A multifunctional carbon dioxide system and its operating method

A carbon dioxide, operating method technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of increasing system input cost, maintenance cost, increasing system operating cost, increasing system failure risk, etc. Conducive to system control, reducing system cost and protecting the ozone layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

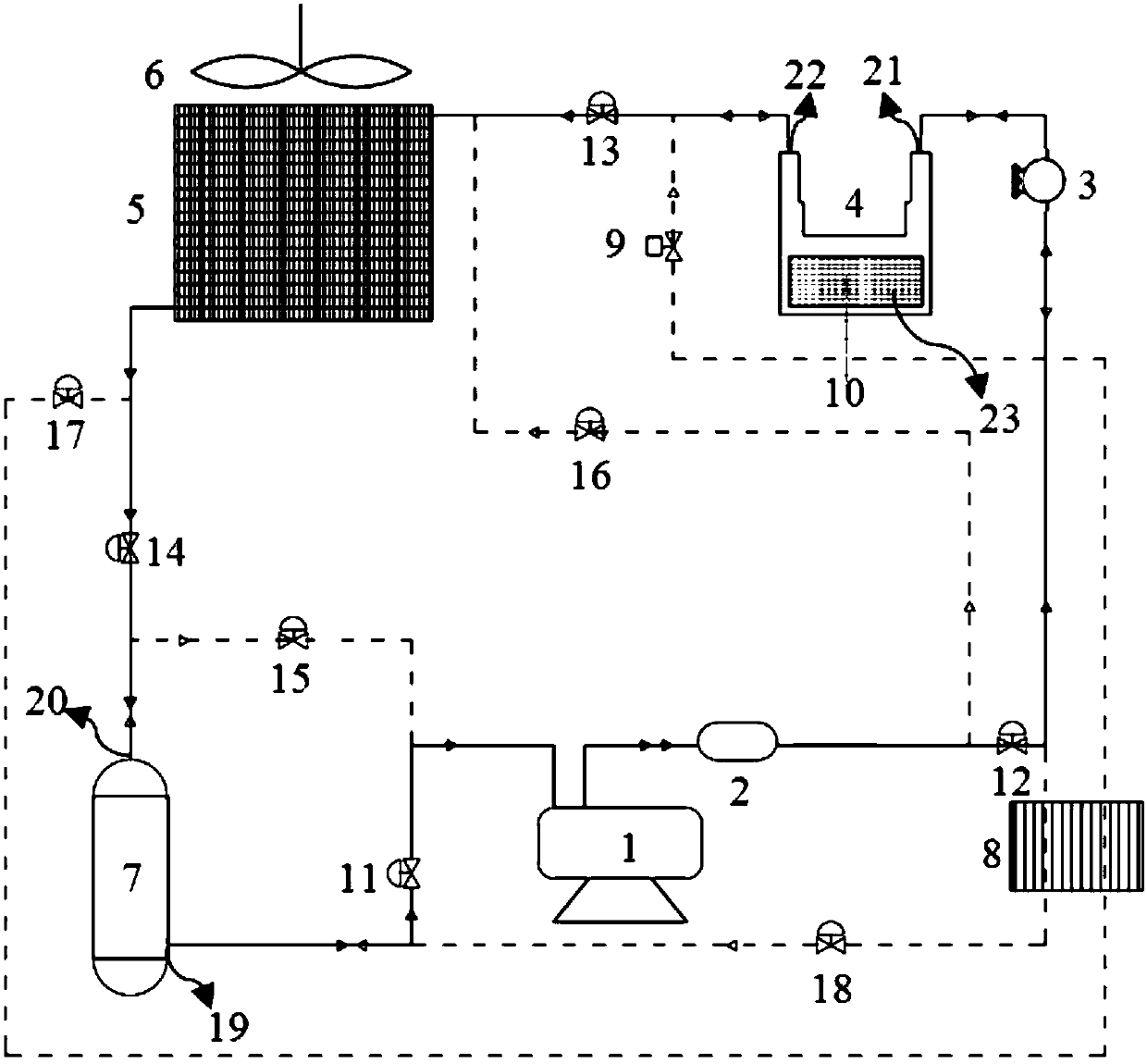

[0032] see figure 1 As shown, a multifunctional carbon dioxide system of the present invention includes an integrated drive device 1, a filter 2, a flow meter 3, a heat exchange cold plate 4, a condensation device 5, a fan 6, a gas-liquid separation device 7, and a plate-type intermediate heat exchange 8, electronic expansion valve 9, temperature sensor 10 and flow control device; condensing device 5 selects a condenser, gas-liquid separation device 7 is a gas-liquid separator, and the flow control device is a solenoid valve 11-18.

[0033] The working medium inlet of the integrated drive device 1 is connected to two branches: one branch is connected to the liquid phase port 19 of the gas-liquid separator through the solenoid valve 11, and the other branch is connected to the gas phase port 20 of the gas-liquid separator through the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com