A vertical pump for a pool reactor

A technology of vertical pumps and reactors, which is applied to non-variable pumps, pumps, components of pumping devices for elastic fluids, etc. It can solve problems such as the fluidity of the transport medium without considering temperature changes, and achieve compact structure , Relieve thermal stress, simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

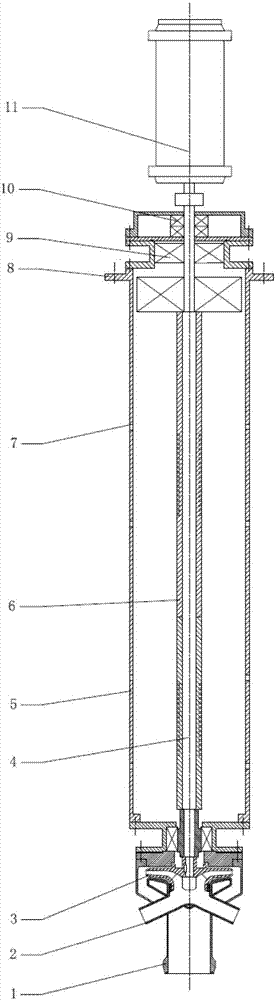

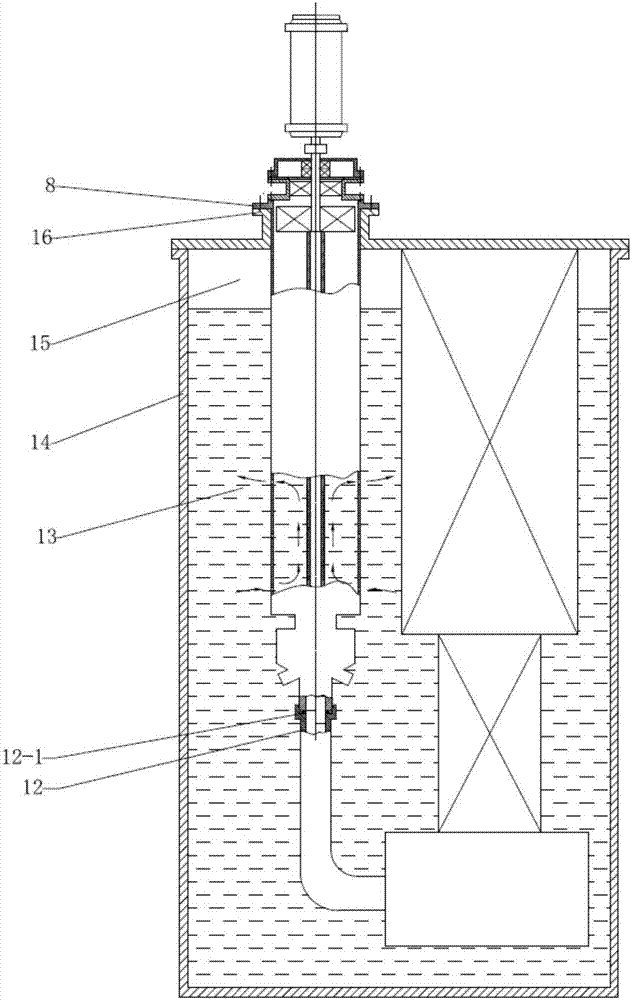

[0034] see figure 1 , the vertical pump for the pool reactor of the present invention includes a pump shaft 4, a vertical pump casing 5, a hydraulic component 3, a power input component 11 and a circulation component 6;

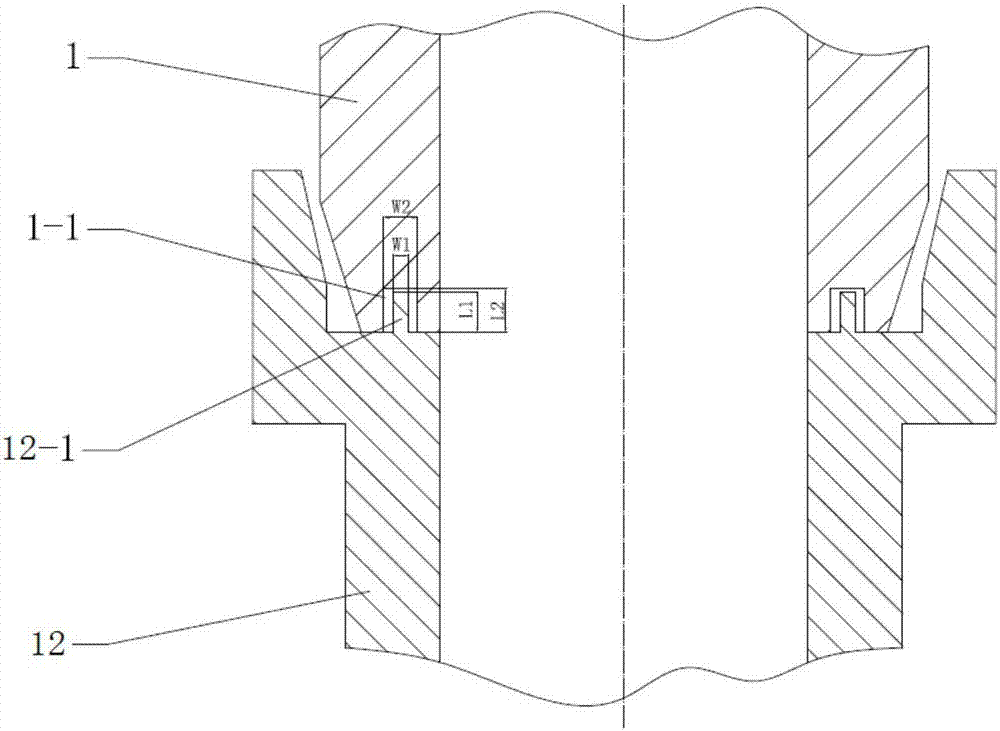

[0035] The pump shaft 4 is arranged in the vertical pump casing 5, the upper end of the pump shaft 4 protrudes from the vertical pump casing 5 to connect with the power input component 11, and the lower end of the pump shaft 4 protrudes The vertical pump casing 5 is connected with the hydraulic component 3, the hydraulic component 3 is connected with the outlet pipeline 1 and the inlet pipeline 2, and the inner wall of the upper end of the vertical pump casing 5 and the pump shaft 4 The seal is realized by the shaft seal part 9;

[0036] The circulation part 6 is arranged on the submerged part of the pump shaft 4, and is used to generate an upward or dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com