A vibrating sewage treatment equipment

A kind of sewage treatment equipment and vibration technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problems of complicated operation process, difficult transfer, high manufacturing cost, etc. , to achieve the effects of convenient promotion and application, prevention of flow dead zone, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

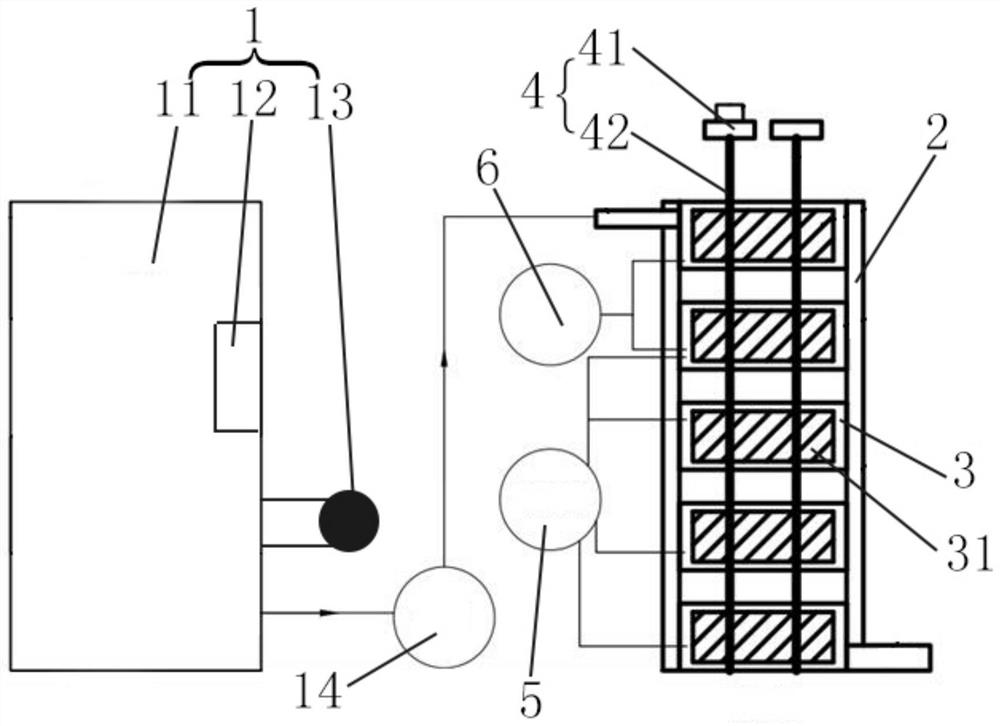

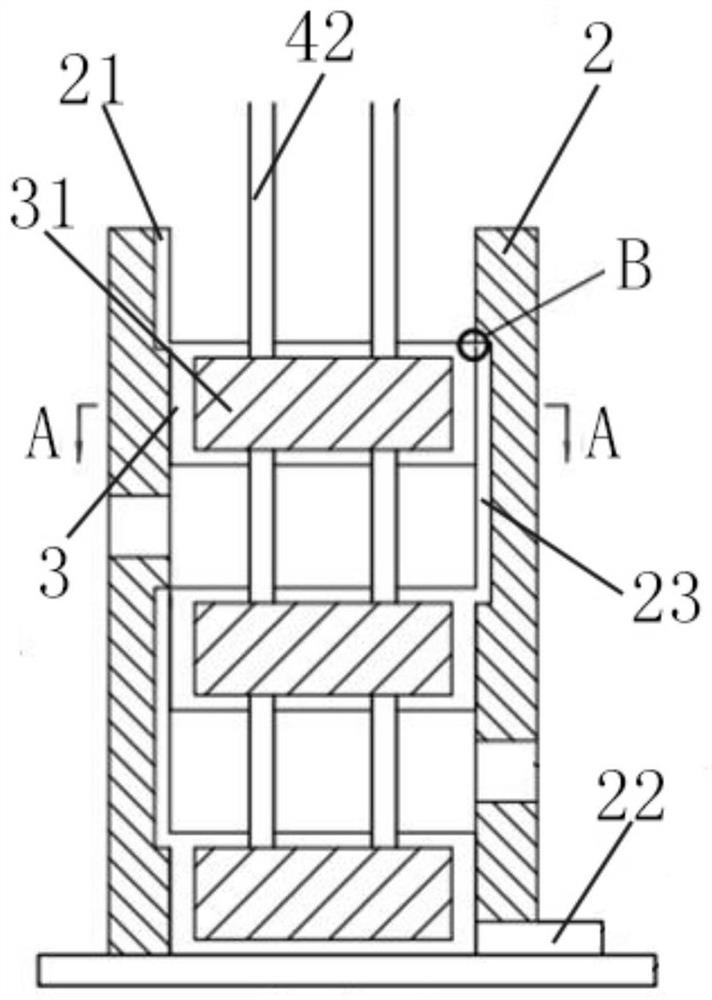

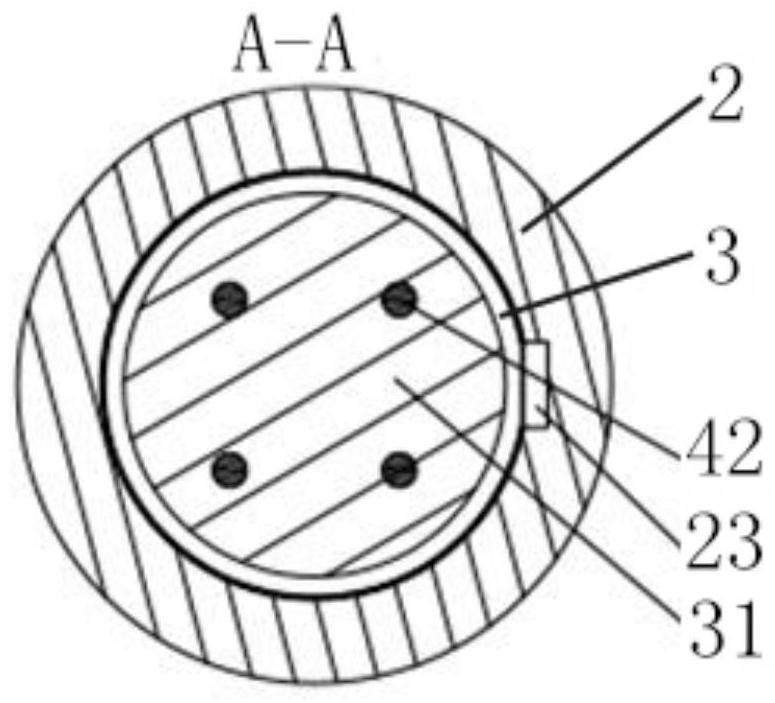

[0038] The invention provides a vibrating sewage treatment equipment, such as Figure 1 to Figure 5 As shown, it includes a pre-processing device 1, a biochemical tower 2 and a vibration device 4. The biochemical tower 2 includes a tower body and a plurality of biochemical units 3 arranged in the tower body. The biochemical tower 2 is preferably provided with a water inlet 21 and a water outlet 22 for inputting sewage and outputting treated water up to standard, and the number of the water inlet 21 and the water outlet 22 can be multiple. Water input and output biochemical unit 3.

[0039] The pre-treatment device 1 is used to send the pre-treated sewage to the biochemical unit 3 (that is, to the biochemical tower 2). During the pre-treatment, the suspended s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com