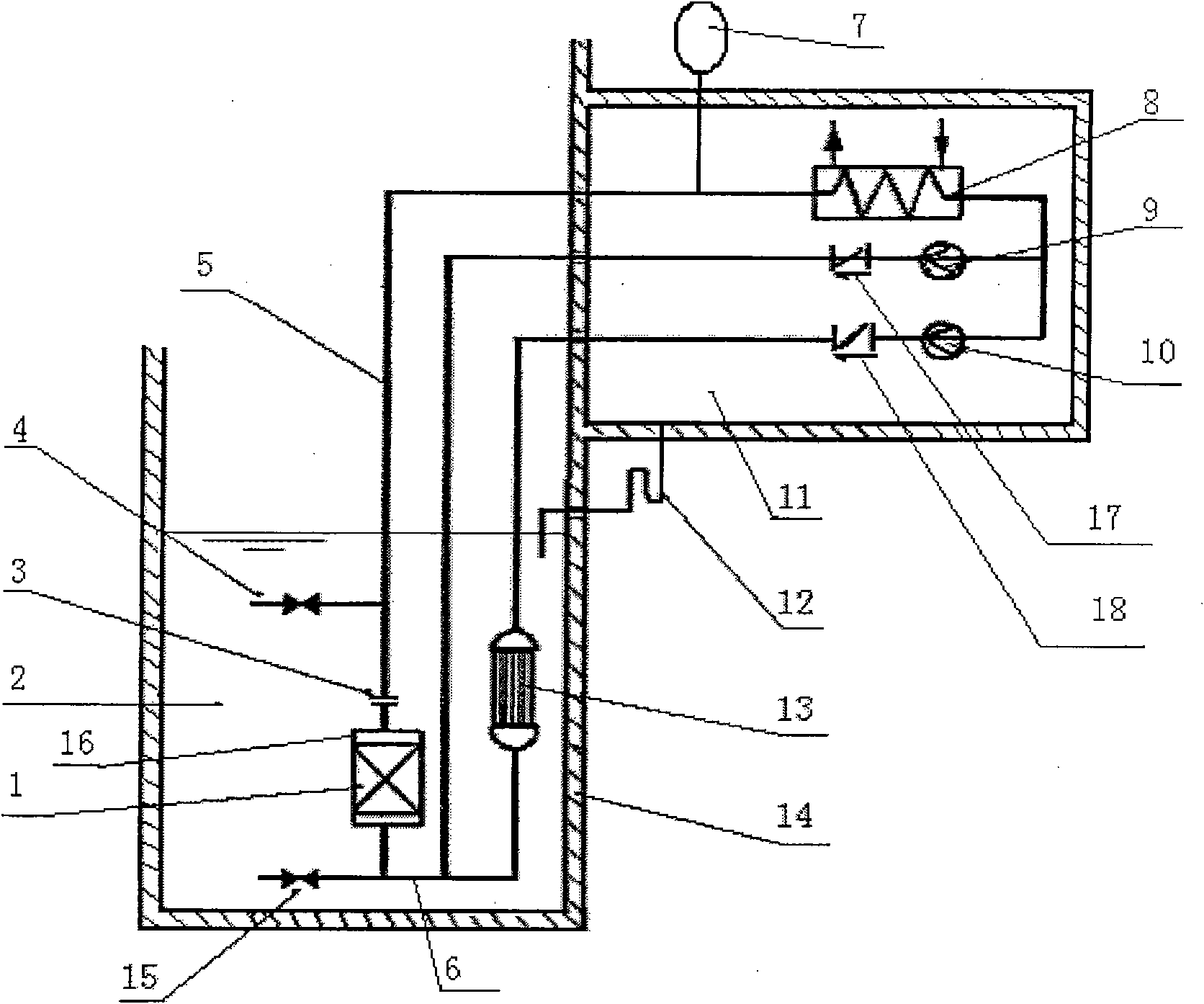

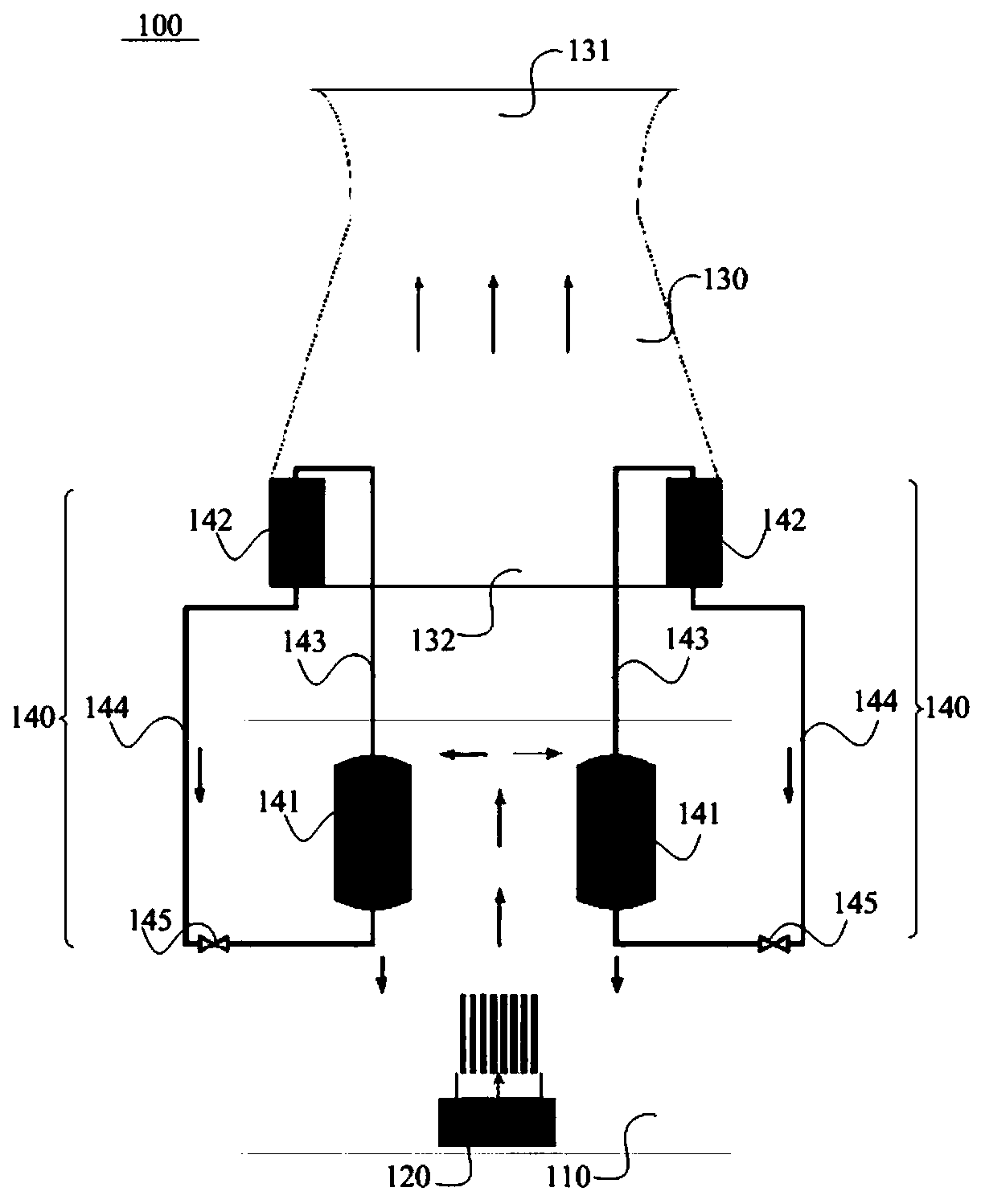

Temperature-triggered passive accident residual heat removal system for pool type reactor

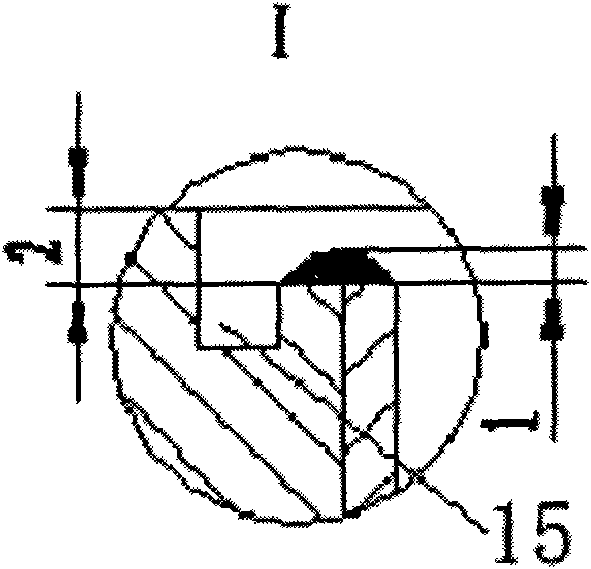

ActiveCN104269194AImprove reliabilityEfficient take awayNuclear energy generationCooling arrangementSystems designFree cooling

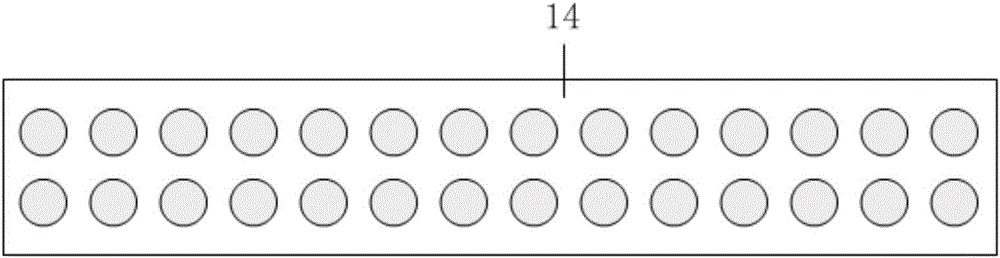

The invention discloses a temperature-triggered passive accident residual heat removal system for a pool type reactor. The system consists of a direct reactor core cooling system and an auxiliary reactor safety container cooling system. The system has the significant advantage that the direct reactor core cooling system and the auxiliary reactor safety container cooling system share one air cooling system, so that the system design of the reactor is greatly simplified, and the construction cost is saved. The auxiliary reactor safety container cooling system realizes natural cooling through ambient air on the outer side of a safety container, and the process has the characteristic of passiveness. The passive accident residual heat removal system is passive, independent, high in efficiency and high in reliability and meets the safety design requirement for the pool type reactor.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

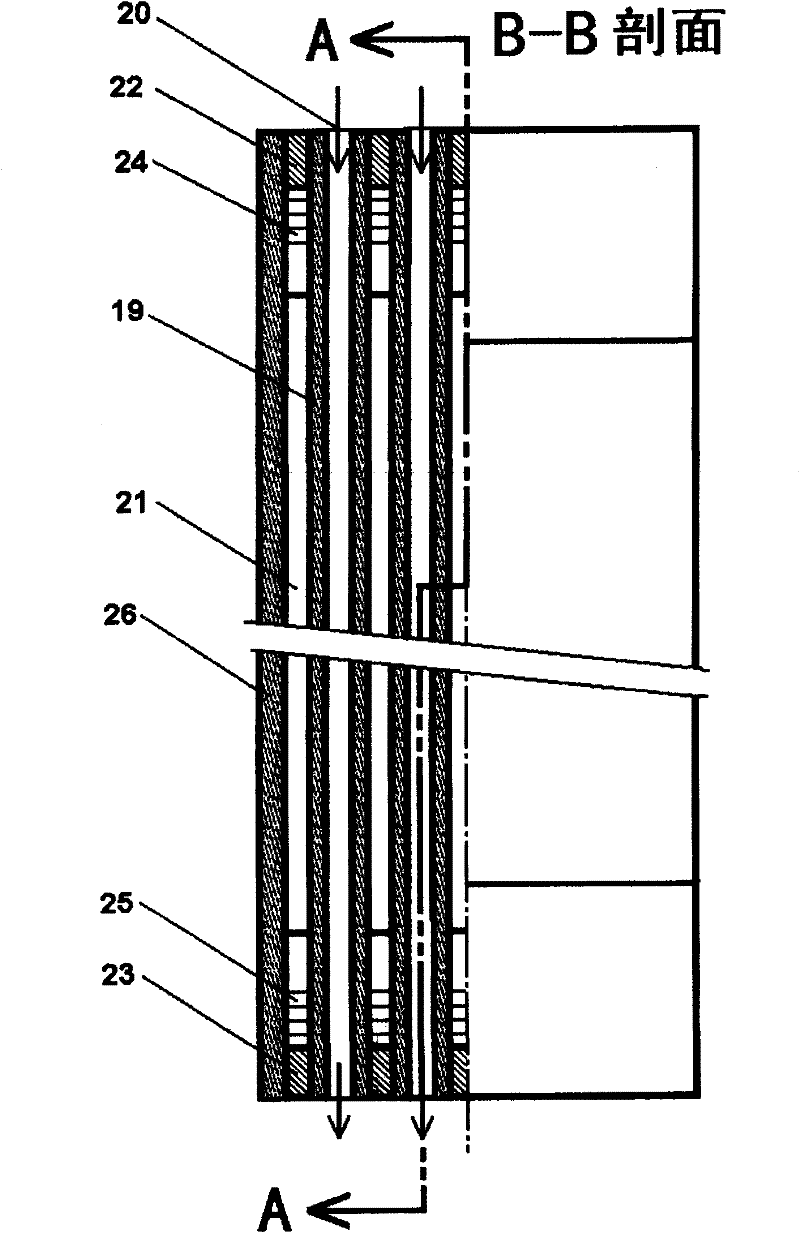

Liquid metal cooling tank type separation system for in-pile cold tank and in-pile hot tank of reactor

InactiveCN103065693AHigh thermal efficiencyImprove insulation performanceNuclear energy generationCooling arrangementReactor systemNuclear engineering

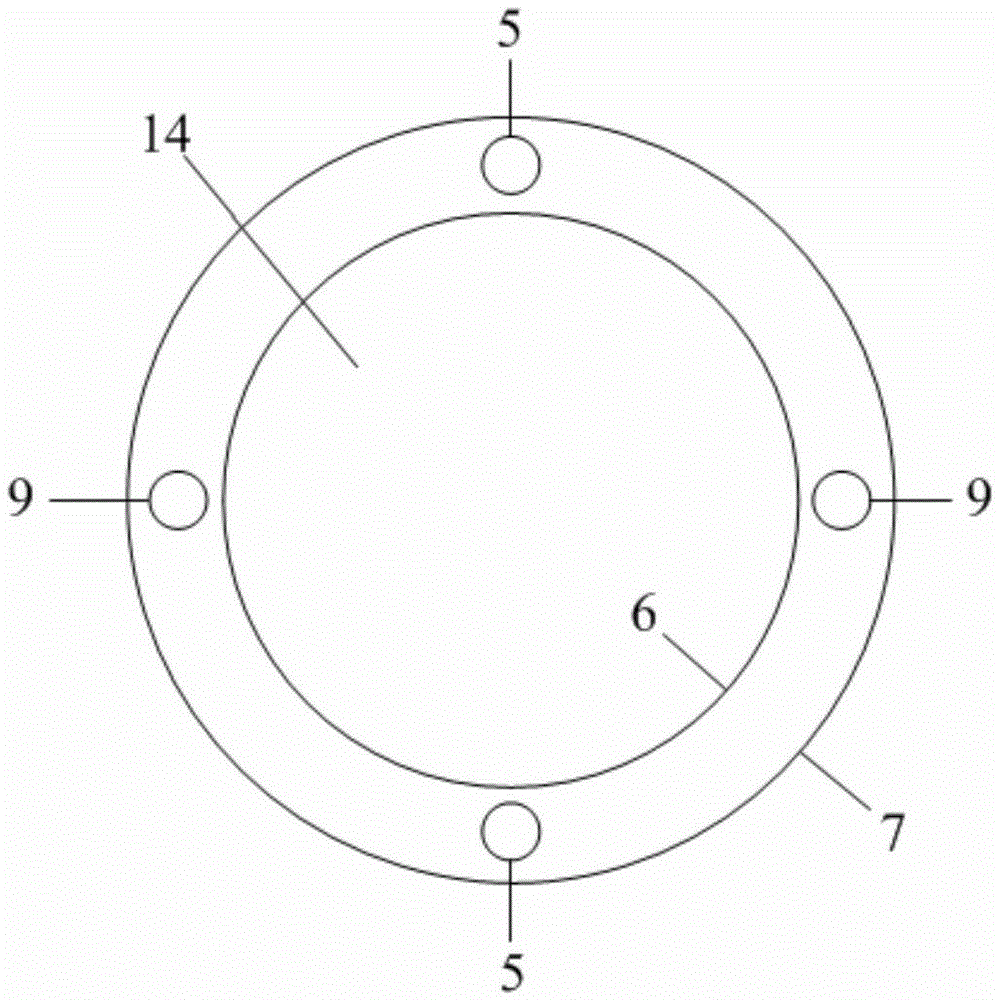

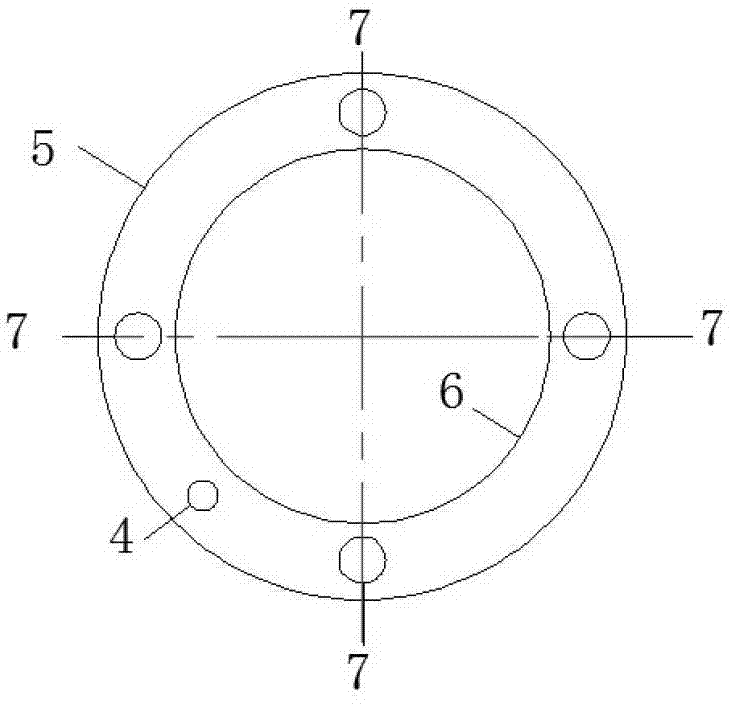

The invention provides a liquid metal cooling tank type separation system for an in-pile cold tank and an in-pile hot tank of a reactor. The separation system comprises a gas storage tank (1), a heater (2), a fan (3), an air inlet valve (4), an in-pile hot partition plate (5), an air outlet valve (6) and a connecting pipeline (7). When the reactor is in operation, the system takes the effect of separating the in-pile hot tank from the in-pile cold tank. At the moment, the air inlet valve (4) and the air outlet valve (6) are in the switching off state and the in-pile partition plate (5) is filled with gas. When the reactor is shut down, the system takes the effect of auxiliary heating of in-pile refrigerant. At the moment, the air inlet valve (4) and the air outlet valve (6) are switched on, the heater (2) and the fan (3) are in operation and gas is introduced into the in-pile hot partition plate (5) from an air inlet and is discharged out of the in-pile hot partition plate (5) from an air outlet. Two functions of separation of the in-pile cold tank from the in-pile hot tank and auxiliary heating of in-pile refrigerant are realized by the same equipment, and thus the complexity of reactor systems is lowered and the economy and the safety of reactors are improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

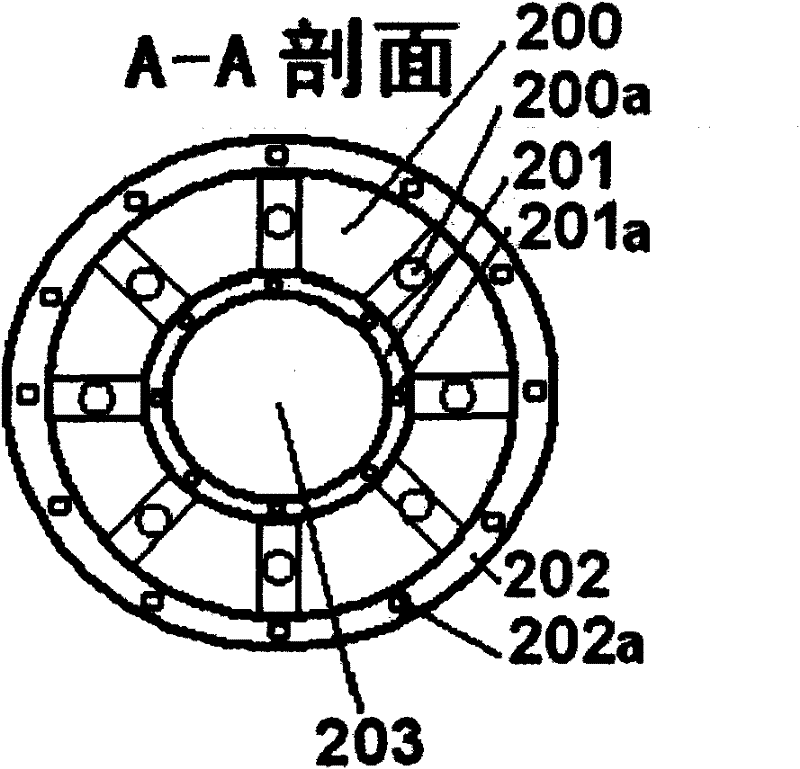

In-pile heat separation system of liquid heavy metal cooling natural circulating pool type reactor

InactiveCN103714868AImprove reliabilityImprove securityNuclear energy generationCooling arrangementNuclear engineeringLiquid state

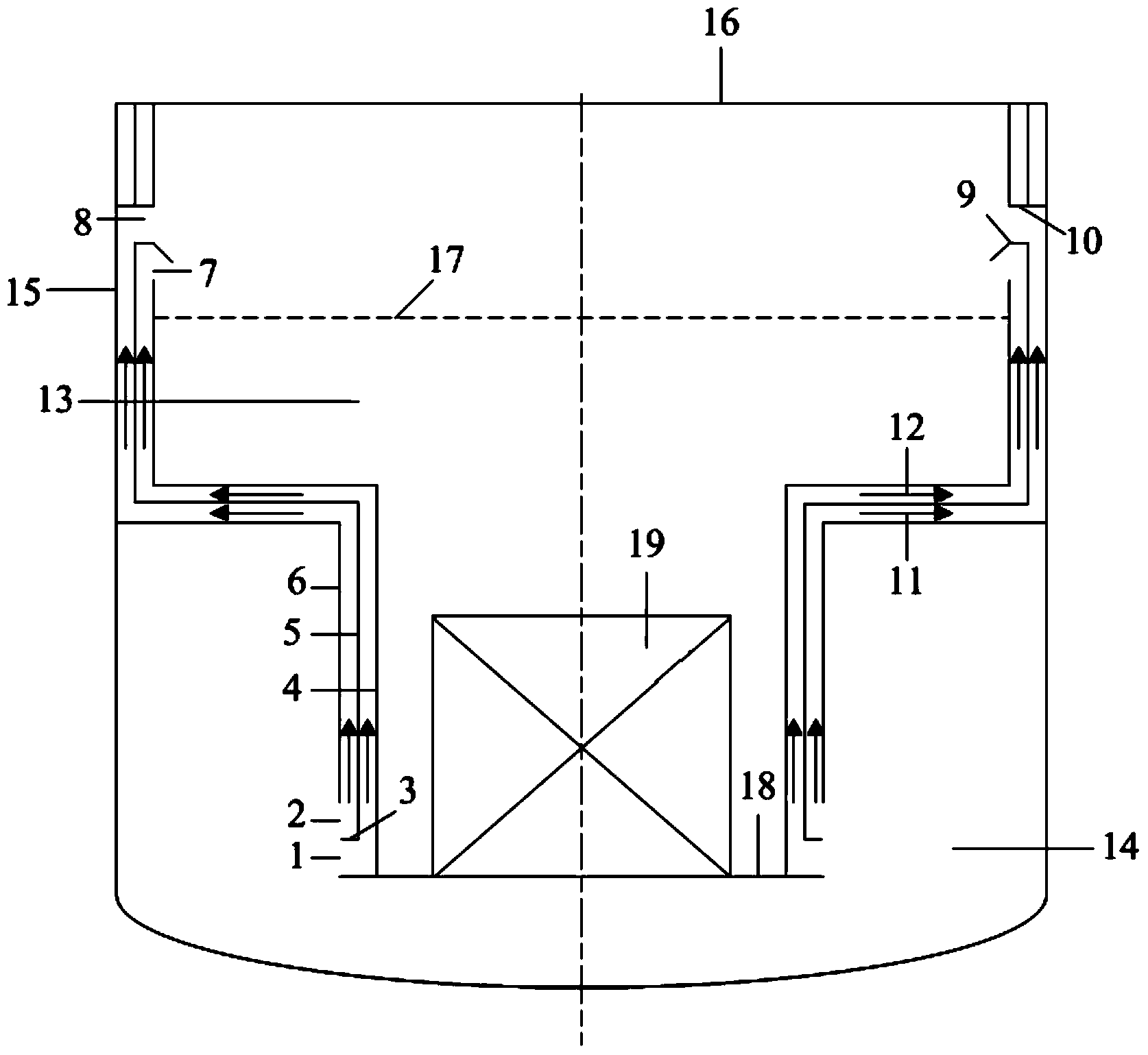

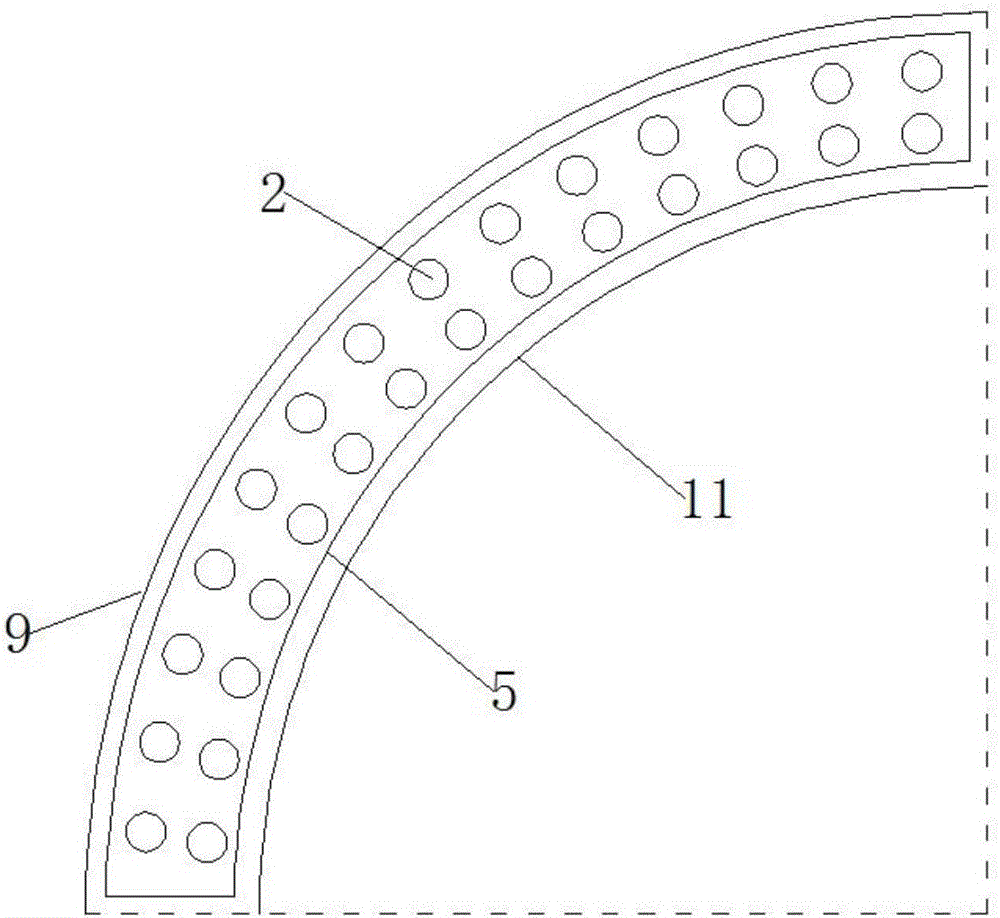

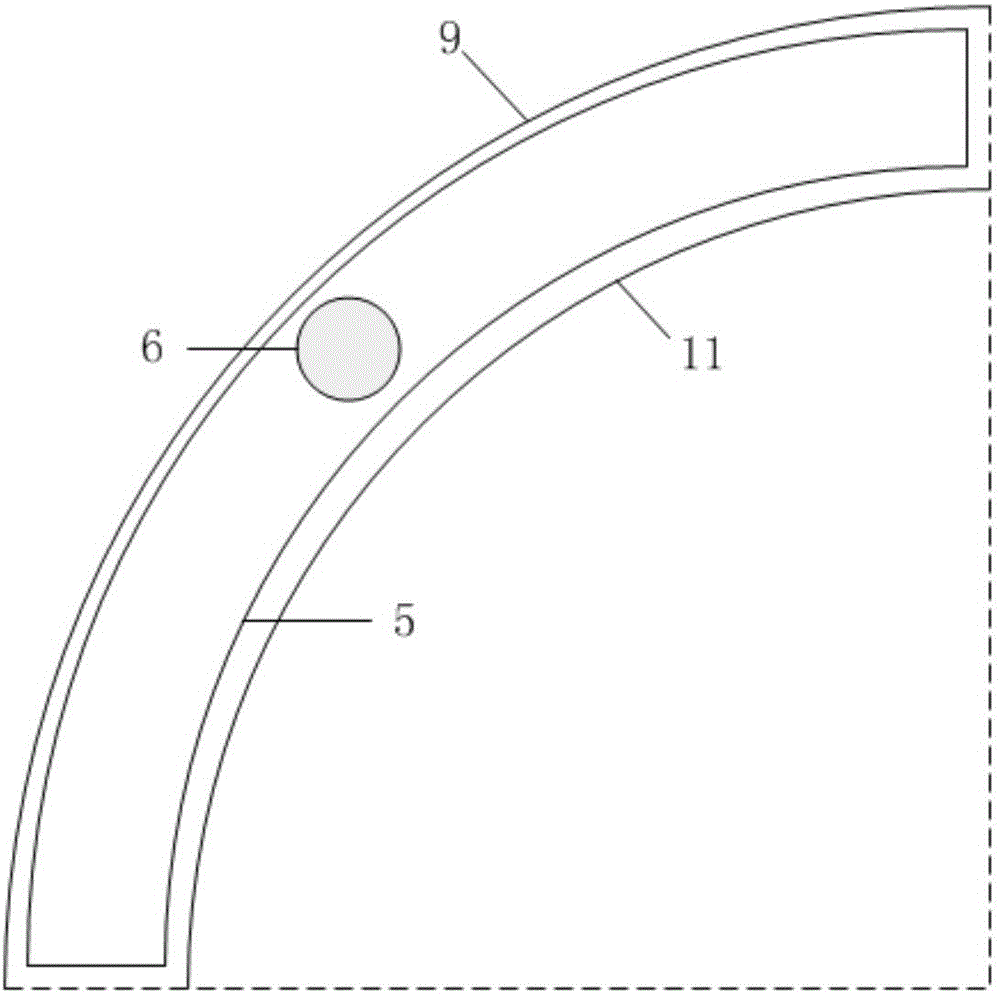

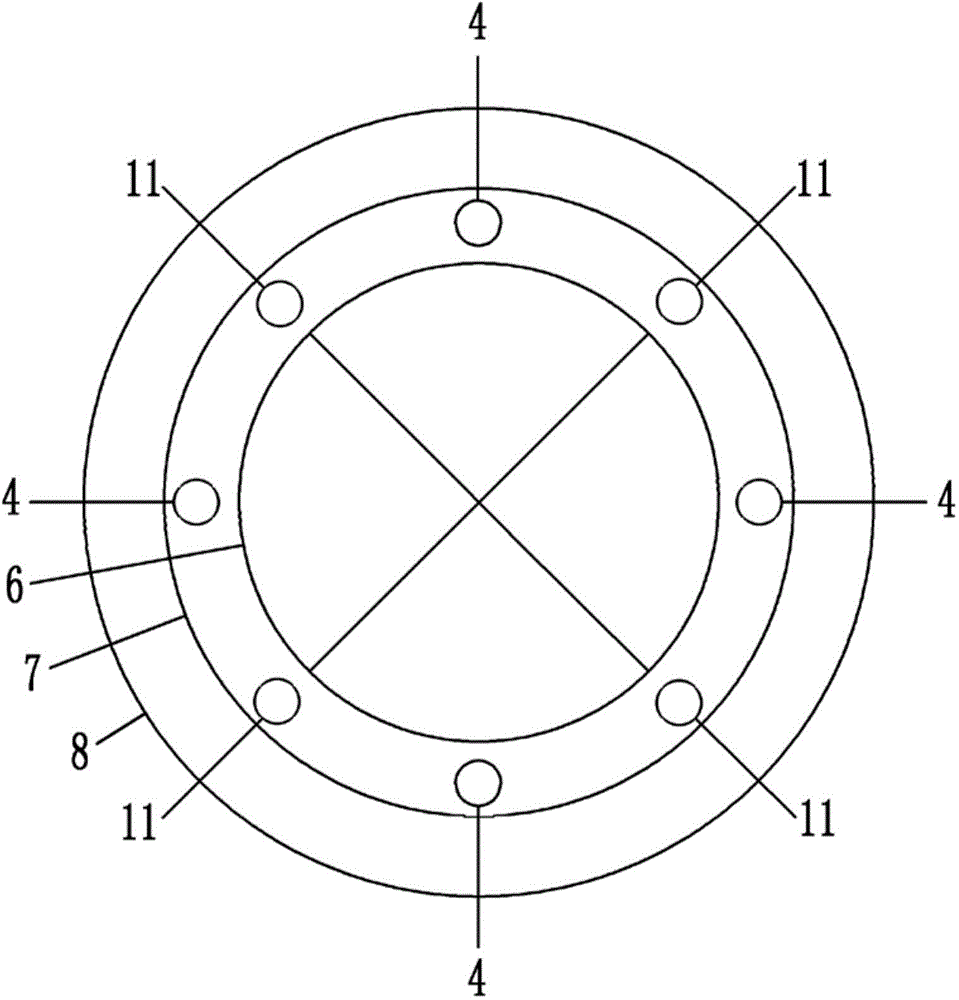

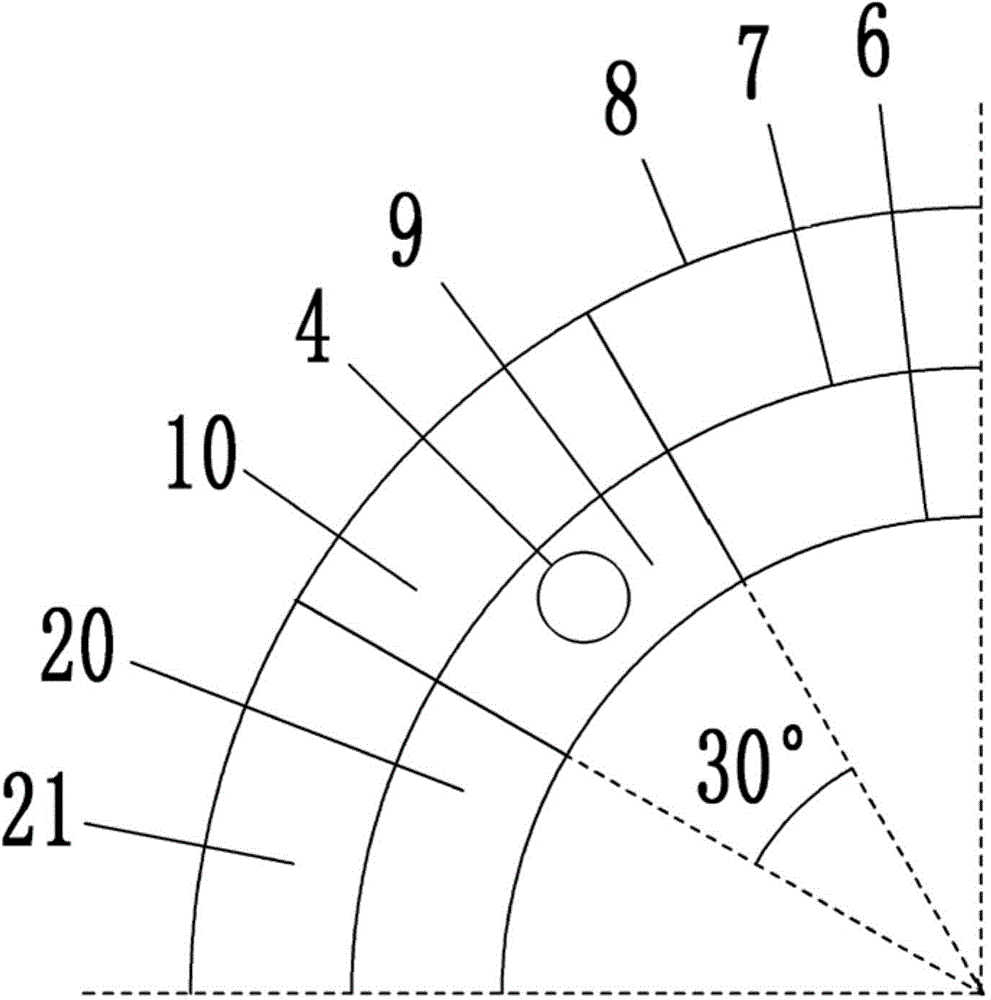

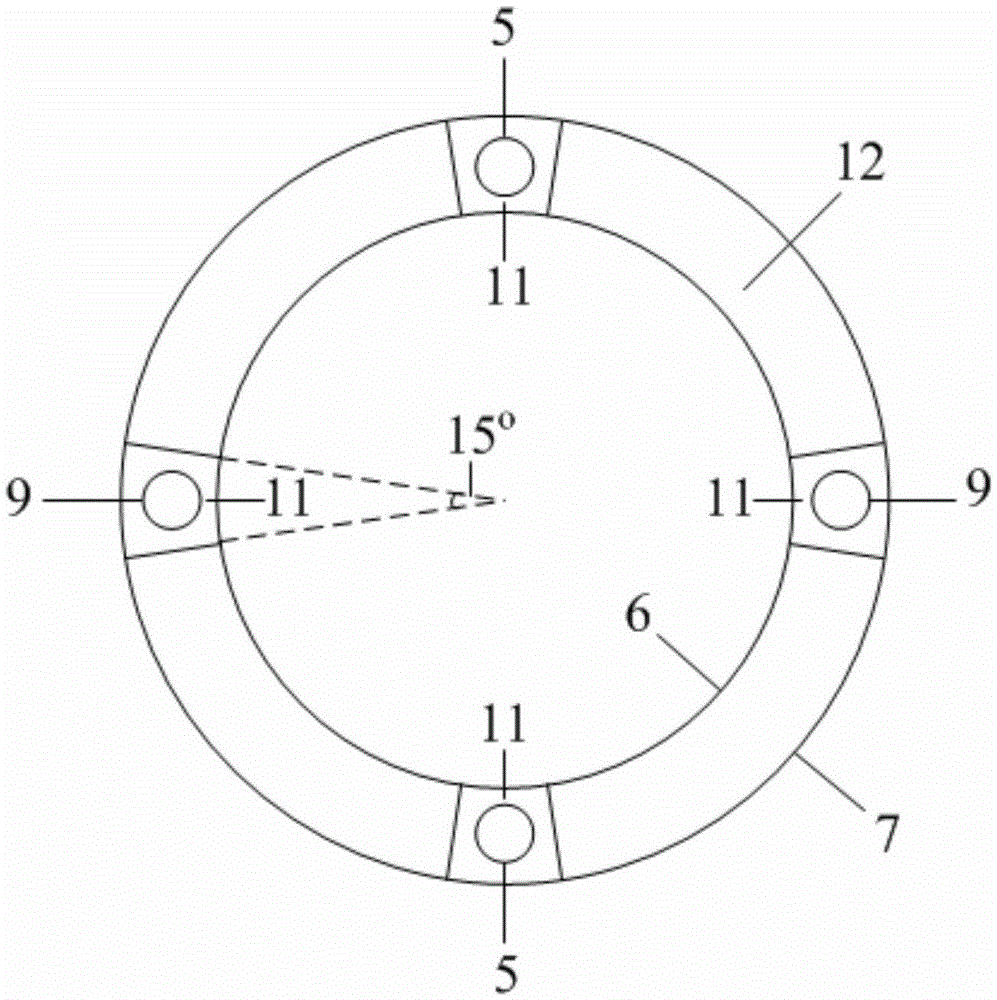

The invention discloses an in-pile heat separation system of a liquid heavy metal cooling natural circulating pool type reactor. The system consists of an inner layer coolant inlet, an outer layer coolant inlet, a coolant inlet baffle, an inner layer heat partition plate, a middle layer heat partition plate, an outer layer heat partition plate, an inner layer coolant outlet, an outer layer coolant outlet, an inner layer coolant outlet baffle and an outer layer coolant outlet baffle. Gaps between the heat partition plates of the system are filled with liquid heavy metal and are communicated with a cold pool; coolants in the gaps between the heat partition plates are used for cooling the heat partition plates from bottom to top under the action of natural circulating driving force and are gathered into a hot pool through the coolant outlets above the heat partition plates. The in-pile heat separation system realizes a function of separating the cold pool from the hot pool in the liquid heavy metal cooling natural circulating pool type reactor; with the adoption of the complete passive design, the system is simple in structure; during running, an in-pile structural member does not need to be added or started; the heat efficiency of the liquid heavy metal cooling natural circulating pool type reactor can be effectively improved, the circulating stability of the coolants of the reactor can be guaranteed, and the economical property and the safety of the reactor can be improved.

Owner:UNIV OF SCI & TECH OF CHINA

Passive decay heat removal system for liquid metal cooling pool type reactor

ActiveCN106653107AImprove shielding effectWon't escapeNuclear energy generationCooling arrangementThermal isolationRadioactive agent

The invention discloses a passive decay heat removal system for a liquid metal cooling pool type reactor. The passive decay heat removal system is composed of a coolant inlet, a gravity-type heat pipe, an upper partition plate, a lower partition plate, a box body, a coolant outlet, a gas riser pipe, an exhaust stack, a thermal isolation layer, pipelines connected between devices, and valves. According to the invention, when a reactor is under accident states like station blackout, water supply interruption of a main heat exchanger or earthquake, a ventilation door of the exhaust stack is opened; cold air from the interior of a reactor containment enters into the box body through the coolant inlet, cools the condensing section of the gravity-type heat pipe and enters the gas riser pipe from the coolant outlet; hot air flows out of the reactor containment through the gas riser pipe; thus, the process has passive characteristic. The passive decay heat removal system provided by the invention has simple structure, is convenient to start, can simultaneously remove core decay heat and prevent radioactive substances in a reactor pit from escaping, and has passiveness, independence and high reliability.

Owner:NANHUA UNIV

Method for automatically producing high-temperature nuclear energy for long term under any power

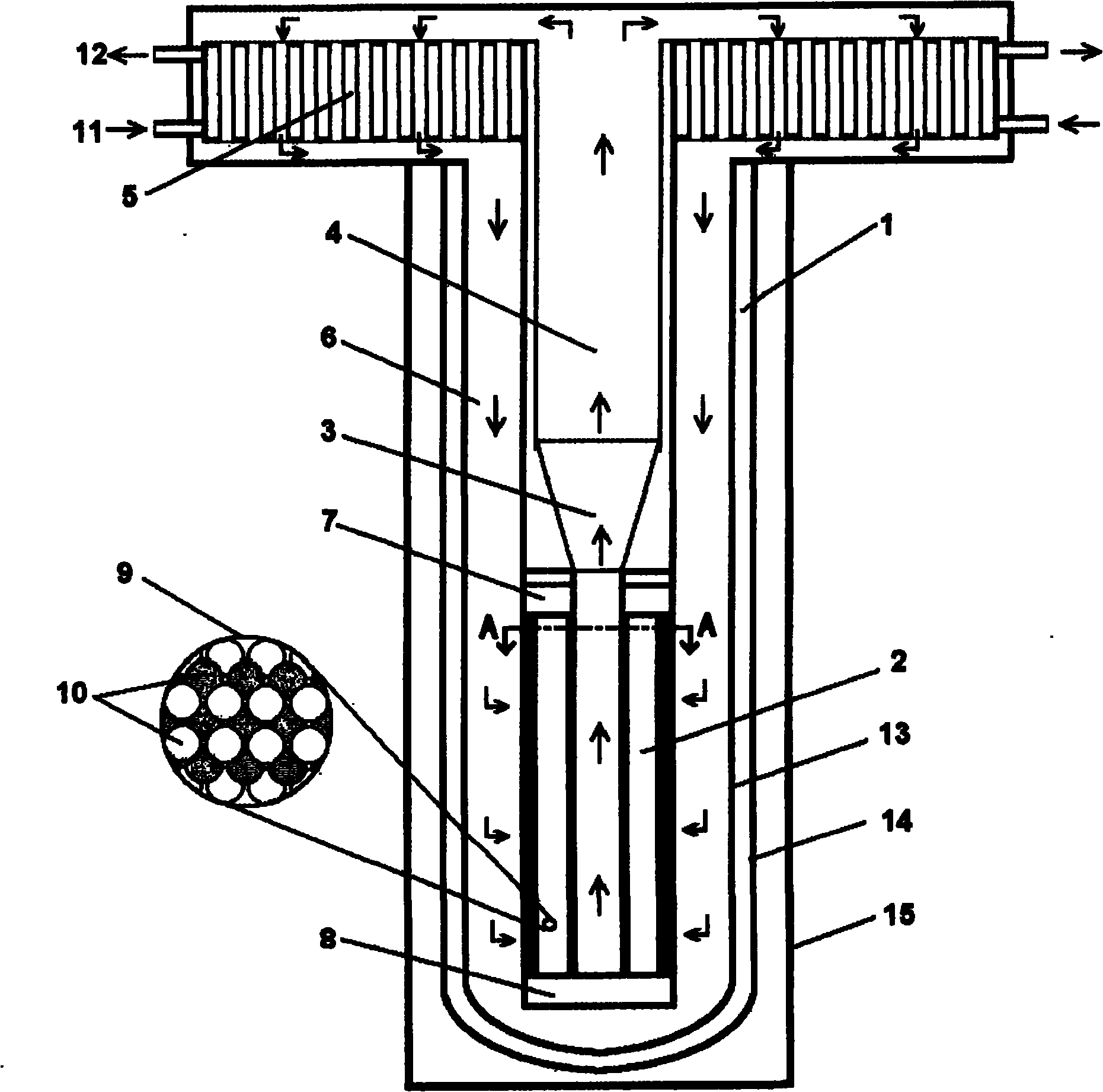

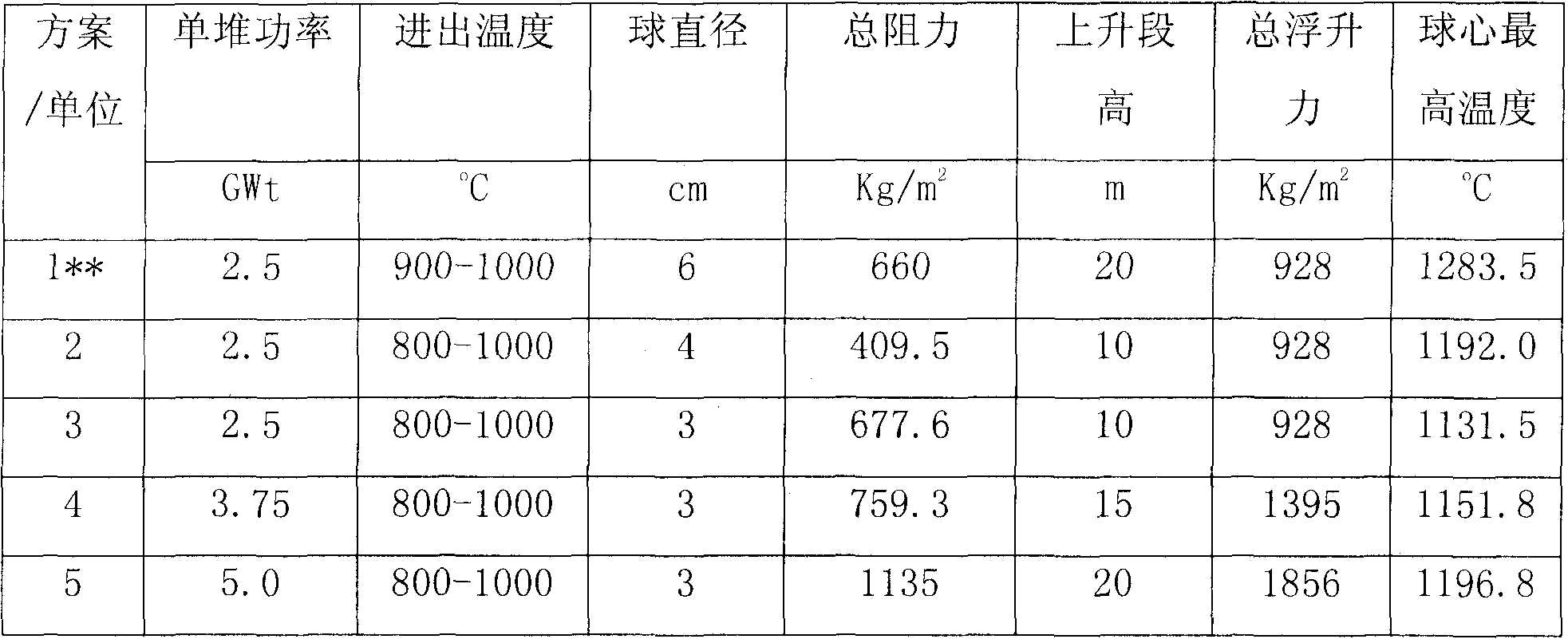

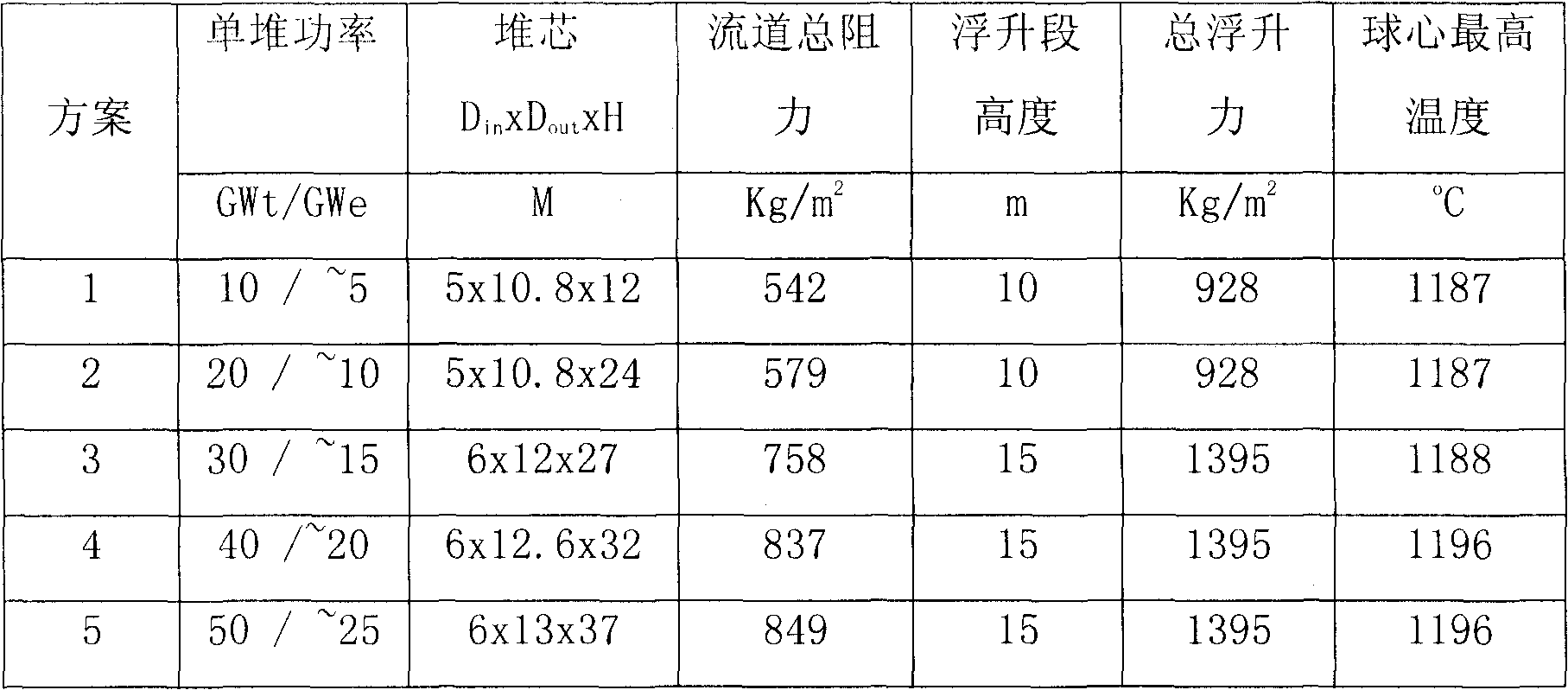

InactiveCN101814325AHigh power outputRealize automatic operationNuclear energy generationHeterogenous reactorsNatural cycleHeat energy

The invention discloses a method for automatically producing high-temperature nuclear energy for long term under any power. The method comprises the following steps of: in a high-boiling point heating medium deep-tank type reactor which runs under the normal pressure, generating a natural cycle with a temperature difference of a high-boiling point heating medium between an ascending flow passage and a descending flow passage in the high-boiling point heating medium deep-tank type reactor; making the high-boiling point heating medium transversely flow by an ultra-low-resistance annular pebble bed reactor in the high-boiling point heating medium deep-tank type reactor with the natural cycle; making the high-boiling point heating medium pass through an ultra-low-resistance open heat exchanger in the high-boiling point heating medium deep-tank reactor with the natural cycle; totally transferring fission produced by the reactor to a secondary high-boiling point heating medium; not arranging a plurality of control-compensation rod bundles in the high-boiling point heating medium deep-tank type reactor; under the function of a negative temperature coefficient of the reactor per se and along with demands on external loads, ending a life cycle of the reactor from the starting to running of the reactor; and when the reactor is automatically run for long, making the secondary high-boiling point heating medium enter an energy-utilization factory through a group of overpressure double-protection valves so as to directly utilize high-temperature heat energy or generate electricity.

Owner:吕应中

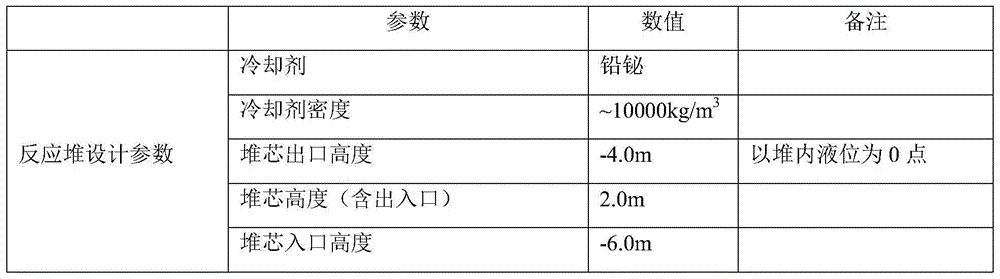

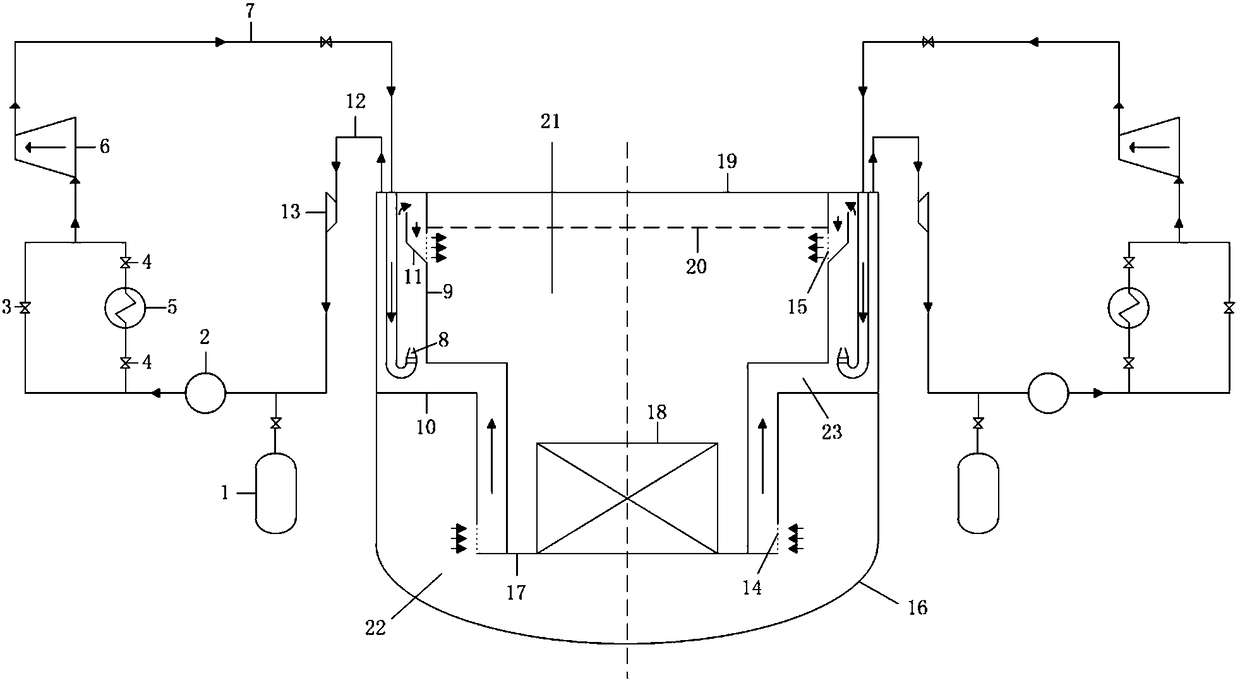

Gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system

ActiveCN106409353AReduce stressReduce heatNuclear energy generationCooling arrangementGas heaterGas compressor

The invention discloses a gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system. According to the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system, when a reactor is at normal operation conditions, a thermal separation valve is opened, an auxiliary heating valve is closed, a gas filter and a gas compressor are turned on, and thermal separation effect is realized by the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system; when the reactor is at low-power running or shutdown condition, the auxiliary heating valve is opened, the thermal separation valve is closed, the gas filter, a gas heater, and the gas compressor are turned on, and auxiliary heating effect is realized by the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system The gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system is simple in structure; activation is convenient; cold and hot pool separation and reactor internal cooling agent auxiliary heating of liquid metal cooling pool-type reactors can be realized at the same time; the complexity of reactor system structure is reduced effectively; reactor economical efficiency and security are increased; application range of the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system is wide; the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system is suitable for both liquid metal cooling pool-type reactors with forced circulation, and liquid metal cooling pool-type reactors with natural circulation.

Owner:NANHUA UNIV

Liquid metal cooling pool type reactor multifunctional in-reactor heat separation system

InactiveCN104916335AImprove natural circulationImprove auxiliary heating efficiencyNuclear energy generationCooling arrangementExhaust valveReactor system

The invention discloses a liquid metal cooling pool type reactor multifunctional in-reactor heat separation system including a gas storage tank, a gas filter, a gas heater, a gas input pipe, a gas inlet valve, an inner heat clapboard, a middle heat clapboard, an outer heat clapboard, an inner heat clapboard fixed steel plate, an outer heat clapboard fixed steel plate, a gas outlet pipe, an exhaust valve, a gas extractor and pipes and valves for connection of devices. Hot and cold pool spacing and auxiliary heating function of a liquid metal in a main container can be realized in a liquid metal cooling pool type reactor, the system is simple in structure, and easy to start, the spacing and auxiliary heating function can be realized in one system, the utilization rate of the reactor system is improved, the complexity of the reactor system is reduced, and the economy and security of the reactor can be effectively improved.

Owner:刘紫静

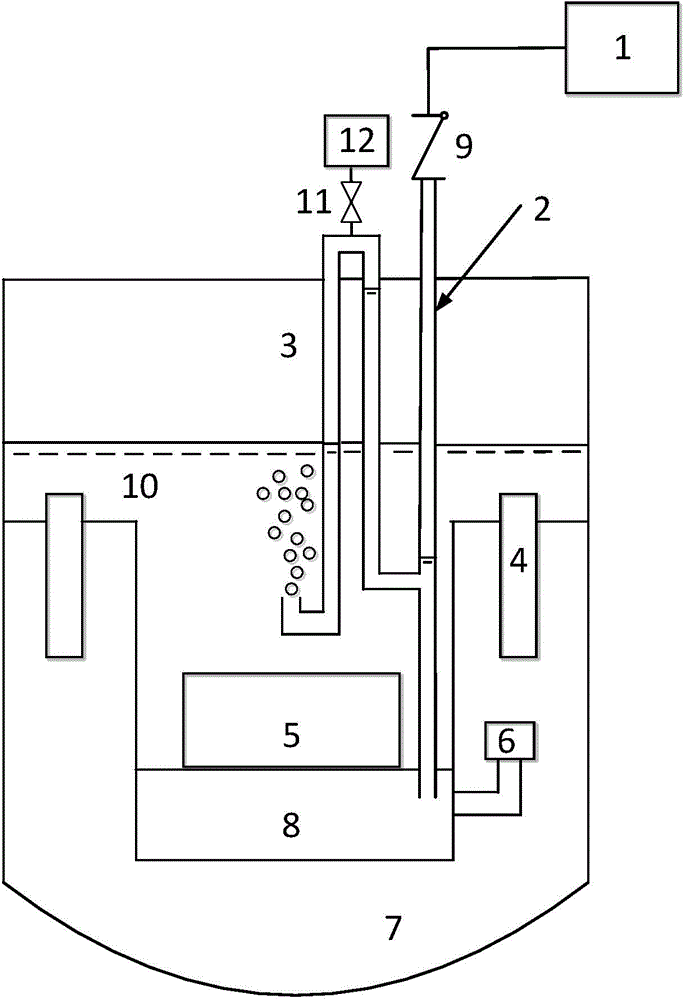

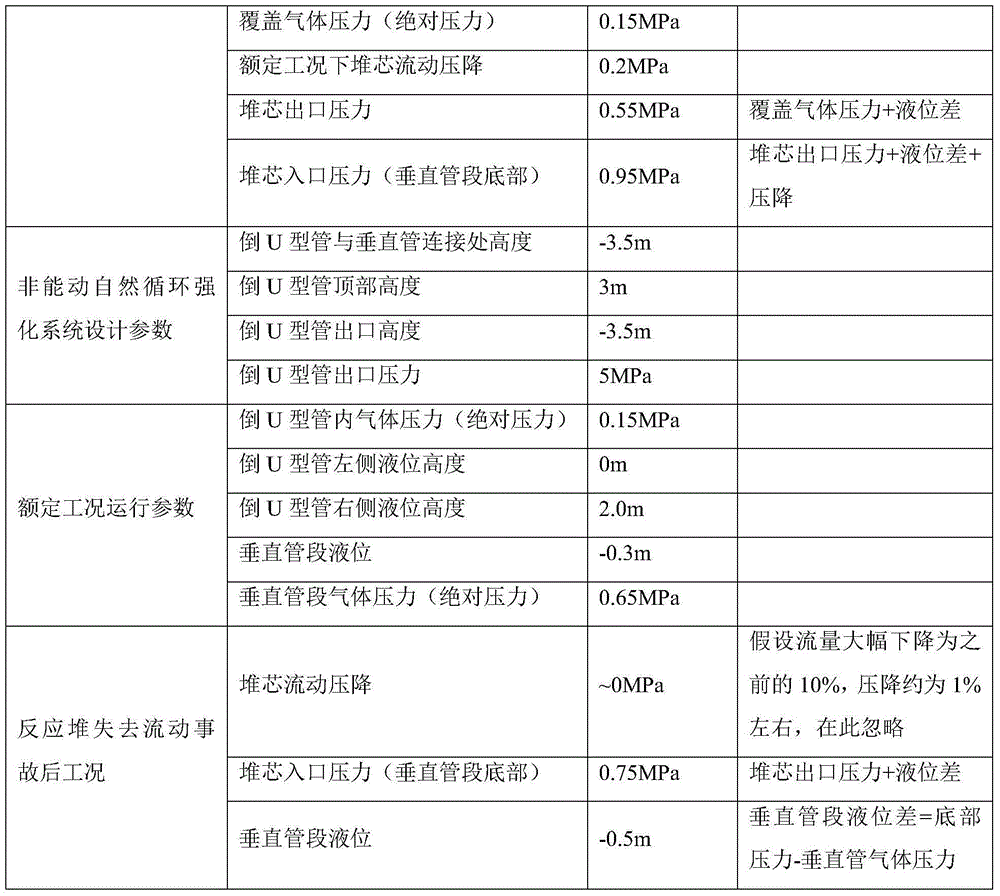

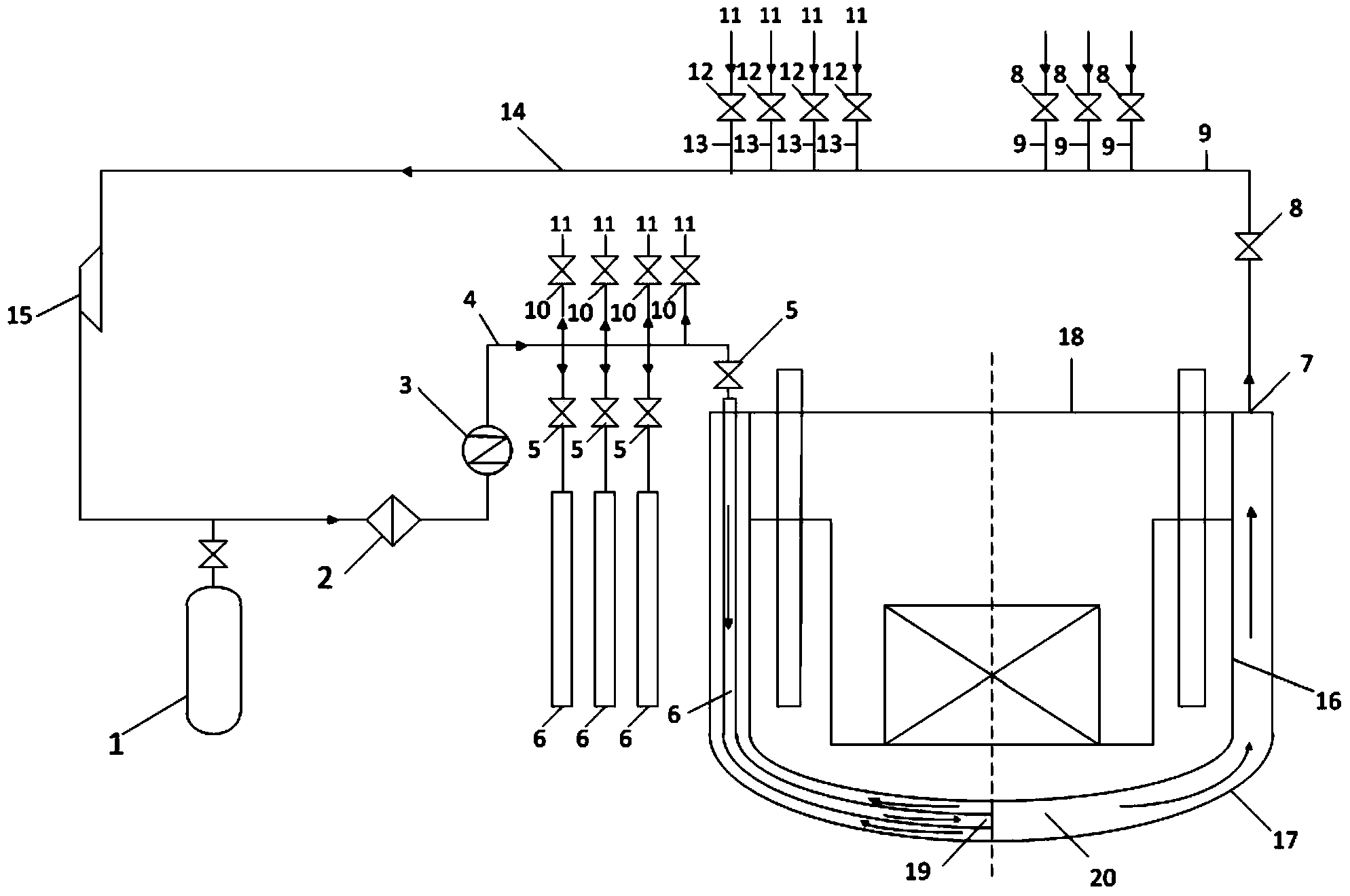

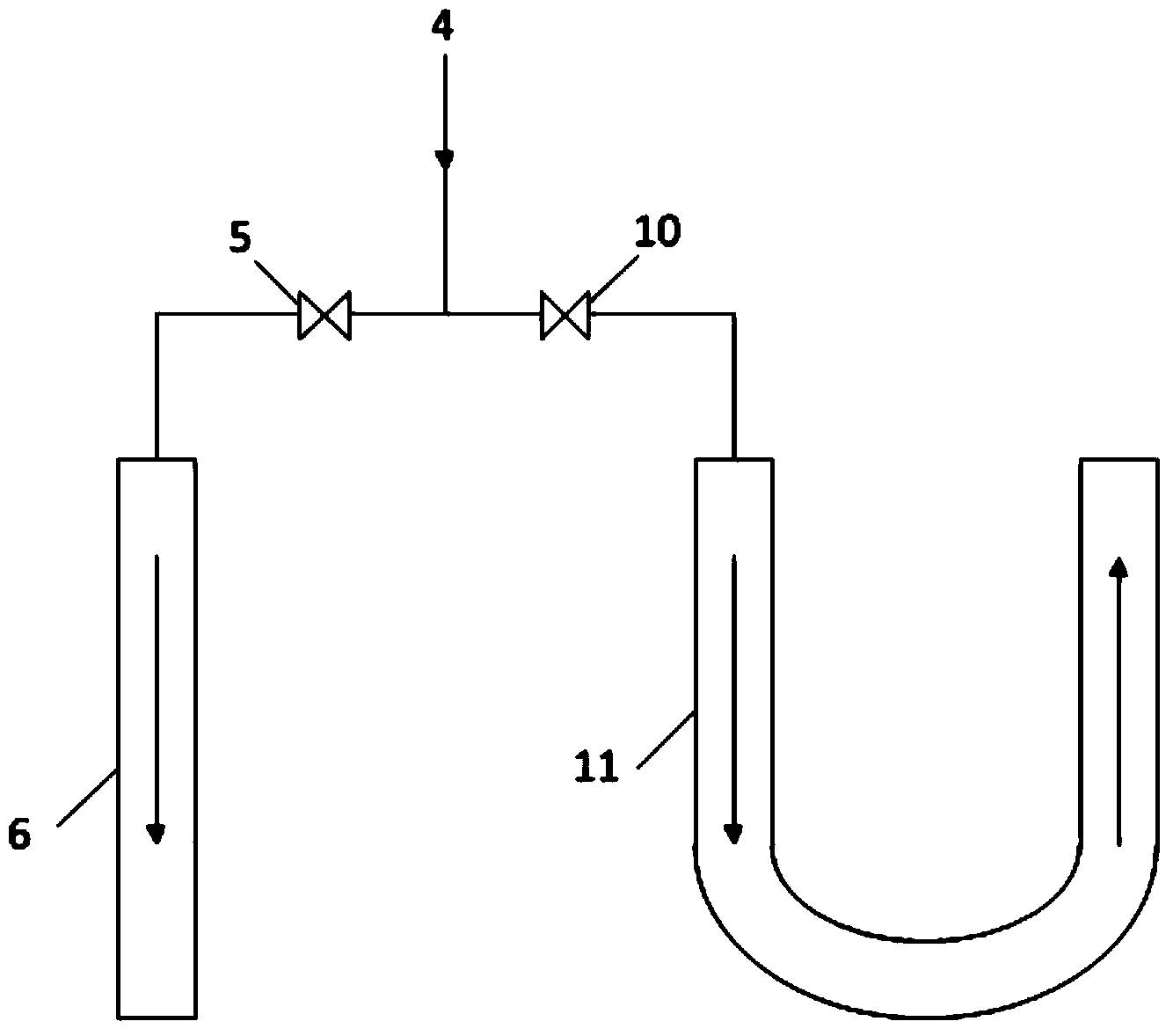

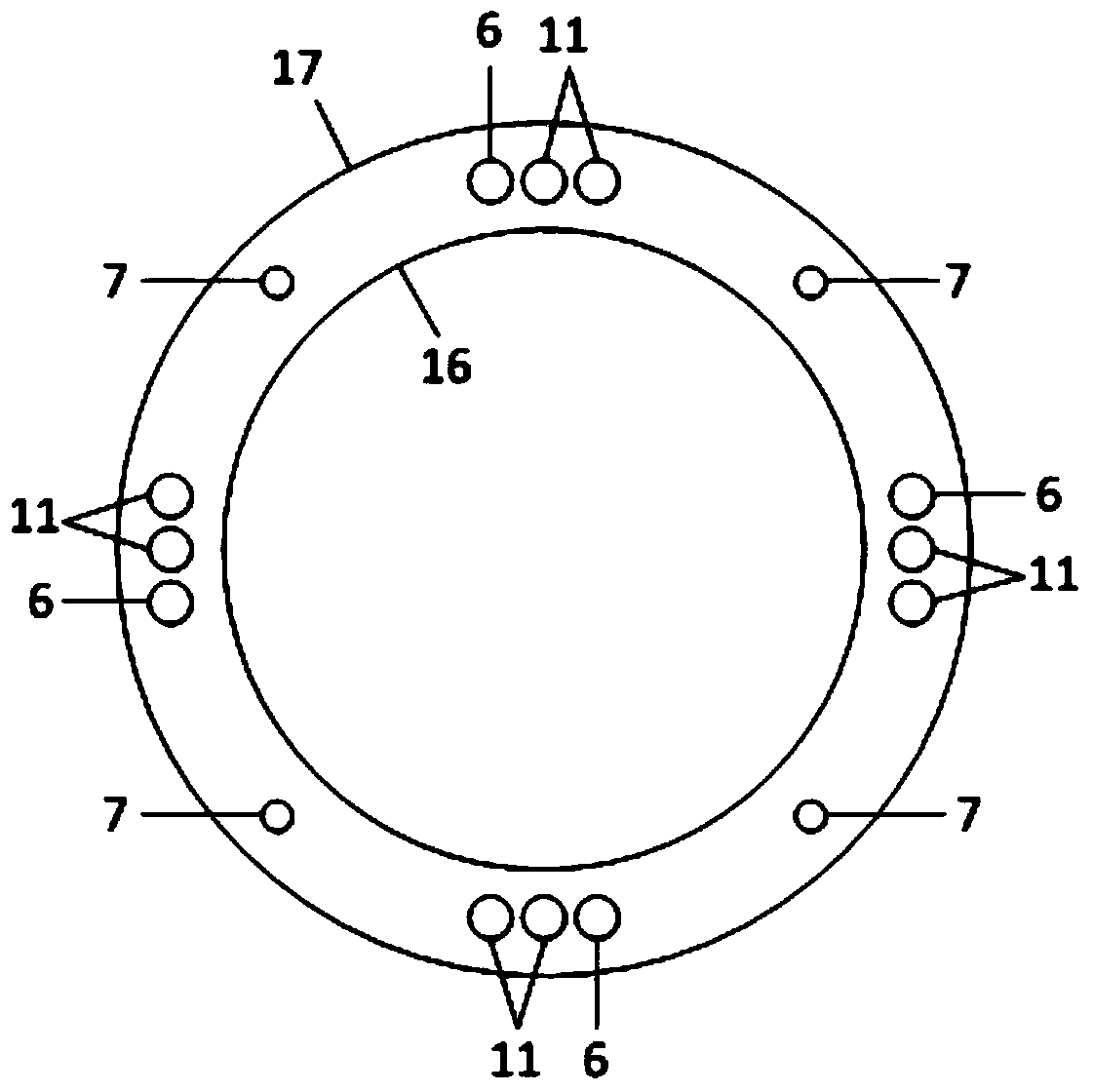

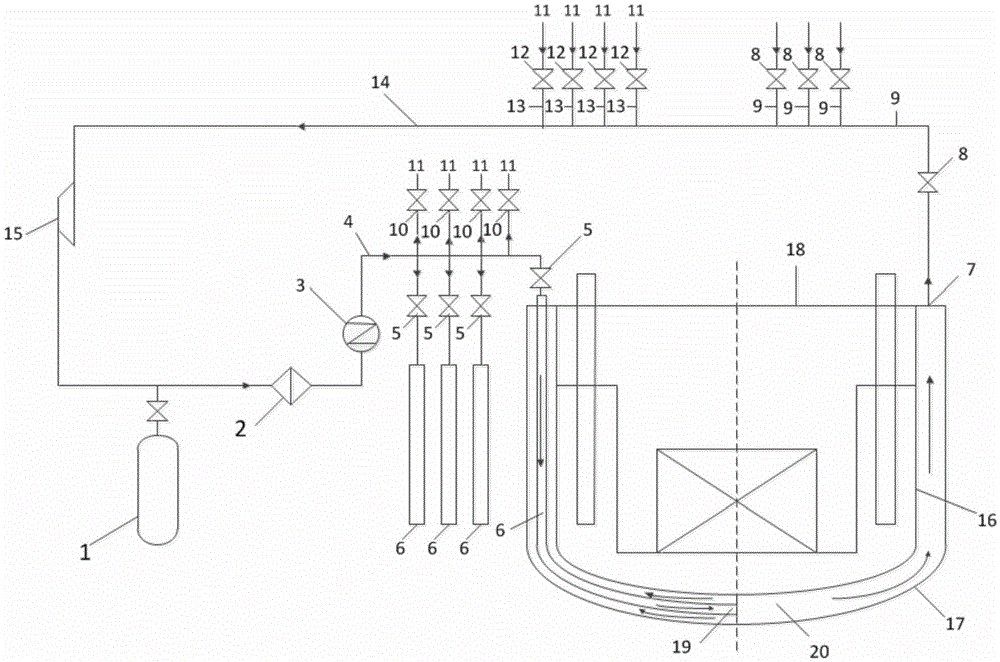

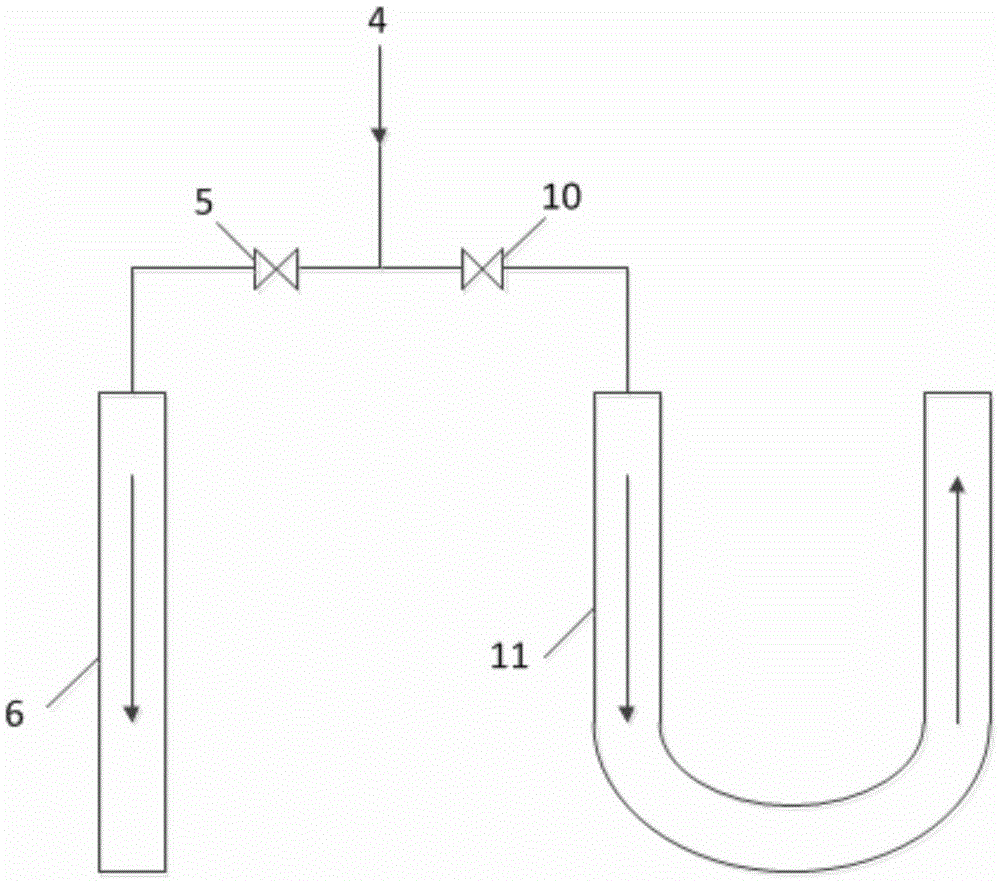

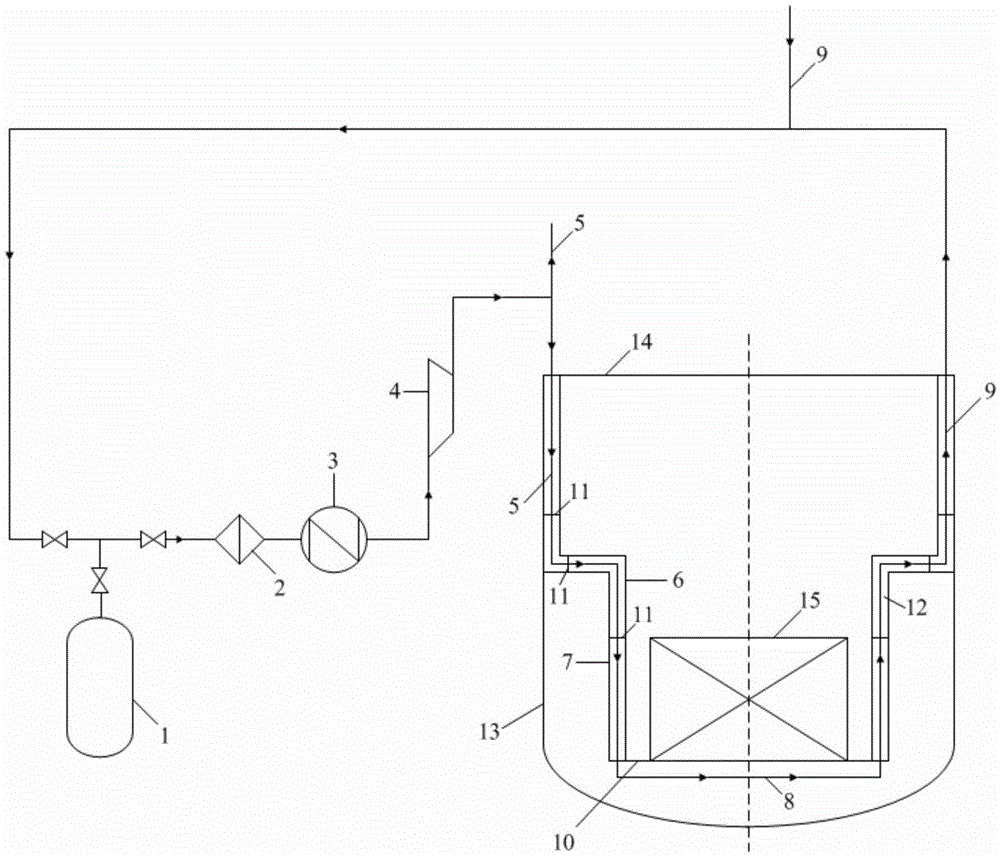

Passive natural circulation intensifying system and method for liquid metal cooled reactor after flow loss

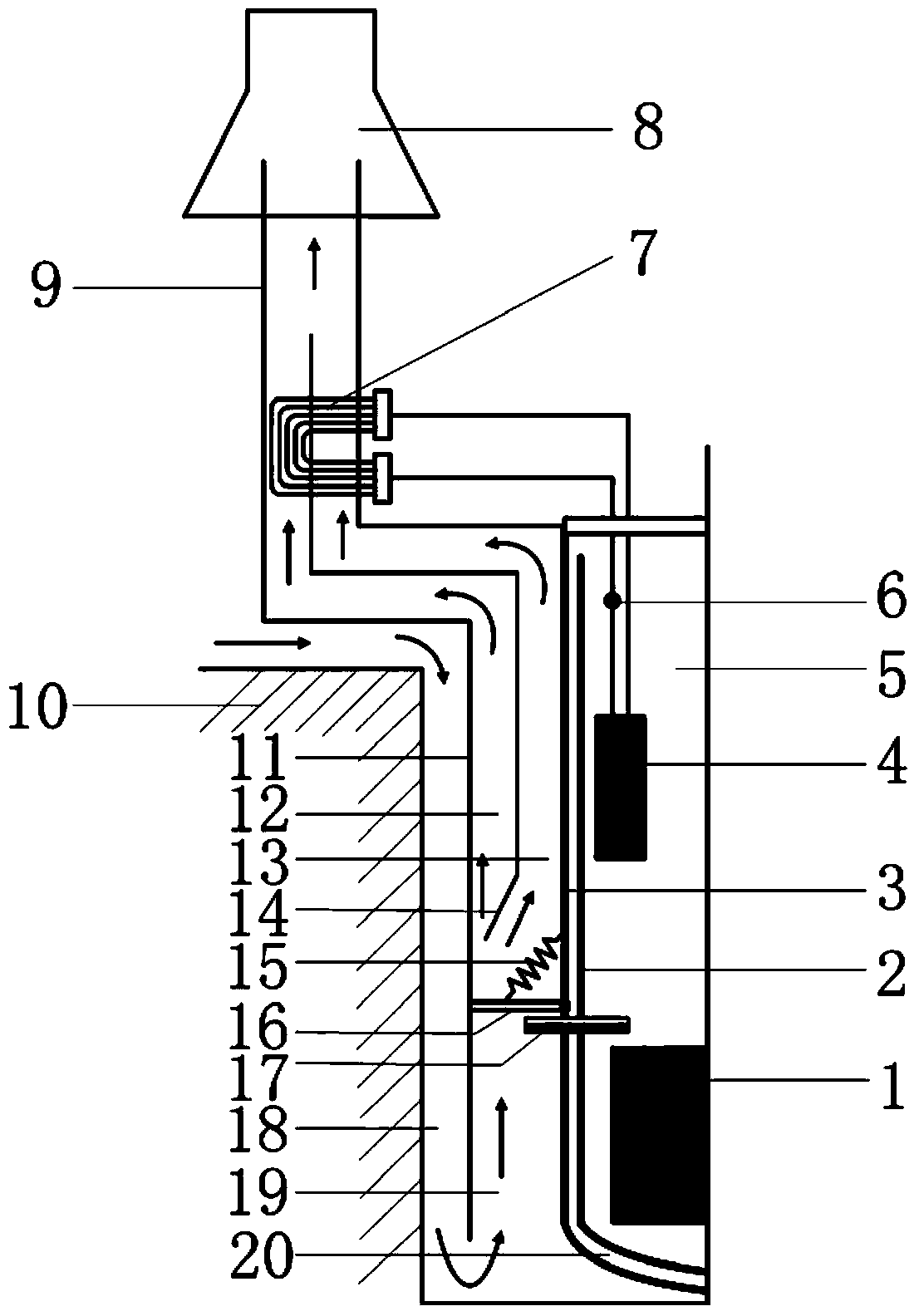

ActiveCN104681108APromote natural circulationNuclear energy generationCooling arrangementNuclear engineeringProduct gas

The invention discloses a passive natural circulation intensifying system and method for a liquid metal cooled reactor after flow loss, and belongs to a safety protection system of the liquid metal cooled reactor. The passive natural circulation intensifying system comprises a high-pressure gas storage tank, a throttle valve, and a vertical pipeline and an inverted U-shaped pipeline which are positioned in a reactor. According to the system and the method disclosed by the invention, due to the connection design of the pipelines, when a main pump loses drive force, the liquid metal cooled pool type rector automatically triggers high-pressure gas to be injected into the upper part of a reactor core by a high-pressure injection tank without any signal transfer; and the injected gas pushes a coolant at an exit of the reactor core to flow upwards, and the natural circulation after a flow-loss accident is intensified. According to the system and the method disclosed by the invention, the automatic start of the reactor can be realized after the forced circulation is lost, and the natural circular flow of cold and hot pool loops is intensified so as to guarantee the effective cooling of the reactor core.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

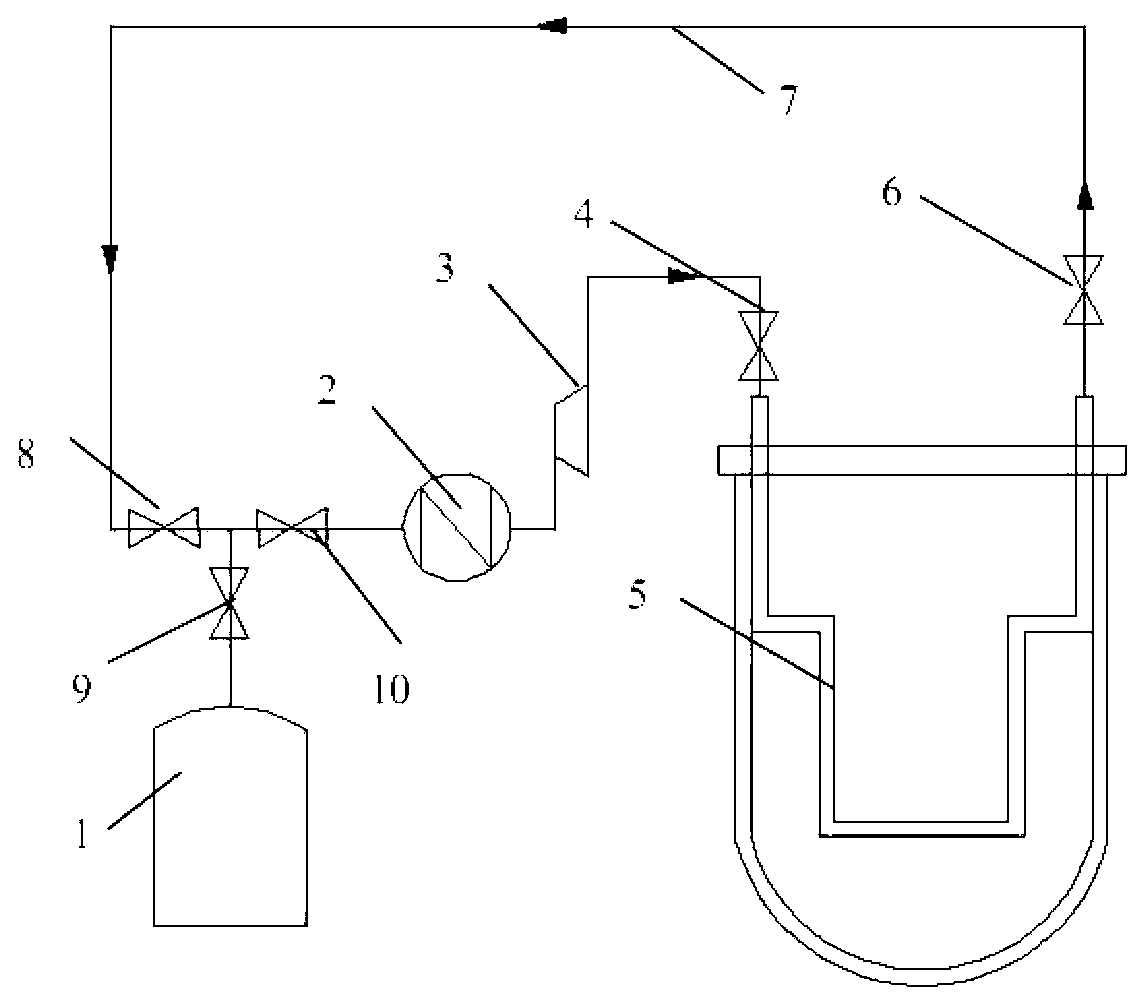

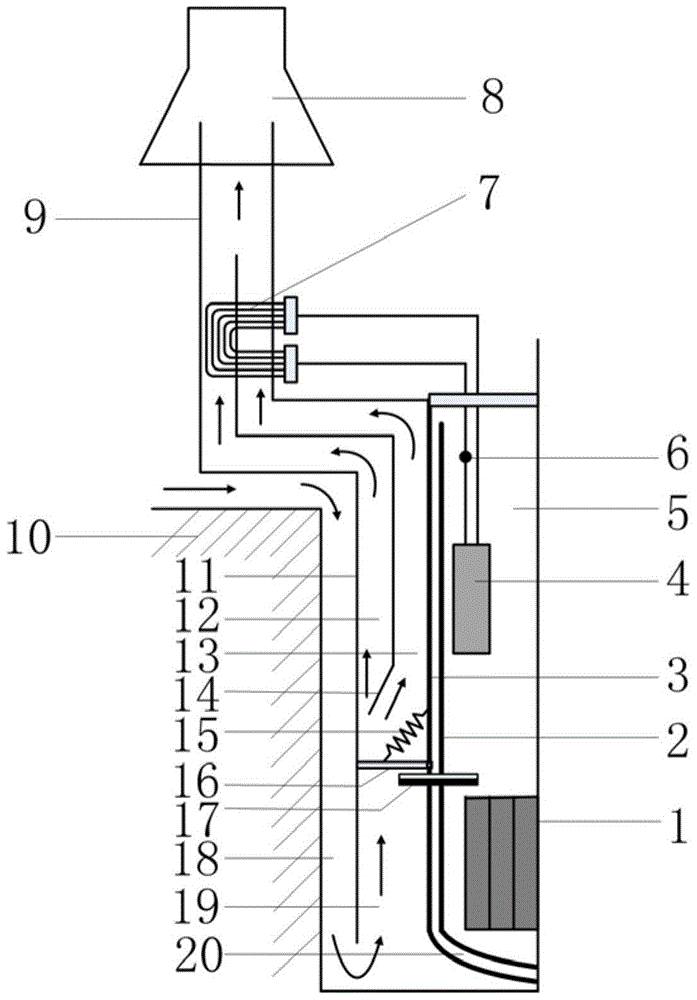

Auxiliary heating system of liquid heavy metal cooling natural circulating pool-type reactor

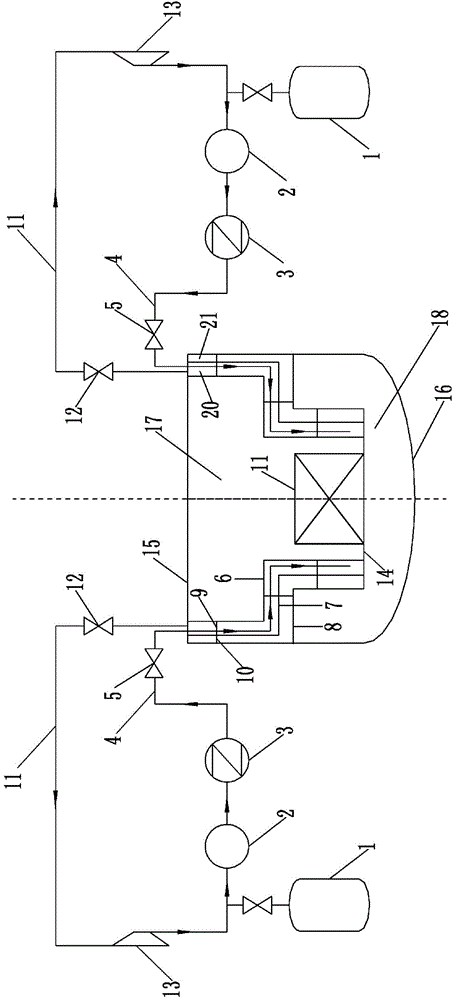

InactiveCN103730171AIncrease powerImprove reliabilityNuclear energy generationCooling arrangementGas heaterAir pump

The invention discloses an auxiliary heating system of a liquid heavy metal cooling natural circulating pool-type reactor. The system comprises a gas storage tank, a filter, a gas heater, a master gas input pipe, a main gas input valve, a main gas input pipe, an extraction opening, a main gas output valve, a main gas output pipe, a gas emergency input valve, a gas emergency input pipe, a gas emergency output valve, a gas emergency output pipe, a master gas output pipe, an air pump, a pipeline and other valves, wherein the pipeline is used for connecting the equipments. By adopting the system, the auxiliary heating function on liquid heavy metal inside the reactor is achieved inside a main container of the liquid heavy metal cooling natural circulating pool-type reactor and a ring cavity formed by a safe container, the system is simple in structure and has independence and reliability, members inside the reactor do not need to be added and started in operation, and the safety of the reactor can be effectively improved.

Owner:UNIV OF SCI & TECH OF CHINA

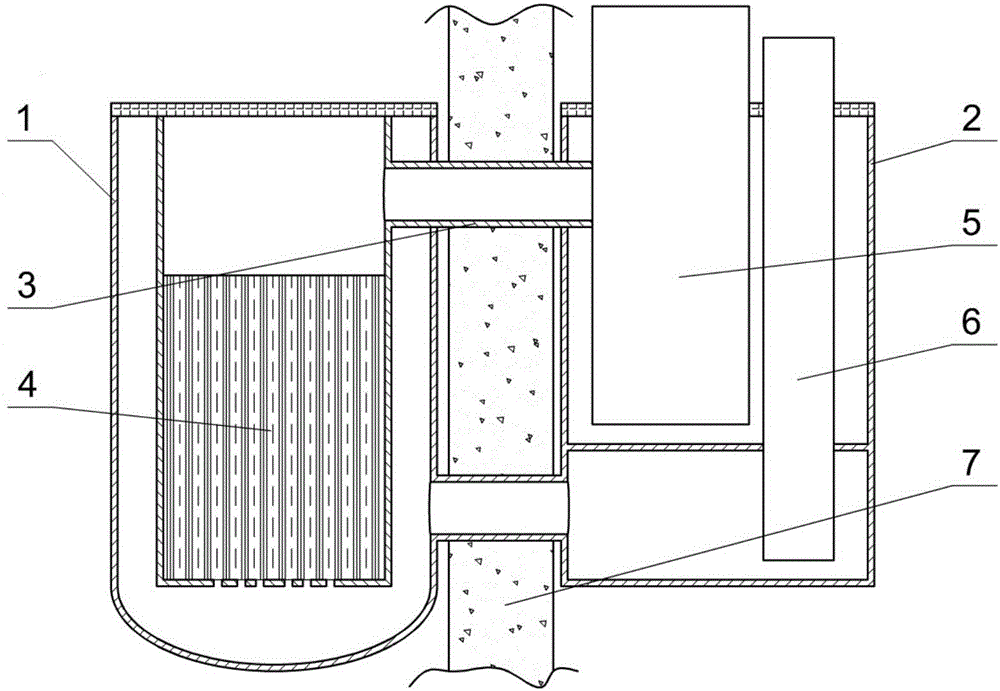

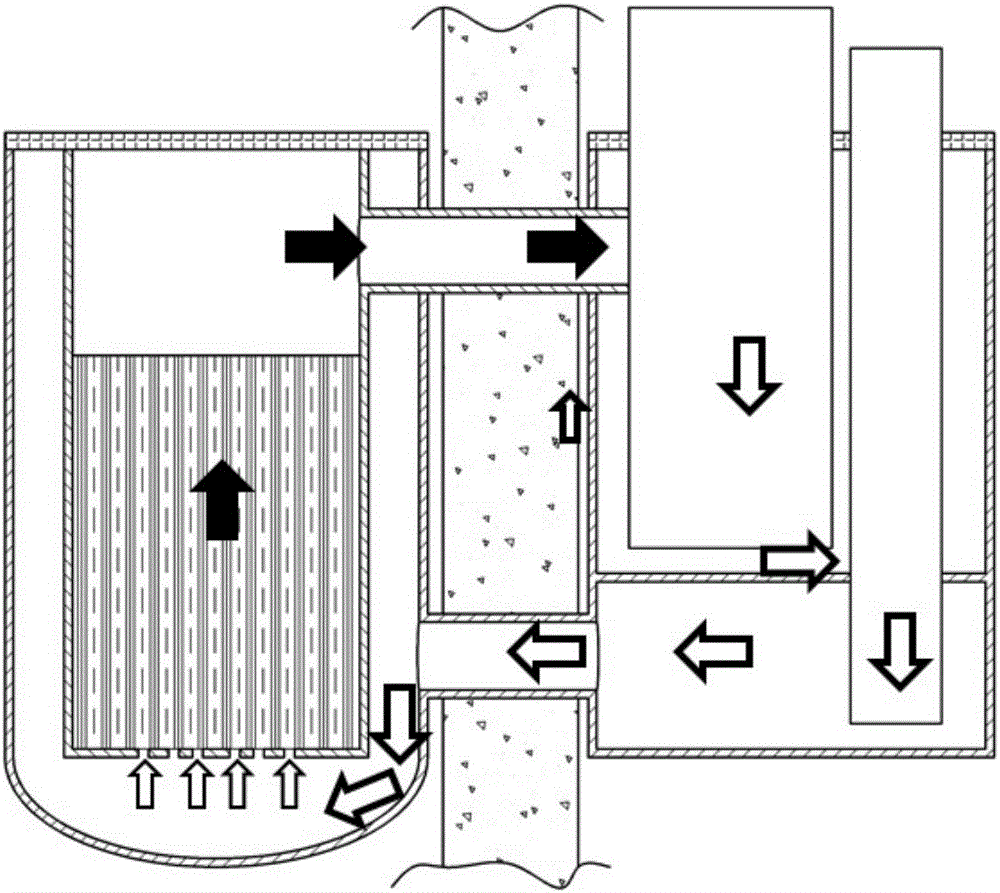

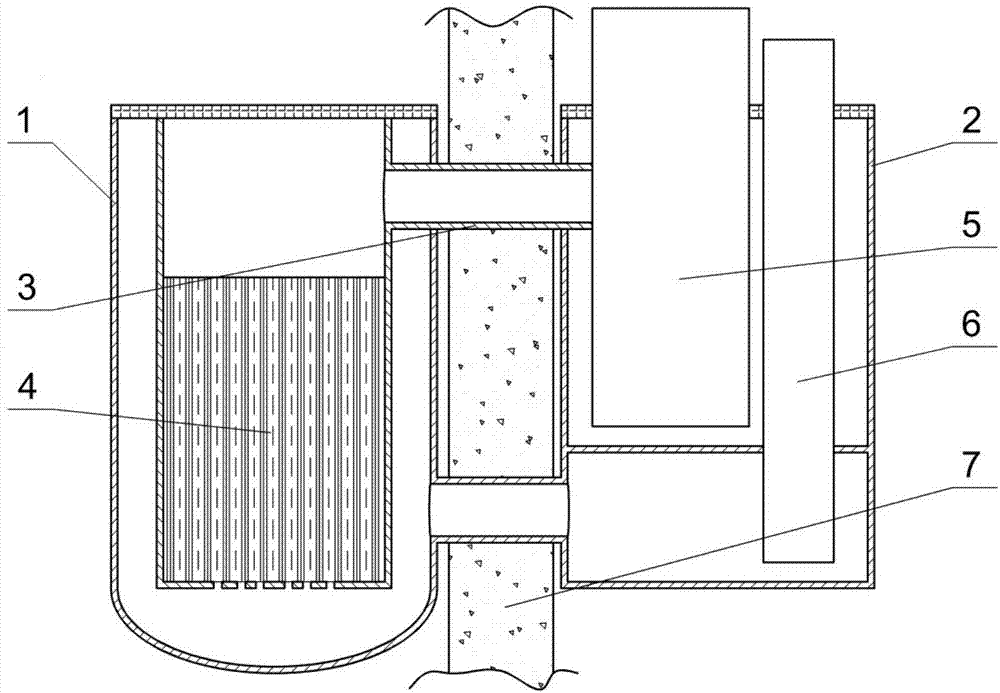

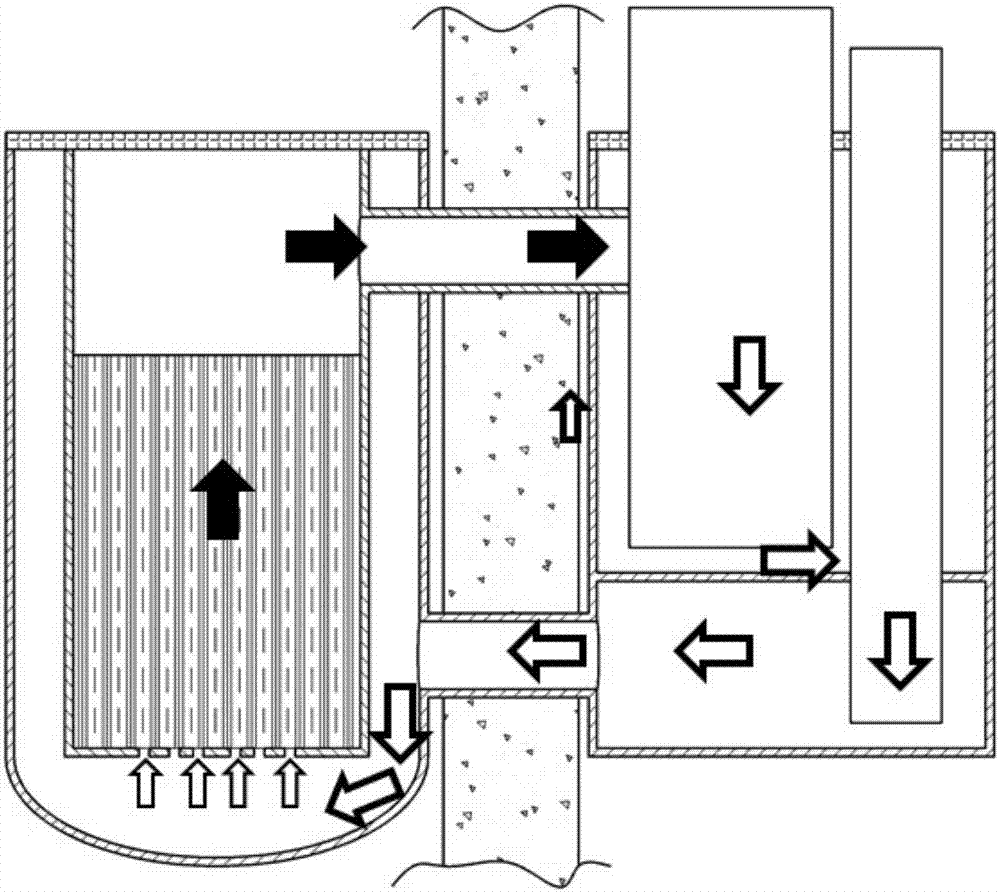

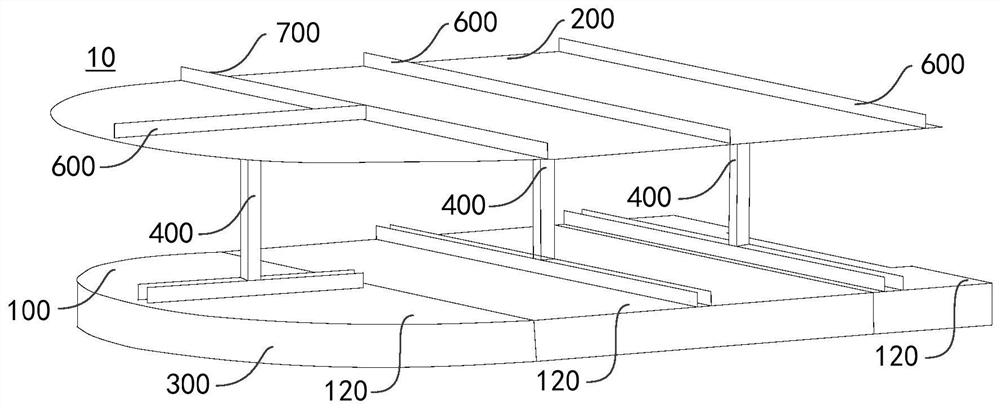

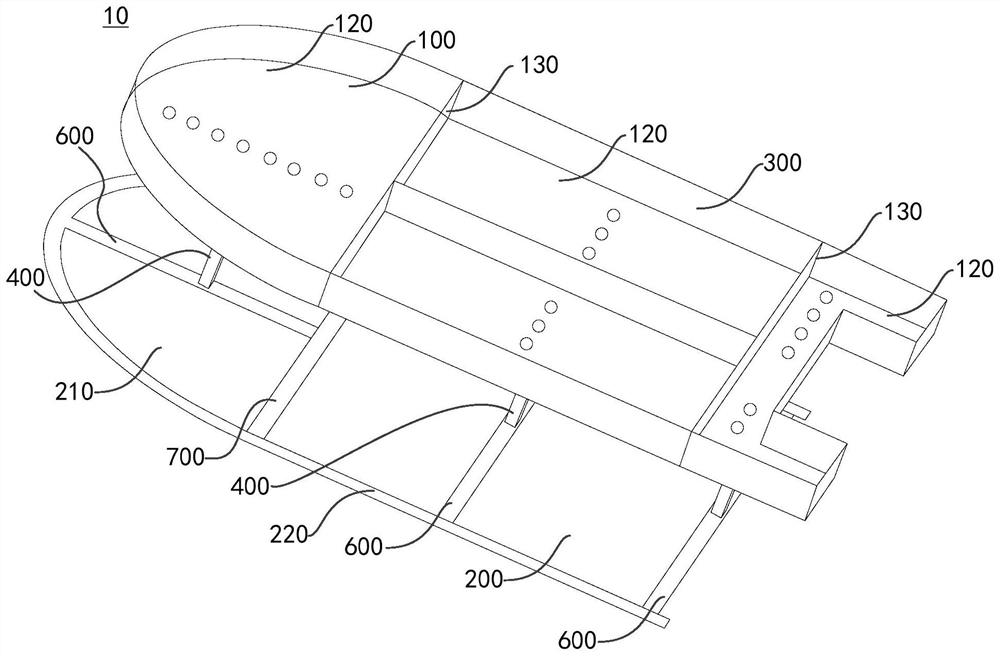

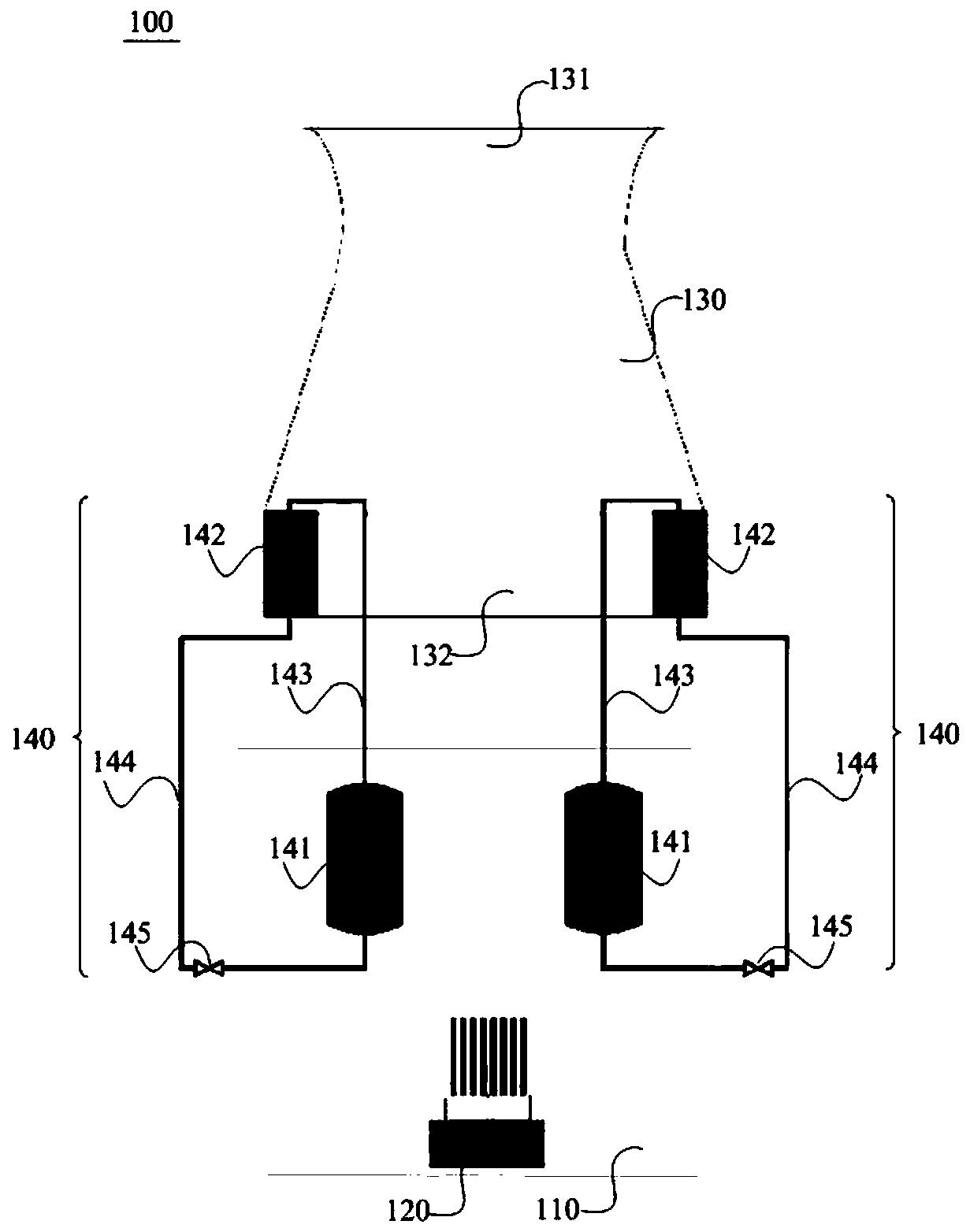

Multi-pond type reactor

ActiveCN106782679AImprove securityReduce risk of leakageNuclear energy generationFast fission reactorsNuclear engineeringIrradiation

The invention discloses a multi-pond type reactor. The reactor comprises a main container, an attached container, a connecting pipeline, a reactor core, a steam generator, a main pump and a neutron shielding body, wherein the main container is used for providing support and containing for the reactor core and the cooling agent thereof; the attached container is used for providing the support and the containing for the steam generator and the main pump and the cooling agent thereof; the main container is communicated with the attached container through the connecting pipeline; the neutron shielding body is installed between the main container and the attached container so as to provide the shielding for the steam generator and the main pump. The reactor disclosed by the invention has the advantages of being less in cooling agent loading quantity and simple in boundary, and the main circulating equipment in the reactor bears the low irradiation strength.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

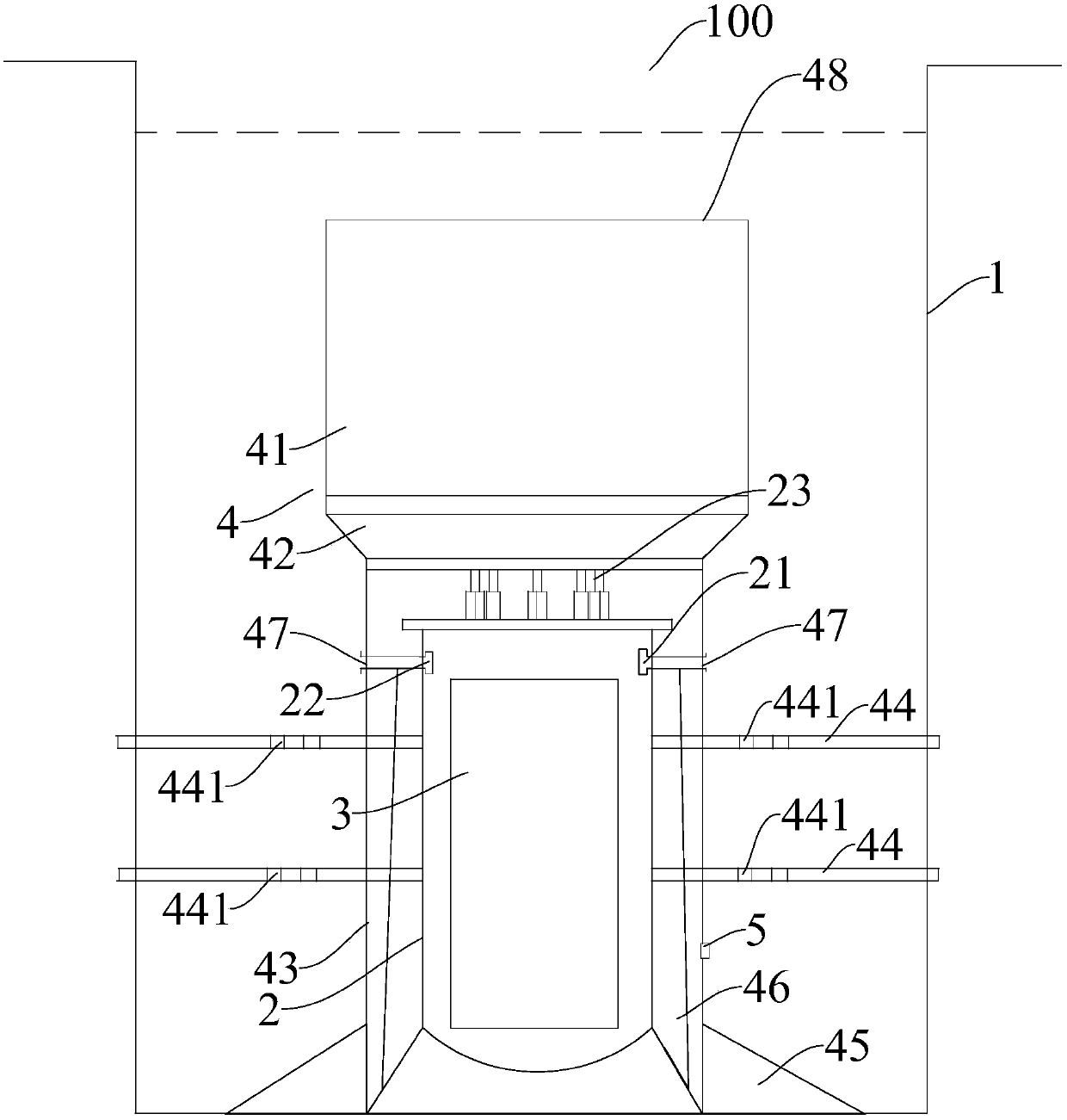

Waterproof and thermal insulation sleeve and pool type reactor with waterproof and thermal insulation sleeve

The invention discloses a waterproof and thermal insulation sleeve and a pool type reactor with the waterproof and thermal insulation sleeve. The pool type reactor comprises a pool, a pressure container, a reactor core and a sleeve, wherein the reactor core is arranged in the pressure container, and the pressure container is provided with a container inlet and a container outlet; the sleeve is fixedly installed in the pool and immersed below the liquid level of the pool; the pressure container is installed in the sleeve so as to be isolated from the pool; and the sleeve is provided with a through hole for a loop pipeline to penetrate through. According to the pool type reactor, the sleeve is sleeved outside the pressure container and the reactor core and can provide a waterproof space fora control rod drive mechanism so as to avoid inconvenience of underwater design or operation, play a role in thermal insulation of the pressure container and the reactor core, reduce heat exchange ofthe wall of the pressure container and reduce heat loss, and the sleeve can play a role in radioactive shielding of the reactor core and reduce radiation quantity, and has good safety and practicability.

Owner:STATE POWER INVESTMENT CORP RES INST

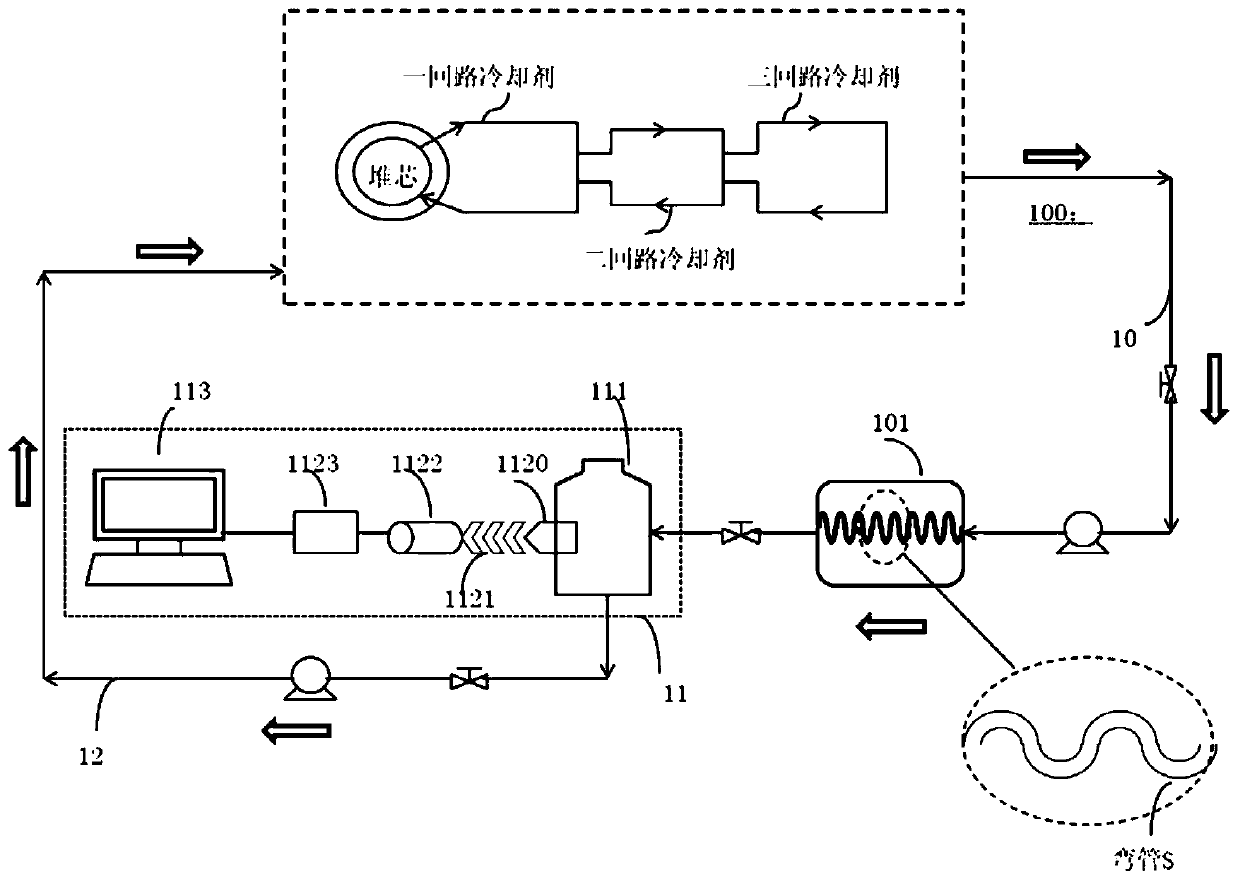

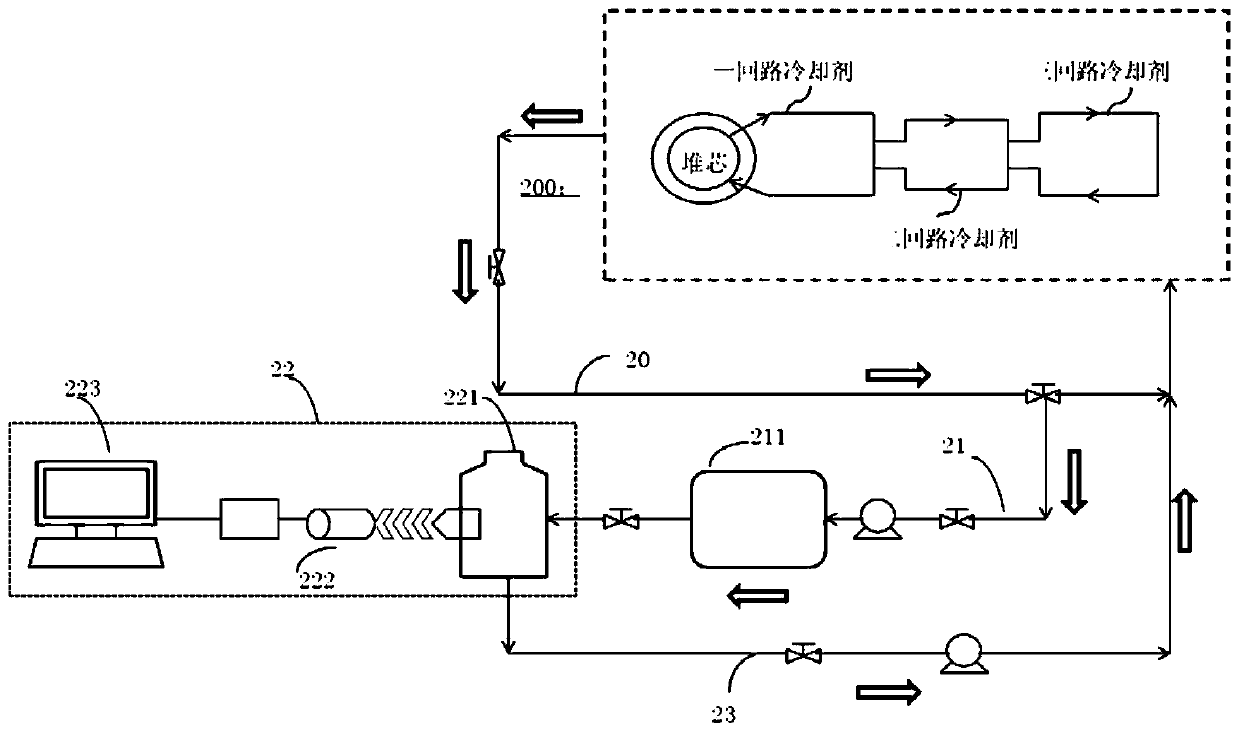

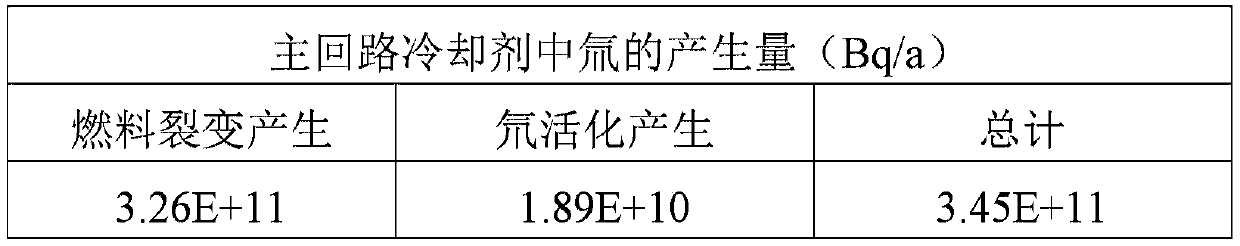

Tritium measurement system and method for pool reactor

ActiveCN111292863AEliminate distractionsReduce radiation dose levelsNuclear energy generationNuclear monitoringNuclear engineeringCoolant flow

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Pool heating reactor and low temperature nuclear heating system

ActiveCN106205747BImprove securityGuaranteed reliabilityNuclear energy generationContainmentNuclear reactorNitrogen

The invention discloses a pool type heating reactor and a low-temperature nuclear heating system, relates to the technical field of nuclear reactors and aims to solve the technical problem that safety and reliability of the existing pool type heating reactorstill needs to be improved. The pool type heating reactor comprises a control rod driving mechanism cover body, wherein the bottom end of the control rod driving mechanism cover body is connected with the top end of a reactorcore shroud to form a sealed space for accommodating a control rod driving mechanism; the sealed space is filled with air or nitrogen; and the pressure of the air or the nitrogen is 4-6 atmospheric pressures.

Owner:启迪新核(北京)能源科技有限公司

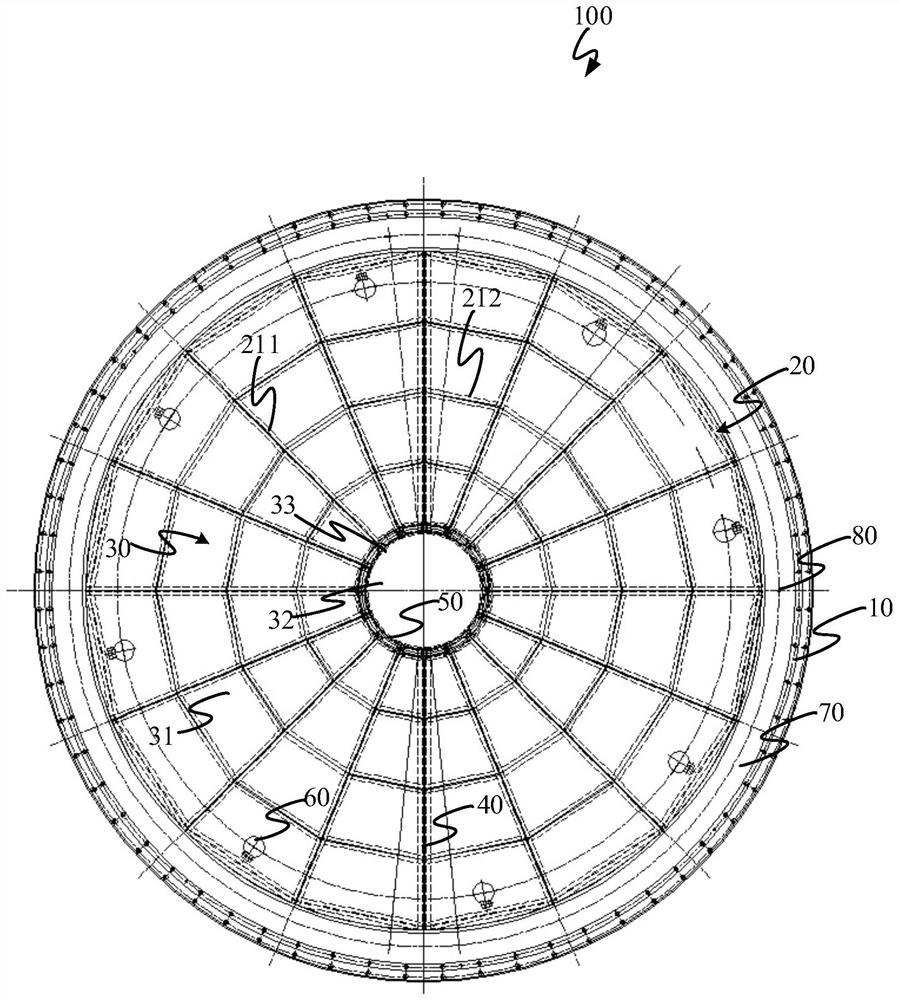

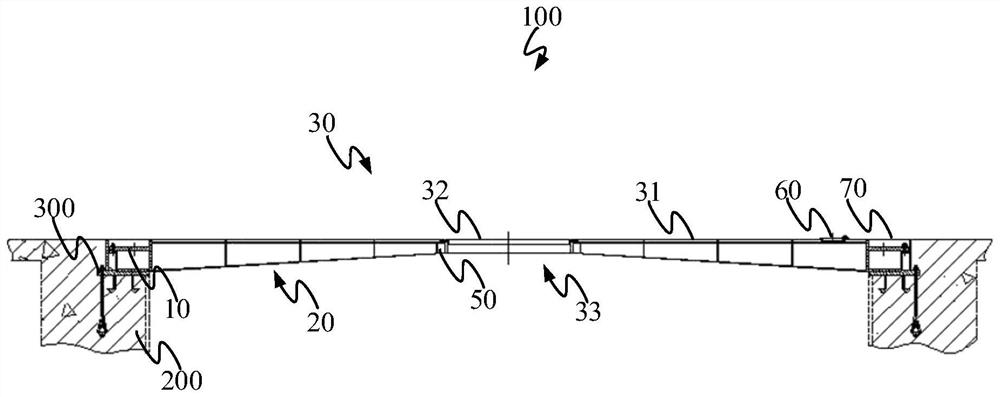

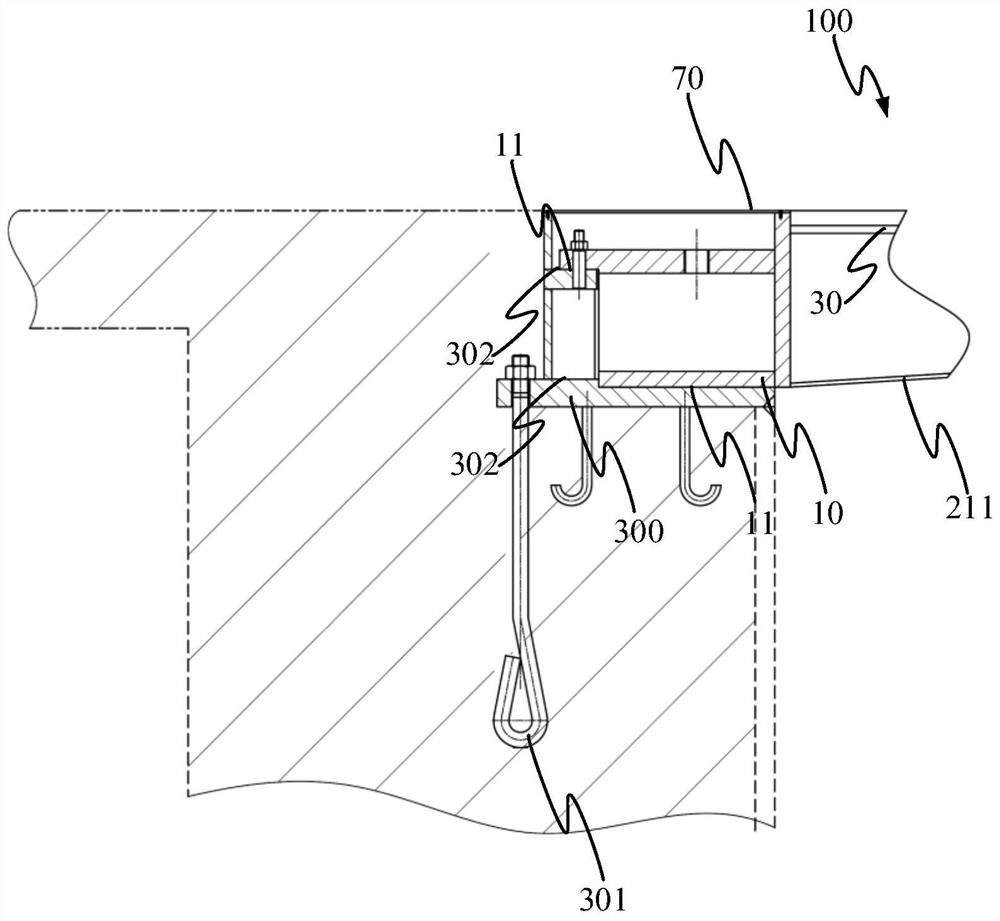

Cover plate device and pool type reactor with same

ActiveCN112037942AAchieve sealingAvoid enteringNuclear energy generationContainmentForeign matterStructural engineering

The invention discloses a cover plate device and a pool reactor with the same. The cover plate device is arranged at the top of a reactor pool, and comprises: an annular mounting structure which is mounted on the pool wall of the reactor pool and is sealed with the pool wall; a supporting structure located on the inner side of the mounting structure and fixed to the mounting structure; and a platebody structure which completely covers the inner side space of the mounting structure, wherein the supporting structure is supported below a plate body structure, the plate body structure and the mounting structure are arranged in a sealed mode, the plate body structure is provided with an opening, and the opening can be selectively opened or closed. The cover plate device is arranged at the topof the reactor pool and is used for sealing the internal space of the reactor pool so as to prevent foreign matters from entering the pool. Meanwhile, the opening capable of being controlled to be opened and closed is formed in the plate body structure of the cover plate structure, when the interior of the reactor needs to be overhauled or subjected to refueling operation, the opening is opened, after the operation is completed, the opening is closed, and therefore the situation that the whole cover plate device is disassembled and assembled due to refueling or overhauling is avoided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

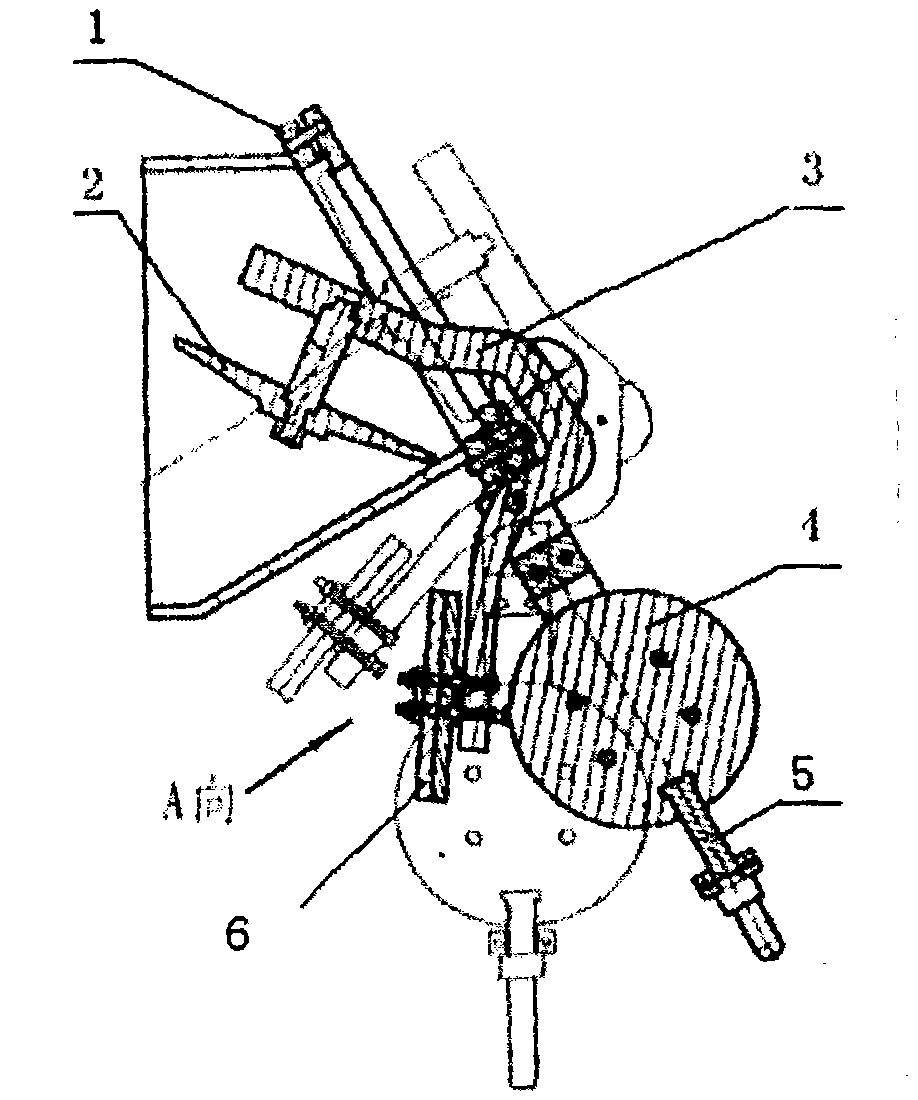

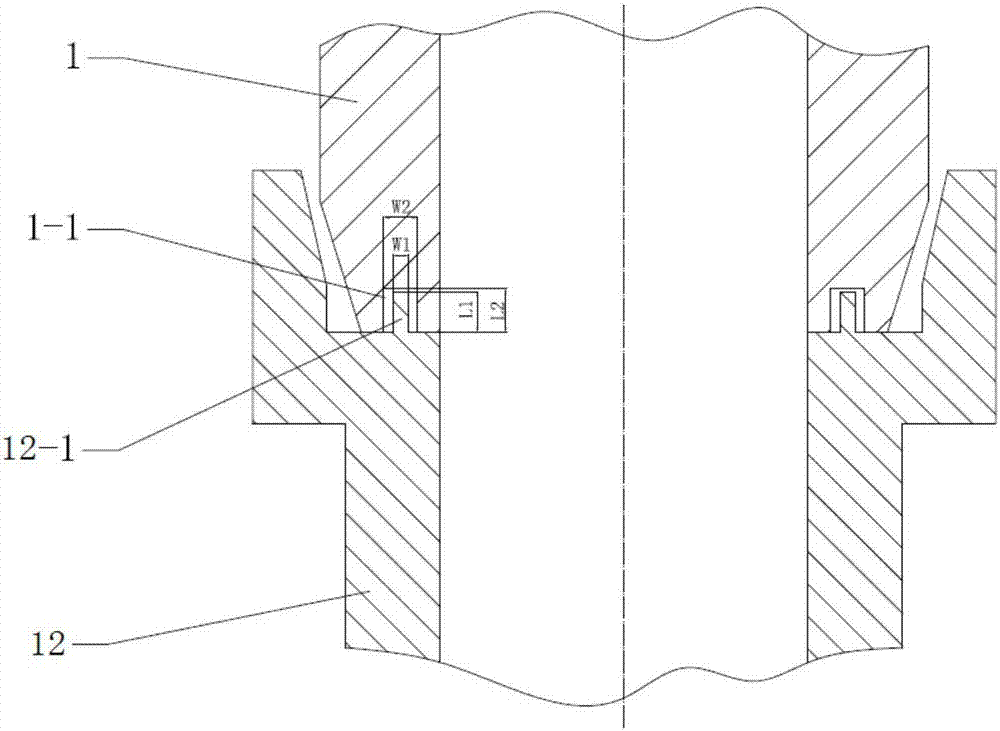

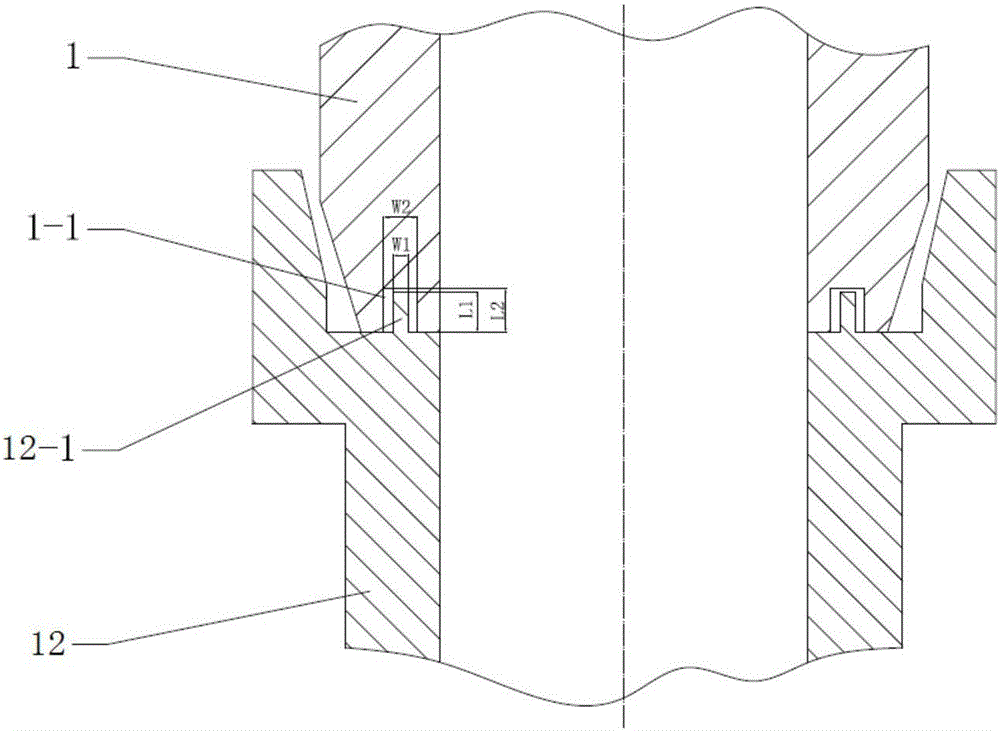

Passive switch for pool type reactor core and pool

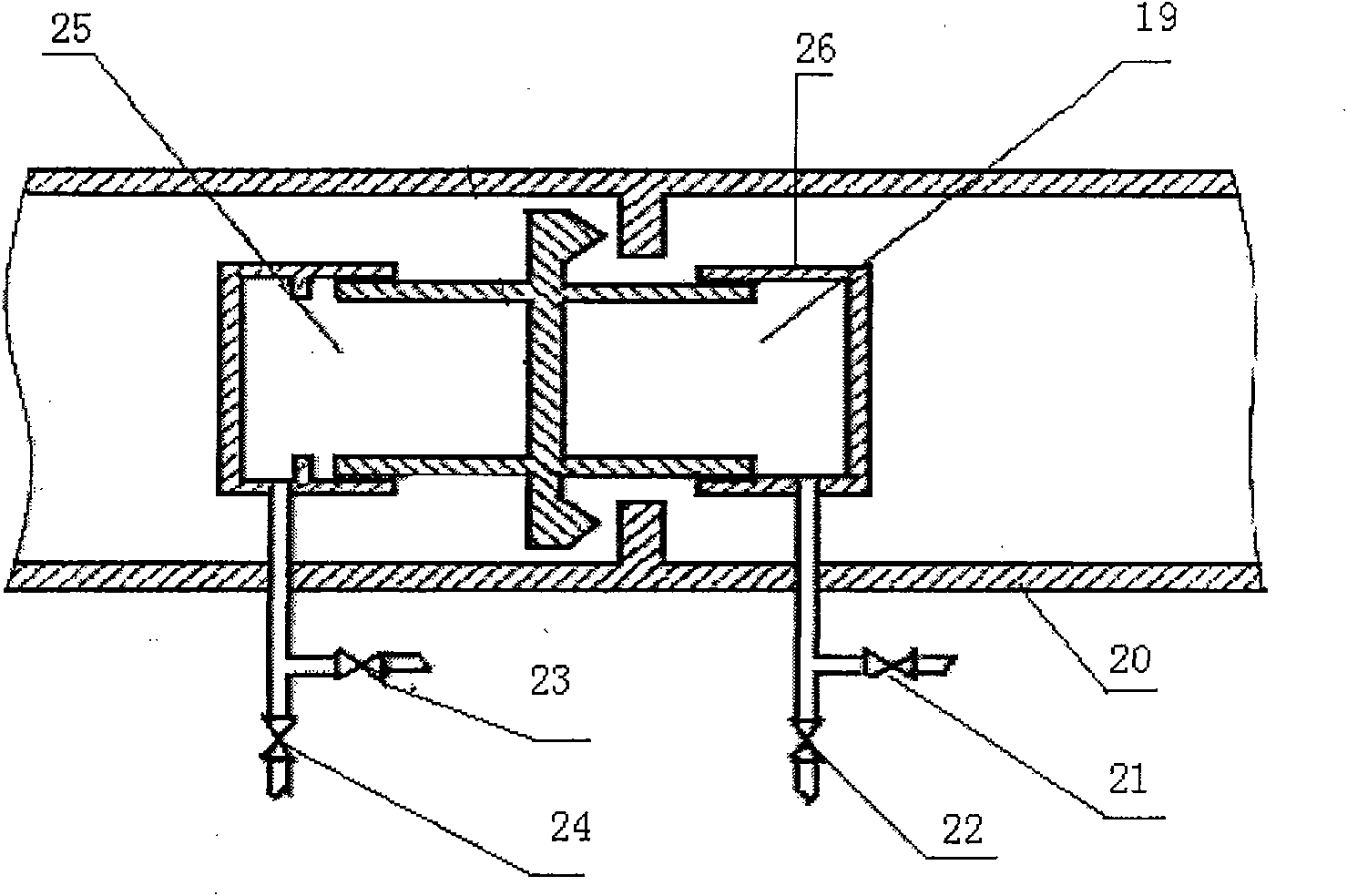

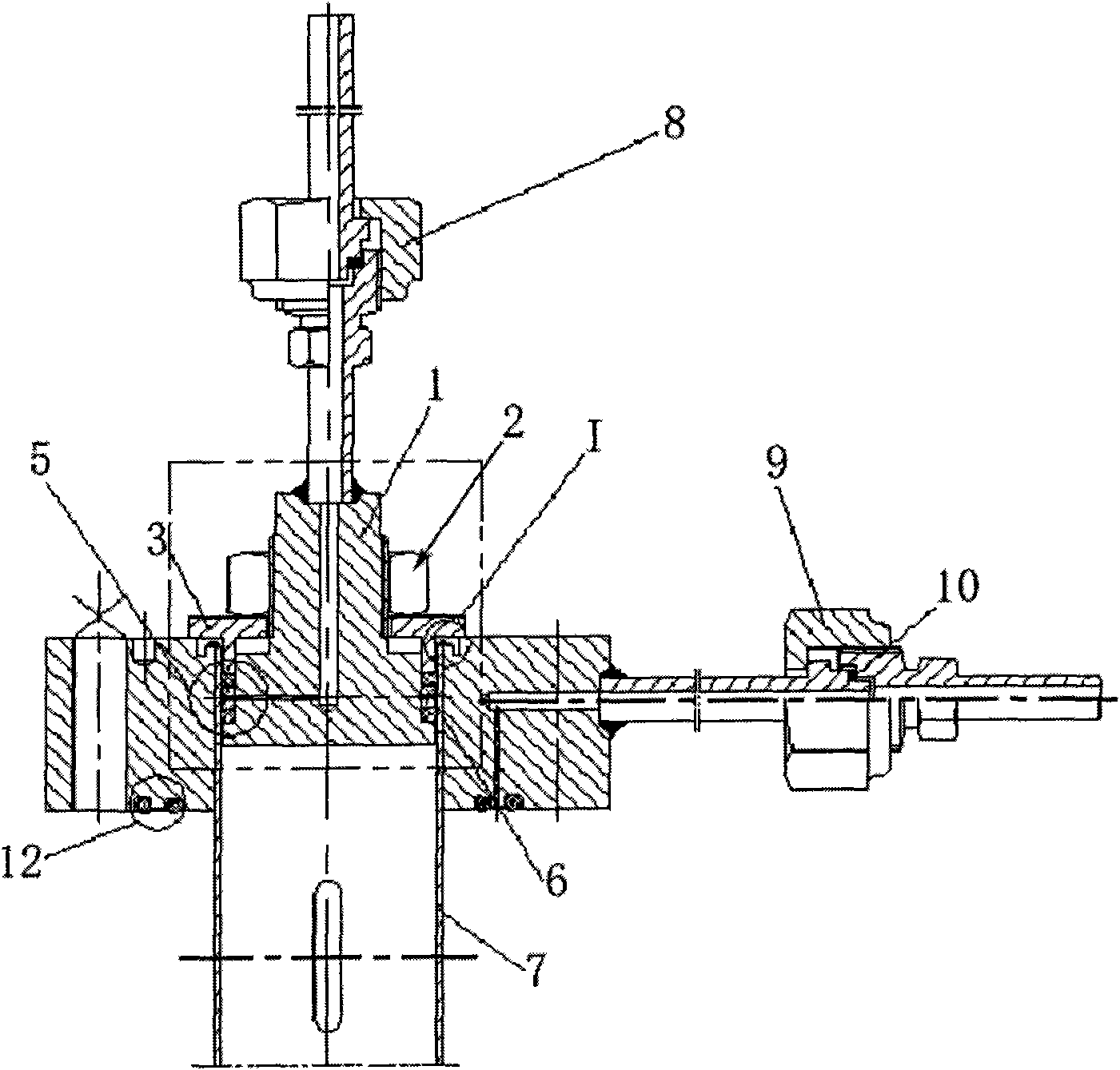

InactiveCN101956850AReduce weightReduce impactEqualizing valvesSafety valvesNuclear engineeringGravitation

The invention discloses a passive switch for a pool type reactor core and a pool. The passive switch is mainly divided into a valve body (1) and a rotating part, wherein the rotating part comprises a damping arm (3) and a counter weight; the damping arm (3) and the counter weight are moveably connected with the valve body (1) through a bracket respectively and are independent from each other; and a valve clack (2) and a damping sheet (6) are connected on the damping arm (3) respectively. The invention provides the passive switch for the pool type reactor core and the pool, which can prolong the service life of a valve, can satisfy different conditions and is turned on or turned off by means of gravity thereof.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A multi-pool reactor

ActiveCN106782679BImprove securityReduce risk of leakageNuclear energy generationFast fission reactorsNuclear engineeringUltimate tensile strength

The invention discloses a multi-pond type reactor. The reactor comprises a main container, an attached container, a connecting pipeline, a reactor core, a steam generator, a main pump and a neutron shielding body, wherein the main container is used for providing support and containing for the reactor core and the cooling agent thereof; the attached container is used for providing the support and the containing for the steam generator and the main pump and the cooling agent thereof; the main container is communicated with the attached container through the connecting pipeline; the neutron shielding body is installed between the main container and the attached container so as to provide the shielding for the steam generator and the main pump. The reactor disclosed by the invention has the advantages of being less in cooling agent loading quantity and simple in boundary, and the main circulating equipment in the reactor bears the low irradiation strength.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Non-kinetic inherently safe tube-pool type reactor

ActiveCN100578683CReliable passive safety systemSafeNuclear energy generationCooling arrangementInherent safetyNuclear reactor

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A flow measurement device and measurement method for a pool-type natural circulation reactor

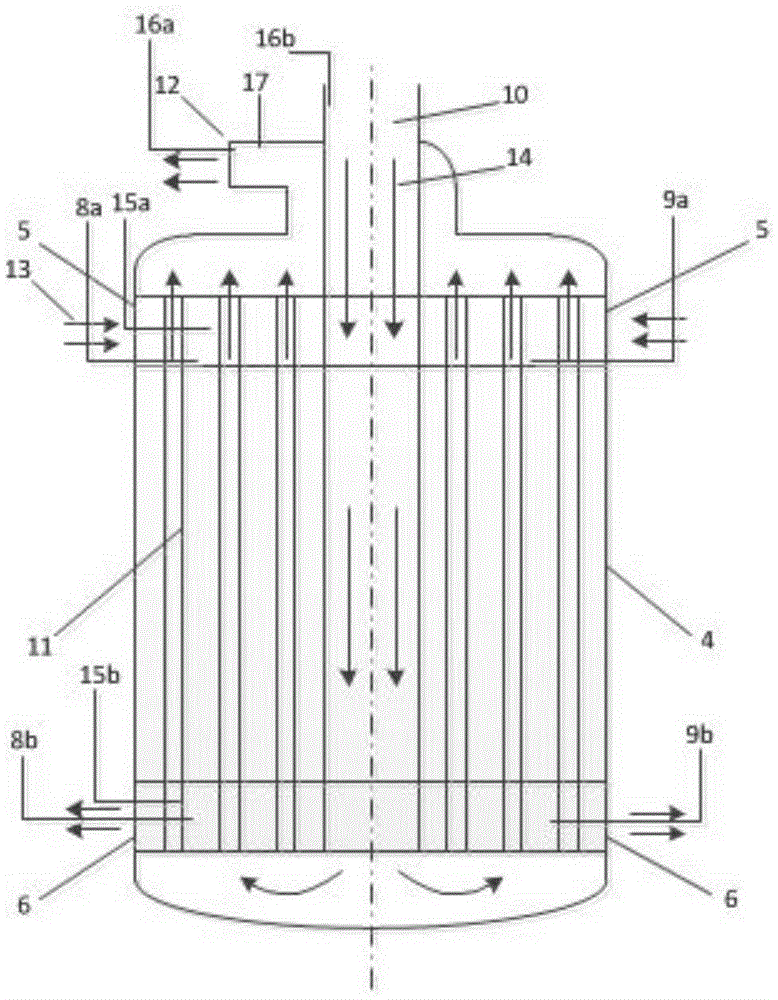

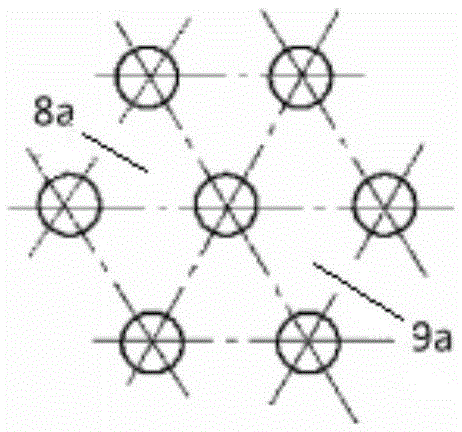

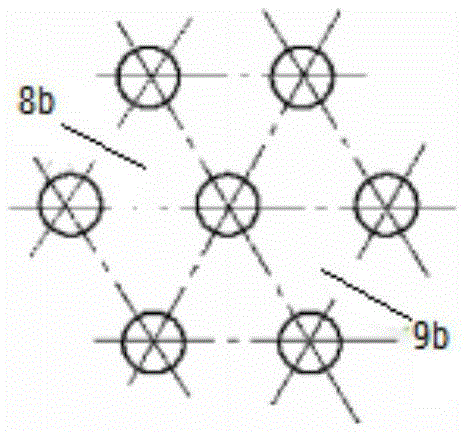

ActiveCN103839600BImprove reliabilityImprove securityNuclear energy generationNuclear monitoringShell and tube heat exchangerCoolant flow

The invention discloses a flow measurement device and a flow measurement method for a pond type natural circulation reactor. The flow measurement device comprises a shell-and-tube heat exchanger, four pressure sensors, two thermocouples and a flowmeter. According to the flow measurement device, a function of measuring a loop coolant flow in the pond type natural circulation reactor is realized, a system is simple in structure, no flow meter is additionally arranged in the reactor, the frequent maintenance problem caused by arranging the flow meter in the pond type reactor can be prevented, and the reliability and the safety of the reactor can be effectively improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Cover body assembly and pool reactor

ActiveCN112967823APrevent evaporationAvoid wastingNuclear energy generationFast fission reactorsRadioactive gasMechanical engineering

The invention discloses a cover body assembly and a pool reactor with the same. The cover body assembly comprises a cover body plate, a mounting piece and an extension plate. The mounting piece is coupled to the cover plate, and the mounting piece is mounted to a pool body defining a pool cavity to mount the cover plate over the water surface of the pool water within the water pool cavity. The extension plate extends from the edge of the cover body plate to one side close to the pool water and is used for being in contact with the pool water. The cover body assembly and the pool reactor can prevent evaporation of liquid, so that resource waste is avoided. The pool reactor simultaneously achieves the effect of reducing the emission of radioactive gas effluents, and ensures the high pressure and ventilation quantity of the filter of the pool reactor.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

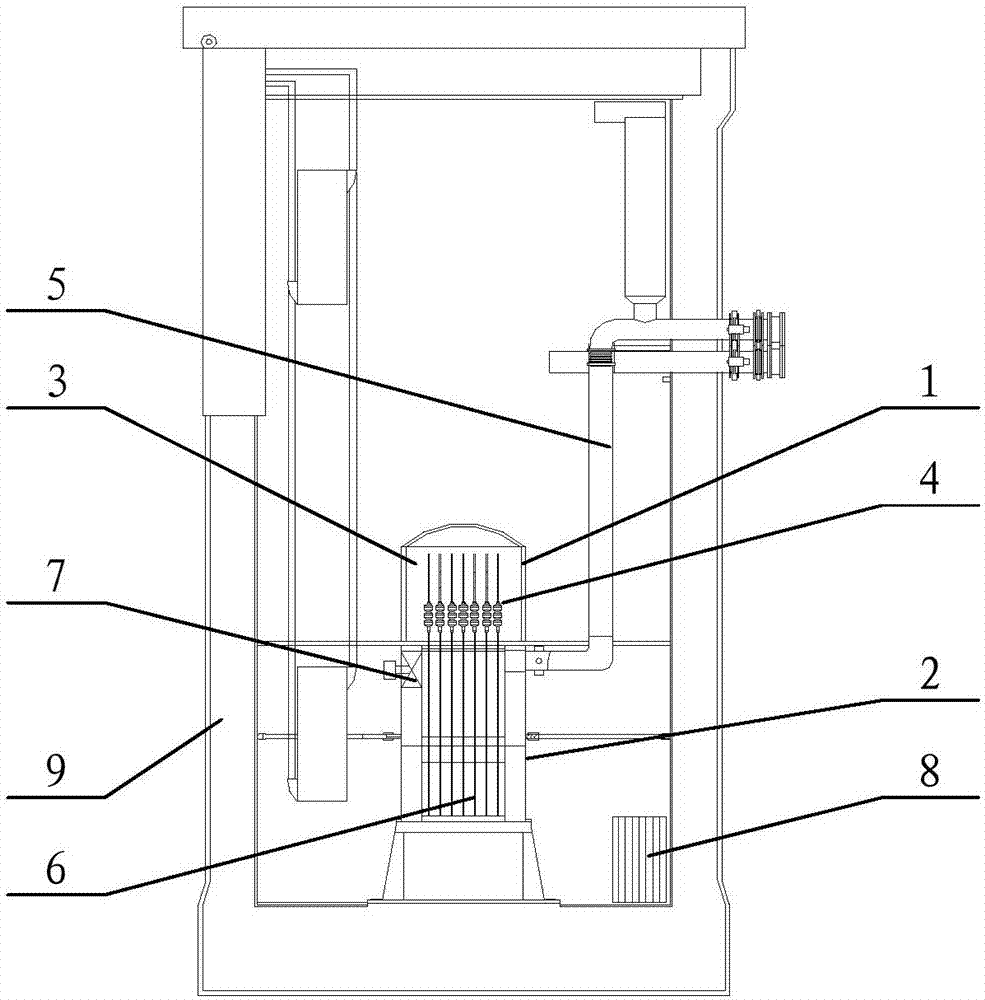

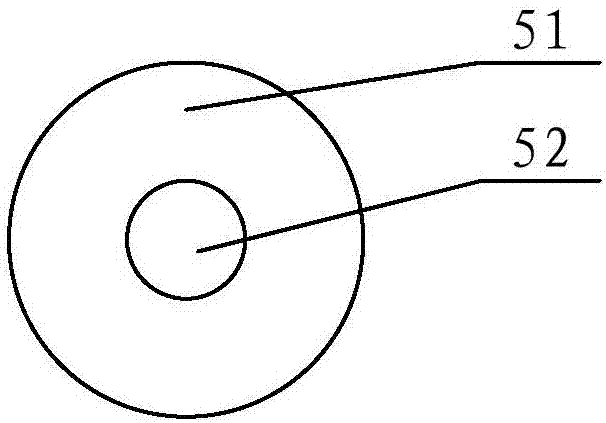

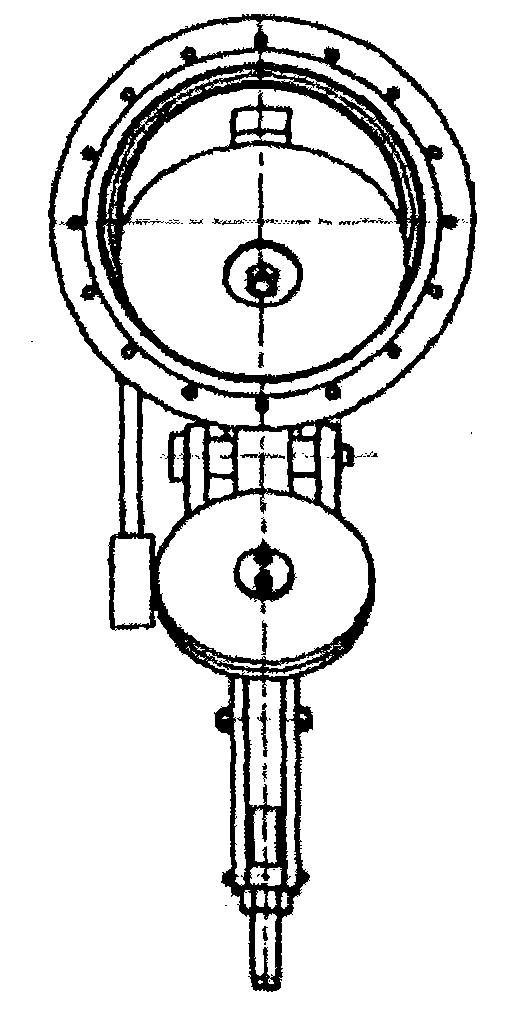

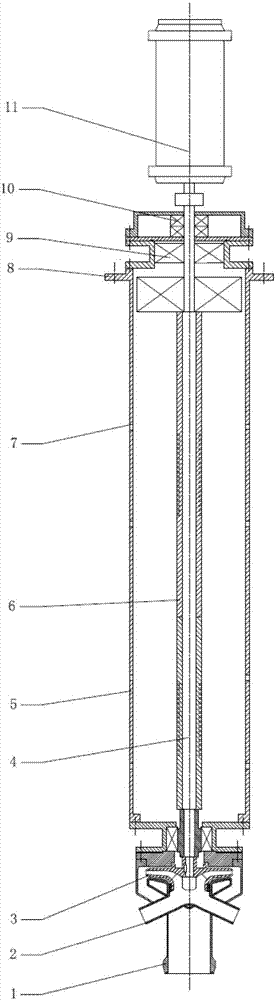

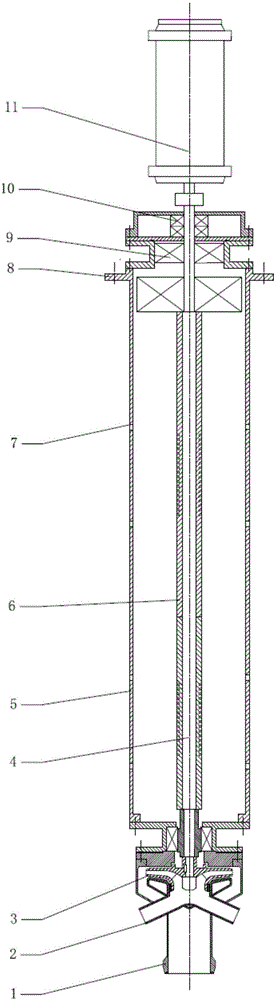

A vertical pump for a pool reactor

ActiveCN106593934BAvoid Flow Dead ZonesCompact structurePump componentsPumpsEngineeringCirculating pump

The invention discloses a vertical pump for a pool type reactor. The vertical pump for the pool type reactor comprises a pump shaft, a vertical pump shell, a hydraulic component, a power input component and a circulation component. The pump shaft is arranged in the vertical pump shell. The upper end of the pump shaft extends out of the vertical pump shell to be connected with the power input component. The lower end of the pump shaft extends out of the vertical pump shell to be connected with the hydraulic component. The circulation component is arranged on the portion, in liquid, of the pump shaft and used for generating upward or downward flowing power when the pump shaft rotates. The portion, corresponding to the circulation component, of the vertical pump shell is provided with two or more communicating holes. At least two of the communicating holes are located at different heights. The vertical pump is mainly applied to the pool type reactor and used as a main circulation pump for driving coolant, and the vertical pump for the pool type reactor can provide a enough pressure head; and besides, because the circulation component is installed on the pump shaft, the coolant in the pump shell can communicate with coolant in a reactor pool, and the coolant in the pump shell is protected against a flowing dead zone.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A liquid heavy metal cooling natural circulation pool reactor auxiliary heating system

InactiveCN103730171BIncrease powerImprove reliabilityNuclear energy generationCooling arrangementNuclear engineeringGas heater

The invention discloses an auxiliary heating system of a liquid heavy metal cooling natural circulating pool-type reactor. The system comprises a gas storage tank, a filter, a gas heater, a master gas input pipe, a main gas input valve, a main gas input pipe, an extraction opening, a main gas output valve, a main gas output pipe, a gas emergency input valve, a gas emergency input pipe, a gas emergency output valve, a gas emergency output pipe, a master gas output pipe, an air pump, a pipeline and other valves, wherein the pipeline is used for connecting the equipments. By adopting the system, the auxiliary heating function on liquid heavy metal inside the reactor is achieved inside a main container of the liquid heavy metal cooling natural circulating pool-type reactor and a ring cavity formed by a safe container, the system is simple in structure and has independence and reliability, members inside the reactor do not need to be added and started in operation, and the safety of the reactor can be effectively improved.

Owner:UNIV OF SCI & TECH OF CHINA

Vertical pump for pool type reactor

ActiveCN106593934AAvoid Flow Dead ZonesCompact structurePump componentsPumpsEngineeringCirculating pump

The invention discloses a vertical pump for a pool type reactor. The vertical pump for the pool type reactor comprises a pump shaft, a vertical pump shell, a hydraulic component, a power input component and a circulation component. The pump shaft is arranged in the vertical pump shell. The upper end of the pump shaft extends out of the vertical pump shell to be connected with the power input component. The lower end of the pump shaft extends out of the vertical pump shell to be connected with the hydraulic component. The circulation component is arranged on the portion, in liquid, of the pump shaft and used for generating upward or downward flowing power when the pump shaft rotates. The portion, corresponding to the circulation component, of the vertical pump shell is provided with two or more communicating holes. At least two of the communicating holes are located at different heights. The vertical pump is mainly applied to the pool type reactor and used as a main circulation pump for driving coolant, and the vertical pump for the pool type reactor can provide a enough pressure head; and besides, because the circulation component is installed on the pump shaft, the coolant in the pump shell can communicate with coolant in a reactor pool, and the coolant in the pump shell is protected against a flowing dead zone.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for automatically producing high-temperature nuclear energy for long term under any power

InactiveCN101814325BHigh power outputEliminate human accidentsNuclear energy generationHeterogenous reactorsElectricityNegative temperature

The invention discloses a method for automatically producing nuclear energy for long term under any power. The method comprises the following steps of: in a high-boiling point heating medium deep-tank type reactor which runs under the normal pressure, generating a natural cycle with a temperature difference of a high-boiling point heating medium between an ascending flow passage and a descending flow passage in the deep-tank type reactor; making the high-boiling point heating medium transversely flow by an annular pebble bed reactor in the high-boiling point heating medium deep-tank type reactor with the natural cycle; making the high-boiling point heating medium pass through an open heat exchanger in the heating medium deep-tank reactor with the natural cycle; totally transferring fission produced by the reactor to a secondary high-boiling point heating medium; not arranging control-compensation rod bundles in the high-boiling point heating medium deep-tank type reactor; under the function of a negative temperature coefficient of the reactor per se and along with demands on external loads, ending a life cycle of the reactor from the starting to running of the reactor; and during the long-time natural cycle, making the secondary high-boiling point heating medium enter an energy-utilization factory through a group of double-protection valves so as to directly utilize high-temperature heat energy or generate electricity.

Owner:吕应中

A liquid heavy metal cooling natural circulation pool reactor internal auxiliary heating system

InactiveCN103730172BImprove heating efficiencyImprove natural circulationNuclear energy generationCooling arrangementThermal insulationNuclear engineering

The invention discloses an auxiliary heating system in a liquid state heavy metal cooling natural circulating pool type reactor. The system comprises a gas storing tank, a filter, a gas heater, a fan, a gas input tube, an inner-layer thermal insulation plate, an outer-layer thermal insulation plate, a bottom heating ring, a gas output tube, a reactor core coolant entrance baffle, a pipeline fixing steel plate, and pipelines and valves connected between the devices. The system realizes the function of assisting in heating liquid state metal in a main vessel of the liquid state metal cooling pool type reactor, has a simple structure, is convenient to start, can build large-space natural circulation of the liquid state heavy metal in the main vessel even if the reactor is at low power or in shutdown condition after being put into operation, guarantees the temperature of the liquid state heavy metal to be above the melting point, and effectively improves the reliability and safety of the reactor.

Owner:UNIV OF SCI & TECH OF CHINA

A temperature-triggered passive accident waste heat removal system for pool reactors

ActiveCN104269194BImprove passive safety featuresEfficient take awayNuclear energy generationCooling arrangementSystems designFree cooling

The invention discloses a temperature-triggered passive accident residual heat removal system for a pool type reactor. The system consists of a direct reactor core cooling system and an auxiliary reactor safety container cooling system. The system has the significant advantage that the direct reactor core cooling system and the auxiliary reactor safety container cooling system share one air cooling system, so that the system design of the reactor is greatly simplified, and the construction cost is saved. The auxiliary reactor safety container cooling system realizes natural cooling through ambient air on the outer side of a safety container, and the process has the characteristic of passiveness. The passive accident residual heat removal system is passive, independent, high in efficiency and high in reliability and meets the safety design requirement for the pool type reactor.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

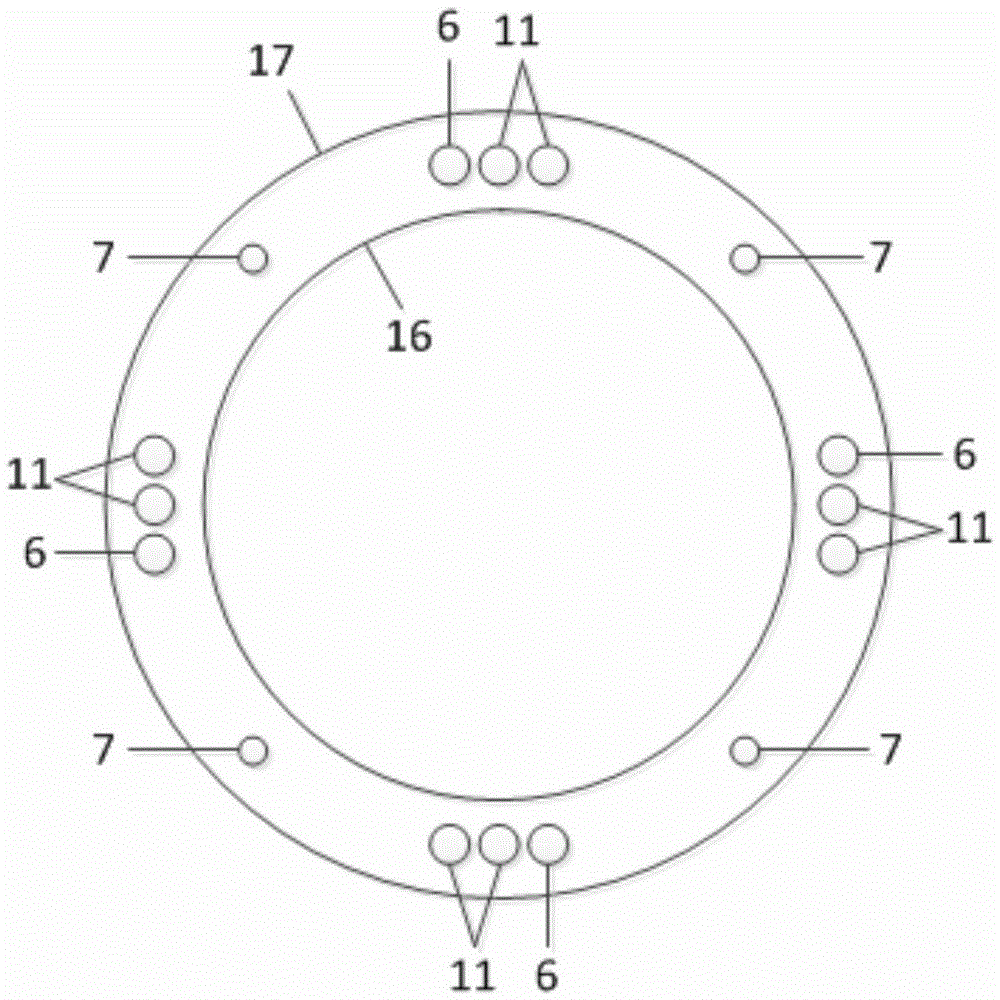

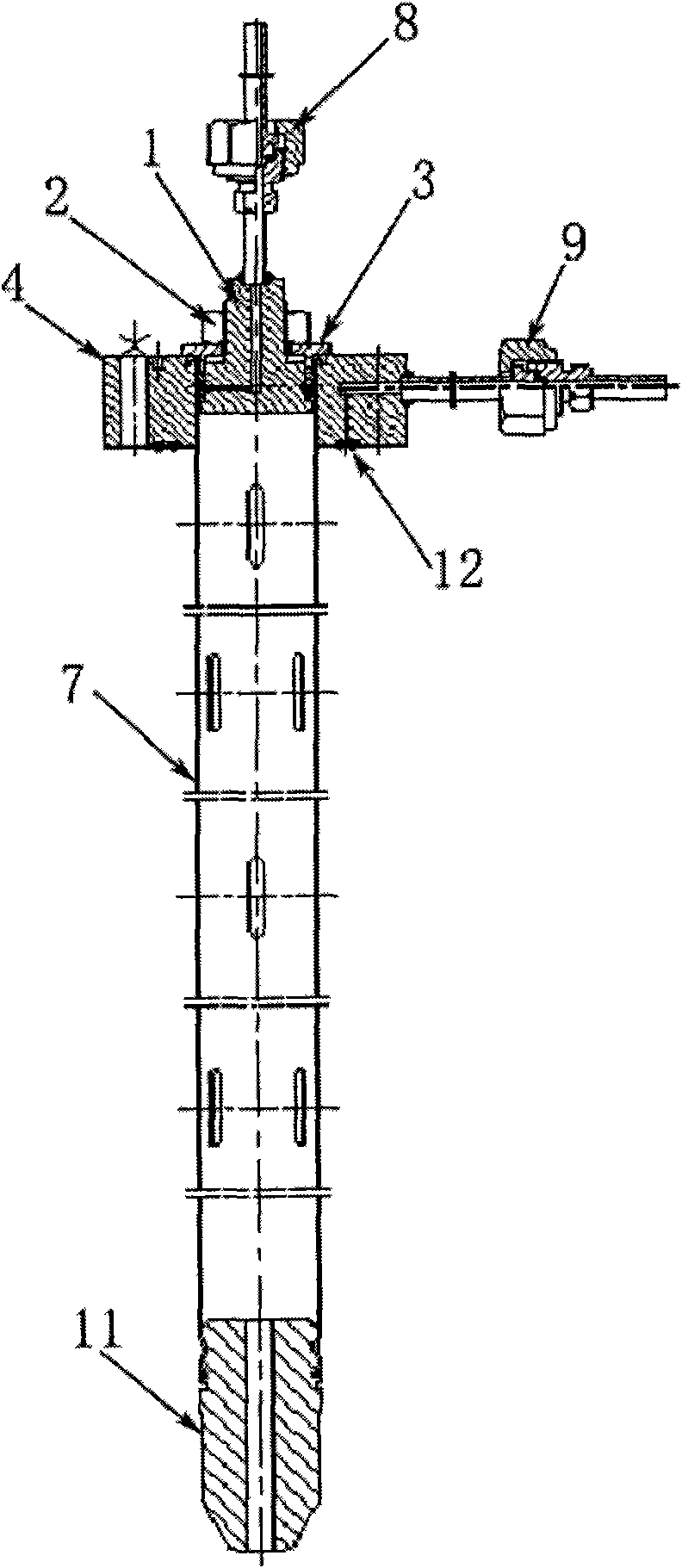

Material irradiation monitoring vertical channel of pool type reactor

ActiveCN101826370AImprove sealingSealed for nothingNuclear energy generationNuclear monitoringStraight tubeSilicon rubber

The invention belongs to the field of reactor monitoring components, in particular to a material irradiation monitoring vertical channel of a pool type reactor. The material irradiation monitoring vertical channel comprises a first leakage detecting device 8, a second leakage detecting device 9, a ring plug 1, a first double-channel silicon rubber seal ring 5, a second double-channel silicon rubber seal ring 12, a nut 2, an end cap 3, a baffle ring 6, a flange 4, a straight tube 7 and a seal head 11. The invention aims to provide the material irradiation monitoring vertical channel which has good sealing performance and can be applied to the pool type reactor in practice.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A multifunctional internal thermal separation system for liquid metal cooling pool reactor based on gas lift

ActiveCN106409353BReduce stressReduce heatNuclear energy generationCooling arrangementNuclear engineeringGas heater

The invention discloses a gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system. According to the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system, when a reactor is at normal operation conditions, a thermal separation valve is opened, an auxiliary heating valve is closed, a gas filter and a gas compressor are turned on, and thermal separation effect is realized by the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system; when the reactor is at low-power running or shutdown condition, the auxiliary heating valve is opened, the thermal separation valve is closed, the gas filter, a gas heater, and the gas compressor are turned on, and auxiliary heating effect is realized by the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system The gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system is simple in structure; activation is convenient; cold and hot pool separation and reactor internal cooling agent auxiliary heating of liquid metal cooling pool-type reactors can be realized at the same time; the complexity of reactor system structure is reduced effectively; reactor economical efficiency and security are increased; application range of the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system is wide; the gas lift-based liquid metal cooling pool-type reactor multifunctional reactor internal thermal separation system is suitable for both liquid metal cooling pool-type reactors with forced circulation, and liquid metal cooling pool-type reactors with natural circulation.

Owner:NANHUA UNIV

Cooling system

PendingCN111508624AEfficient removal of waste heatNuclear energy generationCooling arrangementEngineeringProcess engineering

The embodiment of the invention provides a cooling system. The cooling system comprises an air inducing device and at least one group of cooling loops, wherein the air inducing device is arranged at the upper position outside a pool type reactor water pool and is used for increasing the flow rate of air; and the cooling loop comprises a first heat exchanger, a second heat exchanger, a first pipeline, a second pipeline and a valve. The cooling loop in the cooling system provided by the invention adopts a separated heat pipe principle, passive export of decay heat in the pool type reactor pool can be realized without depending on any active equipment and human intervention, and the cooling system has high safety.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

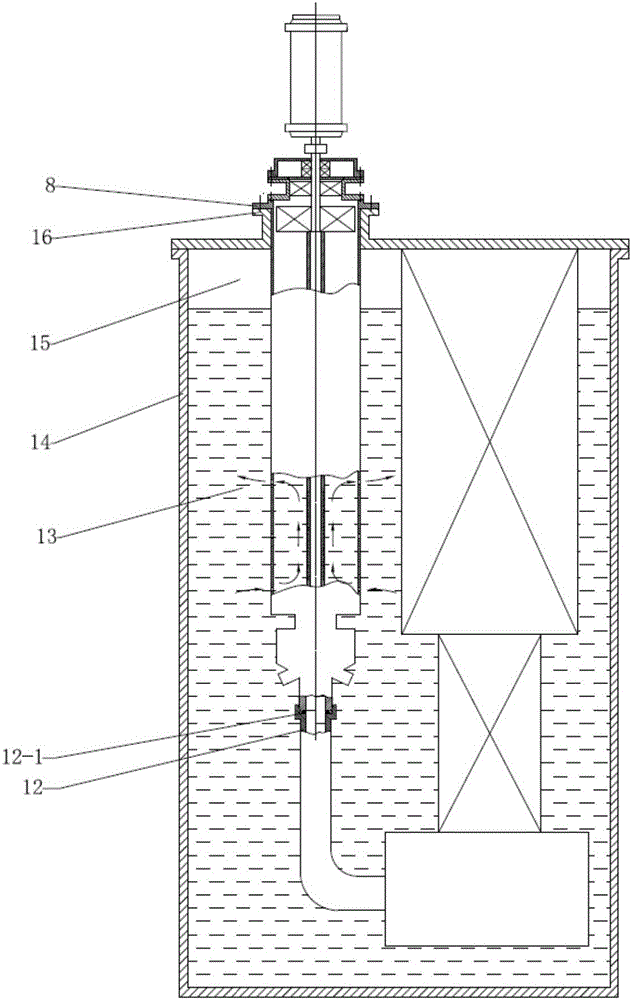

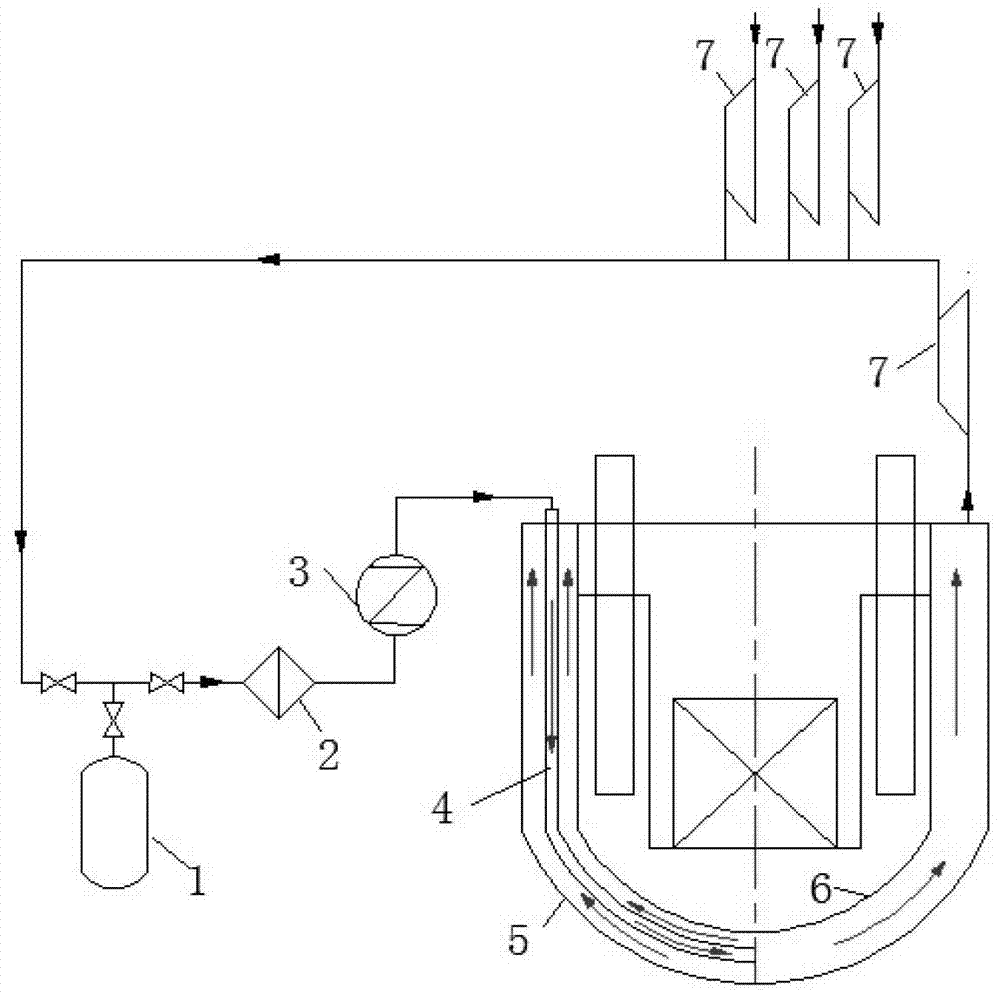

An Auxiliary Heating System for Liquid Metal Cooled Natural Circulation Reactors

InactiveCN103021483BSimple structureImprove reliabilityNuclear energy generationCooling arrangementReactor systemGas heater

The invention discloses an auxiliary heating system for a liquid-metal-cooled natural circulation reactor. The auxiliary heating system comprises a nitrogen storage tank (1), a filter (2), a gas heater (3), a hot nitrogen input pipe (4), a main container (5), a safety container (6), gas extractors (7), pipelines and valves, wherein the pipelines and the valves are used for interconnecting devices. The system has the advantages that the function that a liquid-metal coolant in a liquid metal pool type reactor is subjected to auxiliary heating from the outside of the main container of the reactor is realized, the system is simple in structure, components in the reactor are not required for being added or started during operation, so that liquid metal in the main container can form micro natural circulation after the operation of the system, and meanwhile, the reliability and safety of the reactor can be effectively improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com