Passive decay heat removal system for liquid metal cooling pool type reactor

A liquid metal cooling and waste heat removal system technology, applied in reactors, cooling devices, nuclear power generation, etc., can solve problems such as weak heat removal capacity, affecting reactor economy, complex structure, etc., to facilitate heat discharge and improve Good effect of natural circulation performance and shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

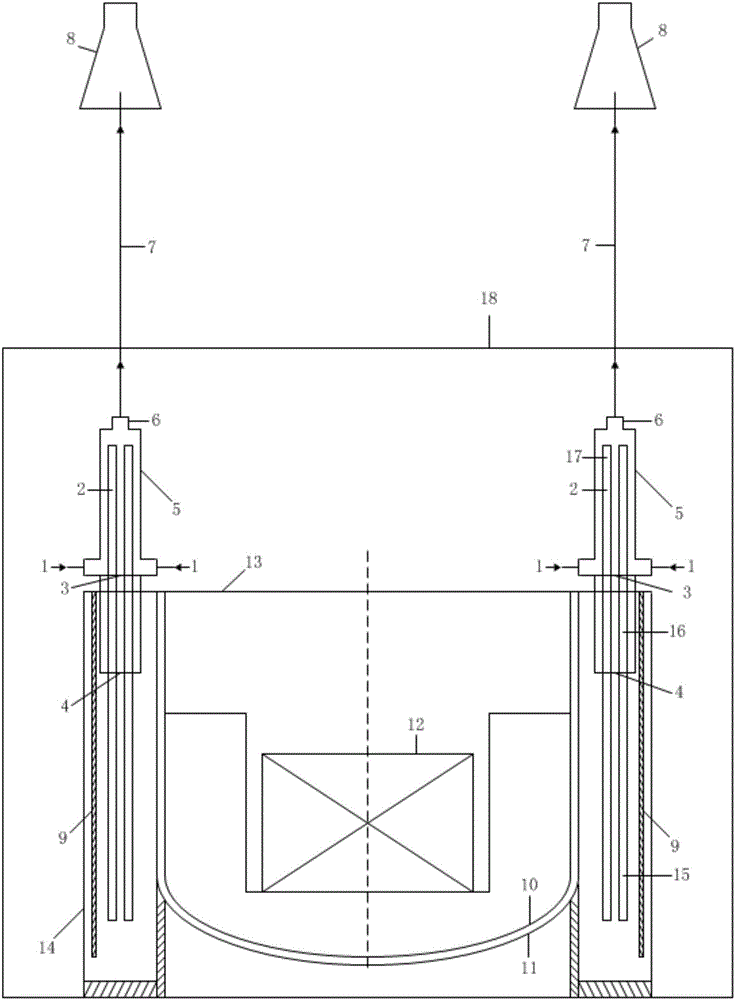

[0023] The present invention provides a liquid metal cooling pool reactor passive accident waste heat discharge system. The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings:

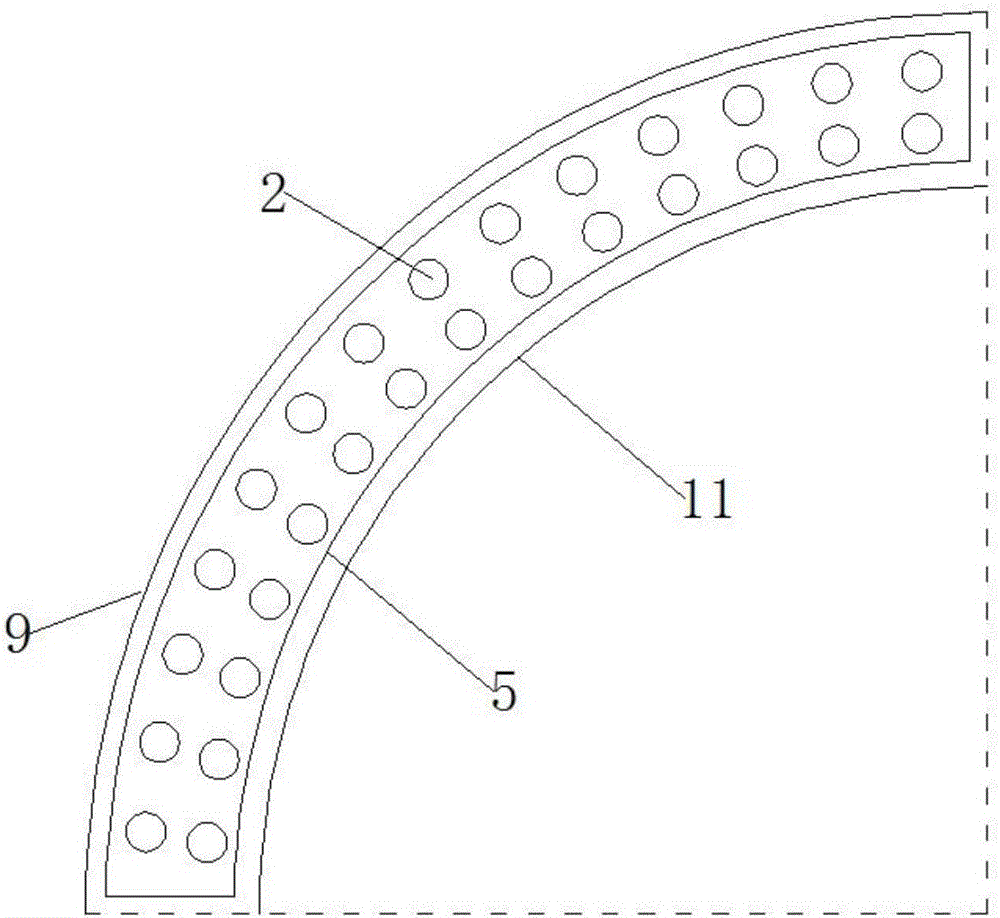

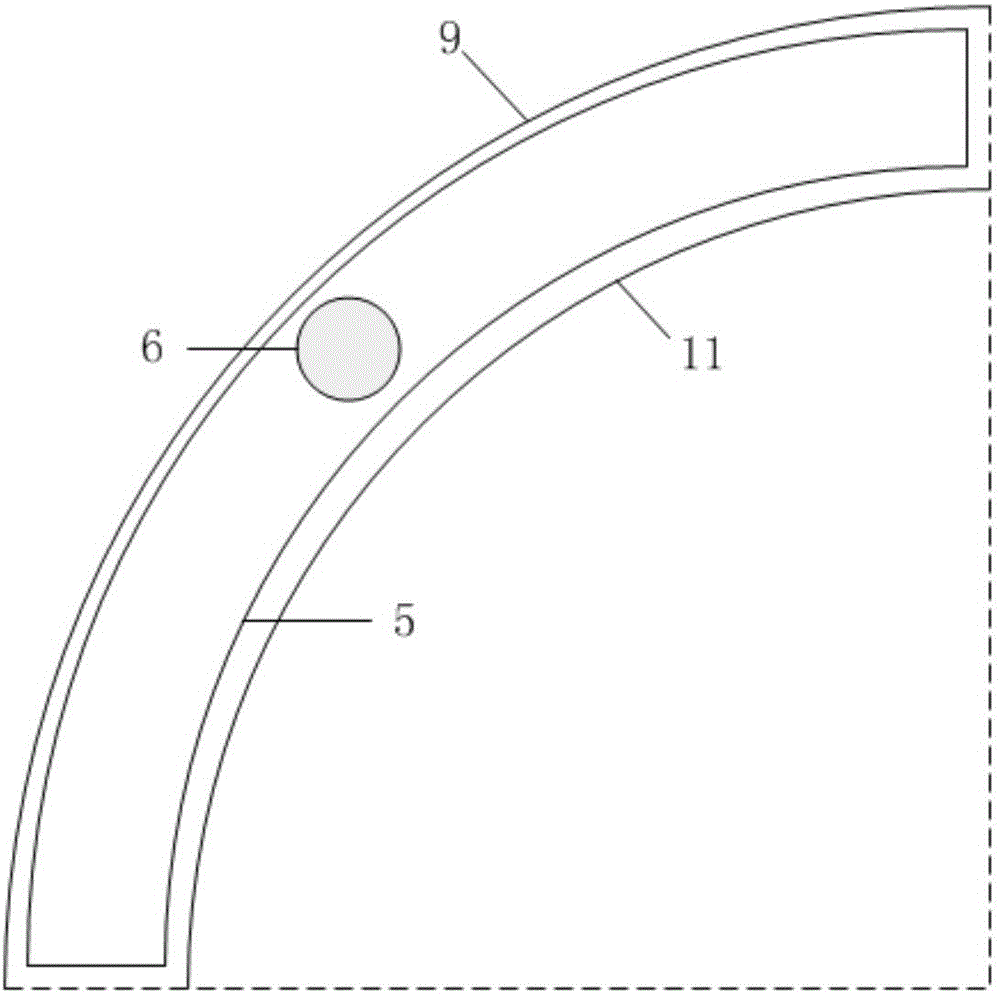

[0024] figure 1 It is a structural schematic diagram of a liquid metal cooling pool reactor passive accident waste heat discharge system of the present invention. The present invention consists of a coolant inlet 1, a gravity heat pipe 2, an upper partition 3, a lower partition 4, a box body 5, a coolant outlet 6, a gas riser 7, an exhaust chimney 8, a thermal isolation layer 9 and equipment and equipment It is composed of connecting pipes and other valves. Wherein the coolant inlet 1 is positioned at the middle part of the box body 5 and above the stack top shield cover 13, and the coolant outlet 6 is positioned at the top of the box body 5; The condensing section 17 is composed of the evaporating section 15 located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com