Novel devolatilization device

A devolatilizer, a new type of technology, applied in the direction of evaporator accessories, chemical instruments and methods, separation methods, etc., can solve the problems of insufficient separation of polymers, short effective devolatilization distance, and influence on devolatilization effect, so as to avoid material The effect of flow dead zone, avoiding temperature discontinuity, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

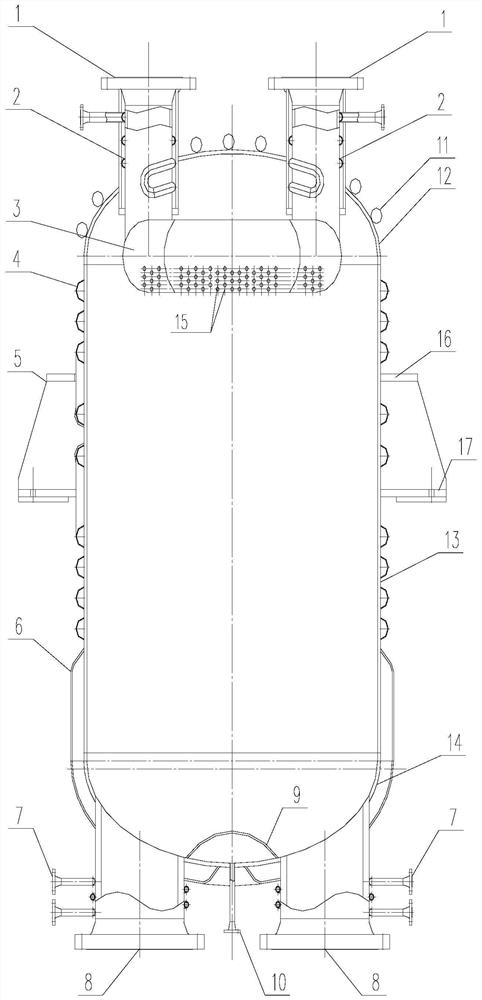

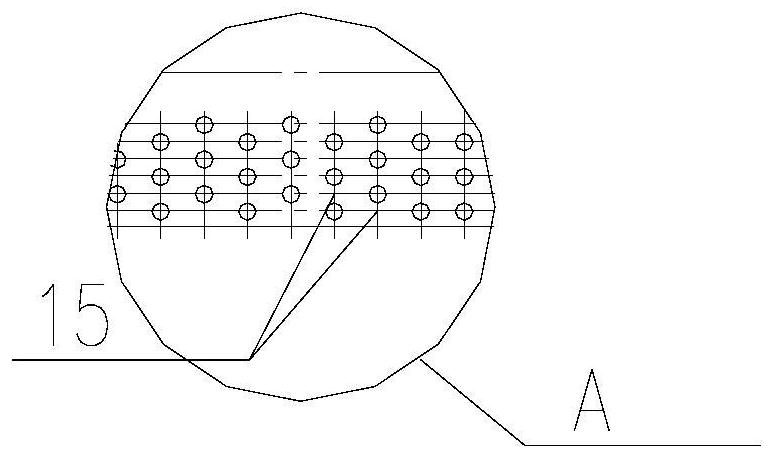

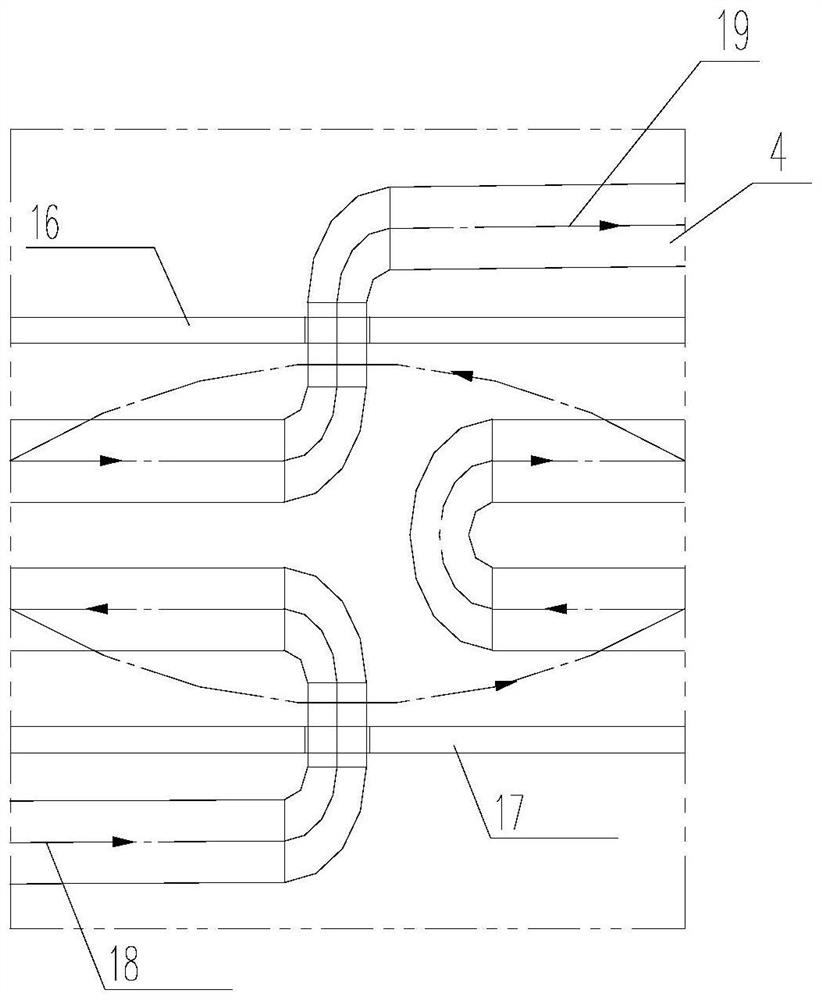

[0018] like figure 1 Shown is the novel devolatilizer of the present invention, which comprises a vertical cylinder, the upper end and the lower end of the cylinder are respectively provided with an upper sealing head 12 and a lower sealing head 14, and a pair of feeding ports 1 are connected to the upper sealing head 12, A pair of discharge ports 8 are connected to the lower head 14 . Inside the cylinder, there is a devolatilization distributor 3 hoisted below the upper head. In order to increase the number of openings of the flow distribution holes on the devolatilization distributor, the devolatilization distributor 3 is formed by connecting a plurality of straight pipes with the same diameter end to end to form a closed outer ring. There are two intermediate connecting pipes communicating with the outer ring pipeline. The lower semicircular pipe wall of the devolatilization distribution pipe is provided with flow distribution holes 15, and the flow distribution holes 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com